Regardless of the sophistication of a manufacturing plant's planning and scheduling systems, many operations encounter constraints on the production floor. These constraints may consist of idle time, over-scheduling, poor process design, or several other variables that, in combination, impact efficient operation. To address these constraints and free up bottlenecks, managers may deploy several solutions. And one of the most effective is that of line balancing.

What is Line Balancing?

Line balancing, or Production Leveling, is a process whereby operator time and machine time are optimized to address constraints and use capacity in the most efficient way possible.

Also known as production smoothing, or by its original Japanese term, heijunka, this technique works by shifting resources, improving workflows, and addressing machine-level capacity, so that machines are given the right product mix of jobs or work orders to allow an equalized and optimized workload.

Line balancing matches the actual production rate with Takt time. Takt time is not related to equipment speed or work experience, and skill. Instead, it is a measure of how fast production must proceed to meet delivery deadlines.

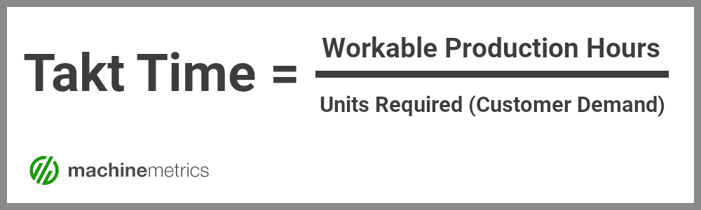

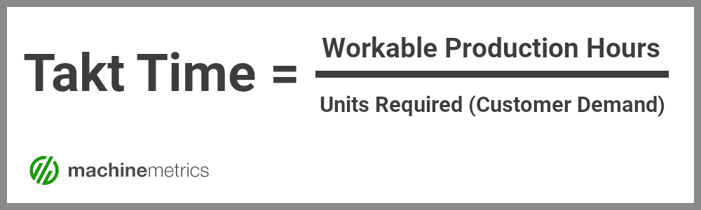

The formula for Takt time is defined as:

Takt time = Workable Production Hours/Units Required to Meet Customer Demand

Why Level Your Production?

Leveling production has many benefits. Overall, it helps smoothen manufacturing operations to run based on customer demand. This “pull” from demand allows material and WIP to incur less variability.

Some of the advantages of balancing a production line include:

Demand Changes

Customer demand will change over time due to seasonality, consumer tastes, adoption of new products, etc. When this happens, takt time will change as well. Line balancing allows managers to react quickly to ensure that production matches takt time.

Waste Reduction

Waste is always on the minds of manufacturing managers. And never so much as when production lines are out of balance. And waste can take many different forms. According to lean principles such as the Toyota Production System (TPS), there are eight types of waste categories within a manufacturing system, all of which can be exacerbated by unbalanced lines. These categories are:

- Defects

- Excess Processing

- Overproduction

- Waiting

- Inventory

- Transportation

- Motion

- Non-Utilized Talent

Unused Capacity

For each process where Takt time is exceeded, idle time for operators and machines will occur. Line balancing allows managers to take advantage of unused capacity to run overall production more efficiently.

Finding both these waste and process inefficiencies can be a challenge, as they are often unseen, or poorly measured parts of the production process, a concept referred to as "the Hidden Factory."

How to Balance Your Production Line

To balance production lines, managers must utilize a holistic and team-driven approach. The operation must be viewed at a high level to determine which lines are encountering constraints. Rather than a single type of constraint, it is common for different production lines to experience various issues that create bottlenecks.

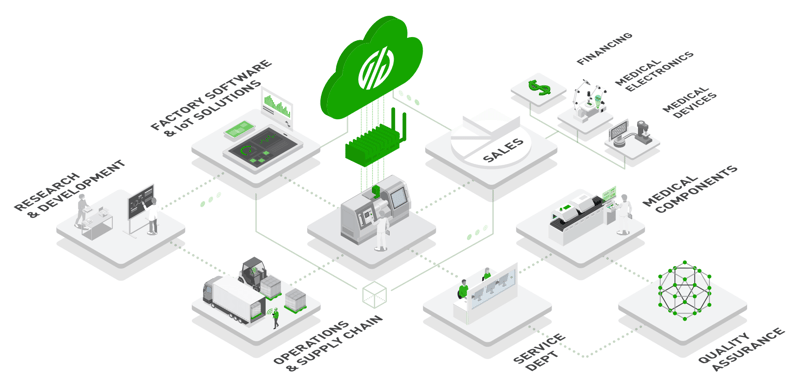

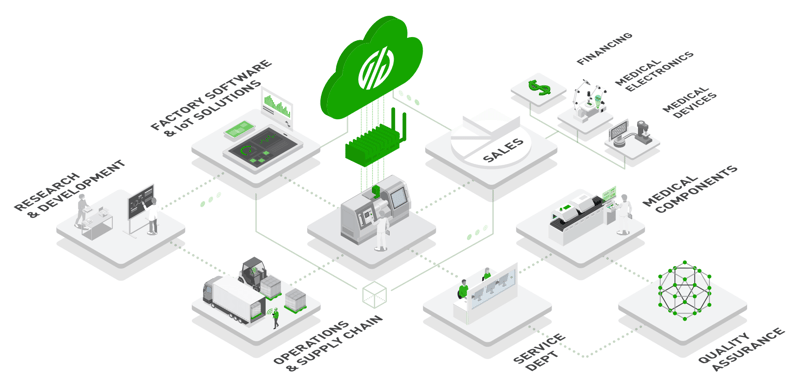

It is also important to bring members from across the organization onto the team. This includes managers, technicians, maintenance, operators, schedulers, and others. These team members will help provide insight into how and why certain lines are constrained. Plus, having a broad and diverse team helps build buy-in for the solutions adopted.

Once the teams are assembled, there are several things managers can do to work toward achieving line balance:

Calculate Takt Time

Without understanding Takt time, manufacturers will not know the production rate required to meet demand. It should be among the first steps taken.

> Takt Time vs. Cycle Time vs. Lead Time

Track Production

Using the calculated takt time as a benchmark, managers can monitor production to see if they are meeting takt time or not.

> MachineMetrics Real-Time Production Tracking Software

Process Audits

Here, the activities for each process are listed. This may include time and motion studies and other tools in addition to the newly calculated Takt time.

> How to Conduct a Bottleneck Analysis: Strategies and Examples

> A Guide to Manufacturing Process Optimization

> Top 10 Workflows for Manufacturers

Identify Immediate Action

If a machine is not meeting Takt time, there are always several simple, low-cost steps to take to begin relieving bottlenecks. This “low-hanging-fruit” helps build morale and confidence as the project progresses.

> How Shop Floor Control Drives Instant Visibility and ROI

> How to Respond to Downtimes and Alarms Faster with MachineMetrics

SOPs and Standard Work

Defining the proper steps will help keep processes from varying over time. Many manufacturers run operations based on inaccurate or simple unknown cycle times.

> Optimizing Job Standards with MachineMetrics

5S and Visualization Tools

Using a structured system to manage the physical layout will help internalize the new flow to everyone and will help provide a discipline to work within the structure. Also, signs, symbols, charts, boards, and other media can be strategically deployed and positioned to help remind everyone to the right step or process.

With real-time data, manufacturing dashboards and tablets placed at each machine provide visibility for managers and operators to better understand the status of production.

> How to Track Production with a Digital Manufacturing Dashboard

Allocate Resources Accordingly

If the production time is meeting Takt time, the line is balanced. Focus can be placed on other process improvement activities to reduce production times and ensure the ability to accept more demand.

If production is less than Takt time, there may be excess capacity. If this occurs, teams can list the tasks required to complete each production sequence. Tasks can be shifted to minimize idle time, shorten transportation distance, or allocate more labor to slower processes. This may include adding or consolidating workstations, cross-training, and other steps. A balanced line can unlock excess capacity and allow companies the ability to take on more work.

Supercharging Your Line Balancing

Manual tracking and whiteboards can only go so far. The power of a fully optimized and balanced line can only be achieved with accurate, real-time production data that contextualizes data automatically, providing instant insights into shop floor inefficiencies.

MachineMetrics can help managers understand where they can improve and further balance their line using real-time data straight from the machine control as well as with operator input. From bottleneck analysis to fully optimized processes, contact MachineMetrics to find out how to balance your line and supercharge your continuous improvement programs.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments