Connect Your Equipment With MTConnect

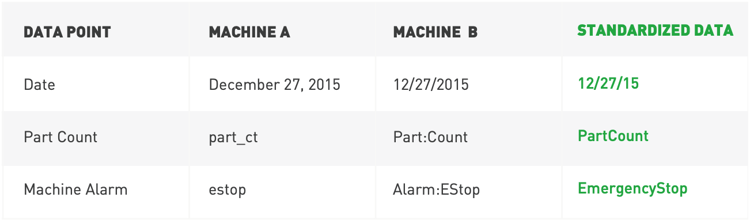

MTConnect standardizes data to enable interoperability between equipment, systems, and devices. By implementing a solution that standardizes data, manufacturers can drive valuable applications across different makes and models of equipment.

Standardizing Machine Data with MTConnect

What is MTConnect?

MTConnect provides a machine-to-machine or machine-to-enterprise communication vocabulary that ensures equipment with similar standardized functions can communicate. As a technical standard, MTConnect enables the retrieval of information from machine tools in order to monitor performance and analyze production data.

Some describe MTConnect as “Bluetooth for Manufacturing" in that it allows the open flow of data between two devices that “speak" the same language. Previously, manufacturing equipment, devices, and software applications had no easy way to "talk" to each other. The reason: they had no common language.

MTConnect takes this countless number of manufacturing equipment, devices, and software, and provides a common language for these systems to communicate. This common language makes it possible to monitor things like the amount of time a machine is in cycle, the delays (downtime) it experiences, and any number of things that can be measured and monitored with data.

Read our complete article: What is MTConnect?

What is MTConnect Used For?

Machine and device builders that comply with the MTConnect standard enable machine-to-machine and machine-to-enterprise communication among those devices and systems via the standardized data item definitions. To a degree, this helps to solve the problem presented by unique proprietary data formats from each connected machine asset. This wide variety of unique data makes the information far less actionable and puts the burden on the end-user to manually standardize the data into a common model. MTConnect is helping to standardize this.

The problem is that many equipment providers continue to use proprietary data formats, and many manufacturers continue to use legacy equipment. Luckily, more and more machine builders are complying with the MTConnect standard. Others offer out-of-the-box adapters that can be easily deployed by end-users.

What is the MTConnect Standard?

According to MTConnect, “The MTConnect standard (ANSI/MTC1. 4-2018) offers a semantic vocabulary for manufacturing equipment to provide structured, contextualized data with no proprietary format. With uniform data, developers and integrators can focus on useful, productive manufacturing applications rather than translation.”

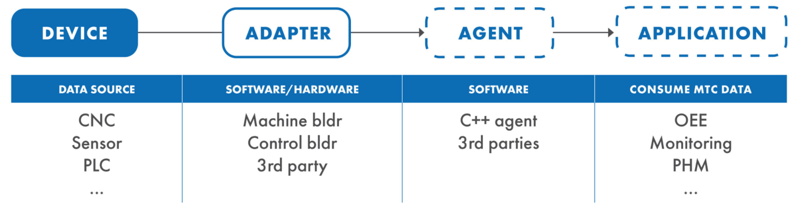

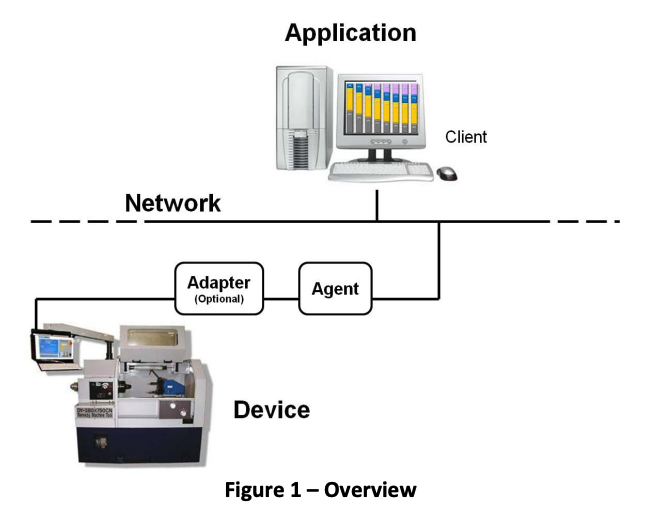

The MTConnect standard defines data tags and the behavior of a software agent, which takes the form of a standardized data model and semantic vocabulary. Machine and control builders may decide to use MTConnect as their native language, or it may be necessary to use an adapter to convert the proprietary data to the MTConnect Data definition. The device builder may have an out-of-the-box adapter available for use (for example, Okuma) or a user may have to leverage a third-party adapter.

What is an MTConnect Adapter?

An MTConnect Adapter simply translates the language of a device (a machine asset, control, sensor, etc.) into the MTConnect Data definition. MTConnect adapters may be provided by the device maker, built by an end-user, or purchased from a third-party software provider.

For equipment that uses MTConnect as its native language, an adapter would not be necessary.

What is an MTConnect Agent?

An MTConnect Agent is a piece of software that collects and organizes the MTConnect data from either the adapter or straight from the machine (if the asset uses MTConnect as its native language).

The Agent will receive and process requests for data made from an application. These applications may be OEE software, machine monitoring software, MES, etc.

Is MTConnect Free?

Yes, MTConnect is free.

As an open, extensible standard, MTConnect has no licensing fees. End users can freely use MTConnect and machine builders, device makers, and software providers can also integrate MTConnect into their products as long as they accept the MTConnect licensing agreement.

How Do I Connect to MTConnect?

This is a challenging question to answer directly, as it depends entirely on the machine or equipment with which you are trying to connect. However, there are essentially three types of connections possible, based on the MTConnect capabilities (or lack thereof) of the equipment in question:

- MTConnect Native Devices: These machines and equipment have MTConnect built into them, meaning that there is no need for data standardization via an adapter or other means. These devices can communicate with the MTConnect standard out-of-the-box, so it will be very easy to monitor these devices in any MTConnect compliant software.

- MTConnect Translation Dependent Devices: These types of machines offer a proprietary data format and will require an MTConnect adapter to standardize to MTConnect compliant data.

- MTConnect Data Connection Dependent Devices: This type of equipment does not provide the data required by the software application that an end-user will interact with. Often the case with legacy machines, it will be necessary to use what the MTConnect Institute calls a "Connection Unit" to collect data from the device. For example, in the case that there is not a machine without a connection point for data extraction, IoT sensors could be added to the machine.

How Do I Ensure Connectivity to All Equipment?

This is where a connectivity solution like MachineMetrics comes into play. MachineMetrics is an Industrial Data Platform that enables connectivity to any make and model of equipment, including legacy machines.

MachineMetrics is the leading platform to collect, monitor, analyze, and drive action with manufacturing equipment data. Our platform easily captures data from your manufacturing equipment and provides a complete toolkit to drive actionable insights for frontline workers and other factory floor systems that improve the efficiency and quality of production.

Whether the equipment is MTConnect native or not, you can easily connect and collect data across all your devices for complete operational visibility.

Want to see the platform in action? Book a Demo Today.