The digital transformation of industrial production enterprises relies on the internet of things (IoT) for connectivity, visibility, and deeper insight into performance. And although the success of Industrial IIoT within manufacturing is accelerating revenue growth, challenges relating to cybersecurity, high investment costs, and implementation still exist. These challenges have led many manufacturers to turn to DIY IIoT with the aim of mitigating risk or managing cost.

But how successful have DIY IoT implementations been?

A Cisco research study sheds some light on the success rate of implementing IoT yourself. The study took into consideration six phases of implementing an IoT strategy, including strategic planning, design and architecture choice, implementation and deployment, management, support, and data analytics. The results showed that approximately 50% of all DIY IoT projects failed while organizations who chose to work with vendors generated higher returns from the investments made.

The question remains: Why is there such a high failure rate for DIY IoT? There are four primary downsides to do-it-yourself IoT initiatives:

- The High Cost of Building an IoT Platform

- Difficulty of Scaling out of Pilot Purgatory

- Intense Competitive Pressures

- Technical Shortfalls and Human Error

High Cost of Building an IoT Platform

Although the initial cost of engaging a vendor to handle IoT implementation through its IoT platform and hardware deployment are considerable, the alternative is more capital intensive in the long run. The example of a regional food distributor interested in tracking and managing a fleet of 2,000 trucks highlights these differences.

In this case, the initial cost of purchasing and engaging a vendor to set up the connectivity equipment, IoT devices, and manage data analytics on its IoT platform is approximately $200,000. This cost also comes with subscription plans to the IoT platform at approximately $24,000 annually. On the other hand, the total cost of an enterprise-grade DIY project may start at a $100,000 but balloon to approximately $2.6 million within 5 years. These increased costs are accrued from handling regular updates, deploying additional IoT devices and managing the data analytical aspects in-house which all add to the total cost of ownership.

Want to See the Platform in Action?

The time invested must also be taken into account. Statistics show that it takes approximately 30 months to build an IoT platform from scratch and successfully deploy within an enterprise. The design and development of hardware, its applications, and a functional IoT platform account for the time expended for a DIY IoT project. While vendor-specific solutions can be rolled-out immediately once an implementation strategy has been created and agreed to.

Scaling Out of Pilot Purgatory

The best-laid plans are only as good as their implementation. With IIoT, enterprises can purchase all the shiny hardware, sign up to a cloud platform and still fail to scale out of the proof of concept stage. Statistics show that approximately 70% of enterprises fail to scale out of pilot purgatory when planning to implement IIoT strategies. This highlights the knowledge and skill gap most DIY enthusiasts lack, which leads to the challenges enterprises face with scaling out of purgatory.

Competitive Pressures

The competitive edge IIoT provides enterprises depends on how it is implemented and the time frame of its implementation. With 75% of manufacturers integrating IIoT to enhance their business operations, any delays in implementation could lead to enterprises lagging behind the competition. Rushing to develop a DIY IIoT strategy could also result in shoddy implementation and no returns on the investment made.

Technical Shortfalls and Human Error

A recent study puts human error or employee negligence as the top cyber security threat enterprises face. According to the study, 96% of Americans think employee negligence contributes to breaches. A further study by Kaspersky states that 52% of businesses now admit that their employees are their biggest weakness in IT architecture security.

These statistics put the challenges of setting up and managing IoT architecture in-house in the right perspective. Stakeholders will have to rely on the technical abilities and security sensibilities of the tens or hundreds of employees with access to the IoT platform. Thus, even with a cybersecurity standard or regulation in place, these regulations cannot predict or account for employee negligence.

Best Practices for Adopting IIoT

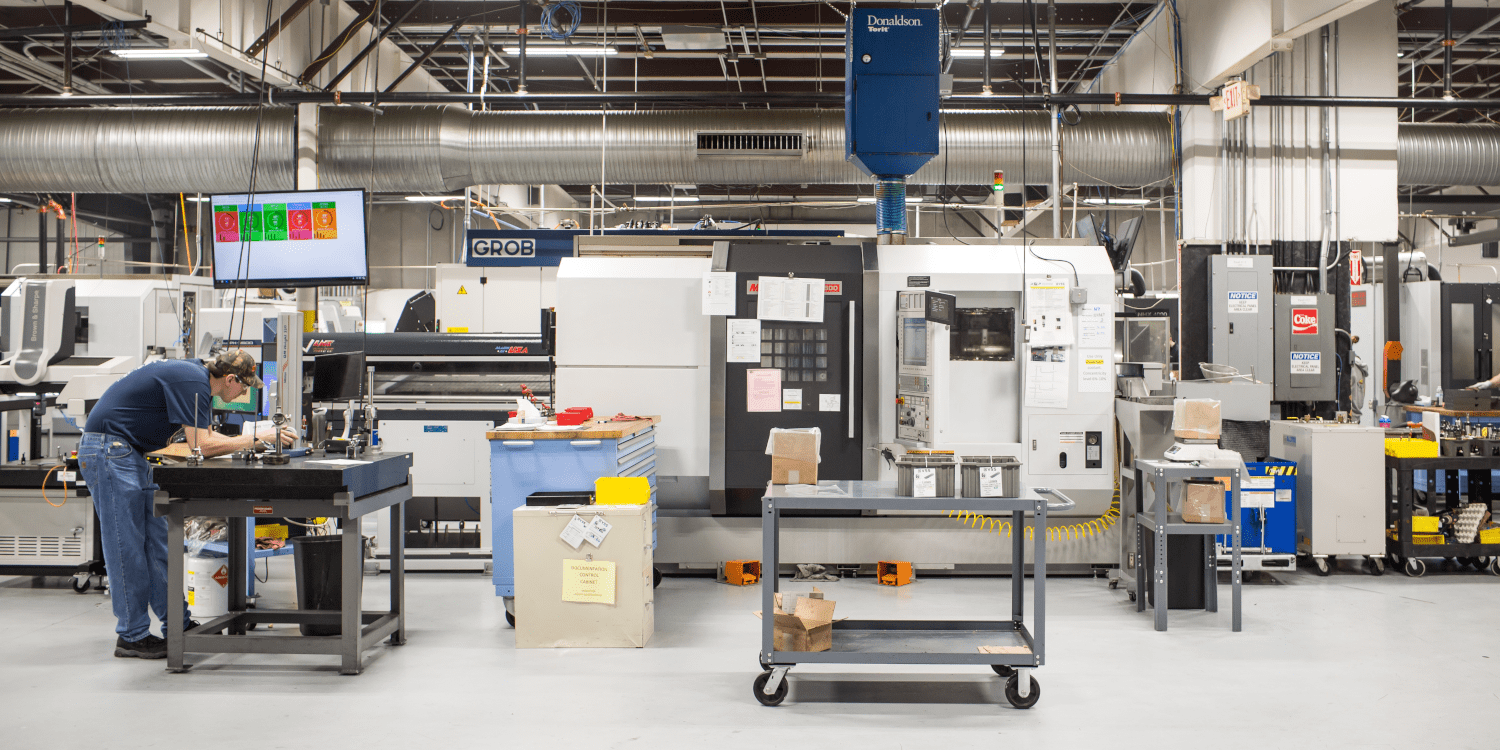

Successful IIoT initiatives depend on selecting hardware and software solutions that meet the specific requirements of an existing ecosystem. Any approach that simply relies on purchasing what looks good while overlooking the needs of the assets within a shop floor will struggle to scale out of purgatory.

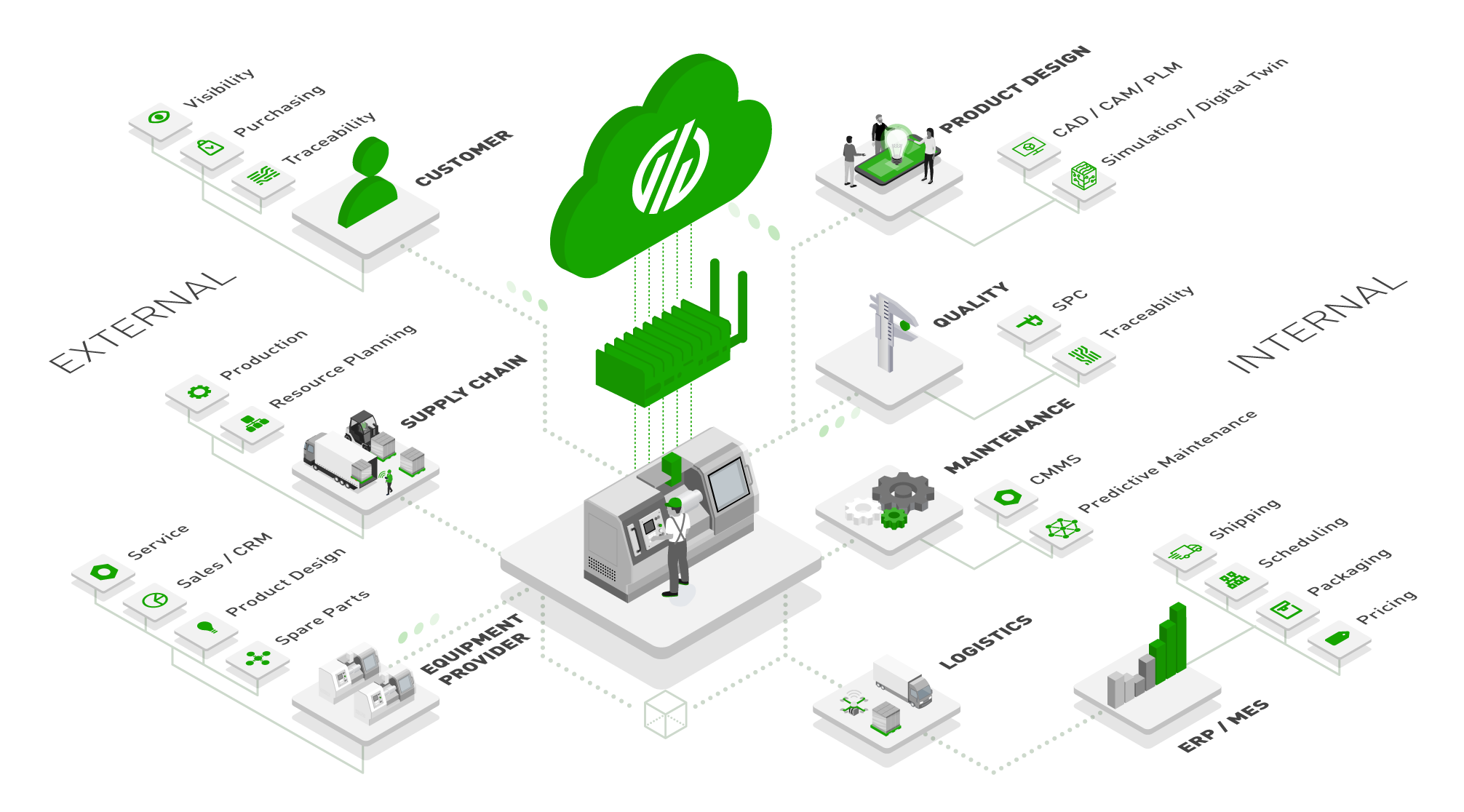

If you choose to use the ‘buy and build’ approach, leveraging on platforms that provide services outside your key competencies is recommended. An example of such a platform is MachineMetrics. MachineMetrics helps you expedite time-to-value and provide the foundation for scaling Industrial IoT across your business operations, while prioritizing internal resources towards your competencies.

Should You Purchase an IoT Platform or Build One Yourself?

Available research has shown that going the DIY path with regards to IoT implementation is a less viable option to take. As for those who have taken that route, only 29% have found some fulfillment and received returns on the considerable investments they made. This makes it important for every industrial enterprise to remember that the goal is to capitalize on IIoT to enhance operational processes and not to become a digitization enterprise.

With MachineMetrics, the process of integrating a data-driven approach that beats the competition is simplified. Today, MachineMetrics Manufacturing customers are gaining tremendous value and witnessing 20% increases in manufacturing efficiency on average within the first month. You can learn more about the value proposition enterprise-grade IoT platforms by analyzing the features of the MachineMetrics IoT Platform.

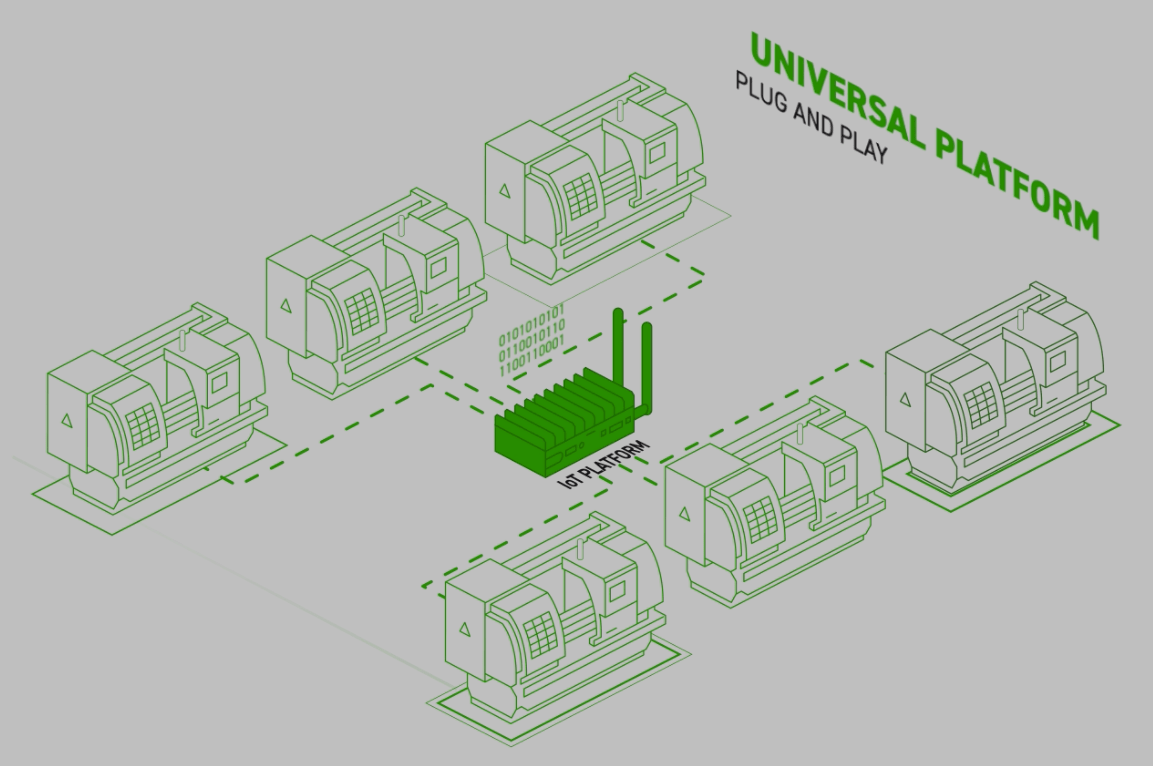

Plug-and-play Machine Connectivity

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments