Connect Your Equipment With OPC-UA

OPC-UA is a standard for the exchange of data from devices and sensors to management systems and the cloud within industrial automation environments. As a machine-to-machine communication protocol, OPC-UA outlines specifications for the mapping of data, accessibility, security, as well as other characteristics. This ensures the standardization of data from OPC-UA-enabled equipment.

Connecting Devices and PLCs with OPC-UA

What is OPC-UA?

OPC stands for Open Platform Communication. As Industry 4.0 becomes increasingly common, this protocol is being used for control functions, industrial automation, and data collection for industrial IoT applications.

The UA in OPC-UA stands for "Unified Architecture," meaning that the protocol isn’t platform-dependent. It’s a highly extensible standard and is inherently more secure because it uses certificate exchange and other point-to-point encryption methods.

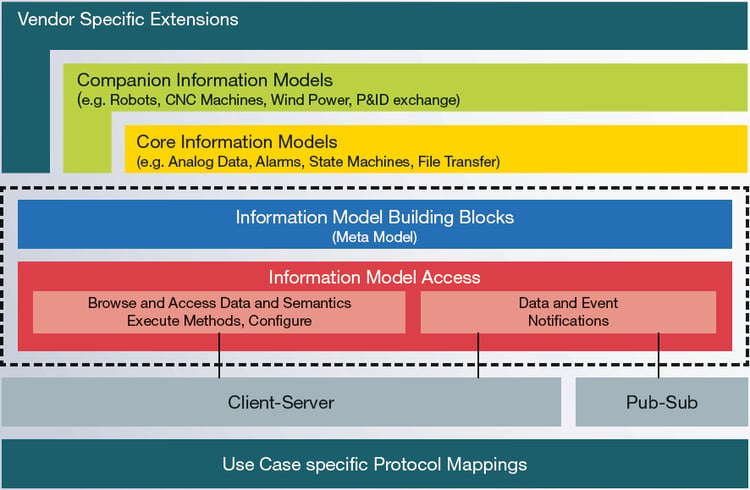

The multi-layered architecture of OPC UA provides a “future proof” framework to ensure new solutions can be compatible with OPC UA now and in the future. [Source]

The multi-layered architecture of OPC UA provides a “future proof” framework to ensure new solutions can be compatible with OPC UA now and in the future. [Source]

What is OPC-UA Used For?

OPC-UA lets users connect to remote devices at the edge or in the cloud.

Features include device management, diagnostics, asset management, monitoring, enterprise reporting, quality control, data acquisition, event monitoring, and more.

Because it’s compatible with Windows, Android, macOS, and Linux, more remote devices can be deployed across a greater ecosystem for monitoring.

The ability to quickly act on insights makes the system more efficient and impactful. More access by stakeholders means a more optimized use of industrial IoT assets.

How Does OPC-UA Integrate into Industrial IoT Assets?

With OPC-UA, any device using the standard can be integrated into the platform without coding. After plugging in the device, it will automatically configure the capabilities of the system and structure the data collected.

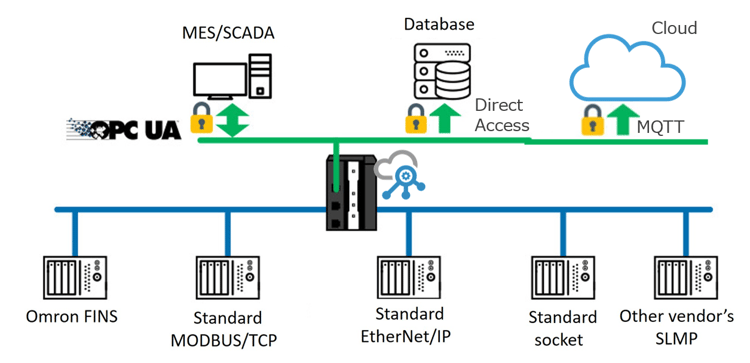

OPC-UA doesn’t require a VPN, and the gateway enables a secure connection for outgoing data to the cloud when the gateway is established. OPC-UA can also be used in the cloud and at the edge.

[Source]

What is an OPC Server?

OPC-UA allows for OPC to be used as a client or a server; it will provide data to various devices and applications to control equipment functions. OPC-UA server applications allow data exchange for machine-to-machine and PC-to-machine communication.

OPC server uses include:

- HMIs on the factory floor

- RTUs in field service applications

- PLCs inside industrial equipment or control cabinets on the shop floor

- PC-based applications on desktop or tablet computers

After an OPC Server converts the communication protocol from the hardware into an OPC protocol, the OPC client can consume the information and also send commands to the hardware. [Source]

What is an OPC Client?

OPC-UA enables data exchange across a wide range of familiar industrial systems when used in client applications. As most of these applications have specific purposes, standardized data is used to drive the specific functionality of that application.

OPC-UA clients use one of three models:

- Data Access: This allows the discovery of devices and servers. It also establishes a secure communication channel.

- Alarms and Conditions: This enables the real-time monitoring of alarms and conditions. It also enables instructions for where to deliver and what response to trigger.

- Historical Access Data: This allows historical data to be accessed, analyzed, compared with current conditions, and updated as required.

Examples of OPC-UA client applications include:

- SCADA systems

- Visualization systems

- MES

- Machine Data Platforms

The Impact of OPC-UA

Many machine data platforms are a patchwork of different devices, sensors, OEM equipment, and PLCs. These devices and systems use communication protocols to communicate. However, devices from various OEMs may use one protocol, such as Modbus, Profinet, DH+, and others, while a second PLC or device uses a different protocol.

These protocols result in a system with less-than-optimal communication integrity. It also requires programming knowledge, and each communication protocol requires companies to keep a catalog of that protocol’s programming commands.

OPC-UA operates as a single “language” for machine-to-machine communication, enabling it to work across platforms. This capability eliminates the roadblocks encountered in early IoT adoption, where language barriers and bottlenecks required reconciling through additional programming or devices.

What are the Benefits of OPC-UA?

Expectations for a robust machine data platform have become more sophisticated. The preference is for open platforms that allow custom-built applications and features within a universal architecture. OPC-UA benefits include:

- Platform Independence: OPC-UA integrates with any software and operates on any operating system. It’s also capable of cloud and embedded system use.

- Extensibility: Manufacturers who have already spent vital capital on platforms want systems that can be extended without significant updates or changes. OPC-UA is flexible and allows additional assets, devices, or application software to be added at any time without compromising the system or requiring other programming. Remote employees can access and respond to the same data as an HMI user on the shop floor or a planner using a PC in an office.

- Plug-and-Play: OPC-UA is a plug-and-play communication system. It discovers new networks for added assets, vendors, or clients and adds them seamlessly, configuring their network and integrating them into the parent network.

- Ease of Use: Traditional automation devices require high-level knowledge for programming components like PLCs and adding new nodes and gateways. OPC-UA requires no programming; devices connect quickly to an available OPC-UA server and are auto-discovered into a machine data platform.

- Security: The security of cloud-based platforms has been a growing concern over the last decade. As OPC-UA is a communication layer for machine-to-machine and machine-to-cloud communication, it operates with two security layers. The first layer sets up an encrypted channel connection between the client and server. The second layer uses authentication procedures to verify the user and their permissions.

Is OPC-UA Free?

Yes, OPC-UA is an open-source standard. The OPC Foundation also offers a free OPC-UA Client.

How Do I Ensure Connectivity to All Equipment?

This is where a connectivity solution like MachineMetrics comes into play. MachineMetrics is a Machine Data Platform that enables connectivity to any make and model of equipment, including legacy machines.

MachineMetrics is the leading platform to collect, monitor, analyze, and drive action with manufacturing equipment data. Our platform easily captures data from your manufacturing equipment and provides a complete toolkit to drive actionable insights for frontline workers and other factory floor systems that improve the efficiency and quality of production.

Whether the equipment is OPC-UA enabled or not, you can easily connect and collect data across all your devices for complete operational visibility.

Want to see the platform in action? Book a Demo Today.