Key Takeaways:

- Turning manufacturing data into actionable insights improves operational efficiency.

- Effective data strategies require real-time analysis and integration with workflows.

- Operationalizing data helps companies make informed decisions and boost productivity.

History has shown that technology often flips the script on a particular headache. Fifty years ago, most people had three channels on their TV, and the complaint was that there was nothing interesting to watch. Fast forward to now: there are hundreds of channels and multiple streaming services. People have so many options it's hard to find something they like among the ocean of choices.

Manufacturing's relationship to data has been similar in many ways. Companies have always needed data to improve their operations. But with manual tracking, recording, and analysis, there was only so much data available. That data was often outdated, error-filled, and full of bias or gaps that only added to the headache.

Today, digital solutions like cloud storage have further encouraged manufacturers to collect and store data, often to their own detriment. Like the puzzle of "500 channels and can't find what to watch" on cable, managers find themselves buried in unstructured, unorganized data.

Industry 4.0 technologies - like industrial IoT - allow them to operationalize that data to drive value. The key is turning the ocean of data into usable, scalable, and value-added insights that drive operational excellence.

Let’s take a look at how manufacturers can make this a reality.

Connect

Manufacturing equipment generates millions of data points, but this volume becomes overwhelming when left in its raw state.

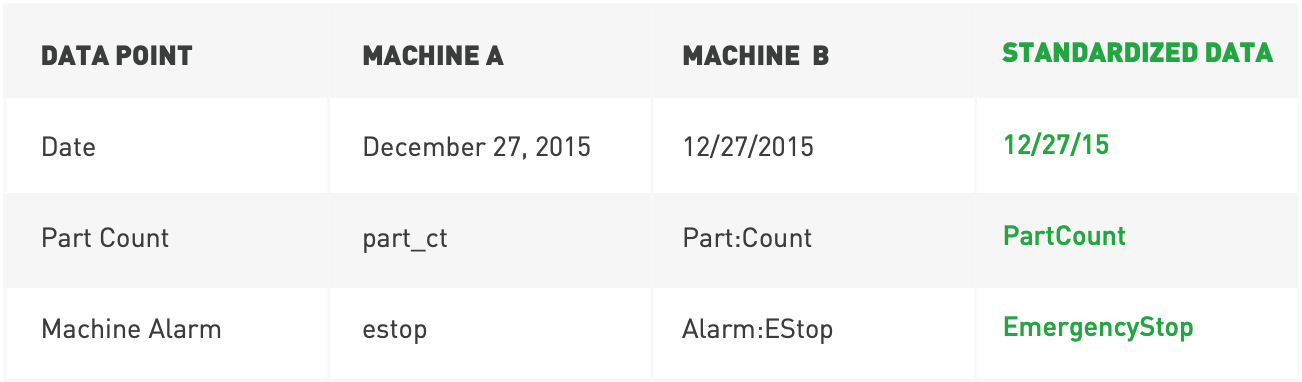

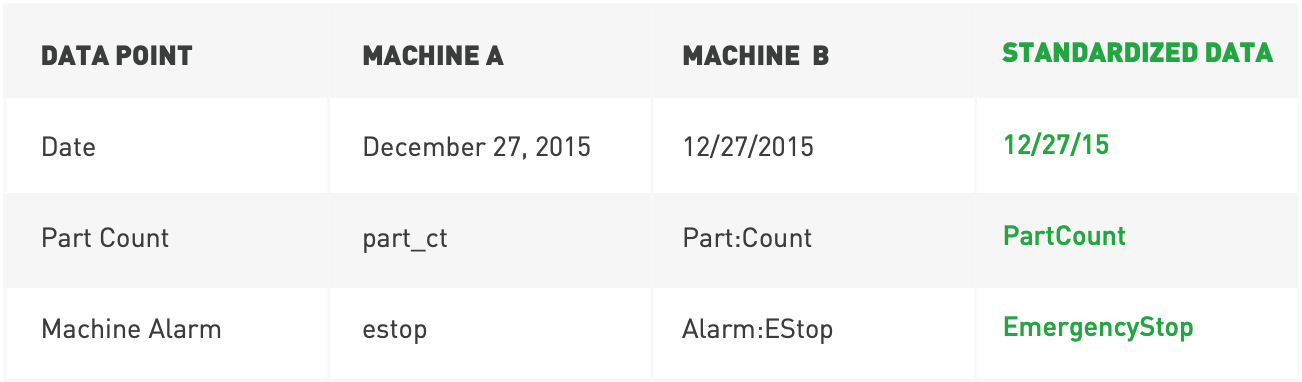

Connectivity platforms enable manufacturers to operationalize this data. Sensors, PLCs, and machine control data can be captured and sent directly to the cloud for cleansing, organization, and standardization. Edge computing devices are also deployed at the machine level and work through nodes in an edge network to partially process data prior to sending it to the cloud.

With MachineMetrics, manufacturers can connect to any machine, from the newest OEM equipment with embedded IoT functionality to older analog machines. This connection transforms data into a standard model.

Not to mention, it prevents manual data collection altogether.

By creating a standard model with edge device compatibility, some data is sent directly to the cloud, some is partially processed, and some is immediately actionable to control and automate equipment at the source.

In addition to creating a standard data structure that aids cloud-based analytics, MachineMetrics relies on three additional variables critical to any manufacturing system:

- Fast-to-value: Manufacturers are wary of new software with complicated and lengthy learning curves. MachineMetrics is a plug-and-play solution, collecting data out of the box in minutes.

- Scalability: As assets are added, moved, and reconfigured, they can be scaled with additional cost-effective devices without a major revamp of the entire system.

- Maintainability: MachineMetrics is easy to maintain, unlike a solution that is configured manually. DIY solutions are also costly, requiring in-house technical resources. Not to mention, they are prone to high rates of failure.

Plug-and-play Machine Connectivity

Analyze

Going directly to the data source during connection reduces time to high accuracy analysis. After all, machines don’t lie! They provide a real-time, accurate stream of data that, with the right solution, enables analytics out of the box.

With structured and contextualized data, manufacturers can drive valuable predictive and prescriptive insights. Because the structured and organized data is centralized in a cloud-based platform, it can be further analyzed, contextualized, and made available to other systems.

The quality of data and analytical insights empower these connected software systems to perform at a rate and capability that was previously limited by the quality and context of data entered.

Business Intelligence (BI), Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), and Computerized Maintenance Management Systems (CMMS) will all find their core functionality and capabilities enhanced by equipment data.

This leveling of the playing field entirely defeats the era of siloed data to enable a single source of truth for improving production processes. Production, maintenance, quality, planning, and supply chain teams all benefit from operationalized data that allows real-time, data-driven decision-making in all areas of the enterprise.

Take Action

Operationalized data enables operators, technicians, managers, and executives to act on the insights generated by machine data. Companies will realize several benefits that drive operational excellence, reduce cost, and optimize processes. Here are a few use cases:

- Production Visibility: Production visibility using real-time data lets operators and managers respond quickly to reduce downtime, lower quality rejects, and improve equipment lifespan.

- Machine Condition Monitoring: Machine condition monitoring enables the development of predictive maintenance strategies to lengthen asset lifespan, reduce spare part costs, and intervene before problems arise.

- Bottleneck Analysis: Some constraints, or bottlenecks, may be related to the staging of materials, operator performance, facility layout, and other issues. Operationalized data allows managers and engineers to develop process improvements and layouts to resolve bottlenecks.

- Root Cause Analysis: Every problem has a root cause. In manufacturing, root cause analysis has long been a manual process of Lean or Six Sigma methodologies. Accurate production data helps to identify the main source of waste.

Manufacturers can now take action because data has been collected and transformed. It is ready for use, which is the entire point of collecting it in the first place. Make better decisions on the shop floor, enable automation, and fuel all your systems with real-time production data to enhance their capabilities.

Leaving the Past Behind

Collected and analyzed data helps put an end to disconnected systems of the past. Advanced analytics achieve this by taking the new torrent of data and rendering insights that managers and staff can consume and apply across the entire operation.

This process tames the tidal wave of data and lets companies use their data effectively. It gives them control over their data to use it in their current state and grow and enhance its benefits against future improvement strategies.

With MachineMetrics pre-built, out-of-the-box reports and intuitive dashboards, companies can immediately put their data to use and improve production visibility across the organization.

But this is only the beginning of the data-driven journey. As managers realize the impact of trends and begin to act on the insights generated from analytics, they can bring to bear powerful advanced workflows that help automate processes.

Using MachineMetrics to Achieve Data-Driven Action

MachineMetrics empowers stakeholders with accurate data without overwhelming users. Device connection is simple and works across any machine type and generation so that manufacturers can focus on manufacturing, not building software.

The MachineMetrics Machine Data Platform lets you automate data capture, transformation, and analysis. With simple-to-install device configuration and an all-inclusive scope for any age or model of machine, MachineMetrics provides you with the tools you need to transform your manufacturing operation. This data-driven action enables you to accelerate process improvement and improve efficiency, capacity, and maintenance.

Plug-and-play Machine Connectivity

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments