What's the Relevance and Importance of Industrial DataOps?

From a manufacturing standpoint, data and operations in regard to data play a role in creating and maintaining a competitive, innovative, agile facility without carrying high risks or other burdens such as excessive inventory. Having data alone isn’t enough to stay ahead—it’s all in what you do with it. As an approach to data analytics, DataOps is all about reducing the time to high-accuracy analyses using automation, statistical process control, and agile methodologies so that manufacturers are able to use the data they collect quicker and with a higher degree of confidence.

For a manufacturer, good DataOps can mean the difference between dominating a rising market and carrying a redundant inventory due to unwittingly entering the market on the far side of a trend. It can help manufacturers stay on top of changing demands, supply chain and logistics information that could have major impacts on business, and anything else that uses data quickly and with a high degree of precision.

Data itself is a raw resource that can be compared to crude oil. In and of itself, there’s not a whole lot to do with it in its basic form. But both oil and data contain potential. Just as we refine oil into gas and then burn it to power supercars and rocket ships, data can be refined through processes optimized under Industrial DataOps, converting raw data into analytics which can then be used to supercharge business decisions quickly and with scientific precision.

The role of DataOps in Industry 4.0 is to take all of the info created and collected by machines, like IIoT devices, and effectively condense them into refined, usable business “fuel” to drive decision-making, rather than be left to sit in a data warehouse, unexamined.

What is Industrial DataOps?

Industrial DataOps is a way to manage how data is handled within an organization with a focus on speed and usability. This can include processes, automations, and workflows as they relate to the refinement of data into usable analytics. This is especially important in the face of ever-increasing data streams that have become too unwieldy for many businesses to handle. DataOps provides a way to systematically and effectively manage data so that it is utilized to its fullest extent at a speed which will keep the resultant analytics still relevant to the company.

The four C’s of the Industrial DataOps methodology, according to the Manufacturing Leadership Council:

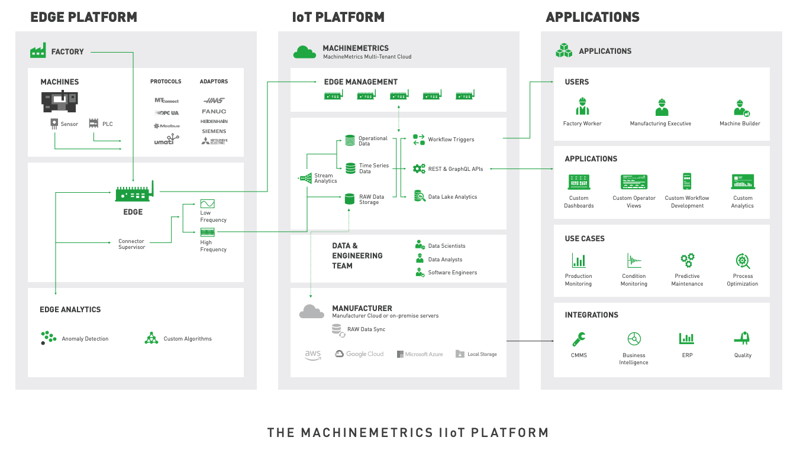

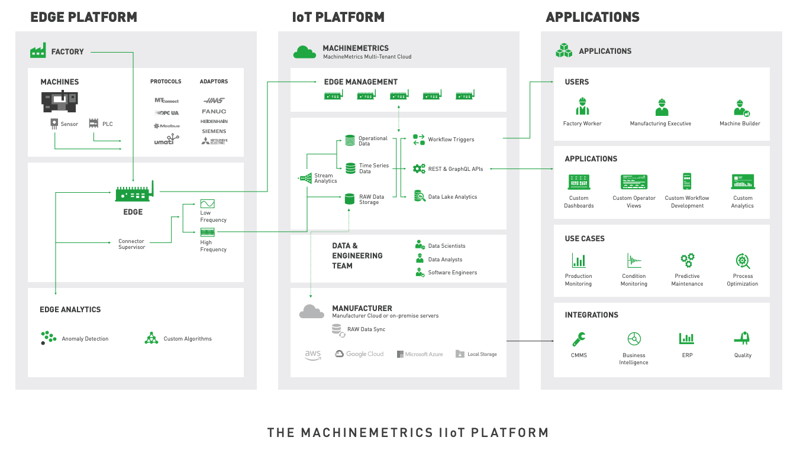

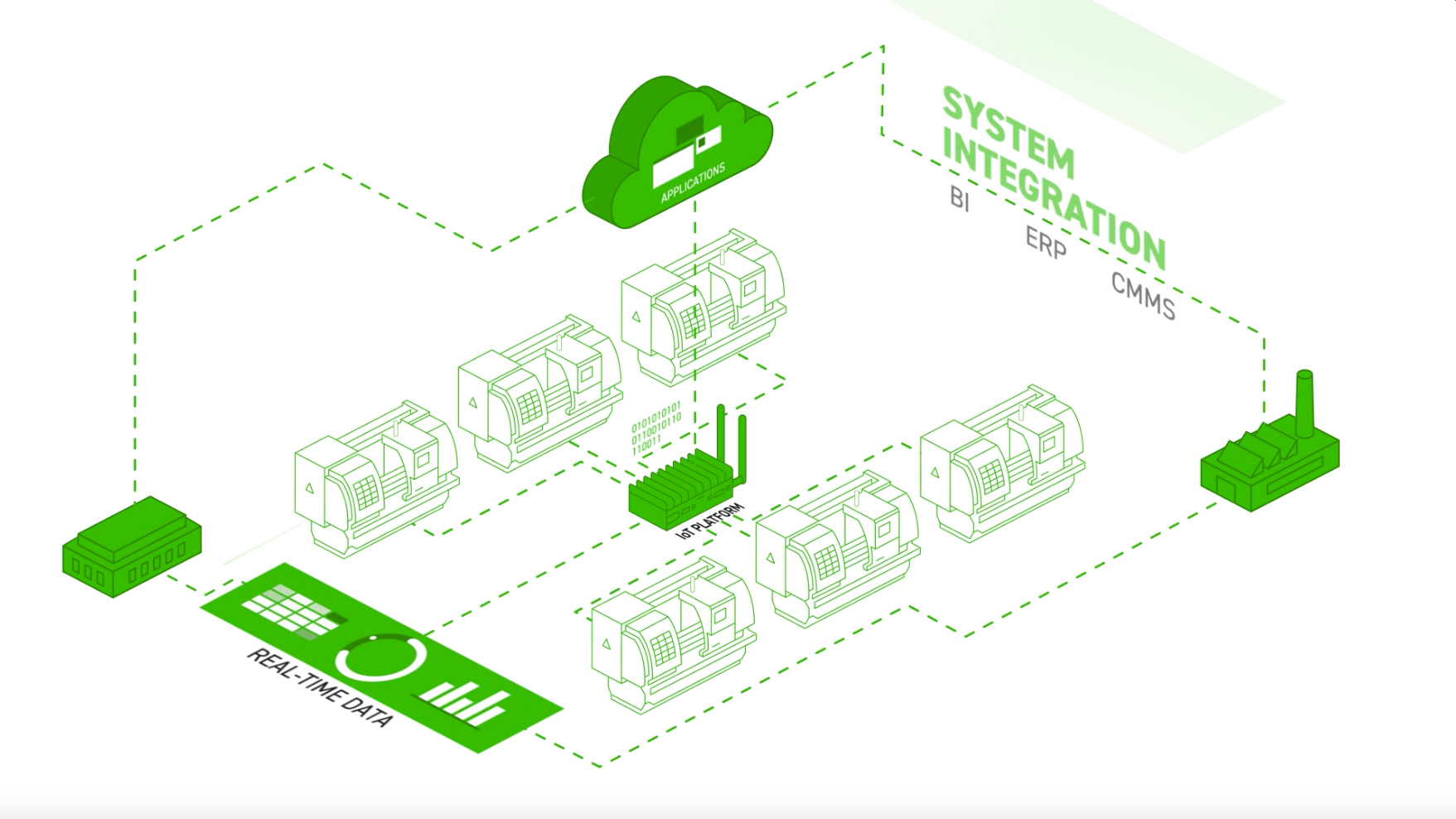

- Connected data is where silos break down and data intermingles. This allows for deeper and more complex analysis that would otherwise be infeasible. Connected data makes use of IIoT, cloud, and edge technology (the technologies that underpin what we offer at MachineMetrics).

- Curated data is when the data comes together in a form that will become usable. Data engineers essentially collect relevant bits of data and clean them up for analysis to make sure the results are as accurate as possible. They take overwhelming pools of data and pare them down to what’s relevant to a particular question or scenario.

- Contextualized data has added layers of information and expertise to give it context that the numbers alone don’t show. If a manufacturing line starts and stops three times in fifteen minutes right after an equipment failure, there is a high chance that each “start” was actually testing the replaced parts for functionality, accuracy, and alignment. An industry expert can spot this and offer context, whereas, by the numbers, this could easily be misinterpreted.

- Cyber-confidential refers to the need for cybersecurity to scale in parallel to increased connection and customization. Customer data must be protected at all costs, but this can complicate matters for security and data governance professionals.

Companies Are Drowning in Unusable Data

As mentioned above, many companies are sinking under the weight of their data stores. Without a way to contextualize and curate data, many hoard the figures they’ve worked hard to collect without a method to nix the overwhelm and actually use the info for decision-making. This is especially true for early adopters of Industry 4.0 equipment who expected plug-and-play results after data collection. Instead, companies have found that much of the data they have collected doesn’t contain the information they need to make sense of it, connect it with other data streams, or use it for analysis—at least in its current form. In essence, they’ve got warehouses of crude oil and no refineries or equipment that can extract its value, not the straight gasoline they thought they were signing up for. Some of that data contains customer information, putting the company at risk for zero value-add.

In order to overcome this, companies need to manage the flow of information as well as standardize, normalize, and contextualize data. With the right connectivity, security, and analytics environment software, companies can turn data streams into insights rather than burdens to bear.

The Difference Between DataOps and DevOps

DevOps is a merging of software development and information technology operations. Its focus is on the speedy development of software at scale with high quality and predictability.

DataOps also seeks to improve quality and speed as well as predictability and scalability, but the focus of DataOps is on data analysis rather than software engineering.

The Benefits of Industrial DataOps

With the crux of DataOps being a system for effectively collecting and using data, there are countless tangible benefits for manufacturers. Here are a few of the primary benefits for industrial organizations that enable a successful data operations program:

- Collaboration and communication boosts by breaking down silos and blurring boundaries between departments in a way that leads everyone to work together.

- Faster time to production and increased flexibility come from faster insights and short testing cycles through the use of automation.

- Quality and reliability both gain a boost from DataOps because there is constant monitoring for issues and bottlenecks preceding, during, and after any major changes. It is continuous improvement in very much the same vein as lean manufacturing and Kaizen.

- Self-service that reduces the need for experts due to easier development and deployment enables business users to develop their own solutions and see them in action quickly.

- Boosting security and managing the influx of data

- Managing inconsistencies and adding context, standardization, and normalization to data to make it usable

Industrial DataOps Use Cases

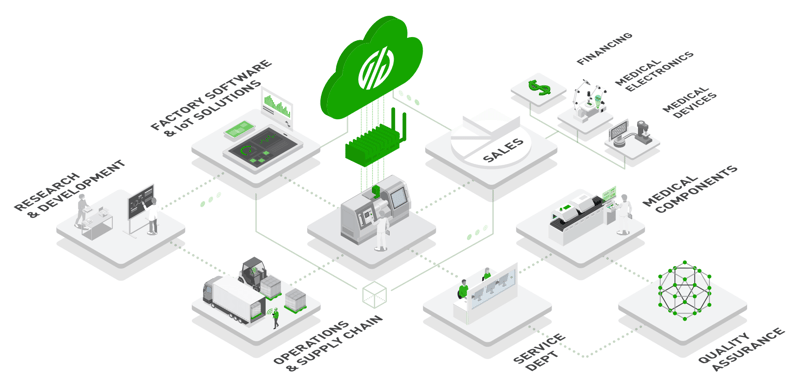

DataOps has a variety of industrial applications that work to support the continuously developing and complex data landscape of Industry 4.0. Primarily, DataOps helps streamline the use of data and analytics throughout organizations, providing visibility and ease of access to different levels and departments of an organization. Below we cover a few of the primary use cases of Industrial DataOps.

Data Warehousing and Data Management

Data warehousing and data management get a revamp with DataOps, evolving from a complex landscape filled with uninterpretable and disorganized data overload into a streamlined process that both allows for quicker, more agile decision-making on the fly and automation to free up minds and other resources to focus on completing other jobs. MachineMetrics can capture huge swathes of data from machinery all across the production floor, then transform that data into something that is usable, e.g. organized, standardized formats of information that can be combined in real-time to fuel decision-making or accessed via the cloud for deep, insightful analysis.

Dashboards and Reporting

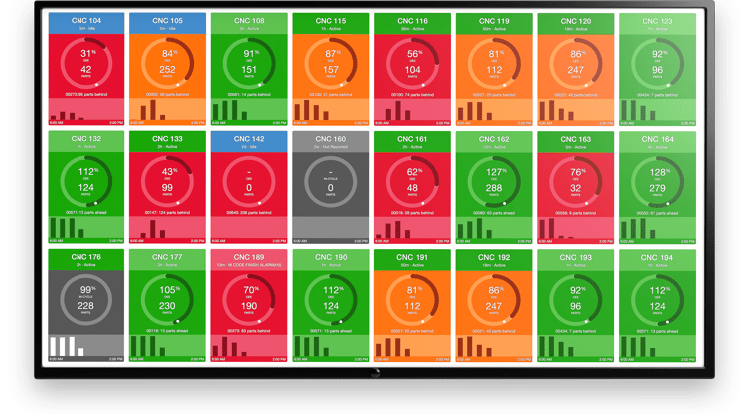

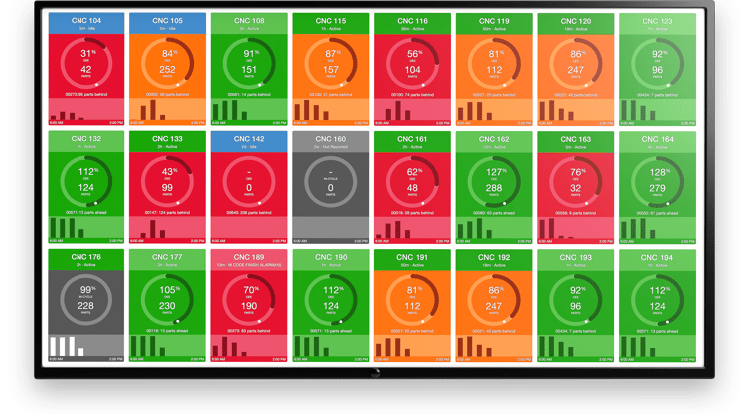

Dashboards and reporting are a staple of manufacturing. From the once humble whiteboard to the intuitive, digital displays of today, measuring and tracking results has long guided next steps for manufacturers. With MachineMetrics dashboards, you don’t have to worry about inaccuracies or unreadable handwriting on a whiteboard (or forgetting to log the info before it gets erased.) Instead, you’ll have access to any production data, whether it be part count for the current shift or machine utilization rates from a year ago. You can even tailor your display for your audience, so that floor workers can see how many parts need to be produced and if they’re on track, while executives and directors can see the big picture—all with a few simple clicks.

The MachineMetrics Current Shift Dashboard collects and displays real-time data on shop-floor machines to give operators and managers visibility into production.

The MachineMetrics Current Shift Dashboard collects and displays real-time data on shop-floor machines to give operators and managers visibility into production.

Data Science

Data science and DataOps go hand in hand. In this union, data science moves out of the experimental realm and into everyday use, delivering ROI that stakeholders can readily see. At MachineMetrics, our tools create effective pipelines that help data scientists speed through problems in ways previously unheard of, especially since they spend less time cleaning data, thanks to our data transformation engine. For example, manufacturers can leverage their in-house teams or work with the MachineMetrics data science team to predict and prevent tool failure.

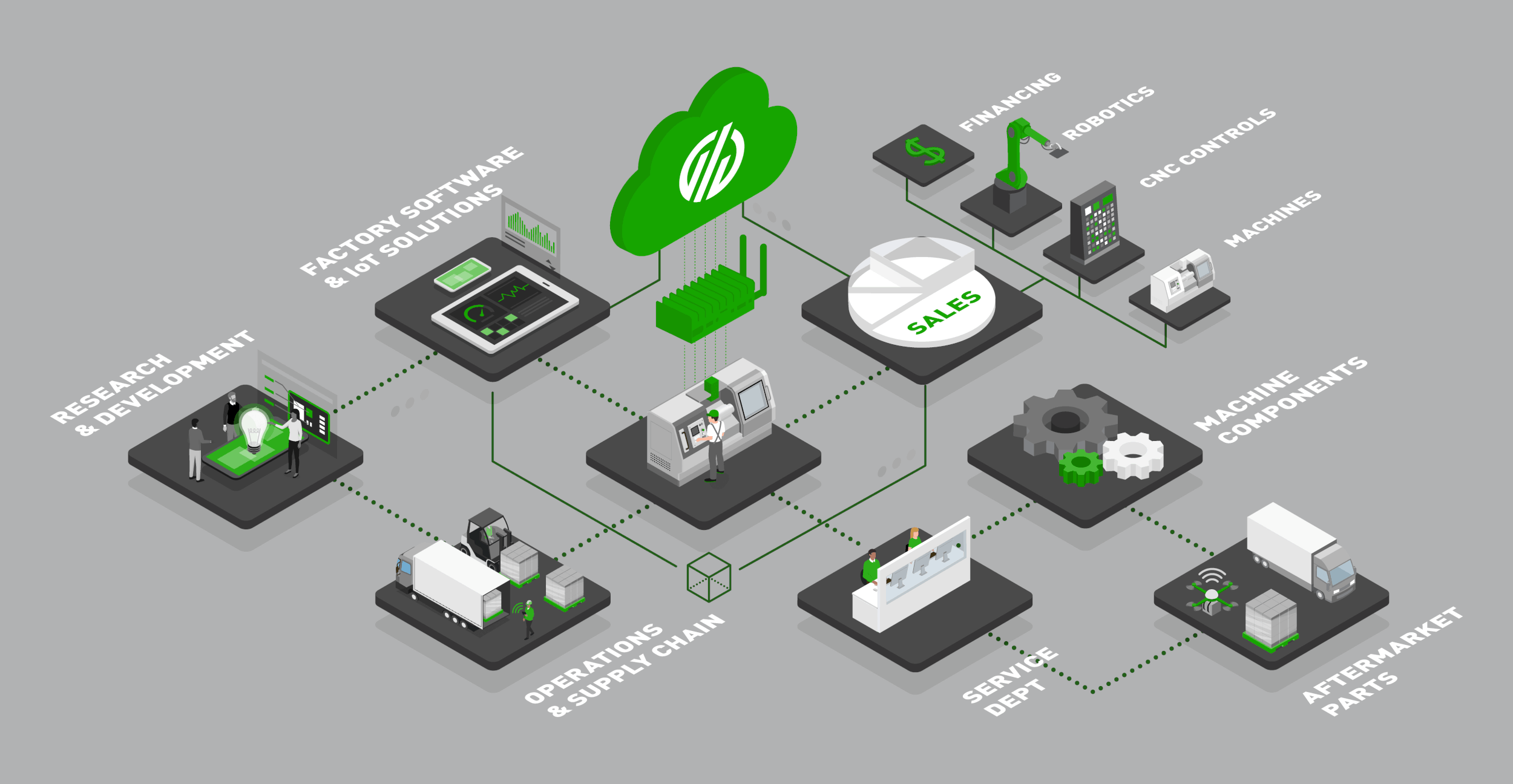

Application Development

Application development also gains a boost from DataOps, with streamlining, customization, and communication capabilities at the forefront of these benefits. With MachineMetrics, you get apps pre-built out of the box that can have your organization seeing ROI in no time. Plus, you can build your own custom applications so your data works for you just the way you want it to. Not to mention the ability to easily integrate with other systems (ERP, MES, CMMS) to build out automated workflows. The sky's the limit.

What is an Industrial DataOps Platform?

An Industrial DataOps platform manages DataOps at every level of the data lifecycle, from data sources through to data consumption. This is a streamlined approach to managing data that results in high standardization and accuracy as well as ultra-fast turnarounds as compared to disparate DataOps functions. With an Industrial DataOps platform, data flows seamlessly through the process of cleaning and refining and into visualizations and reports that are ready to be used to make business decisions.

An industrial DataOps solution would generally include the ability for local edge processing as well as cloud processing, security features at scale befitting an industrial setting in order to safeguard data, connections with other industrial IT systems, cleaning and contextualizing data, and managing the flow of information.

DataOps platforms have a goal of helping manufacturers use their data to drive value as fast and effectively as possible. By this logic, data is simply a means to an end, with the end goal being decision-making that improves production efficiency. But the only way for that to be possible is if there is a program for data to be collected, transformed, and accessible to drive that decision-making. This is where Industrial DataOps platforms thrive.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments