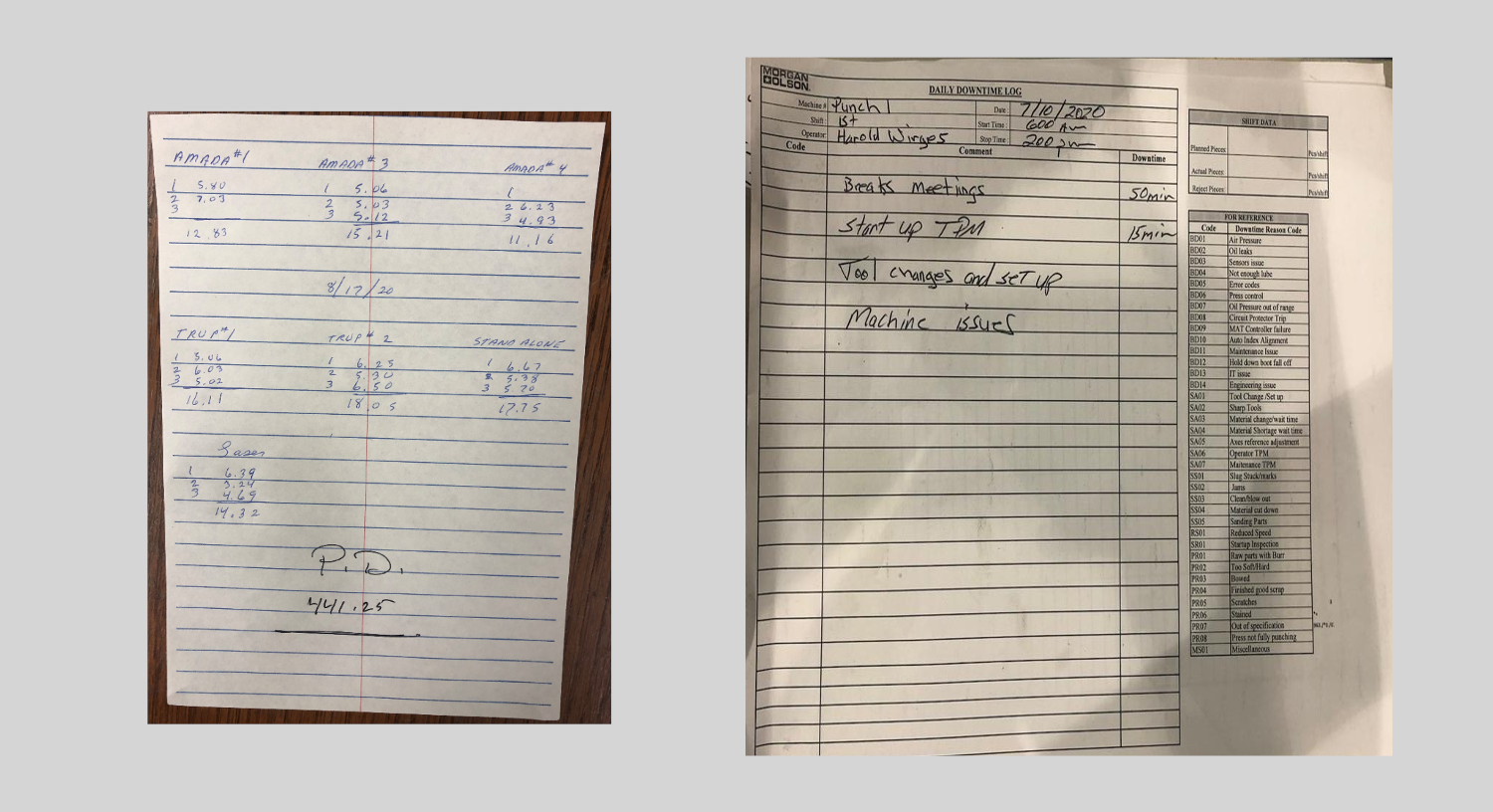

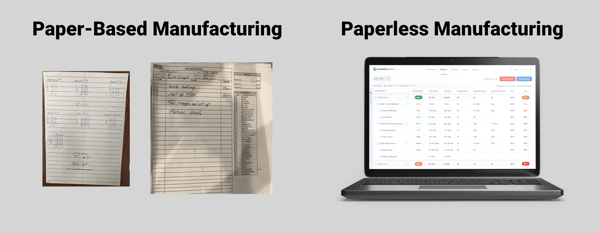

In traditional manufacturing operations, production visibility was limited by manual processes for tracking data. Operators, technicians, and managers relied upon a sea of charts, graphs, forms, and hand-written notes to understand where production processes were at for the shift, day, or week. This information was often outdated by the time it reached those who needed it.

Something like this...

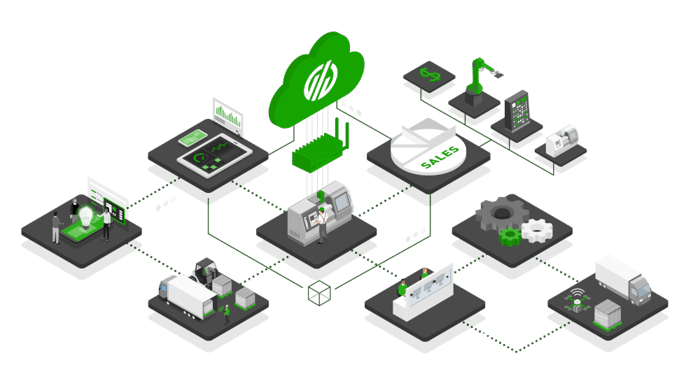

Today, real-time visibility in manufacturing businesses is possible because of IIoT technology, advanced monitoring, and analytics platforms. Real-time data visibility increases production efficiency by allowing companies to track actual production rates, machine conditions, labor utilization, raw materials flow, and more… in real-time.

Something like this...

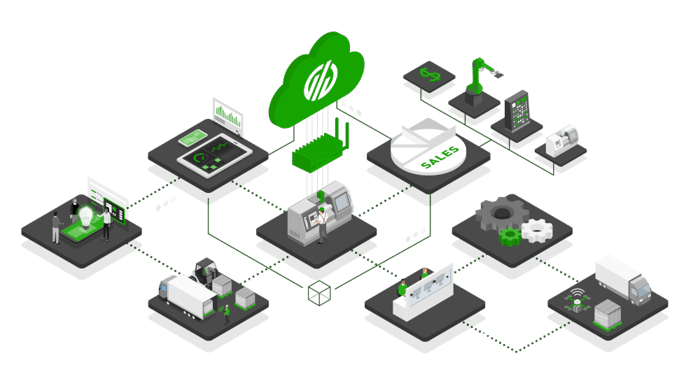

By using connected factory assets and IIoT devices, manufacturers have deep insight into product performance and can even receive actionable insights to solve problems before they happen. Managers can zoom into the factory floor, machine level, operator level, or even individual spindle performance to manage production.

The Cost of Poor Visibility

With ever-increasing material and operational costs, many manufacturers are choosing production monitoring systems to reduce costs and enable collaborative manufacturing. This cutting-edge technology can monitor supply chain movement, inventory, and operational data like cycle time, downtime, and OEE to help companies uncover opportunities that poor visibility inhibits.

Poor data visibility leads to a multitude of problems, and with them, high costs:

Human Error

Human error is a pervasive problem in manually tracking production. Everyone makes mistakes, from forgetting to log information, transposing number orders, and incorrectly labeling or identifying downtime causes. People are also subject to bias, such as not logging a piece of information the same way another employee would, or simply rounding numbers.

When the opportunity for human error is multiplied by many employees in a complex manufacturing environment, visibility is unreliable. This tends to result in poor decision-making, inaccurate benchmarks, and reduced efficiency.

For example, many manufacturers are quite surprised to learn that average utilization rates stand at just 28%.

Manual data collection is time-consuming, inaccurate, delayed, and not actionable.

Manual data collection is time-consuming, inaccurate, delayed, and not actionable.

Redundant Data Entry

Manual data tracking often includes sending data to downstream or ancillary departments. In these cases, there’s a risk data will be entered a second time. This mistake may be due to oversight. Or, it may be due to interoperability issues between software in departments (such as quality or maintenance) that don’t work well with manufacturing software.

Each department entering the data multiple times costs the company in labor. Redundant data may also increase other costs if decisions are based on averages or duplicated information.

Production Inefficiencies

Poor production visibility means higher operational costs because managers may miss the “why” of a problem. When delayed data is combined with human error, it’s often too late to fix the problem, and waste or downtime has already happened.

Because data is inaccurate, root cause analysis isn’t possible for any recurring issues contributing to operational efficiency. This reduces the effectiveness of current manufacturing process improvement initiatives and means that critical contributors to inefficiency aren’t included as improvement opportunities.

Plug-and-play Machine Connectivity

Poor Decision Making

Manually tracking data means that critical information is delayed from reaching the hands of decision-makers. And when it does arrive, it’s filled with errors, redundancies, and missing information. These gaps mean that decisions are made based on insufficient data.

Even in the best manually kept systems, information will contain errors. But there’s also a low absolute limit to how much information can be recorded by hand. Because the volume of data is smaller and the analysis is human-based, deeper insights and lower costs aren’t possible.

How to Enable Real-Time Production Visibility

Gaining visibility is critical in modern manufacturing to lower costs and increase operational inefficiency. To realize those benefits, data must be real-time, accurate, and available to those who need it.

Here are a few ways to enable real-time production visibility:

Collect Production Data

The first step to real-time production visibility is collecting data. Advanced IIoT devices, sensors, and edge devices allow companies to capture data at the source and transmit it to a cloud-based analytics platform. Manual data collection simply doesn't cut it.

Many of today’s equipment OEMs embed IIoT capability in their machines. There are also out-of-the-box machine connectivity solutions, like MachineMetrics, that ensure connectivity to both modern and legacy equipment. Data from sensors and edge devices eliminate the bias, inaccuracies, and costs associated with manual data collection strategies.

Identify Core KPIs and Develop Benchmarks

Identifying core KPIs - and others that are made possible with automated data collection - help establish a true picture of where production is and what’s happening.

KPIs can be used to benchmark production so that progress can be quickly measured. Benchmarking also helps companies understand where they are in terms of cost savings and in comparison to their competition.

As mentioned before, the average manufacturer has a 28% rate of utilization. In many cases, MachineMetrics users are greatly surprised by this as they had assumed their utilization rates were higher.

It’s not until you have accurate production data that you will have a clear gauge of performance.

Root Out Data Silos

Real-time data must be organized and structured for analysis. So, all relevant areas where data is generated or used for decision-making must be connected to the data stream.

Advanced production monitoring solutions like MachineMetrics can collect, contextualize, and standardize production data for immediate visibility and actionability. These platforms can also integrate with existing software to unsilo data and provide a single source of the truth for more accurate decision-making.

For example, you can ensure accurate production data (such as cycle times and part counts) are updated in an MES, or you could push machine condition data into a CMMS for automating maintenance activities.

Develop Visuals Such as Dashboards and Reports

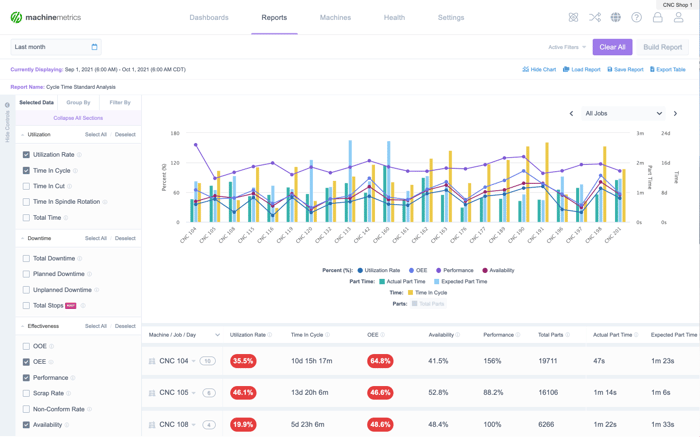

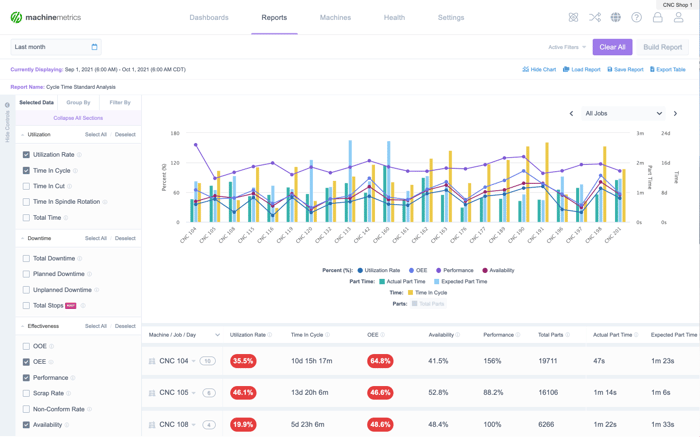

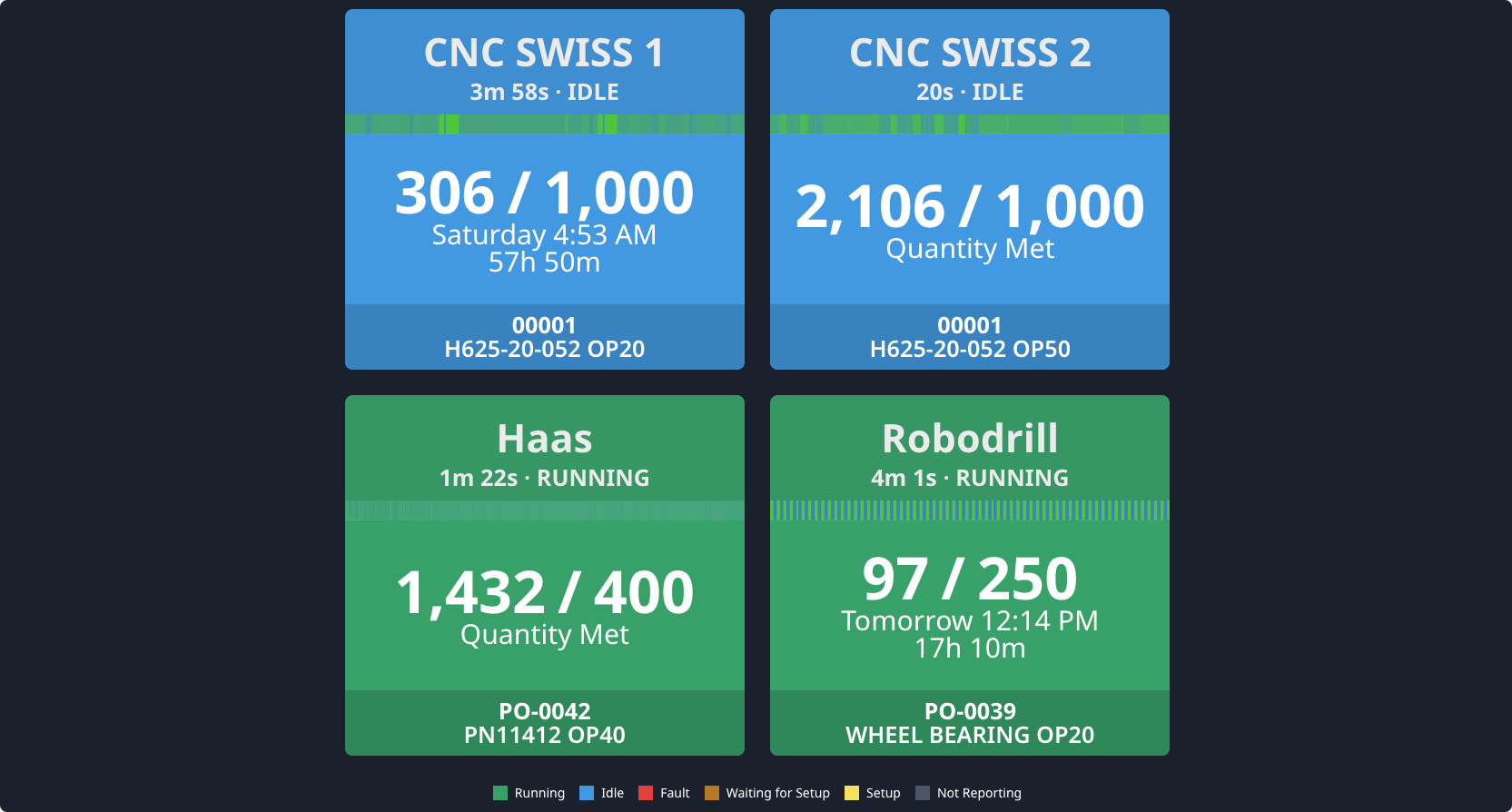

The right platform returns structured and analyzed data to the production floor or relevant department in real-time. To make the best use of these insights and increase productivity, you can create customized reports that provide users with information that is relevant to their machine, task, or department.

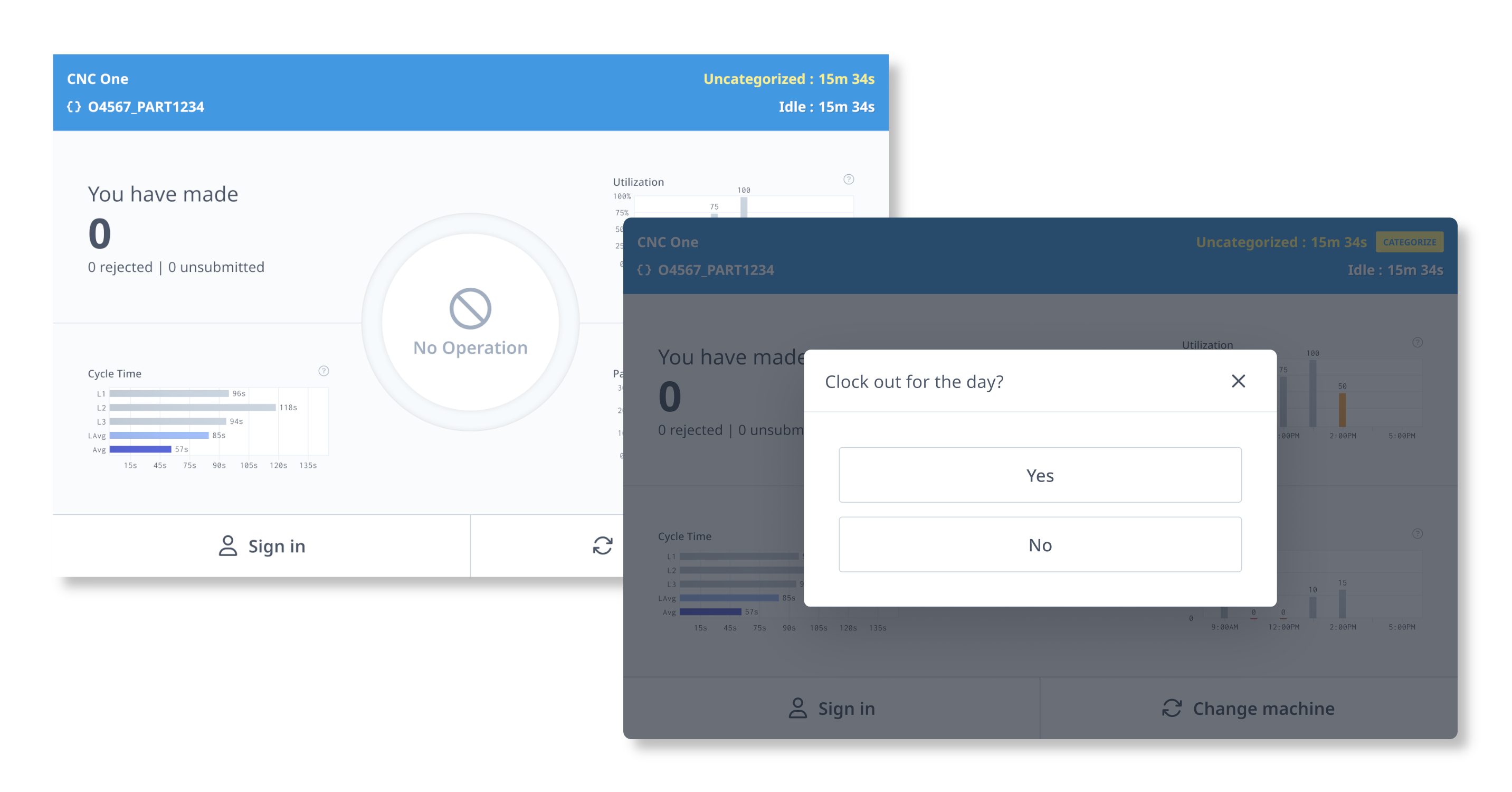

- Operators can use screens and dashboards near their machines to see how they are performing against part goals for the day.

- Continuous Improvement Managers and Manufacturing Engineers can analyze historical data to identify bottlenecks and waste.

- Maintenance Managers can view downtime reports and build automation to increase response rates (or prevent the downtime altogether).

Intuitive and highly visual dashboards with Pareto charts, performance graphics, and current and historical query capability will help users turn insights into action. They can also add data to contextualize the insights, then add to the subsequent analysis to hone the system further.

The MachineMetrics Report Builder allows users to pull in the data they want to see, how they want to see it. View historical data, identify bottlenecks, analyze processes, and more by pulling in OEE, downtime, part counts, cycle times, and more.

The MachineMetrics Report Builder allows users to pull in the data they want to see, how they want to see it. View historical data, identify bottlenecks, analyze processes, and more by pulling in OEE, downtime, part counts, cycle times, and more.

How MachineMetrics Drives Production Visibility

Increasing data visibility is easier than ever. The MachineMetrics production monitoring platform provides you with solutions to achieve real-time production visibility. MachineMetrics easily connects to both digital and legacy analog equipment, providing real-time, accurate production data.

Out-of-the-box reporting and dashboards help visualize data and insights in the format you need for your production processes. Intuitive, interactive dashboards also provide operators, technicians, and managers with relevant data and increased visibility. This ensures the right people have the right data at the right time to make informed decisions.

Notifications and alerts can also be configured to help you drive efficiency improvements with automated communication across the production floor. These timely alerts increase efficiency, drive faster responses, improve maintenance strategies, and drive sharper decision-making.

As a flexible system, MachineMetrics can also integrate with MES, MRP, ERP, BI, CMMS, and other management systems to ensure all stakeholders within a production environment can base their decisions on the most accurate data possible.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments