MaxAI has arrived! Learn all about it

here

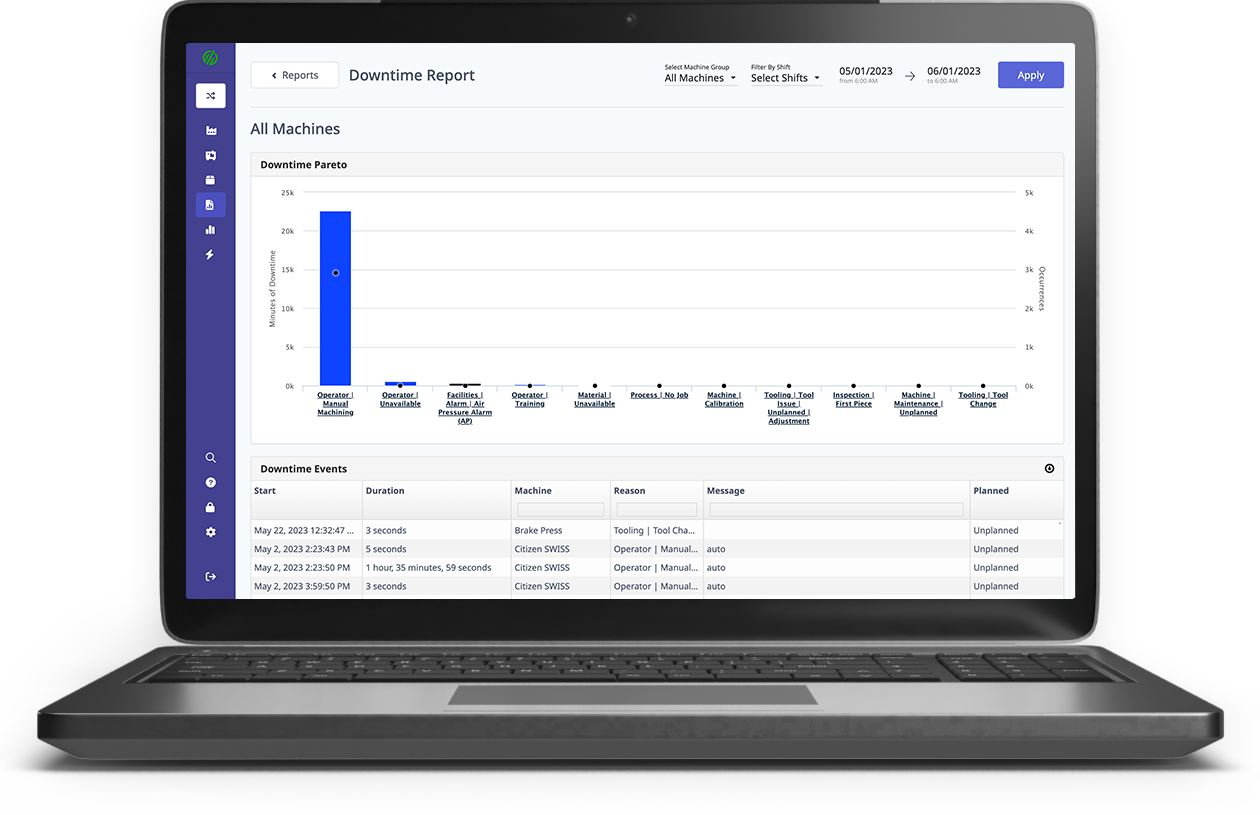

Tracking production efficiency is critical in any manufacturing industry. And you wouldn’t fix a car without running diagnostics first, so why rely on outdated, incomplete data to drive improvements on your plant floor?

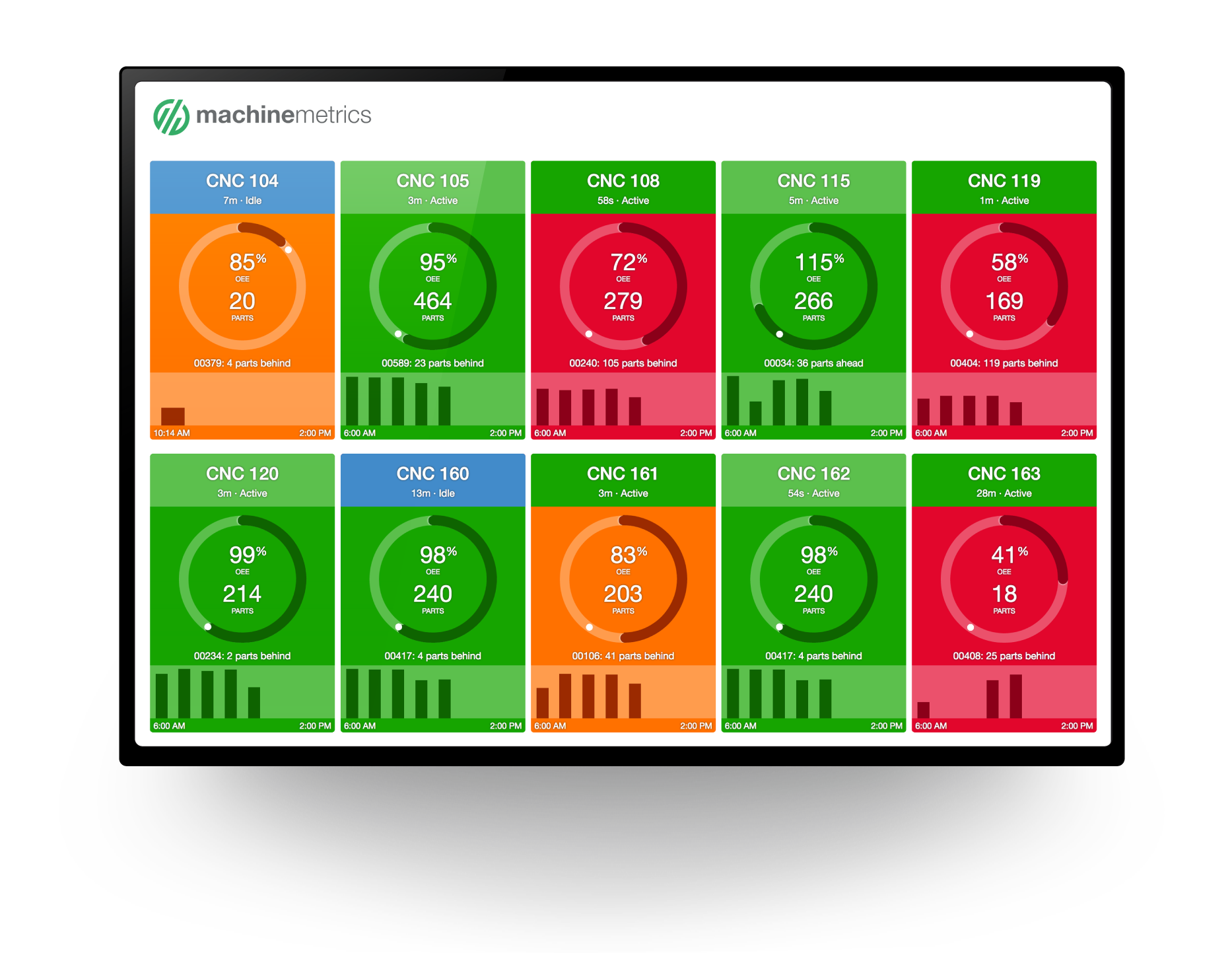

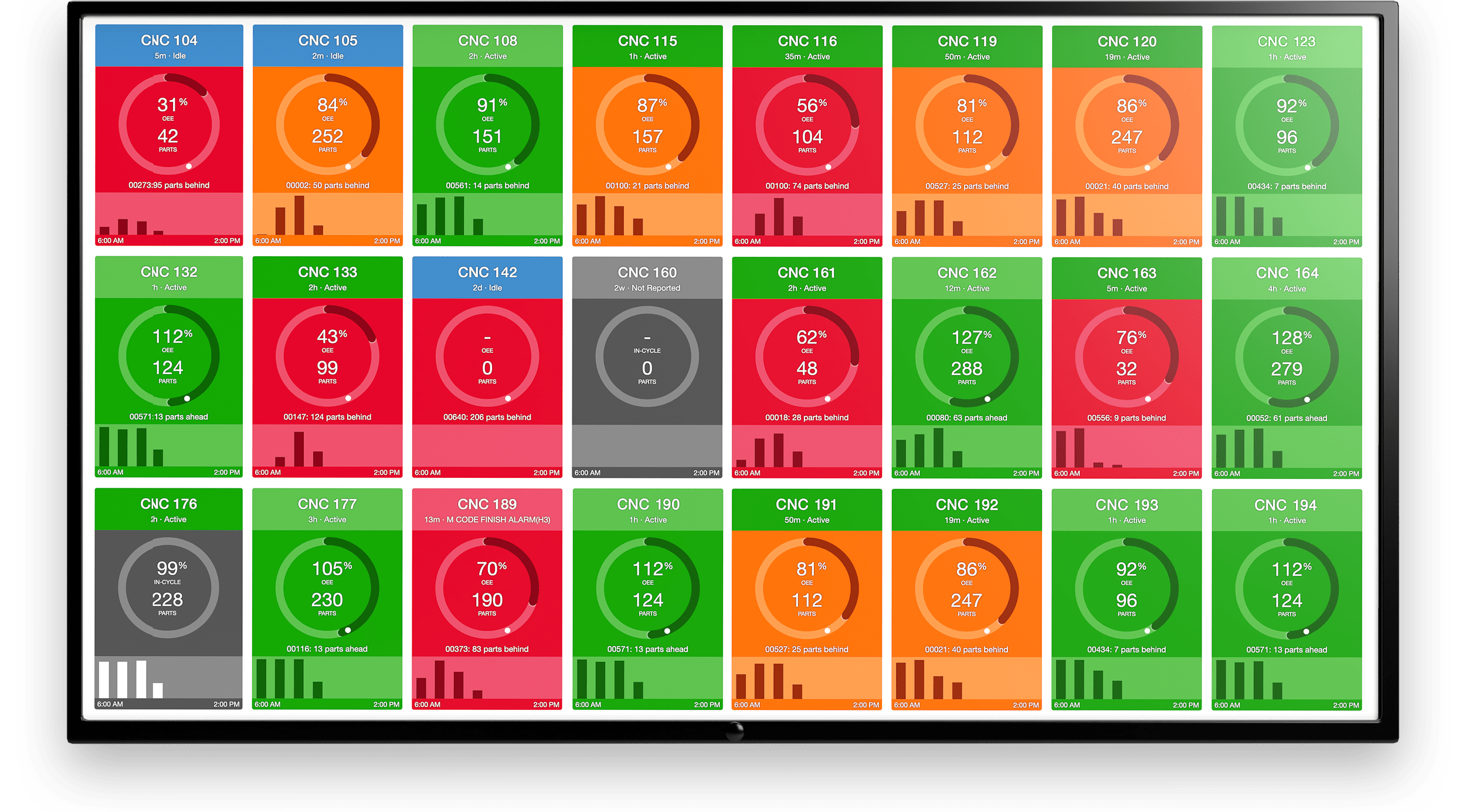

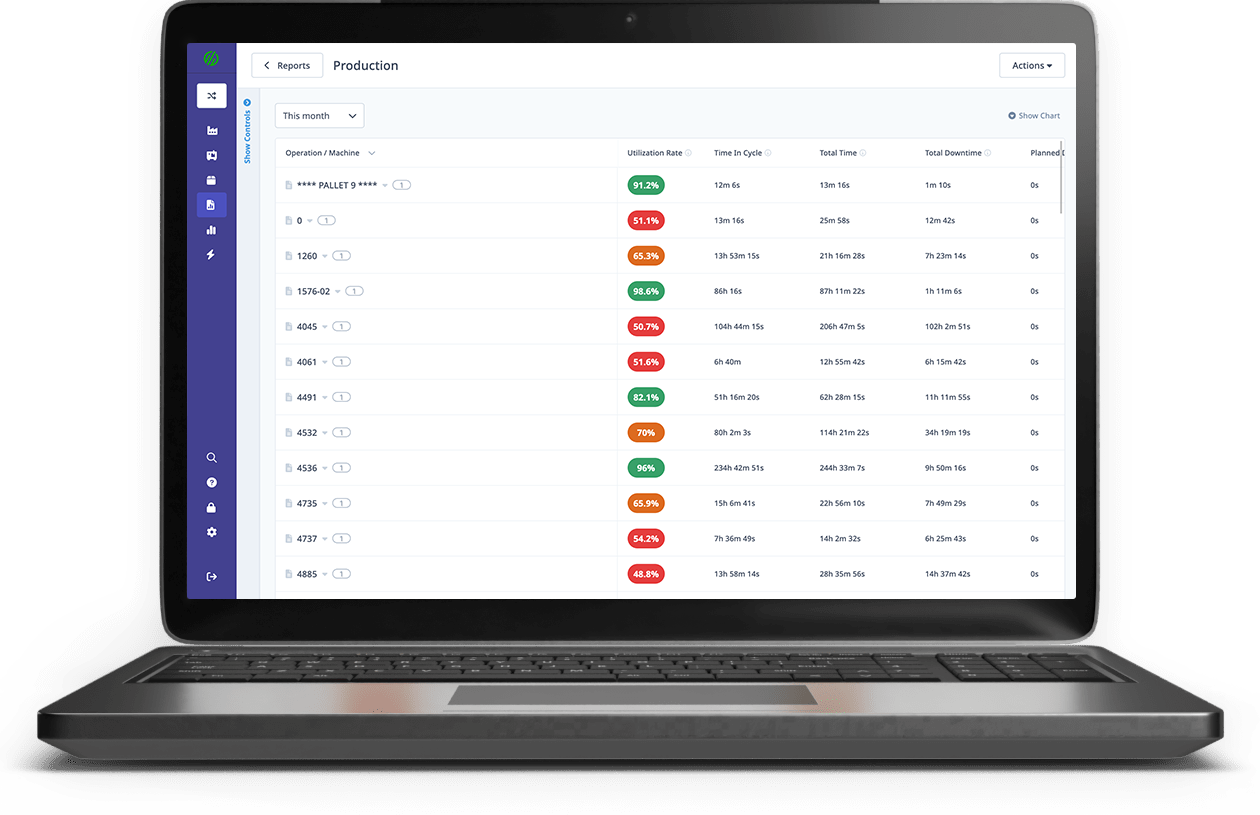

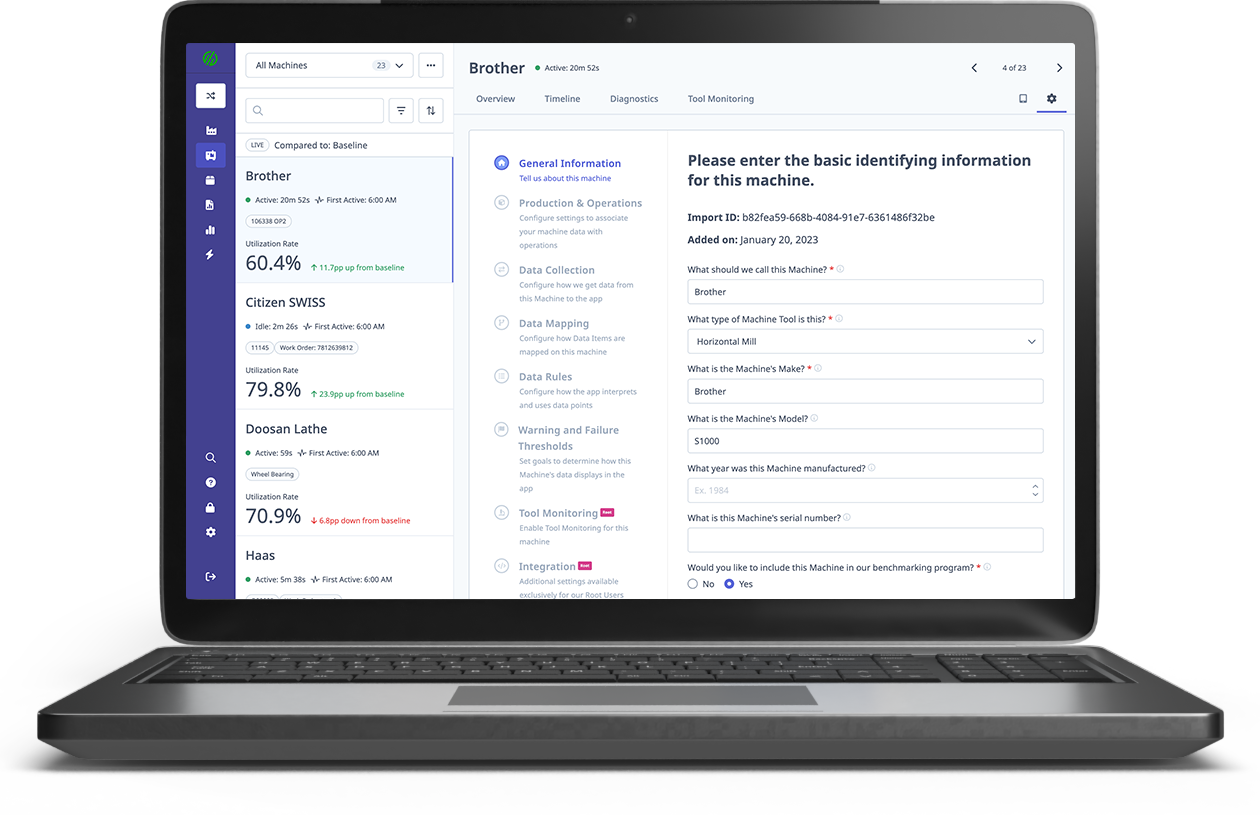

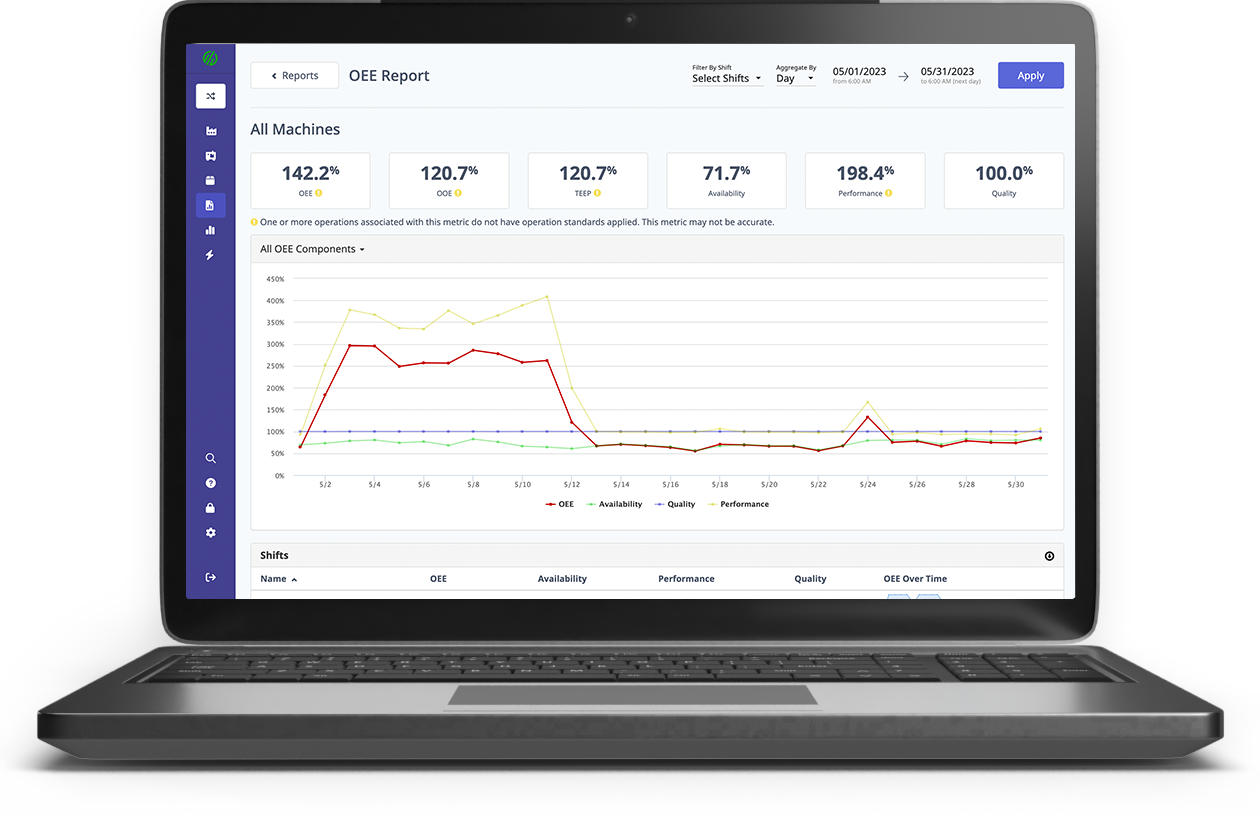

MachineMetrics production tracking software is a fully automated solution that gives you real-time (yes, real-time) visibility into critical areas like OEE, machine utilization, and downtime so you can quickly eliminate bottlenecks, increase capacity, and maximize efficiency.

The data you need to make faster, smarter, and more confident decisions is already there. You just need to tap into it. MachineMetrics features simple, “self-install” machine connectivity and a cloud-based solution that gives your team instant access to insightful production data they can actually use.

An enthusiastic MachineMetrics customer once told us that all we need to say on our website is “it just works.” They’re not alone. For our customers, the results speak for themselves: on average, they are able to increase manufacturing efficiency by more than 20%. With MachineMetrics, ROI is achieved in a matter of weeks - not months or years.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowEasthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027