What is Machine Operator Efficiency?

Machine Operator Efficiency, or MOE, measures the performance of industrial machinery operators. Represented in the form of a percentage, it takes into consideration time, parts created, and part quality to effectively measure shop floor employee performance.

Shop floor supervisors and plant managers can use MOE to evaluate the performance of their employees, just as they would use Overall Equipment Effectiveness (OEE) to evaluate industrial equipment performance.

Despite the major capital expenditures of purchasing industrial equipment, manufacturers are well aware that people are their most important asset. MOE allows managers to better understand and improve the performance of their shop floor employees by spotting inefficiencies, enhancing training, improving data collection strategies, and enabling visibility.

The Benefits of Tracking Operator Efficiency

By tracking operator productivity, you can better understand operator performance, whether that be across a plant, a shift, or individually. This provides insight into which plants, shifts, and operators are driving the best and worst performance:

- Who generates the most quality parts?

- Who creates the least scrap?

- Is downtime consistent or pooled within certain shifts?

With data to understand machine operator efficiency, manufacturers can begin to take action to improve their operational productivity.

For example, managers can reallocate employees accordingly, such as assigning low-skilled and high-skilled operators based on the complexity of a given job. Or they may realize that employees are overburdened, meaning it is time to hire additional staff.

How Do You Calculate Operator Efficiency?

The machine operator efficiency formula: Overall Labor Effectiveness, or OLE, is a useful manufacturing KPI for determining the effectiveness of machine operators.

Measuring operator efficiency takes into consideration the time operators spend working, the number of parts they create, and the quality of parts produced. In many ways, it is similar to OEE but measures the efficiency of the operator versus the efficiency of a piece of equipment.

Like OEE, there are three parts to this formula:

- Availability: Total time of productive operator work / Time Scheduled for Work

- Performance: Actual number of parts produced / Expected number of parts produced (based on cycle times)

- Quality: Quality parts produced / Total parts produced

Each of these variables will be represented by a percentage, which is then multiplied together to create a percentage that is representative of Overall Labor Effectiveness:

Availability x Performance x Quality = Overall Labor Effectiveness

Lets' run through a quick example. Keep in mind, this could be applied to an individual, a shift, or an entire plant:

Availability

An operator is scheduled to work 100 minutes, but due to machine downtime of 20 minutes, only has 80 minutes of productive work.

80 productive minutes / 100 minutes scheduled for work = 80% availability

Performance

With cycle times of 1 minute, and given that there are 80 productive minutes available (see above), the operator should be expected to create 80 parts at 1 minute per part. But, for sake of example, let's say that he creates 78 parts.

78 parts produced / 80 parts expected to be produced = 97.5% performance

Quality

Out of the 78 parts created, there are only 70 that pass inspection and are able to be sold.

70 quality parts created / 78 total parts created = 89.7% quality

Now we can take each of these variables and multiply them together:

80% availability x 97.5% performance x 89.7% quality = 70% OLE

Source: Trinity Precision

Source: Trinity Precision

How Do You Increase Operator Efficiency?

You now have an understanding of what machine operator efficiency is, how to calculate it, and how it can help manufacturers make better decisions on the shop floor. But, how can you improve operator efficiency in the pursuit of driving greater productivity? Below we discuss a variety of solutions that empower your operators to make better, faster decisions and deliver high-quality parts on time.

Develop Accurate Standards of Work

By having accurate work standards, including jobs, setups, and cycle times, manufacturers have a better overall understanding of the actual expected production performance they should hold operators accountable to. If manufacturers do not have the data to develop accurate work standards, they will have no way of knowing if operators are high or low performing.

With a solution like MachineMetrics, data from machines, operators, and systems can be collected and tracked in real-time, and job standards can be updated to reflect any changes. This allows manufacturers to always be working from an accurate performance benchmark.

Learn more about optimizing job standards with MachineMetrics.

Enable Shop Floor Visibility

The beauty of real-time data collection is that the information can be democratized across the organization, from corporate management down to the machinists and operators on the shop floor.

In order to improve the performance of operators, you must give them the tools to make better, faster decisions on a daily basis. This takes the form of visible dashboards across the shop floor which can inform operators of where they stand against production goals.

Plug-and-play Machine Connectivity

Further, these tools can be used to visibly identify problems (such as machine downtime events) so that issues can be resolved as soon as possible.

MachineMetrics supports this in two specific ways:

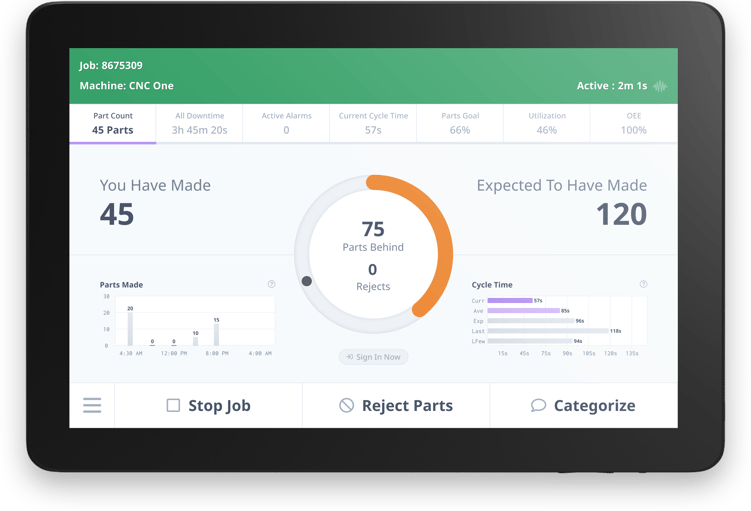

Shop Floor Dashboards

Large monitors across the shop floor provide an overview of a given cell, or the entire shop floor, showcasing the status of each piece of equipment and where it stands against production goals. This is especially useful for spotting machines that are falling behind or are inactive.

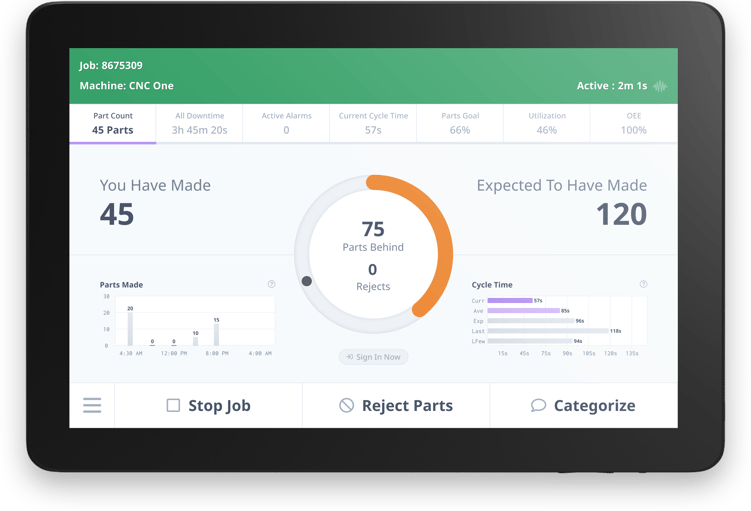

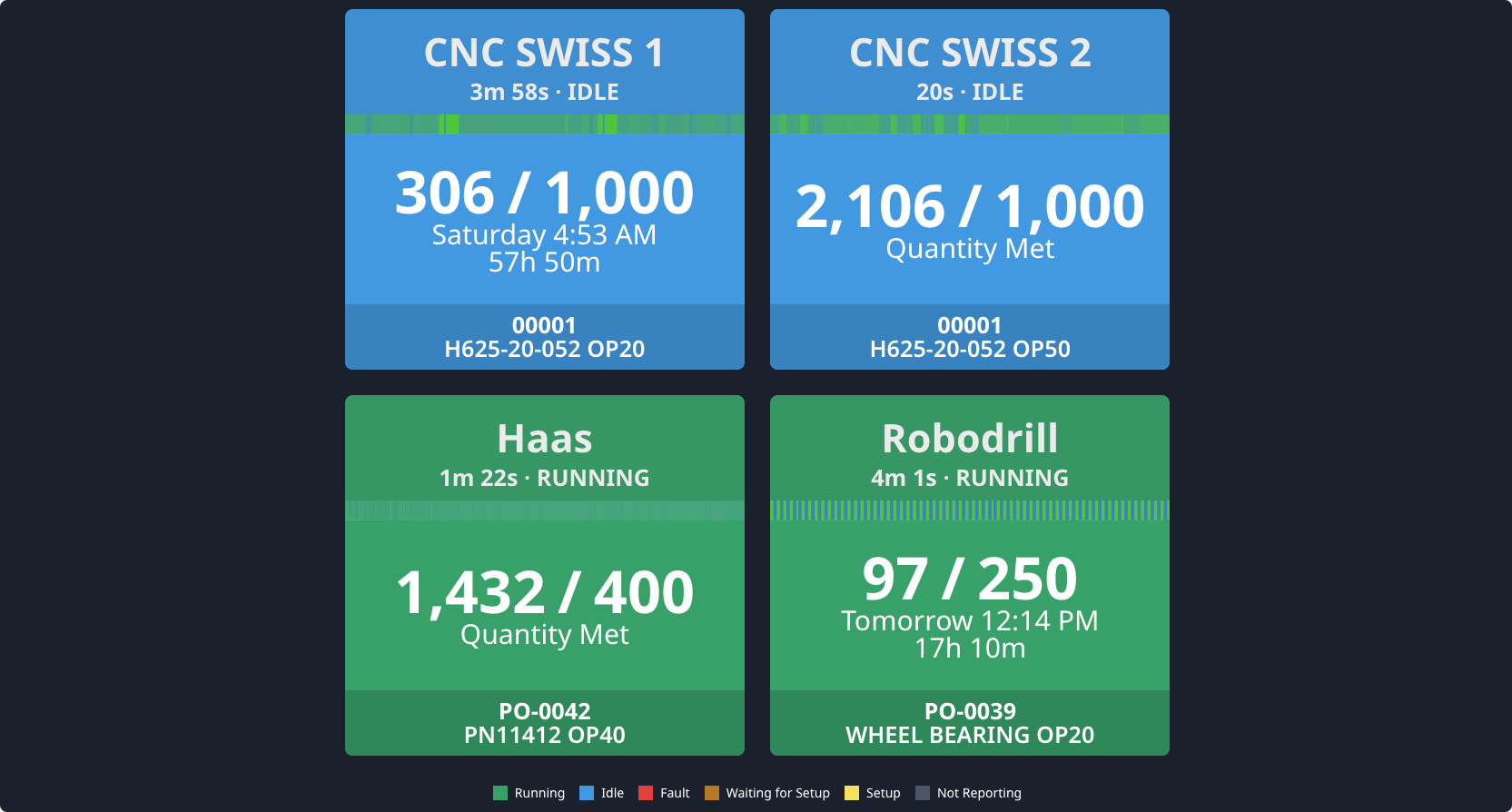

Operator Dashboards

Placed at each machine, the operator dashboard is a tablet that operators can interact with to manage their responsibilities more effectively. They can have a close-up view of their performance against production goals, as well as document reasons for downtime and quality issues.

The MachineMetrics Operator Dashboard provides immediate insight for operators. Not only can downtime and quality issues be logged, but operators can call for help or trigger workflows right from the machine.

Automate Communication

Communication and the sharing of information is one of the biggest roadblocks to manufacturing success. Manual tracking, unconnected systems, and tedious production meetings tend to slow the many problems operators experience on a daily basis.

MachineMetrics helps to improve communication, as well as enable automation, to significantly improve the performance of operators and other shop floor personnel.

Directly from the machine, operators can easily notify their manager of problems or even call for support from materials managers, quality teams, or maintenance, in order to resolve problems before they even happen.

Learn more about how MachineMetrics workflows can enable process optimization and automation across the shop floor.

Develop an Incentive Program

Developing incentive programs based on operator performance is a great way to implement a friendly competitive system to motivate operators. Such programs can be successfully implemented to ensure personal accountability by focusing not on operator performance against other operators, but simply against predefined benchmarks.

In this way, all operators have the chance to "win" and any time operators are performing above the standard, the organization is winning as a whole.

And even if you do not roll out an incentive plan, you can still use production data from operators to drive performance evaluations.

Improve Your Training

With systems in place to understand operator and equipment performance, managers will have a better understanding of where opportunities exist. They can pinpoint bottlenecks, areas of inefficiency, and see what shifts, jobs, machines, and operators are high performing, and which are not.

This information can be used to develop stronger training material and leverage the successful components of the factory floor to ensure that the less successful components have the tools needed to drive productivity forwards.

Improving Operator Performance with MachineMetrics

MachineMetrics enables real-time machine connectivity, and layers on key contextual data from operators providing a complete, real-time view of the factory floor. Managers across the operation, as well as operators, have instant visibility and accountability with out-of-the-box dashboards, reports, and applications.

Learn how our customers drive a 20% increase in efficiency on average within their first month. Book a demo with our team today or listen in to how an operator at one of our customers' plants is using MachineMetrics:

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments