The Connectivity Problem

While buzzwords such as predictive maintenance, artificial intelligence, digital twin, and augmented reality have promised to enable the fabled digital transformation of manufacturing, when it comes to Manufacturing 4.0, most practical applications start and end with machine connectivity.

Simply put, most manufacturers are unable to see what’s actually happening on the shop floor in real time because their machines are not connected to any sort of data collection or data visualization system. This inability to both see and use data to drive continuous improvement leads to massive inefficiencies that affect every component of a company’s operations, from the shop floor all the way to the C-Suite.

Many manufacturers are hesitant to connect their machines to any sort of network for fear of data security, let alone have their data leave the factory into the cloud – thus, most machine data visualization companies submit to doing an on-premise implementation. You’re looking at the new problem of siloed data, which makes it tough to aggregate enough data to drive any sort of real impact. Imagine if Netflix tried to build a recommendation engine but only had data from one household.

The Discrete Manufacturing Challenges

So, how does one get this data and make it visible? For manufacturing, it’s not necessarily as easy as slapping a few sensors on a piece of equipment. Discrete Manufacturing, for example, has unique challenges that are difficult to address when considering collecting manufacturing data:

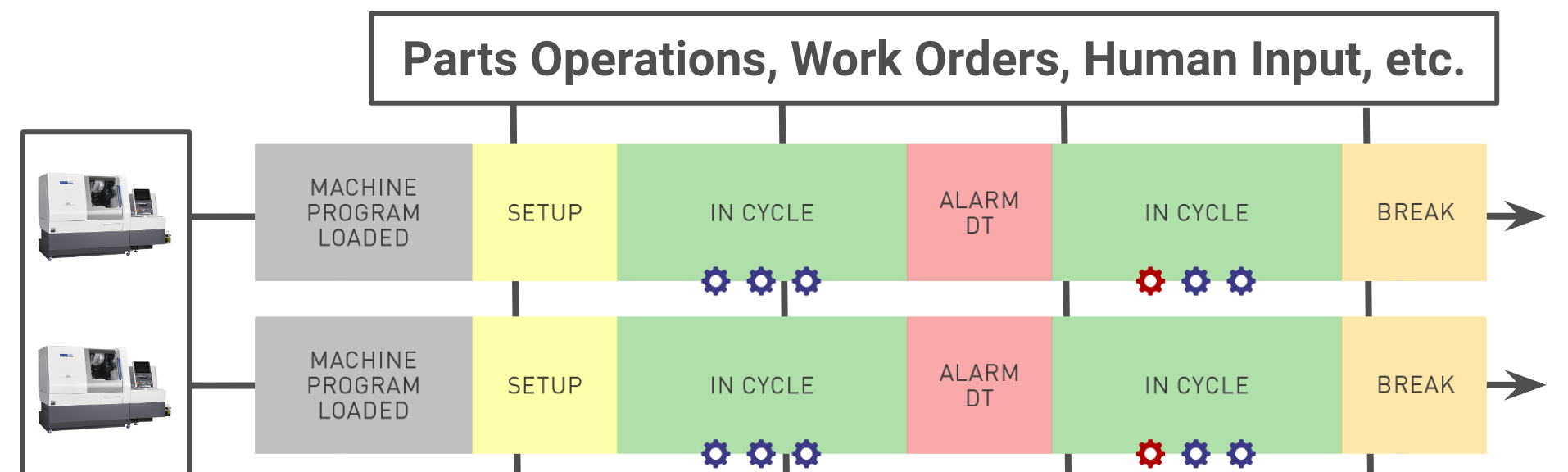

- Data Variety: Not only are there many distinct types of equipment — Lathes, Mills, Plastic Injection Molding, Stamping, Laser Cutters, Robotics, etc — depending on the mechanisms available for acquiring data from those systems, the data points can be very diverse. To provide effective tools for analyzing that data across these distinct systems, the data must be transformed into a common data model. Not only does each machine control have its own mechanism for gathering data, data points can even differ by the Family, Make, and Model of the machine using that control as well as the version of the software running on that control.

- Data Volume: Manufacturing equipment, and discrete manufacturing equipment in particular, is very complex. A machine is a large system of components that work in coordination resulting in hundreds of distinct data points that change constantly. Depending on the application, there may be situations where it is required to capture data at rates of 100Hz or 100KHz. Platforms consuming this must analyze data at multiple levels within the system to avoid sending and storing unnecessary data when only the aggregate or computed result is sufficient. These systems must be capable of performing complex processing where it is most appropriate — at both the edge and in the cloud.

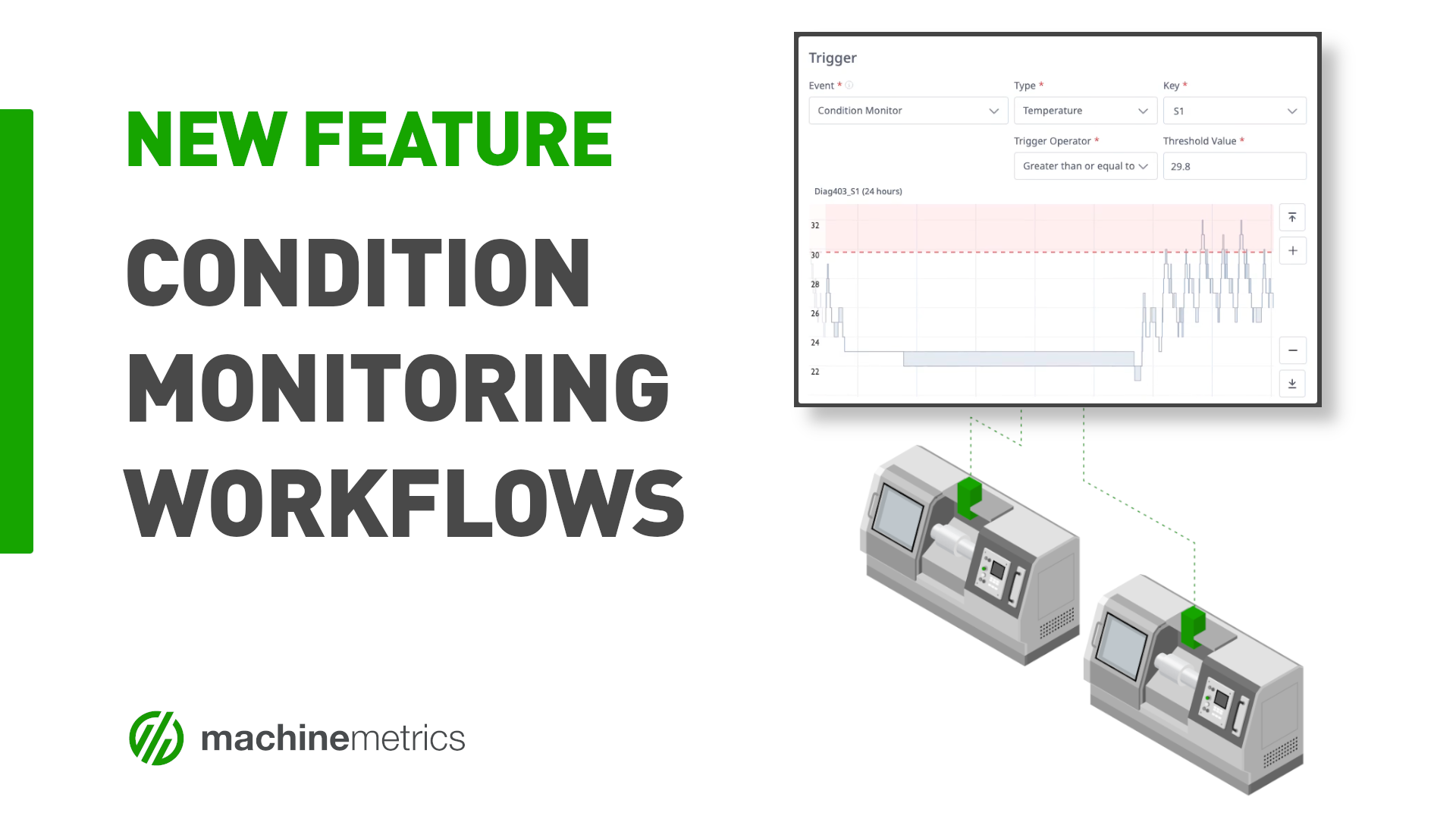

- Data Speed: While some systems can provide value with low fidelity and high latency, certain IoT use cases require much more real-time data to be effective. Edge technology is required to process high volumes of data, make decisions in milliseconds or less, and act to potentially prevent damage to the machine or the workpiece. Even dashboards that provide visibility into a jobs performance can gain tremendous value from low latencies — drawing immediate attention into a process that’s falling behind or failing.

- Number of disparate systems: Integrating legacy systems is a complex task. Having robust data models for each application serving the vertical are required to adequately capture events. Further, having a deep understanding of how the data from each of those systems interact within manufacturing is also necessary to be able to make correlations and provide coherent analysis for process improvement.

- IT Infrastructure: Highly elastic and scalable systems are a new entrant to manufacturers and their IT organizations. Due to the intense processing and storage requirements of IoT, it can be prohibitively costly to overprovision a system for peak load at all times. Systems must automatically adjust, adding and removing resources as necessary. Utilizing secure cloud systems with virtual hardware architectures programmed to be highly available, scalable, and fault tolerant with multiple data centers separated geographically for disaster recovery are even more important when considering the value that a successful IoT initiative can bring an organization.

Discrete manufacturing introduces even more complexity. This starts with the complexity and variability of the machines in discrete manufacturing plants. There are many different machine manufacturers and no one plant has only one brand of machine. The many different machines also have different control systems and communication protocols. The machines are of different vintages ranging from new with modern controls to 20 or 30 years old with limited control capability. Connecting to, and collecting data from, the various plant assets is a significant undertaking, considering most of these machines were never designed to provide data for the kind of holistic, factory or enterprise-wide analytics solutions companies are focused on enabling.

Discrete manufacturing plants not only require data to be collected and transformed but also presented in real-time, in a standard and consistent format that can be analyzed and leveraged to optimize processes and operations across the plant. Thus, it's extremely difficult for multi-industry IoT platforms to account for these manufacturing industry-specific relationships.

Discrete manufacturers investing in Manufacturing 4.0 are hoping to answer two basic questions: “What’s happening?” and “Why is it happening?” To properly answer these questions and actually deliver business value, one needs to understand their data within the context of their operations. This requires a singular focus on the vertical in order to realize the immediate and continuous value promised when undertaking a Manufacturing 4.0 digital transformation initiative.

So what’s the solution?

With the complexity introduced by these challenges, it should be no surprise that manufacturers often find themselves paralyzed when it comes to taking this first crucial step forward.

At MachineMetrics, we saw the opportunity to develop a vertically integrated platform that was not just easy to connect but also feature-rich and extensible to create continuous value and innovation for manufacturers. Our secret sauce is, in reality, in providing a solution and a clearly defined roadmap of use cases to enable a manufacturer to not just connect their assets but to drive both rapid and continuous value with that data. Here’s how we do it:

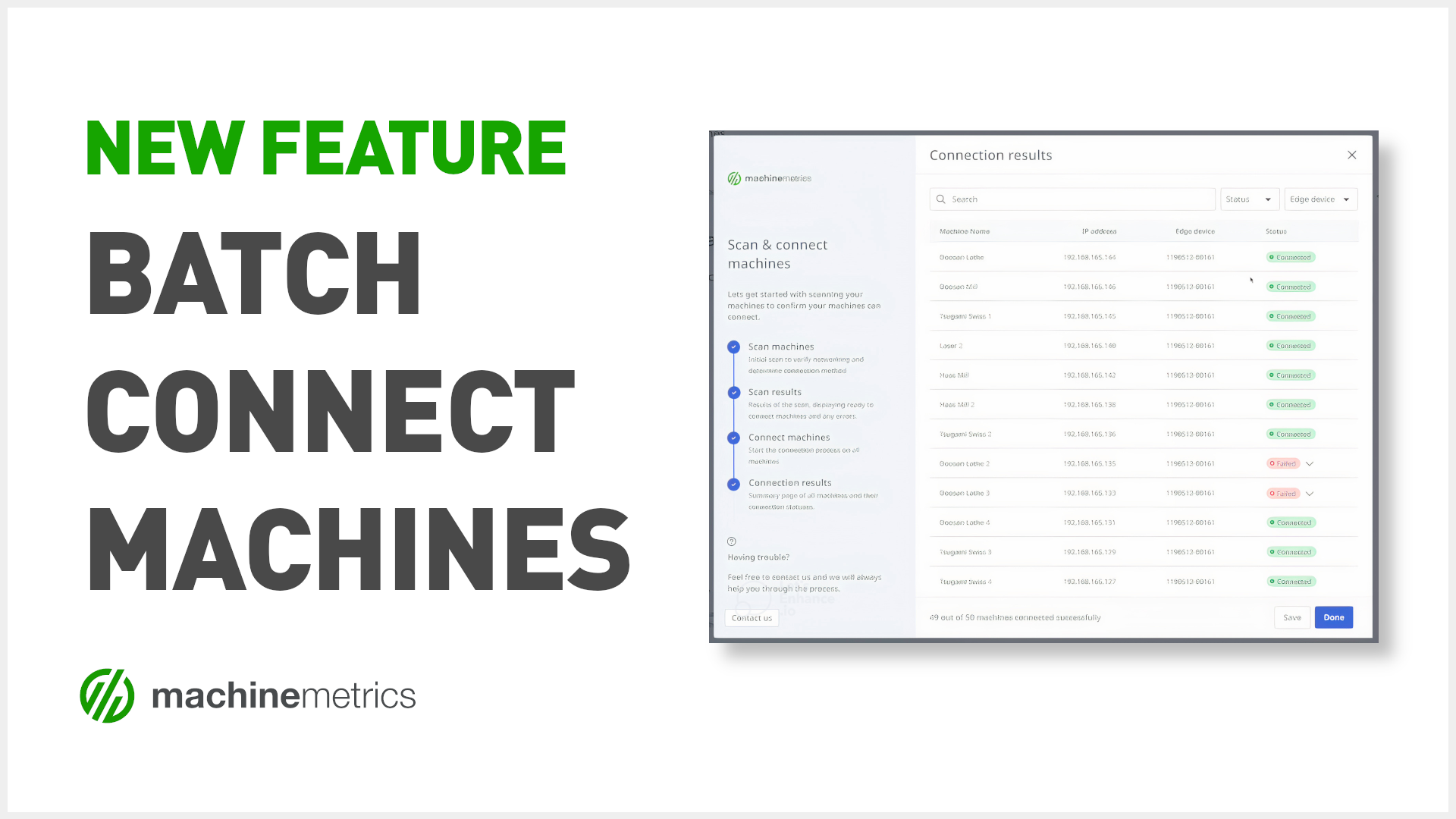

STEP 1: Connect to the data: With an edge device that can connect via ethernet, wifi, or cellular, we’re reducing the friction on your IT department that most likely can support at least one of these three internet connectivity.

Step 2: Collect the data - MachineMetrics took on this problem head-on by creating a plug and play data infrastructure and mapping system that facilitates rapid connection to and collection of data from any type of discrete manufacturing asset, regardless of brand or age.

STEP 3: Transform the Data: Here’s the special sauce - Collecting the data is not good enough as discussed above in our Data Variety challenge; it must be transformed to a standard format that can easily by consumed by any analytic tool or technology.

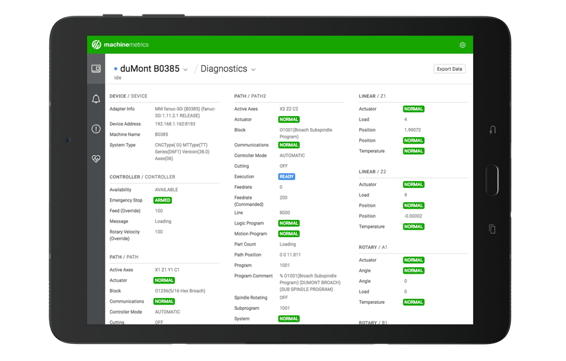

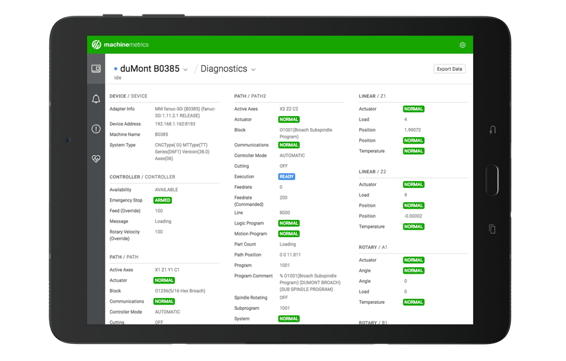

.png?width=533&name=comp_tablet_view-(1).png)

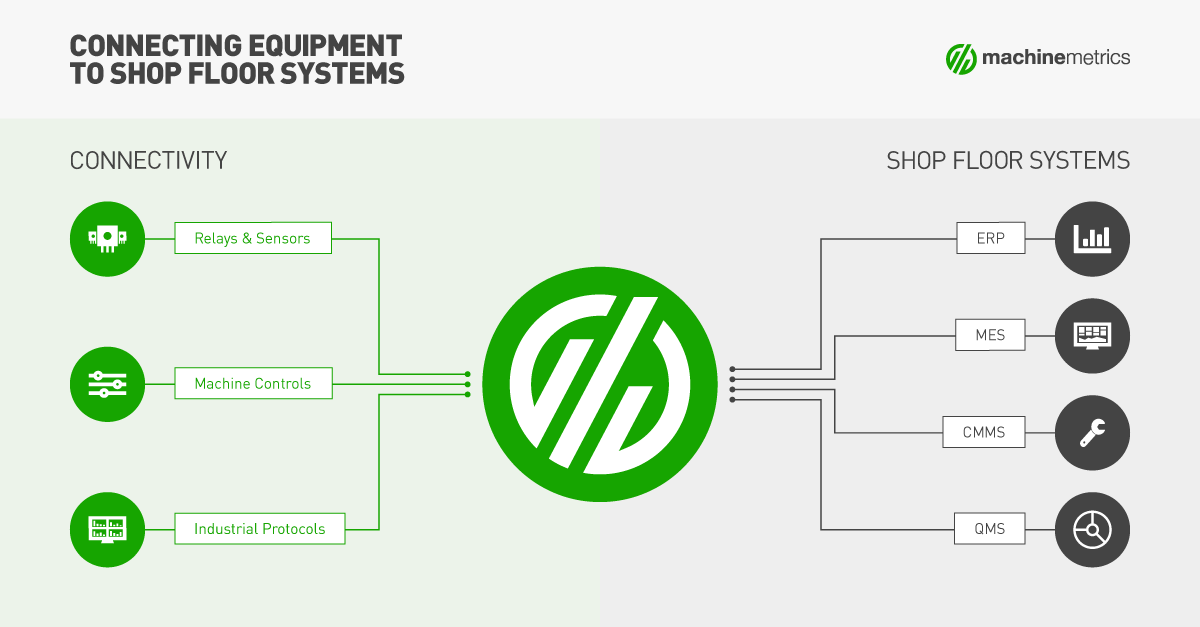

STEP 4: Analyze the data - storing the data in a secure manner in a cloud infrastructure is the backbone of the analytics that will be primary drivers of value for manufacturers. With standardized, transformed data, we provide descriptive, diagnostic, predictive, and even prescriptive analytics through the dozens of various out-of-the-box dashboards, reports, notifications, and ML/AI capabilities or allow our customers to leverage this usable data to power their own innovation, whether it be through Tableau, Microsoft BI or power apps, or through integrations with ERP, CMMS, or quality management systems for extensible value.

.png?width=550&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Final Thoughts

Enabling any Industry 4.0 initiative starts with a data infrastructure that facilitates rapid connection to any type of asset, regardless of brand or age, capturing and transforming data to a standard format that can easily by consumed by any analytic tool or technology, and storing the data and analytics in a secure manner in a cloud infrastructure.

This was not a simple task and took years of hard work: we first simplified IoT connectivity with an inexpensive edge device that enables secure ethernet, wifi, and cellular communication while connecting directly to machine tool PLCs and controls using dozens of custom software adaptors developed to automatically unlock, map out, collect, and standardize the available data points (Status, Modes, Alarms, Overrides, Load, Speeds, Feeds, and more). We then added the ability to add sensors or connect legacy equipment with digital and analog I/O that is configured and managed remotely through a web interface. This task, to enable the connection, collection, and standardization of every piece of discrete manufacturing equipment was paramount as every manufacturer has a wide variety of equipment types and ages that require require data to be unsilo-ed from.

Any Industry 4.0 discrete manufacturing initiative should start with a robust data infrastructure and common user experience, complemented with the analytic technologies and tools needed to harvest value from data. Thus, our data collection and infrastructure is the foundation of the MachineMetrics Vertical Service Platform. Once transformed, this data can then be made actionable in a number of different ways that drive value for all consumers of manufacturing data. Without this transformation of data, most companies will continue struggling to deliver on the promise of Industry 4.0 for manufacturers.

Learn more about how you can improve operational efficiency with Industry 4.0. Download this FREE eBook now.

Learn more about how you can improve operational efficiency with Industry 4.0. Download this FREE eBook now.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.png?width=533&name=comp_tablet_view-(1).png)

.png?width=550&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Learn more about how you can improve operational efficiency with Industry 4.0. Download this FREE eBook now.

Learn more about how you can improve operational efficiency with Industry 4.0. Download this FREE eBook now.

Comments