Context

Track Operations from Machines

Automate production runs from machine data and trigger workflows when production falls behind.

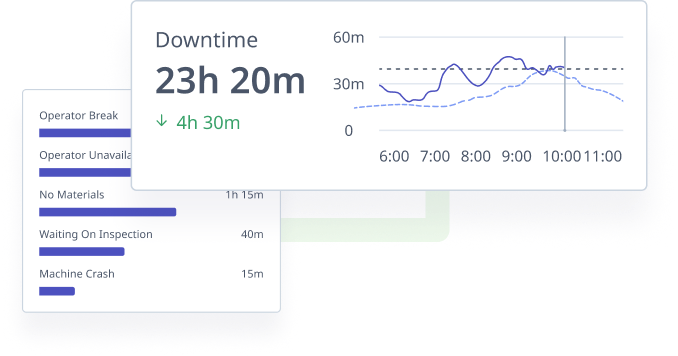

Baseline

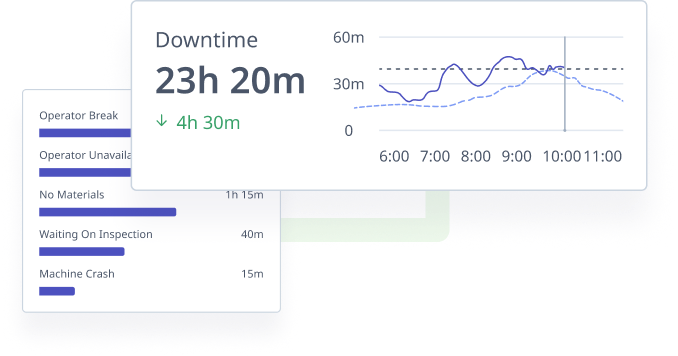

Understand Downtime and Changeovers

Downtime events are categorized from machine alarms or manually by operator interface. Track and optimize setup/changeover.

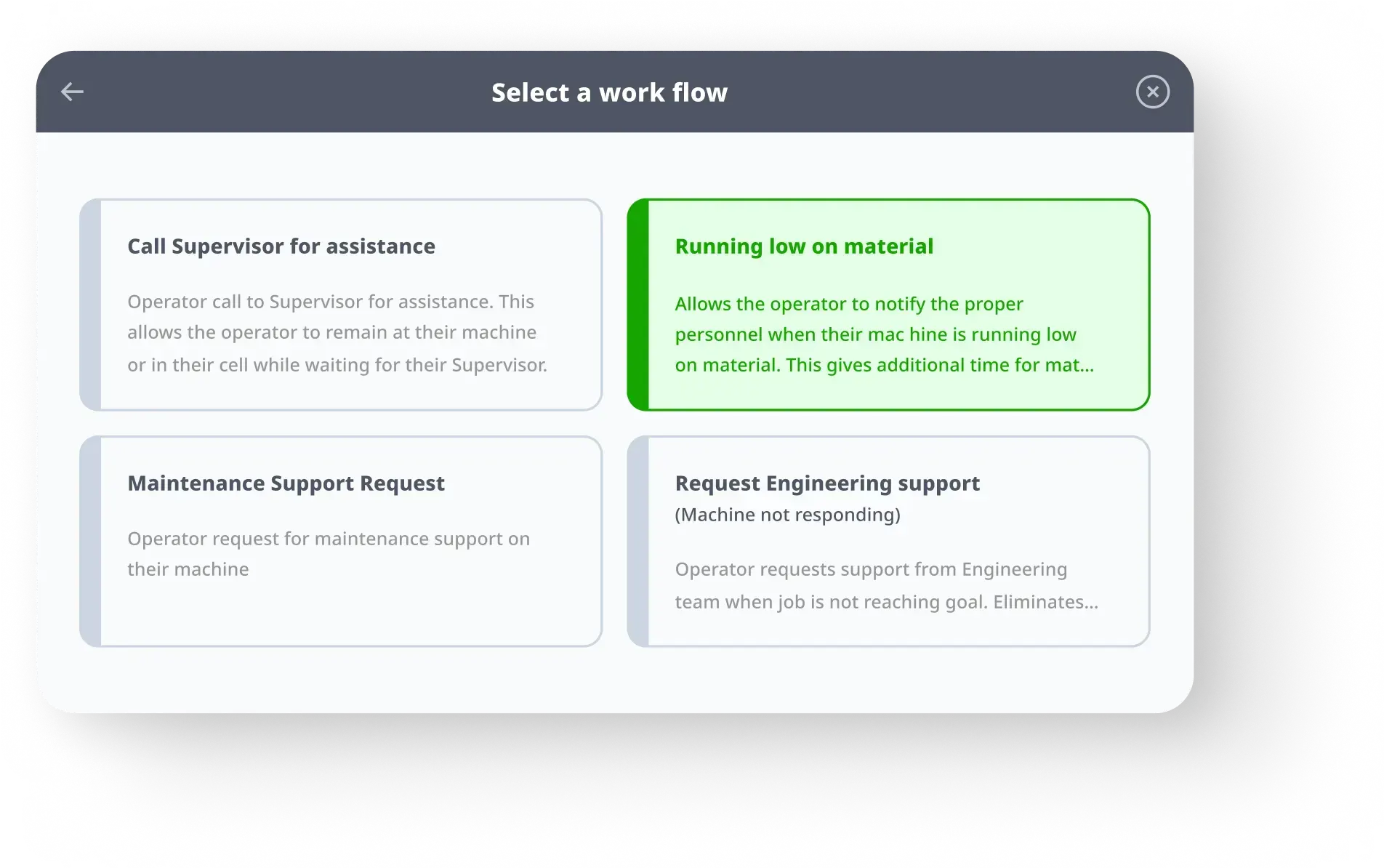

Communication

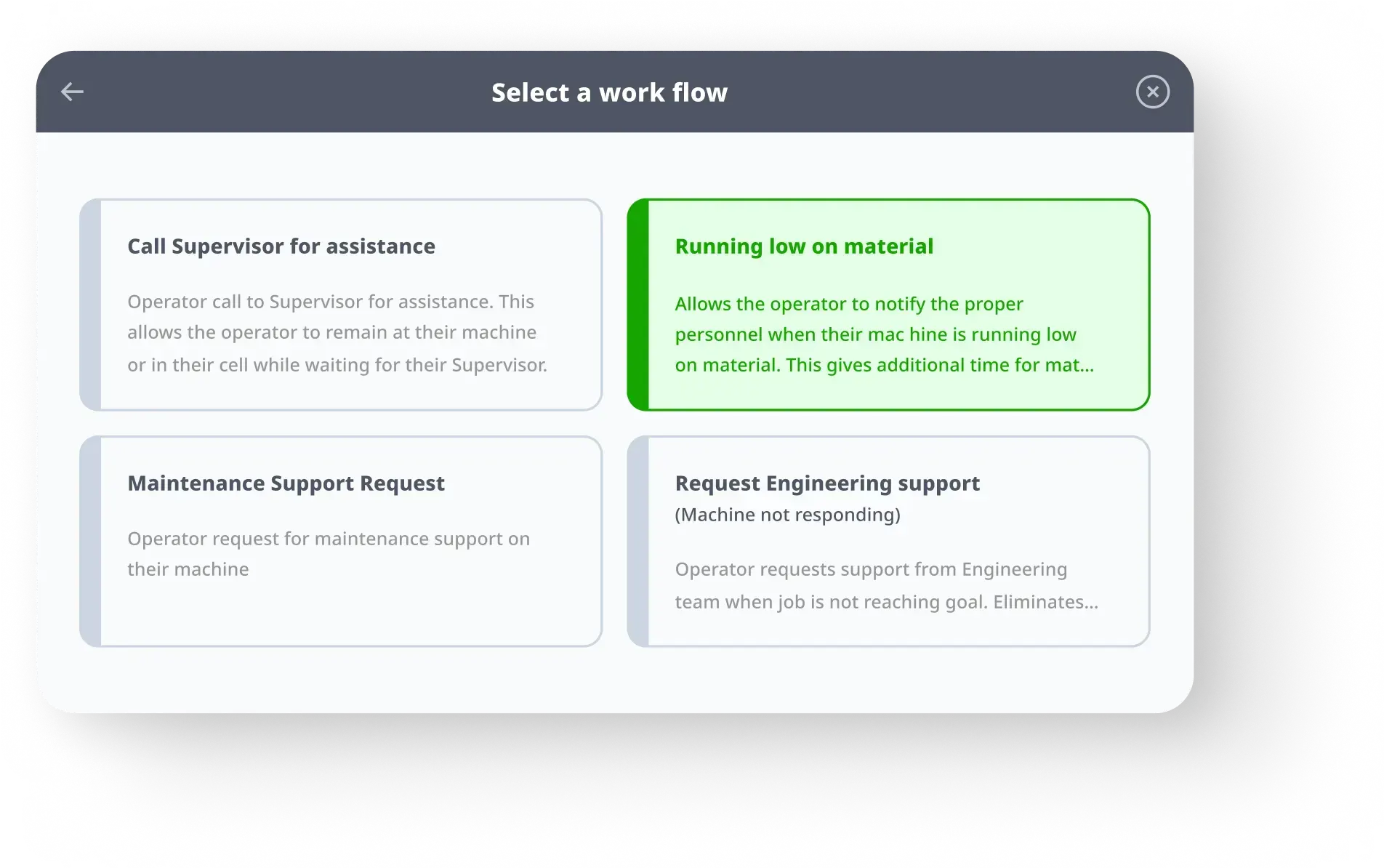

Automate Tasks with Workflows

Use automated workflows to get help from a manager, notify maintenance, or request material at a machine.

Visibility

Machine, Plant, and Enterprise Analytics

Identify critical areas of improvement at every level, then drill down to find exactly where you need to improve.

Status

Drive On-Time Delivery

Get a true understanding of cycle time across all part operations. Know the status of work orders to take action when production falls behind.