Collect And Analyze Machine Data with Fanuc FOCAS

FOCAS is an Ethernet or HSSB-based proprietary protocol developed by Fanuc and compatible with Fanuc controls. Software applications can access Fanuc Control data using the FOCAS Library, enabling automated machine data collection and production monitoring.

Exploring Fanuc FOCAS Connectivity

What is Fanuc FOCAS?

Fanuc FOCAS is the standard protocol for collecting data from Fanuc CNC machines. It is a widely adopted industrial communication protocol as many machine tool builders use Fanuc CNC controllers to control their equipment.

FOCAS is composed of a set of library files (.dll), that can be accessed by applications to retrieve most of the information inside of the CNC. MachineMetrics uses these libraries to access information directly from the control via ethernet.

Common data that is available through FOCAS are CNC state (running, idle, alarm), part count information, program name, number, size, and date modified, tool and work offsets, alarm number and text, feed overrides, parameters, positional data, spindle speed and Modal data.

What is Fanuc FOCAS Used For?

Fanuc offers a range of connectivity solutions, enabled by the FOCAS protocol, that drive out-of-the-box proprietary machine monitoring capabilities, as well as support for third-party control systems and IoT platforms.

With a machine monitoring system or machine data platform, like MachineMetrics, users can drive even greater operational visibility and actionability with the FOCAS-supported equipment data.

Below, we discuss some of the proprietary solutions offered by Fanuc and driven by the FOCAS library files.

What Fanuc Solutions Does FOCAS Drive?

There are a number of out-of-the-box Fanuc software solutions available for use with any FOCAS-enabled equipment and based on the Fanuc FOCAS API. You can find these FOCAS Automation Solutions (FAS) below, each of which supports some form of machine connectivity, data collection, and communication to support shop floor visibility.

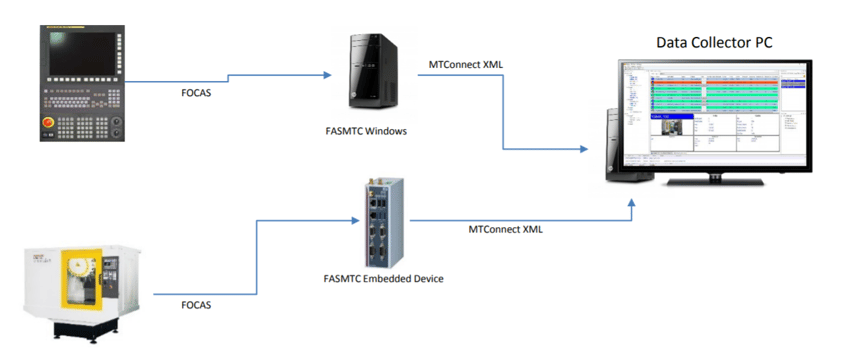

Fanuc MTConnect Server

Fanuc MTConnect Server (FASMTC) is a solution to support the standardization of data to the MTConnect standard. The FASMTC software can be installed on an industrial PC, embedded PC, or other PC at the machine tool and is used to transform the data from FOCAS into the structured MTConnect XML. FASMTC consists of both an MTConnect adapter as well as a standard MTConnect agent. Learn more about FASMTC.

Fanuc MT-Linki

MT-Linki is FANUC's proprietary machine tool monitoring solution. The software allows manufacturers to connect their shop floor to a PC using Ethernet. Users can then visualize the shop floor in a color-coded format to understand equipment performance. It helps enable connectivity to FANUC CNC and robots, as well as non-FANUC CNCs, PLCs, or devices via MTConnect or OPC-UA. Learn More About MT-LINKi.

FASData

FOCAS Automation Solution Data (FASData) is a plug-and-play version of MT-Linki that is less comprehensive. Described as "plug-n-play", FASData has the ability to connect to modern and legacy FANUC CNCs that have either an Ethernet or HAAS connection, as well as non-FANUC equipment via MTConnect and OPC-UA. Learn more about FASData.

FASConnect

FOCAS Automation Solution Connect (FASConnect) is a windows-based software that allows users to manage data from Fanuc controls on a network. The files can be transferred to and from PCs and CNCs to ensure the effective communication of CNC data. This data includes such information as part programs, PMC, data, parameters, macro variables, and more. Learn more about FASConnect.

FASBacCNC

FOCAS Automation Solution Backup CNC (FASBacCNC) is a network-based backup solution for FOCAS-enabled Fanuc CNCs and is as an add-on for FASConnect. To prevent the loss of files on CNC equipment, FASBacCNC automatically backs up the CNC files that have been created. Learn more about FASBacCNC.

FASOPC

FOCAS Automation Solution OPC (FASOPC) is an OPC server that supports the collection of machine data. This is helpful to industry professionals who are standardizing on OPC. Learn more about FASOPC.

FASScreens

FOCAS Automation Solution Screens (FASScreens) is a collected of screens that end users can deploy for use on Fanuc HMIs. This prevents users from developing and manually customizing HMIs to their individual preferences. Learn more about FASScreens.

What Connection Types Are Available for FOCAS?

When collecting machine data from any FOCAS-enabled equipment, including non-FANUC CNCs, there are essentially two connection types available. The FOCAS libraries access the CNC data using these connections, and automated data collection solutions like MachineMetrics use the FOCAS libraries to access the CNC data.

- Ethernet

- High-Speed Series Bus (HSSB)

What is Fanuc HSSB?

High-Speed Serial Bus (HSSB) connectivity refers to a connectivity method that relies on a fiber optic cable, making the connection far more reliable and faster than a standard Ethernet cable connection.

What is the FOCAS Library?

FOCAS is composed of a set of Dynamic-link Library files, or DLL files, that can be used by applications to retrieve most of the information inside of the CNC. The FOCAS Library allows users to customize functions and develop applications, communicating with the CNC via Ethernet or HSSB (High-Speed Serial Bus) connectivity.

Common data that is available through FOCAS are CNC state (running, idle, alarm), part count information, program name, number, size, and date modified, tool and work offsets, alarm number and text, feed overrides, parameters, positional data, spindle speed and Modal data.

There are two FOCAS Libraries available, and which is used depends on the PC operating system and the CNC that data collection is occurring on:

- FOCAS1:

- Library for CNC other than FS30i/31i/32i/35i, FS0i-D/F and PMi-A(32 bit version only)

- Supports Windows 95, 98, Windows NT4.0 (Service Pack 4 or later), Windows 2000 Professional, Windows XP Professional, Windows Vista Business, Windows 7 Professional

- FOCAS2:

- Library for FS30i/31i/32i/35i, FS0i-D/F and PMi-A(32/64 bit version)

- Supports Windows 2000 Professional, Windows XP Professional, Windows Vista Business, Windows 7 Professional 32bit/64 bit version, Windows 8 Pro 32bit/64bit version, Windows 10 Pro/IoT

Learn more about the FOCAS Library here.

What is the Difference Between MTConnect and Focas?

MTConnect provides a machine-to-machine or machine-to-enterprise communication vocabulary that ensures equipment with similar standardized functions can communicate. As a technical standard, MTConnect enables the retrieval of information from machine tools in structured XML in order to monitor performance and analyze production data across different brands and models of equipment. Learn more about MTConnect.

On the other hand, FOCAS is a proprietary protocol developed by Fanuc and compatible with Fanuc controls. It is Ethernet or HSSB based and offers a library of DLL files (FOCAS Library) with which software applications can access data from Fanuc controls.

With modern data collection and standardization tools, manufacturers can standardize across these different protocols to develop actionable data models that are interoperable with their analysis and management systems.

In the case of Fanuc, there are MTConnect Adapters available as part of Fanuc's MTConnect Server. MachineMetrics also has a custom machine control connector for Fanuc Controls to ensure that MTConnect compliant software can consume the data.

How Do I Ensure Connectivity to All Equipment?

This is where a connectivity solution like MachineMetrics comes into play. MachineMetrics is an Industrial Data Platform that enables connectivity to any make and model of equipment, including legacy machines.

MachineMetrics is the leading platform to collect, monitor, analyze, and drive action with manufacturing equipment data. Our platform easily captures data from your manufacturing equipment and provides a complete toolkit to drive actionable insights for frontline workers and other factory floor systems that improve the efficiency and quality of production.

Whether the equipment supports FOCAS or not, you can easily connect and collect data across all your devices for complete operational visibility.

Want to see the platform in action? Book a Demo Today.

AI-Driven Tool Anomaly Detection

Our proprietary algorithms detect a wide range of production issues - helping manufacturers to maximize tool life, eliminate scrap, and stop costly downtime.