Did your team finish all the work that was planned for this week?

Many KPIs are used in manufacturing to track production efficiency, quality, labor utilization, production capacity, waste, and more. These KPIs help managers understand how the operation is running and what they can do to improve.

The more accurate the tracking and data, the more valuable the KPIs are to those who need them. The measurement of schedule attainment should be included in the mix to give leaders an understanding of how effectively they are meeting production goals.

Are you at 85% of planned production? 100? We will also dive into how you can more accurately plan and execute production by collecting data from the shop floor.

What is Schedule Attainment?

Schedule attainment is a straightforward calculation expressed as a ratio of completed planned work divided by planned work.

Completed planned work consists of work orders produced and shipped within the original lead time. Planned work is all orders on the schedule for the week (or another measurement period), whether they were completed or not.

Schedule attainment isn’t production scheduling; instead, it’s a global view of how well the manufacturing operation produced orders vs. the planned order position. The formula for schedule attainment is:

Schedule Attainment % = Completed Planned Work / Planned Work x 100

Why is Schedule Attainment Important?

Schedule attainment is vital because it provides insights into how well companies perform to schedule and why they are, or aren’t, performing as planned. For example, low schedule attainment is likely related to some form of waste in production, so it is incredibly important to have a deep understanding of all components of the shop floor.

These insights include things like:

Low schedule attainment may also be related to supply chain deficiencies, including:

- Disruptions in supply

- Lack of supply chain visibility

- Poor vendor quality

- Poor vendor communication

Each issue driving low schedule attainment is measured individually by other KPIs tracking that specific metric. This makes schedule attainment a comprehensive snapshot for insight into how work is being executed.

Why Accurate Data Improves Schedule Attainment

As a high-level snapshot into your operation, schedule attainment can be used to identify areas of improvement. If the production floor completes 80% of its planned work, then focusing on the 20% not completed yields valuable information.

Data is collected in many ways, and many companies still manually collect data. Others collect data but send it off to siloed and disparate software systems that degrade its timeliness and quality. And many have undertaken a digital journey to collect and analyze data using modern solutions.

Accurate data is the key to creating the highest-value schedule attainment metric that shows managers and decision-makers where to focus. The more accurate the data, the better resources are dispatched to trouble spots.

Data accessibility, visibility, and actionability is pivotal to rooting out wastes on the shop floor and driving continuous improvement initiatives to accurately plan and meet production goals.

Plug-and-play Machine Connectivity

How Accurate Data Improves Schedule Attainment

The 20% unachieved schedule attainment in the example above would likely come from a combination of sources. A portion may be due to an ongoing maintenance issue with one class of machines.

Another portion may be due to planner bias based on intuition or “gut feeling.” An operator error or supply chain disruption from a broken communication trail may also have an impact.

Accurate data helps pinpoint the problem to the correct location, also known as root cause analysis. In the case of automated data collection, it’s possible to track issues down to the machine, spindle, operator, or inventory transaction that caused the drop.

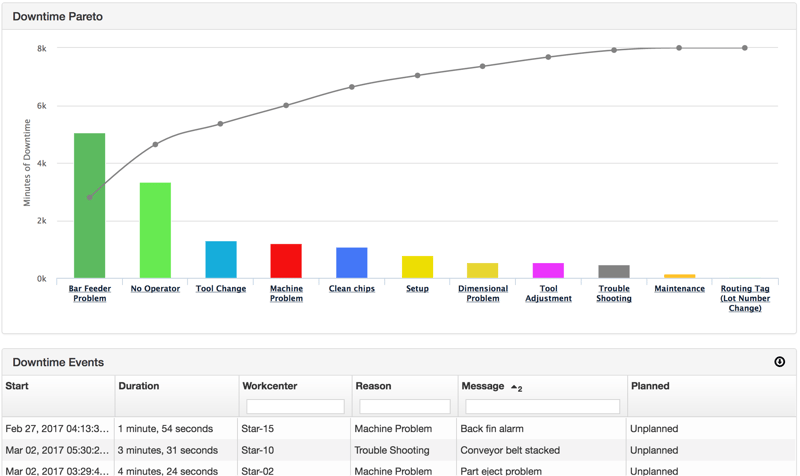

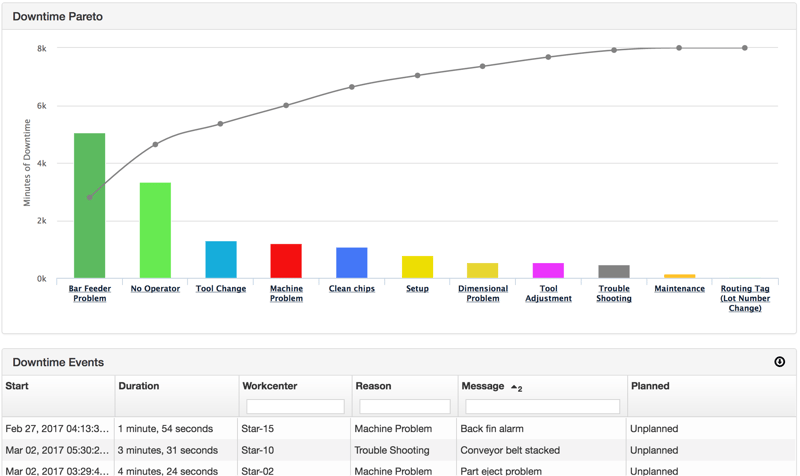

Running a downtime analysis in MachineMetrics to pinpoint the most common reason for downtime events.

Running a downtime analysis in MachineMetrics to pinpoint the most common reason for downtime events.

Accurate data also enables the categorization of problems, helping managers and decision-makers understand which issues to tackle first with process improvement. The lack of accurate data is a critical failing of manual data tracking and analysis in siloed disparate systems that aren’t connected by a production monitoring platform.

In the case of manual tracking, data is inaccurate because it isn’t humanly possible to gain insight beyond a general point. And in the case of siloed systems, the event may be long passed, making the improvement decision wrong or impossible to initiate.

Where to Apply Accurate Data for Schedule Attainment

Machine data is the best source for manufacturing process improvement, inventory optimization, and streamlined data-driven supply planning. Accurate data can be used in any area or department as problems are revealed.

Production

MachineMetrics helps connect machine assets and analyze the production data in real time to reveal actionable insights. These insights are used to improve production efficiency and machine utilization:

- Improve operator training

- Automate workflows across manufacturing

- Eliminate manual tracking

- Automate equipment functions

- Optimize changeovers and setups

- Increase overall equipment effectiveness

- Reduce waste and scrap

As insights and trends are revealed, managers and staff are empowered to implement improvements to any area where problems are detected.

Supply Chain Management

MachineMetrics’ production monitoring platform integrates with other third-party software to provide accurate data to those systems. In addition to ERP, MES, and quality systems, the MachineMetrics platform also works with supply chain management software to address schedule attainment issues by:

- Automating and streamlining vendor communication

- Foreseeing the impact of disruption

- Managing change orders, engineering and design changes, and specification changes

- Enabling accurate and data-driven contingency planning

- Communicating seamlessly with a single version of truth

Maintenance

Schedule attainment is also susceptible to maintenance issues. MachineMetrics can stream data into computerized maintenance management systems (CMMS) to provide real-time data and analytics. This helps manufacturers develop optimized, lower-cost strategies like predictive maintenance to increase equipment utilization.

In addition to real-time data, the MachineMetrics platform uses high-frequency data collection to predict tool or equipment failure before it happens and plan for the repair at the optimal time.

Improving Planning and Execution with Machine Data

Your company’s machine data is one of your most valuable assets. MachineMetrics helps improve schedule attainment by providing real-time actionable insights to address the issues that drag attainment down.

Take Flexco for example. Holding more than 185 patents, Flexco produces belt fasteners, cleaners, and maintenance products for a broad global customer base. The organization is deeply committed to customer success and employs a continuous improvement strategy that focuses on increasing uptime and productivity in both customer operations as well as its own.

Flexco required an accurate understanding of production metrics to optimize its production planning and delivery of goods. Despite experimenting with multiple IoT vendors, the ability to quickly connect machines, drive actionable insights, and unlock valuable use cases remained a challenge.

After implementing MachineMetrics, Flexco collected, standardized, and analyzed production data within a few days to pinpoint opportunities for improvement. With these newfound insights, the company could identify and exploit hidden capacity in its production equipment to meet rapidly growing product demand and ensure on-time delivery.

|

“It works, it’s clear. MachineMetrics has the best ability to collect data across machines. We didn’t want to be in a position where we had different data collection solutions across different equipment. We thought we would have to go down the custom development route but MachineMetrics solved this.”

Read the full story.

|

Jordan Kathe, Industrial Engineer, Flexco

|

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments