Industrial IoT Gateways are pieces of equipment that serve to capture data from equipment, analyze that data, and transmit that data between the local network and the cloud, acting as a gateway for the flow of information.

Connect With IoT Hardware and Devices

Learn about commonly used Industrial IoT hardware and devices, such as IoT sensors, actuators, cables, and edge devices. Discover how these IoT hardware components enable industrial connectivity.

Drive automated machine data collection on both legacy and modern equipment by combining the data-tag mapping capabilities of software with the physical connectivity provided by hardware devices.

I/O Modules

I/O modules are used when equipment is unable to transmit data via an industrial protocol, such as legacy machine assets. I/O modules connect to any sensor, PLC output, or relay within a machine's cabinet, extract data, and send it to an edge device.

IIoT Sensors

Industrial IoT sensors can monitor various environmental and machine conditions such as vibration, temperature, and humidity. Sensors extend the availability of data points for collection, and are typically used with legacy equipment, but may also complement the available data provided by modern equipment.

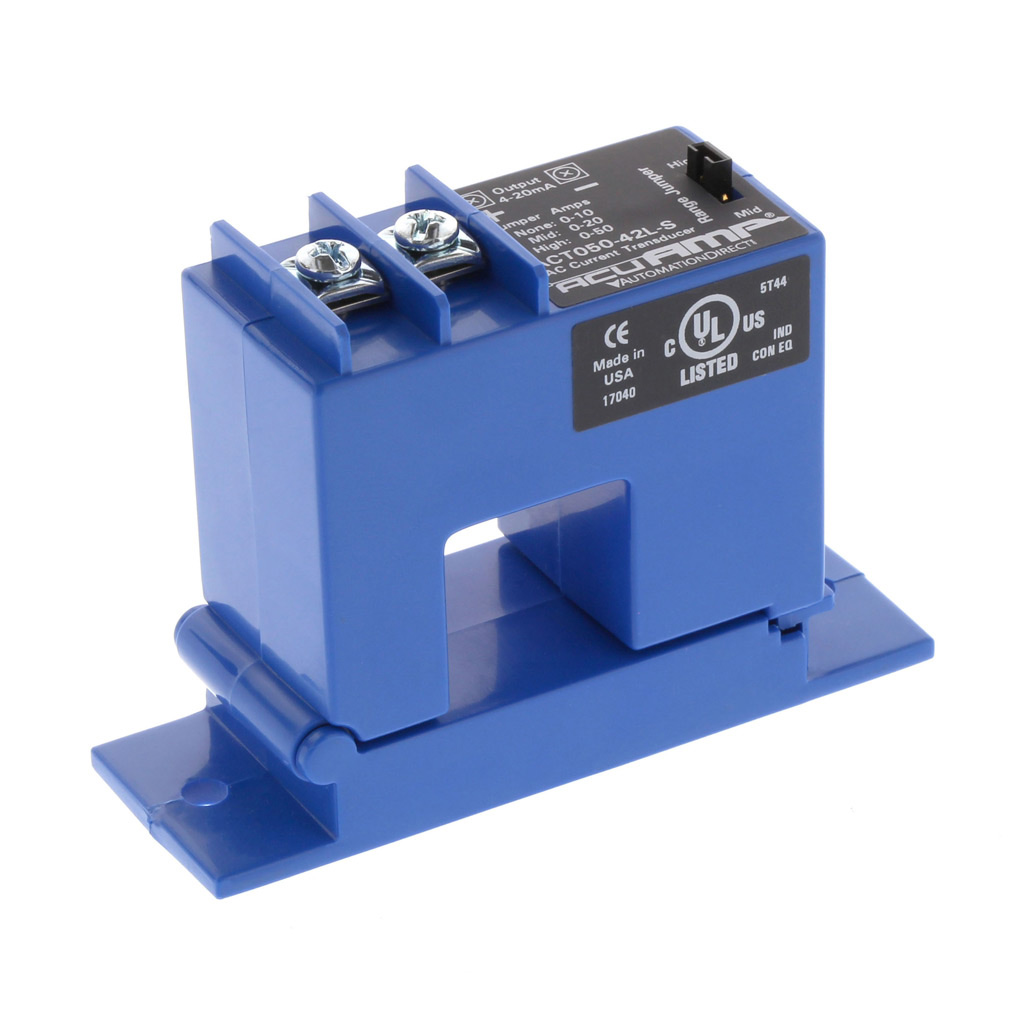

Current Transducers

Connectivity with Ease, and at Scale

MachineMetrics is the leading platform to collect, monitor, analyze, and drive action with manufacturing equipment data. Our platform easily captures data from your manufacturing equipment and provides a complete toolkit to drive actionable insights for frontline workers and other factory floor systems that improve the efficiency and quality of production.

Common Questions on IoT Hardware

What is IoT Hardware?

IoT hardware involves the tangible components and devices used to enable connectivity, such as IoT sensors, computer chips, actuators, cables, and smart devices (such as a tablet). IoT devices help to facilitate the flow of data through a manufacturer's technology stack, enabling organizations to use machine data at every level and department of the organization.

Hardware plays an essential role in successfully rolling out an IoT solution. However, it's important to keep in mind that the variety of data collected is a significant challenge for the manufacturing industry. Leveraging an automated machine data collection solution, like MachineMetrics, is the "secret sauce" living on hardware that makes it possible to easily collect and standardize real-time machine data. This way, managers spend time making better decisions and enabling automation, versus manually trying to collect and standardize data with a do-it-yourself IoT solution.

Is the IIoT Hardware or Software?

As you likely guessed, both.

When deploying the Industrial Internet of Things, there will be both hardware and software components involved as part of a comprehensive data collection, standardization, and processing ecosystem.

IoT hardware involves the tangible components and devices used to enable connectivity, such as IoT Sensors and Actuators. IoT software runs on IoT hardware, and is made up of code that is used to run programs. In the context of IoT, software plays a key part in processing and standardizing the data collected so that it can be easily consumed by systems, applications, and people.

What Are the Hardware and Software Components of IoT?

IoT hardware involved all of the tangible devices that are involved with the collection and flow of data within an IoT ecosystem. On the other hand, the software is executing programs on IoT hardware, ensuring that data is properly processed, contextualized, standardized, visualized, analyzed, etc.

There are many, many types of IoT software as well as a wide range of connectivity devices. Here are a few for the sake of contrasting these concepts.

|

IoT Hardware |

IoT Software |

|

|