Supercharge your predictive analytics with high-frequency machine data. Diagnose, predict, and avoid failures with unprecedented visibility into the condition of your machines with no sensors required.

Most manufacturers are left blind as to when their machines will go down. The result is costly unplanned downtime, unexpected maintenance events, and a reduction in throughput. While there are hidden indicators of when machines are likely to fail, it’s impossible to find these insights by manually capturing machine performance and health data

Aftermarket sensor installations can be difficult to standardize, difficult to install, and are subject to degradation

UNRELIABLEWhere do you place the sensor, and what happens when it gets bumped out of place? Can your customer install and tune the sensor themselves?

INACCURATEImagine you’re trying to learn a new tune on the piano, but the sheet music only has one note out of every ten.

EXPENSIVEInstallation time and costs of sensors add up dramatically.

In 2020, our data science team launched a program focused on the application of high-frequency machine data for predictive maintenance with the goal of accelerating predictive analytics use cases for machine tools. Our team discovered a way to collect data at 1 kHz directly from the control of CNC machines without using sensors that can immediately be used as inputs to time-series or machine learning models to predict machine failures.

Supercharge your predictive analytics applications with high-frequency machine data to diagnose, predict, and avoid failures on your manufacturing equipment. No sensors required.

Understanding why issues have occured on machines in the past has been a notoriously difficult task. While low-frequency data can accomplish condition-based monitoring, Trying to do condition-based monitoring on say, spindle load, requires higher fidelity.

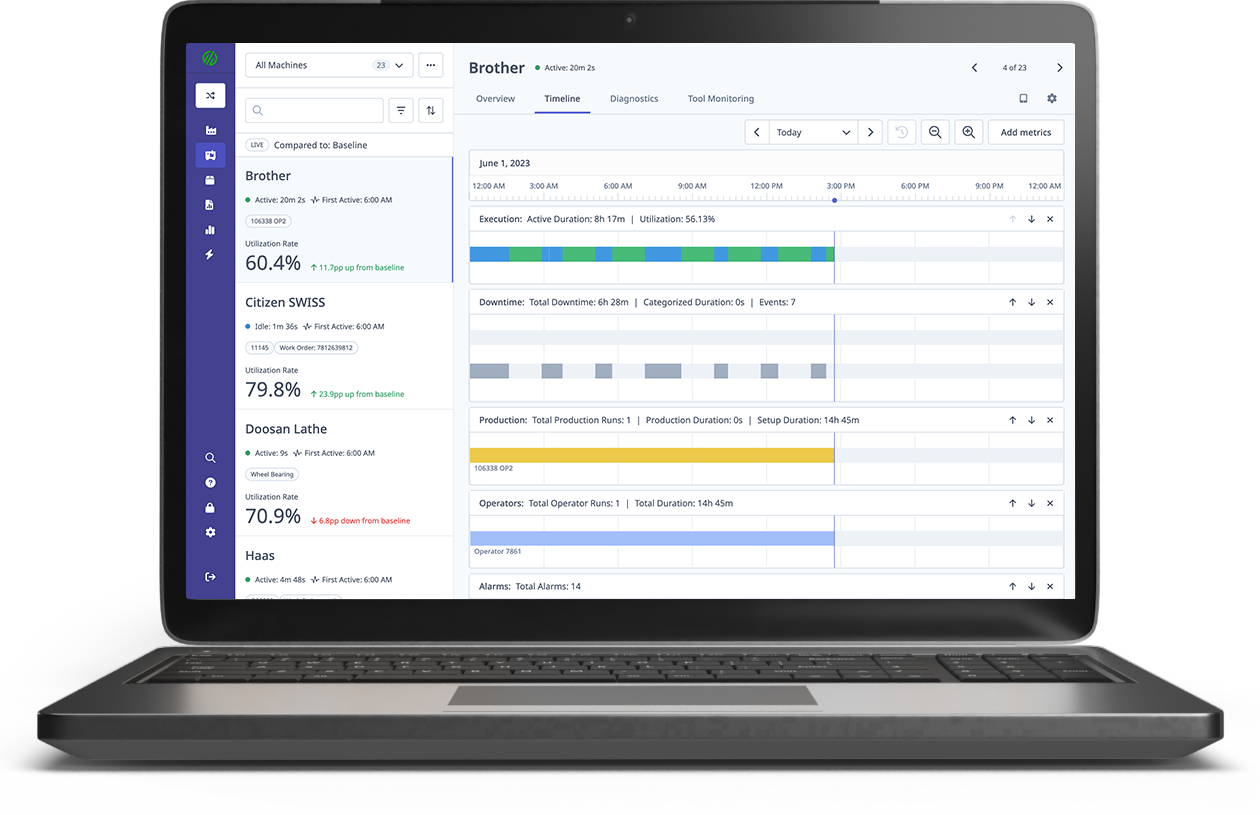

Collecting high frequency data from the control delivers unprecedented visibility and fidelity into the health and condition of the machine, enabling diagnoses that were once impossible.

Use key indicators within your machine performance and condition data to trigger action before a downtime event occurs.

Transform from a calendar-based maintenance program to condition-based or predictive maintenance.

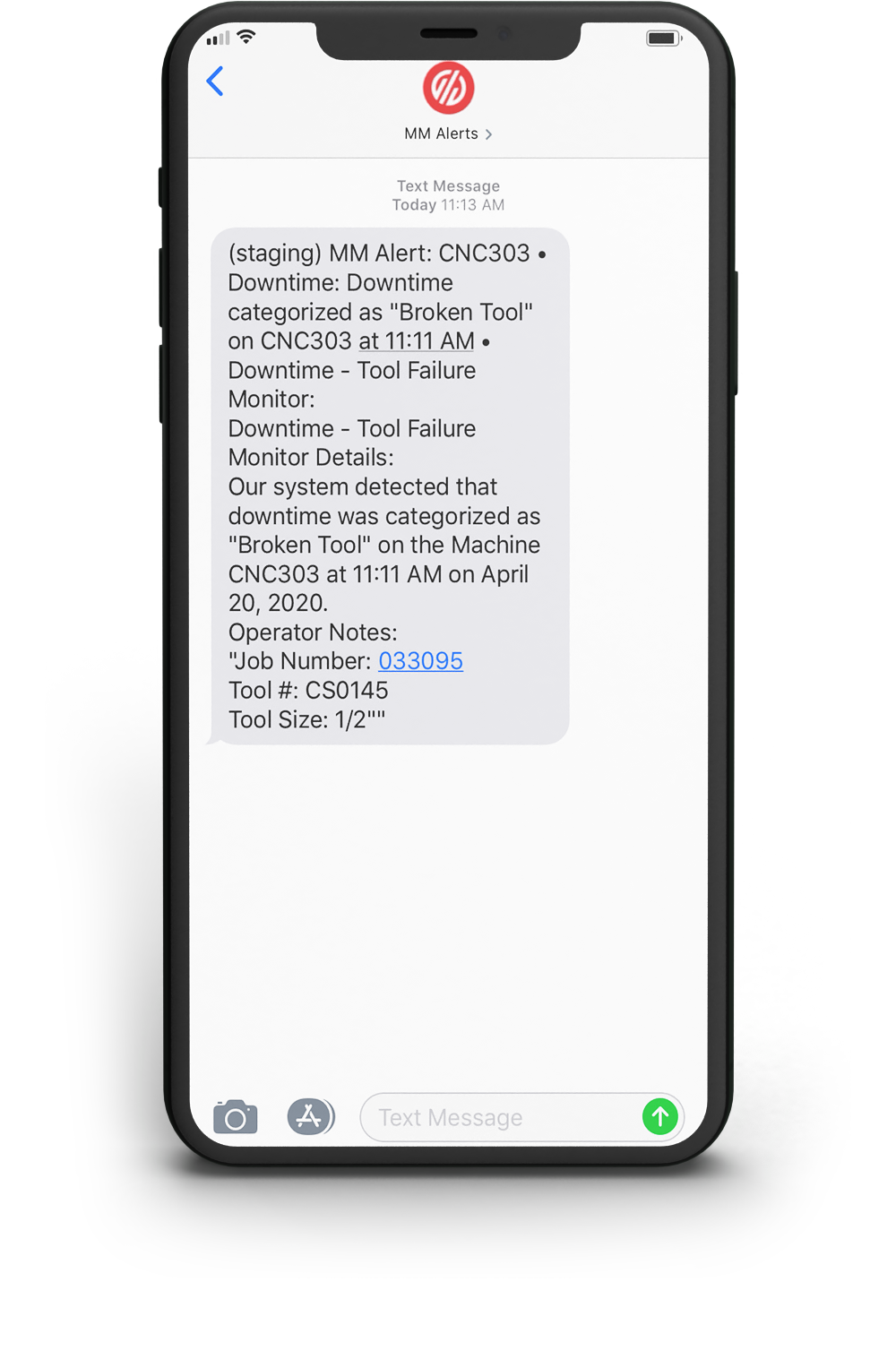

Leveraging high-frequency data on spindle load to determine when the tools will fail, BC Machining can now detect a tool failure with 99% confidence up to 40 minutes before it fails.

We are actuating the machine to perform a Feed-Hold when this algorithm is triggered to stop the breakage from happening.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowEasthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027