Tool breakage has always been a challenge for machining operations. These breaks can occur during regular machining cycles due to tool wear that eventually results in failure. They may also occur due to improper settings, human error, equipment malfunction, or for a variety of other reasons.

When tools break, costs pile up. Downtime means fewer first-quality pieces and potential missed deliveries. It also drives up labor and materials costs from scrap and additional labor for reworkable pieces.

However, recent years have seen a growth in accurate and dependable tool monitoring systems that operate in conjunction with production monitoring to prolong the life of tools or predict their failure.

This article will define tool breakage, discuss common tool break detection technologies, and address ways to avoid a costly break.

What is CNC Tool Breakage Detection?

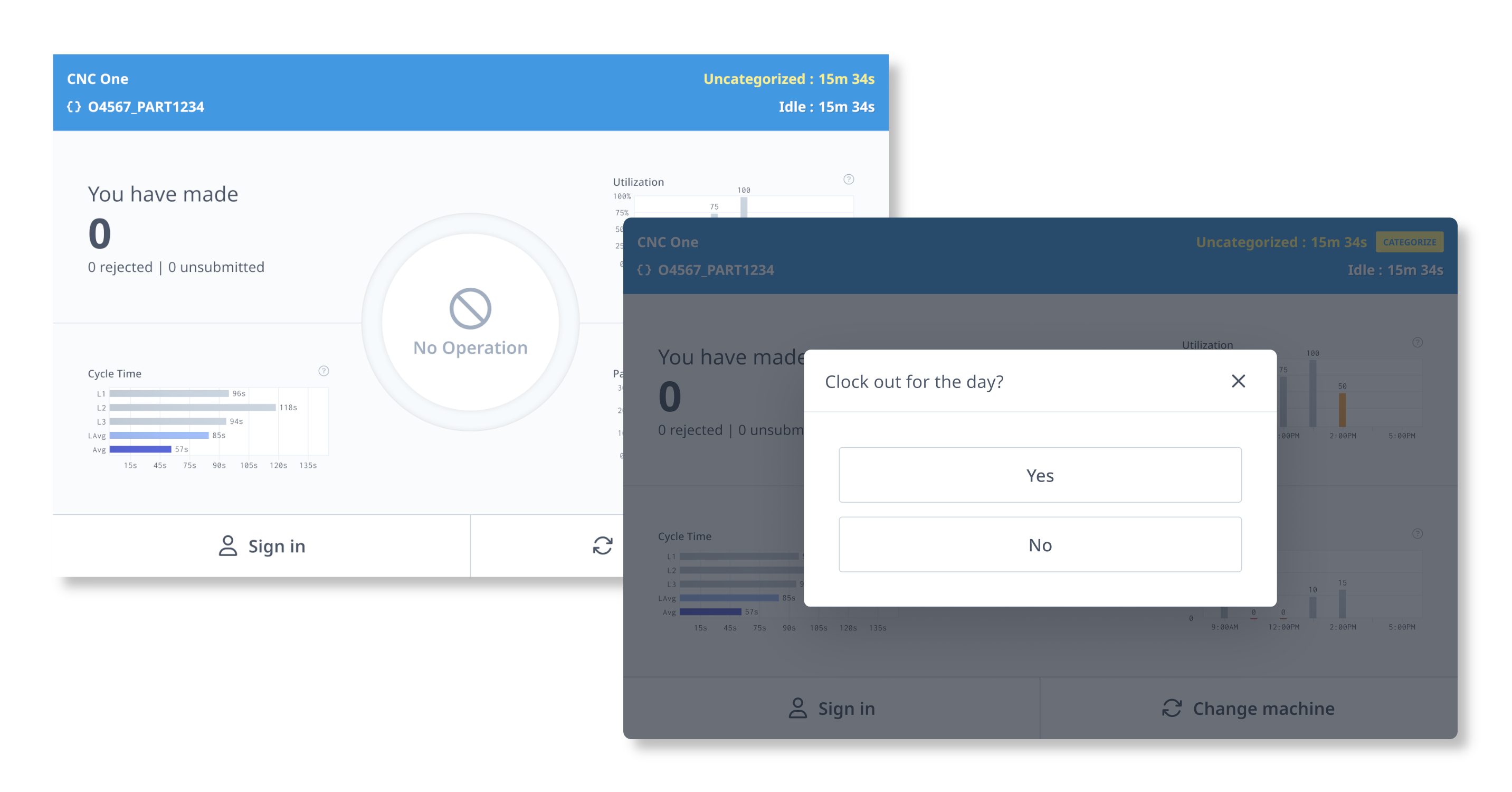

There are a wide variety of tools used in CNC machining. Tool breakage detection consists of control system technologies where the breakage of a tool signals the operator of the break.

When these alarms happen, the machining cycle may stop, allowing operators to replace the tool and prevent damage to the machine. Depending on the type of break, tool detection can help recover a part before it becomes scrap.

Types of Tool Breaking Technologies

Tool break detection offers many benefits, including:

- Better Accuracy

- Reduced Scrap and Rework

- Lower Costs

- Higher Efficiency

- Reduced Operator Handling

There are several active technologies used in CNC machining that enable manufacturers to realize these benefits. The type of system used for tooling breakage detection may consist of one or more of the following technologies.

They’re often tied to production monitoring systems and ideally IIoT platforms that can analyze tooling data in the cloud to better predict breakages in the future - or even powered by AI like MachineMetrics Tool Anomaly Detection and uses high-frequency data to diagnose, predict and avoid failures. This technology is sensorless and uses instantaneous real-time data pulled at an extremely high rate to build accurate tool failure detection models.

Sensor-Based Solutions

Sensor-based detection systems are straightforward. The hardware used to detect breaks is physically attached within the machine. These solutions can be quite expensive, as they require invasive sensors to be placed within machines, which also means that the deployment time will be lengthy.

Sensor-based solutions may be a good choice for tool break detection in equipment where the motion needed to work the piece is straightforward - such as high volume, low mix operations.

Sensorless Solutions

Sensorless solutions can capture data directly from the machine control. The major benefit here is the time to deployment as well as the affordability of the solution. By not appending invasive sensors, there is no risk of voiding a machine warranty.

This automates the monitoring of tool wear and tool breakage and identifies not only when tools break but as they are approaching failure point - applying AI to the data captured is how MachineMetrics identifies anomalies and tooling problems.

.png?width=5760&height=3840&name=MachineMetrics%20Tool%20Anomaly%20Detection%20(1).png)

MachineMetrics Tool Anomaly Detection - an AI-powered sensorless solution.

Contact Technologies

Contact detection technologies use a probe, pad, or other end piece to determine if a tool is broken. Probes can be fixed or moving, depending on the type of machine. Tools will contact probes to determine whether the tool is broken. Contact break detection can be used with both wired and wireless systems.

Like wired technologies, contact technologies are a physical way to detect tool breakage. But these contact devices can be loaded to tool monitoring software in both wired and wireless systems to make tool break detection real time. This means that stopping equipment upon immediate detection can be automated to prevent damage to the machine and save material from the scrap bin.

Non-Contact Technologies

The most common non-contact break detection technology is a laser. Lasers are ideal for detecting breakage of high speed rotation of tools. They’re also highly useful in tools that require thermal monitoring that may deform or break the tool under excess heat. Lasers are only able to measure in two dimensions. For three dimensions, they’re paired with contact technology to capture third-dimension data.

Another non-contact break detection technology is the use of cameras. Cameras are better for small tools compared to lasers. The beam is often wider than the tool in small tools, and cameras can detect breaks with high-resolution pictures of small tool milling.

Keep Tool Breaks to a Minimum

Tool breaks can be minimized through best practices and attention to detail. This helps minimize the cost of tooling and the overall production operation. Best practices include:

- Keep tight control of the average number of tool assemblies and documents handled, so they’re set up correctly for each run.

- Audit set up times to look for root causes of problematic runs that can be reduced with set up adjustments.

- Include tool quality in improvement efforts. The right material for tools will depend on the type of jobs the shop is running; lower quality cutting tool material can increase costs.

- Use production monitoring software. Advanced systems like that offered by MachineMetrics let you take a deep dive into the cause of the breakage to develop improved predictive strategies to mitigate breakage.

Maximize tool life and eliminate scrap

Common Mistakes in Cutting Tool Breakage

Mistakes can lead to tool breakage. Here are examples of common mistakes that lead to tool breakage.

- Wrong Tool Holder or Tool Assembly – Choosing the right tool combination is crucial. This combination includes the right tool holder, tool length, and tool profile.

- Wrong Tool – Choosing the right tool for the material can be the difference between a broken tool and a correct part. Many times, tools aren’t matched with the material used.

- Wrong Speed – On the highway, speed kills. But in CNC, the mistake is often too low of a speed for the cut.

- Wrong Tool Path – This basic programming error fails to account for complex features within a tool path.

BC Machining Turns to MachineMetrics for Predictive Tool Monitoring

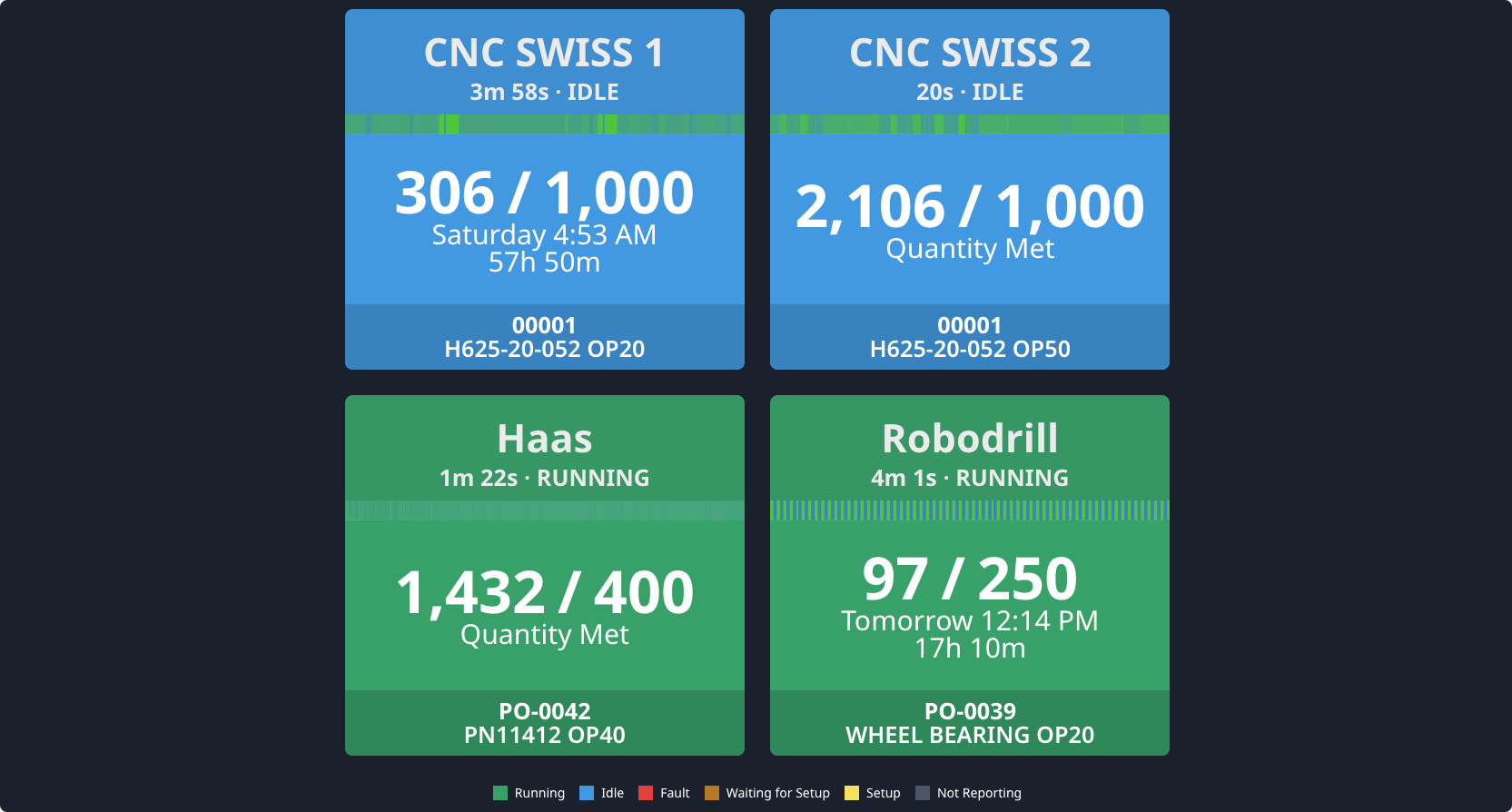

When BC Machining sought help to address continuing tool breakage and high scrap rates, they engaged MachineMetrics for a solution. BC Machining serves the medical, defense, transportation, and power tool industries where precision is critical.

BC Machining had been experiencing excessive tool breakage in their Swiss CNC machines, creating scrap both at the point of breakage and near-end-of-tool-life when parts can vary out of spec.

Using the MachineMetrics solution of capturing high-frequency data and analyzing it through advanced algorithms, BC was able to identify tool breakages to prevent scrap parts.

The drop in lost parts, sorting, and uncertainty translated into near 100% failure detection and a $72,000 annual savings per machine.

Read the complete case study with BC Machining.

MachineMetrics offers a monitoring system for tool assessment that collects data directly from the source – the CNC machine itself. Through custom algorithms designed to monitor torque usage, inputs can be entered into the system as time-series events or machine learning models to predict tool failure accurately.

MachineMetrics' high-frequency data adapter can detect the problems and analyze the data at the edge to automate solutions and alert staff to issues before the failure occurs, preventing costly scrap and downtime. With advanced machine diagnostics, tooling is optimized and incorporated into an aggressive and fully automated predictive maintenance system. To see how MachineMetrics can be deployed to help you get a handle on your tool's health needs, book a demo with our team today.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.png?width=5760&height=3840&name=MachineMetrics%20Tool%20Anomaly%20Detection%20(1).png)

Comments