A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (OEE). Managers can use the bottleneck analysis to gain insights and implement process improvements designed to eliminate the issues.

Below, we’ll discuss this process in detail and explore a real-world case study of how one manufacturer identified manufacturing bottlenecks on their shop floor.

What is a Manufacturing Bottleneck?

A bottleneck in manufacturing is a constraint where upstream work in batches or on a production line arrives faster than the overall production line can handle. The congestion is like the neck of a bottle, or a funnel, that creates inefficiency and drives up costs through increased handling and lower equipment utilization in downstream equipment.

Short-term vs Long-term Bottlenecks in Manufacturing

Short-term manufacturing bottlenecks are temporary in nature and have a minimal impact on production operations. They usually consist of random course-of-business events that can’t be anticipated by a production system or production monitoring software. Short-term bottlenecks may resolve themselves or may need to be corrected once to eliminate the need to address the concern again.

Long-term bottlenecks are more concerning to manufacturers since they ’ re longer in duration and may be more difficult to spot or mitigate. They may result from broken or unoptimized processes or external factors like chronic shortages.

Long-term bottlenecks create unnecessary downtime and reduce production efficiency and morale. They’re often caused by outdated or un-automated equipment, but maintenance can also contribute to them.

Production Bottleneck Examples

Manufacturing bottlenecks can occur at almost any point in a production process, and while the list of examples is long, identifying them and finding a solution is possible.

Common manufacturing process bottlenecks include:

Absenteeism

Absent employees can create short-term bottlenecks when their position cannot be filled due to a missing skillset. This problem is easily corrected by cross-training employees on critical skills and requiring advance notice of absence whenever possible.

Training

Bottlenecks can occur if training is inconsistent across jobs. While one operator may be fully versed in a task, a new operator may need additional resources. Standard work and automated workflows will help staff understand which tasks need to be done and in which order.

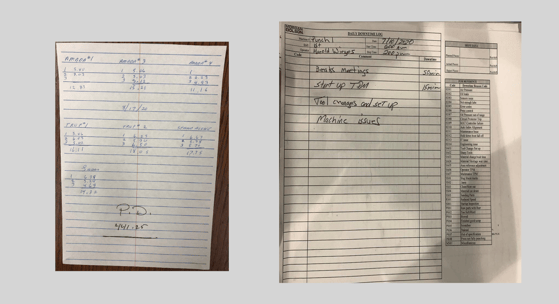

Manual Production Monitoring

Manual production monitoring is fraught with human errors such as missing data, transposed numbers, and bias. It ’ s also time-lagged, and data is often outdated by the time a problem is identified. Automated production monitoring platforms like MachineMetrics eliminate human error and provide actionable insights in real time.

Plug-and-play Machine Connectivity

Reactive or Preventive Maintenance

If maintenance only reacts to breakdowns or uses outdated preventive maintenance strategies, machine downtime will increase and create a manufacturing bottleneck. A machine data platform with advanced machine monitoring software will provide prescriptive insights that help reduce downtime, optimize the ordering of parts, and schedule maintenance during planned changeovers.

Manual Change Orders

Manual change orders can create bottlenecks as changes move slowly through the system. They may also not arrive at all machines at the same time. Automated workflows and standard work mean new information and instructions are available immediately to all who need them.

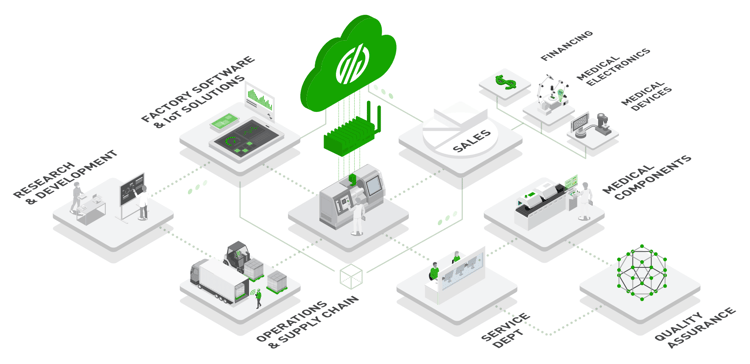

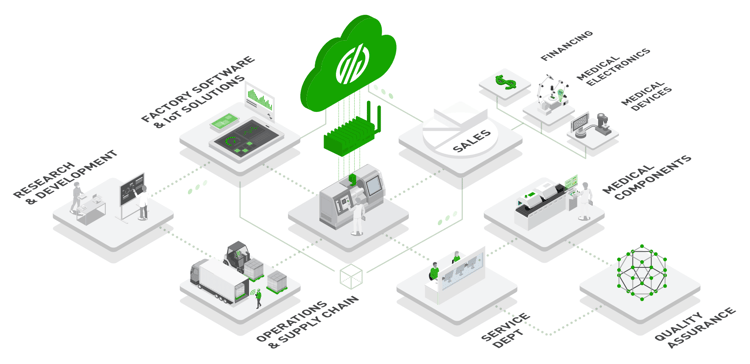

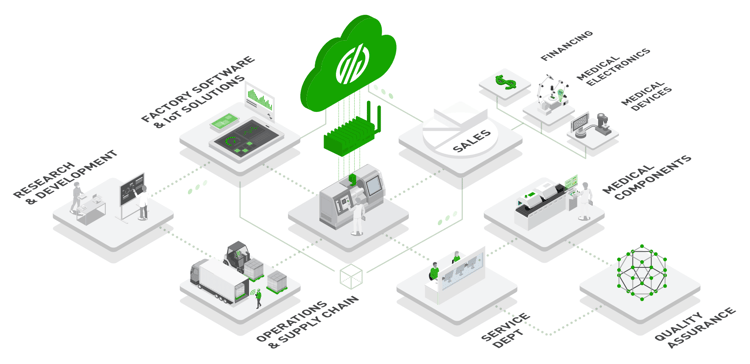

Integrating the systems, machine, and people on a shop floor can reduce bottlenecks thats result from technology siloes.

Integrating the systems, machine, and people on a shop floor can reduce bottlenecks thats result from technology siloes.

Common Causes of Bottlenecks in Manufacturing

Manufacturing bottlenecks can occur from a variety of sources, each with its own dynamics and solutions. These sources include:

Communication

Communication between teams or departments is critical. When these communications are verbal or paper-based, they can cause a bottleneck in manufacturing. This type of bottleneck may be as simple as an operator going on a break or a lost clipboard. This can be solved by deploying automated machine data collection solutions.

Manually collected production data is time consuming and error prone, leading to poor communication and insights.

Manually collected production data is time-consuming and error-prone, leading to poor communication and insights.

Processes

Process bottlenecks are task-driven constraints where the number of requests for a production machine exceeds the equipment's maximum throughput capacity. An example would be a drill press station that receives requests from several upstream machines, each requiring different hole sizes and depths. Time taken to change the tool and set the depth starves the downstream components.

Resources

Sometimes resources can cause bottlenecks. One example is labor hours available for specialized skill sets. If one technician is required to split their time between two or three specialized pieces of equipment, the flow of different parts can create a resource bottleneck where the labor hours available for each are less than what is available.

Technology

Technology bottlenecks often occur with fragmented software systems in siloed original equipment manufacturer (OEM) machinery. If these systems have no interoperability, the time required to program settings at each production step creates a bottleneck in manufacturing. If a programmable CNC machine is in the production stream before a manually set drill press, the technology is mismatched, prohibiting communication and interrupting the workflow.

Integrating the systems, machine, and people on a shop floor can reduce bottlenecks thats result from technology siloes.

Integrating the systems, machine, and people on a shop floor can reduce bottlenecks thats result from technology siloes.

How Much Do Bottlenecks Cost Your Business?

The effect of bottlenecks can be analyzed across several categories. First, bottlenecks cost time: machine time, higher lead times, and more. All that time reduces available production capacity for more orders and drives up the cost per unit of production.

Bottlenecks also cost in terms of productivity. Each long-term bottleneck sends ripples across downstream processes, reducing productivity per employee. As productivity falls, efficiency drops and orders become late.

Morale can also be impacted by bottlenecks. Employees want to keep processes moving and may become frustrated when a process isn’t moving as it should. This lowers morale and creates workarounds that are costly and may create bottlenecks for another process.

Finally, bottlenecks cost money. All the examples above have a dollar value that can be staggering. The cost of a long-term bottleneck in manufacturing can range from hundreds per hour to thousands or even hundreds of thousands, depending on the industry and size of the enterprise.

Benefits of Analyzing Your Bottlenecks

Analyzing bottlenecks has several key benefits. For one, it helps eliminate waste. Any constraint that slows or stops production will generate waste in the form of labor, material loss, or capacity loss. A practical bottleneck analysis will help eliminate this waste.

A second benefit is increased knowledge among managers. By understanding the reasons for the manufacturing bottleneck, managers can not only correct existing bottlenecks but also helps in the design of future production lines or production expansion.

| Increasing OEE by 30% and Capacity by Millions: Learn how instant shop floor visibility resulted in a 30% increase in OEE, a more effectively leveraged workforce, millions of dollars in increased capacity, and increased throughput via the reduction of bottlenecks. Watch the full video featuring OEE Director Matt Townsend. |

How to Conduct a Bottleneck Analysis

Bottleneck analysis requires looking at the entire production process. While data and performance on each piece of equipment in the line are needed, the bottlenecks often occur during the transition, staging, communication, or setup phase.

In addition to looking at the overall production process, bottleneck analysis needs to include people issues such as labor, training, and skillsets. It may also require a review of the supply chain to address any material constraints. And, of course, measurable performance such as machine speed, equipment age and capability, and capacity analysis must be included.

Conducting a production capacity analysis requires a tremendous amount of data collection to be effective. This means collecting production data, collating it, standardizing and analyzing it for trends, and spotting the areas where bottlenecks occur.

Tools and Strategies

There are many well-established strategies available to identify and resolve bottlenecks on the shop floor. We document several of these below:

DMAIC

DMAIC stands for Define, Measure, Analyze, Improve, and Control. It is a Six Sigma process improvement tool that allows continuous feedback loops to refine a process once a bottleneck has been addressed.

Theory of Constraints

Ideal for bottleneck analysis, the theory of constraints helps teams identify the biggest limiter for achieving the best results. Once the limiting factor is identified, it’s adjusted and improved until the constraint is eliminated.

Root Cause Analysis

Every constraint has a root cause. By digging deep to uncover a root cause, systemic improvement can be achieved, eliminating "band-aid" solutions. It focuses on the how and why aspects of the constraint.

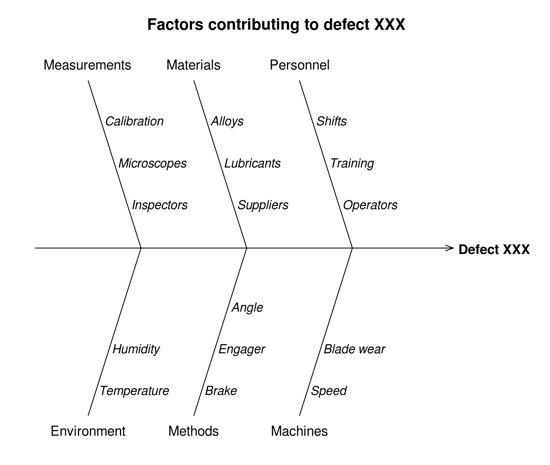

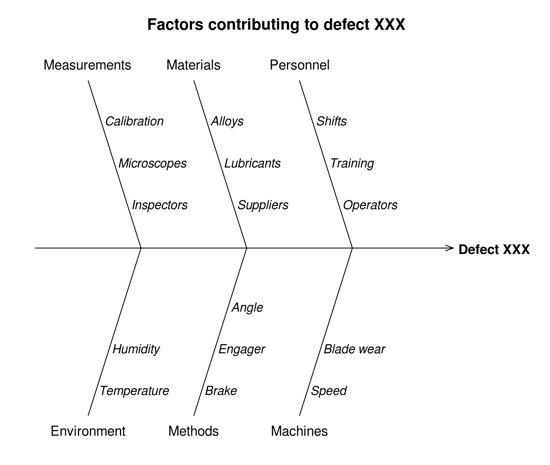

Fishbone Diagram

A fishbone diagram approaches the cause and effect of a bottleneck in manufacturing. The problem is the "head" of the fish, and the causes feed into the spine. This is an effective tool that helps teams visualize the problems as they iterate solutions.

A fishbone diagram, also known as an Ishikawa Diagram, shows the factors contributing to a problem. [Image Source]

A fishbone diagram, also known as an Ishikawa Diagram, shows the factors contributing to a problem. [Image Source]

Plan-Do-Check-Act

A continuous improvement tool, PDCA approaches improvement from a cyclical view. The cycle can be repeated endlessly to improve the system further.

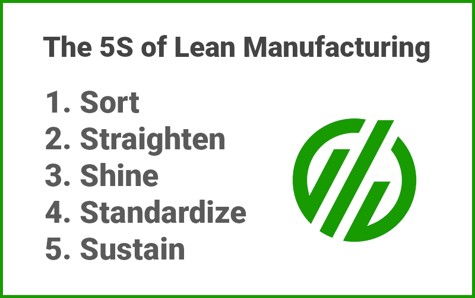

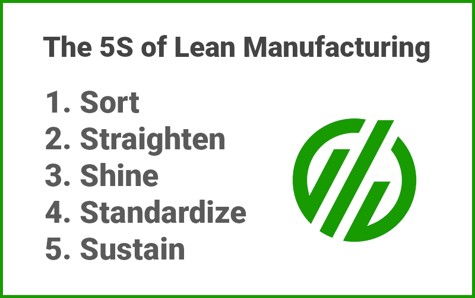

5S Framework

By addressing the physical space, constraints can often be uncovered and addressed. 5S Framework – most have heard of the sort, set, shine, standardize, sustain components of 5S framework in the context of lean. It’s a hands-on physical and easily visualized tool when conducting an analysis.

Value Stream Mapping

Another lean tool, value stream mapping captures the information and materials for a process. It’s also highly visual for teams conducting bottleneck analysis and is meant to eliminate constraints by including only optimized steps that add value.

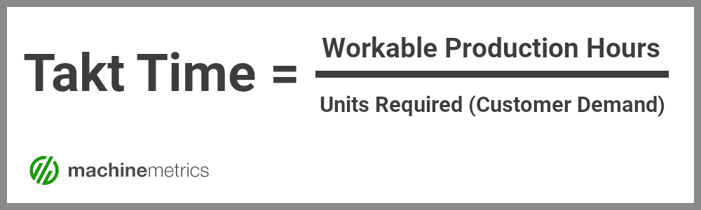

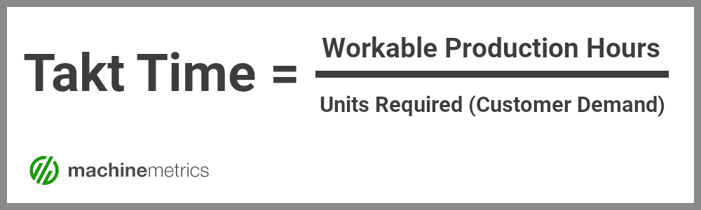

Takt Time

Any bottleneck analysis will include measurements of takt time, the time required to produce a product, and the materials, labor, and equipment available. An optimized takt time will act as a benchmark and will help identify maximum capacity and labor constraints.

Case Study

Avalign Technologies, a medical device manufacturer with facilities across the US, was experiencing difficulty in tracking OEE and machine downtime, leading to issues on the shop floor that included poor machine performance, unclear standard operating procedures, and production bottlenecks.

In this exclusive video case study hosted by AWS, OEE Director Matt Townsend discusses the impact of deploying MachineMetrics across four of Avalign's facilities.

Learn how instant visibility into shop floor performance resulted in a 25-30% increase in OEE, a more effectively leveraged workforce, millions of dollars in increased capacity (without additional equipment), and increased throughput via the reduction of bottlenecks.

MachineMetrics is helping Avalign pursue its goal of providing best-in-class medical equipment by giving the company full control of machine and operational data to build a strong, competitive advantage in the marketplace.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments