Holding more than 185 patents, Flexco produces belt fasteners, cleaners, and maintenance products for a broad global customer base. The organization is deeply committed to customer success and employs a continuous improvement strategy that focuses on increasing uptime and productivity in both customer operations as well as its own.

Flexco required an accurate understanding of production metrics to optimize its production planning and delivery of goods. Despite experimenting with multiple IoT vendors, the ability to quickly connect machines, drive actionable insights, and unlock valuable use cases remained a challenge.

After implementing MachineMetrics, Flexco collected, standardized, and analyzed production data within a few days to pinpoint opportunities for improvement. With these newfound insights, the company could identify and exploit hidden capacity in its production equipment to meet rapidly growing product demand and ensure on-time delivery.

Flexco's manufacturing capabilities cover various production processes like progressive stamping, cold heading, CNC milling, and automated assembly. This diversity creates a complex challenge for managing the process-related input data required to drive strong alignment between production planning and execution.

Before MachineMetrics, many of Flexco’s machines were at full capacity, and additional production wasn’t feasible. The company needed a way to identify hidden capacity within other areas of the operation. Previous solutions failed to collect data from the multiple types of equipment in the plant and drive value quickly enough for an acceptable ROI.

Management needed to find a scalable way to maintain an accurate and up-to-date understanding of cycle times, machine capacity, and process variability. Identifying the most problematic and frequently occurring causes of downtime was essential.

MachineMetrics automated and standardized Flexco’s data collection, enabling decision-makers to spend less time sorting through spreadsheets and more time finding and implementing opportunities for improvement. The platform's advanced analytics and actionable insights allowed management to directly measure the before and after effects of improvements in real-time and make adjustments as needed.

The flexibility of the MachineMetrics Machine Data Platform worked seamlessly with all different types of machines and data formats. This integration was a key differentiating factor for Flexco.

MachineMetrics provided the most turnkey and scalable solution that prioritized an intuitive user experience and aligned with the team's technical abilities.

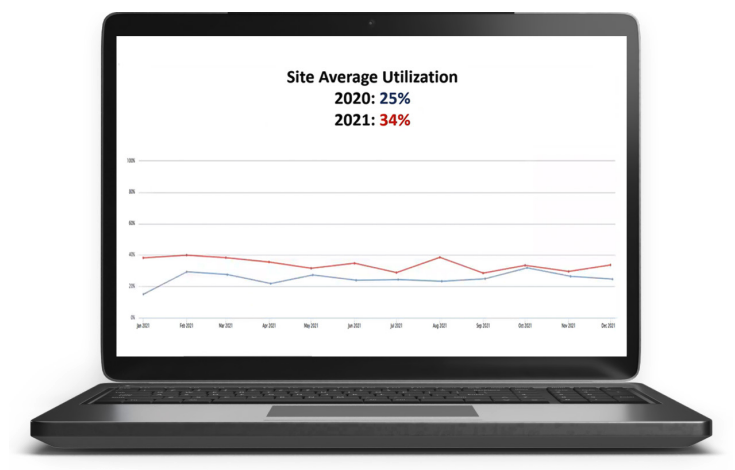

Flexco leveraged its diverse machine data almost immediately after implementing MachineMetrics. Demand had skyrocketed on one product line, so MachineMetrics analyzed the utilization of other equipment in the facility to identify a machine that had low utilization. Flexco then re-tooled the lower utilization machine and redeployed it to the product line that was in trouble.

Utilization of the reworked machine quickly rose from 3% to 30%, representing a 16.5% increase in productivity to support increased demand.

MachineMetrics pointed Flexco in the right direction with machine data and advanced analytics across the facility. Flexco believes that rolling out digital transformation initiatives across all of its processes is the next evolution in its commitment to customer success.

Data visibility, a key component of digital transformation, was accomplished using HMIs such as tablets and shop floor dashboards. Improved visibility across the shop floor has led to a 100% increase in employee engagement.

These results have driven Flexco's plans to further leverage machine data for process improvements, and it plans to link MachineMetrics to its ERP and other business intelligence software.

Flexco

Jordan Kathe, Continuous Improvement Manager

Agriculture, Logistics, Pharmaceutical,

Mining, and Many More

Lathes, Grinding Machines, Cold Stamping, CNC Milling, Automated Assembly

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Easthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027