MaxAI has arrived! Learn all about it

here

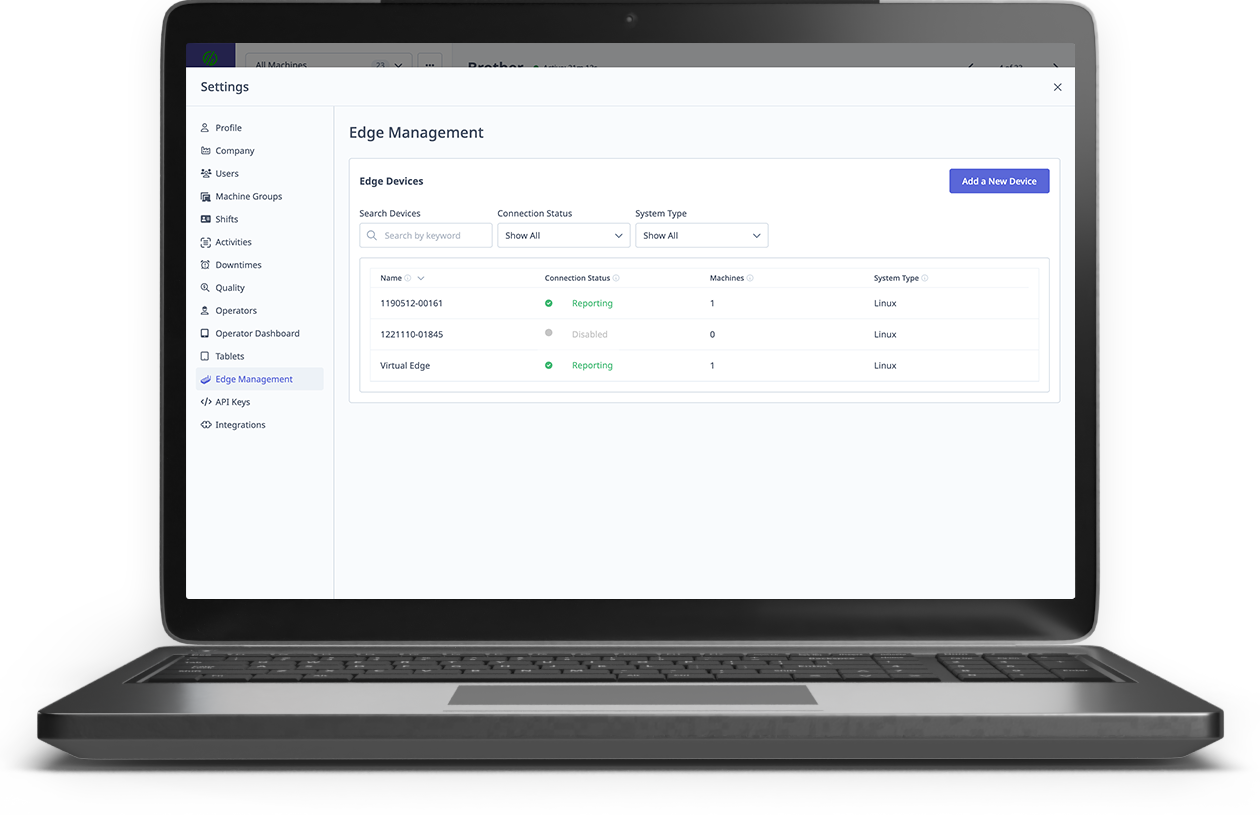

The foundation of any factory's digital transformation begins with the automated capture, transformation, and contextualization, of machine data. MachineMetrics Edge Platform provides a scalable solution for manufacturers that can be self-installed to easily collect data from any piece of equipment and enable actionable machine insights in a matter of minutes.

MachineMetrics Edge Platform and Cloud platform make a powerful 1-2 punch for manufacturers to make decisions at every level of their organization to increase their throughput and efficiency.

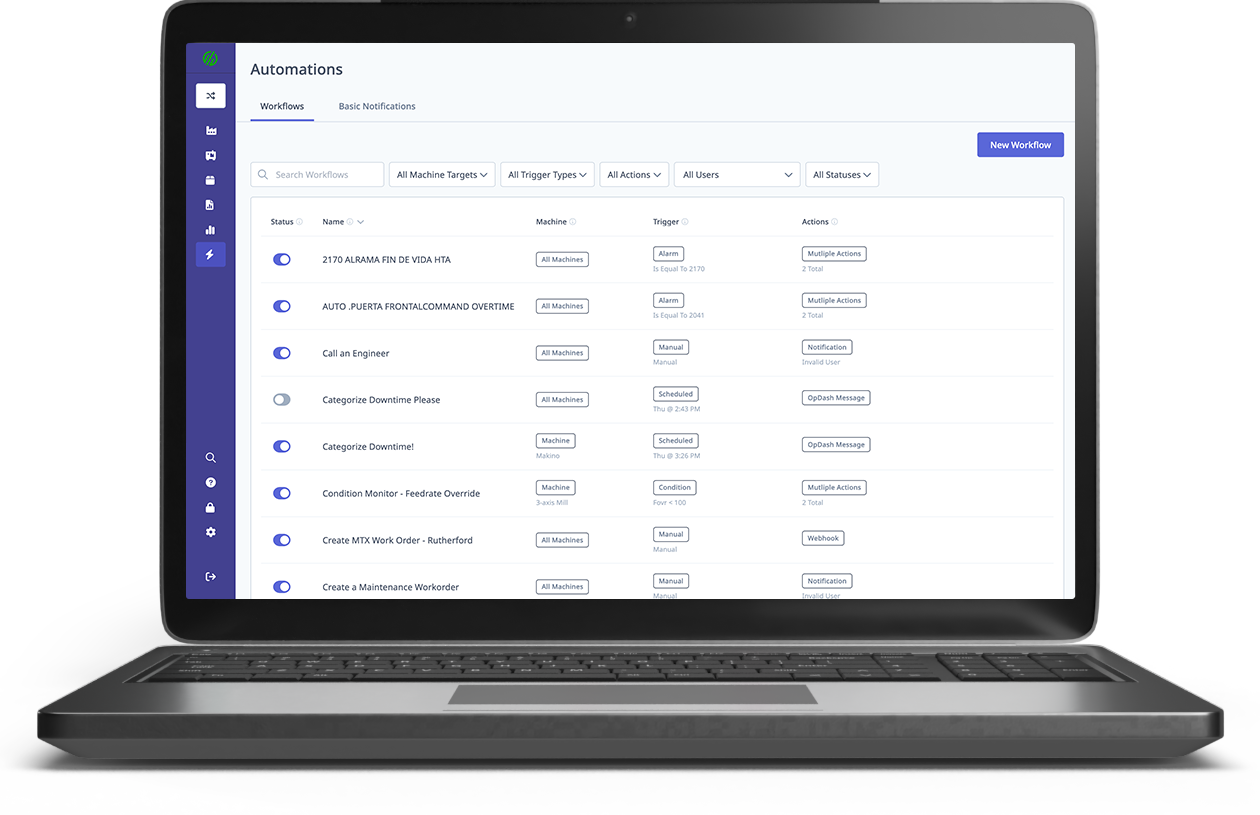

Our cloud platform provides the necessary capabilities to enable data collection, analytics, reporting, and data extensibility across the digital factory, as well as a location to train algorithms from large sets of historical machine data.

There are also hundreds of use cases where reaction time is the key to creating value, where sending real-time data to the cloud prevents that analysis from happening quickly enough. When these algorithms need to be deployed, MachineMetrics Edge is the solution that manufacturers should look to.

Manufacturing companies need to be able to make decisions at three different levels: at the machine level, at the factory level, and at the business level. By incorporating both edge and cloud capabilities, companies can maximize the potential of both approaches while minimizing their limitations.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowEasthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027