We get a lot of questions from manufacturers around the difference between the Edge and the Cloud. Edge and cloud computing are often misunderstood to be mutually exclusive but, while they may function in different ways, leveraging one does not preclude the use of the other. In fact, they actually complement one another quite well.

For manufacturing, the goal of edge computing is to process and analyze data near a machine that needs to quickly act on that data in a time-sensitive manner. It needs to make a decision right now with no delay.

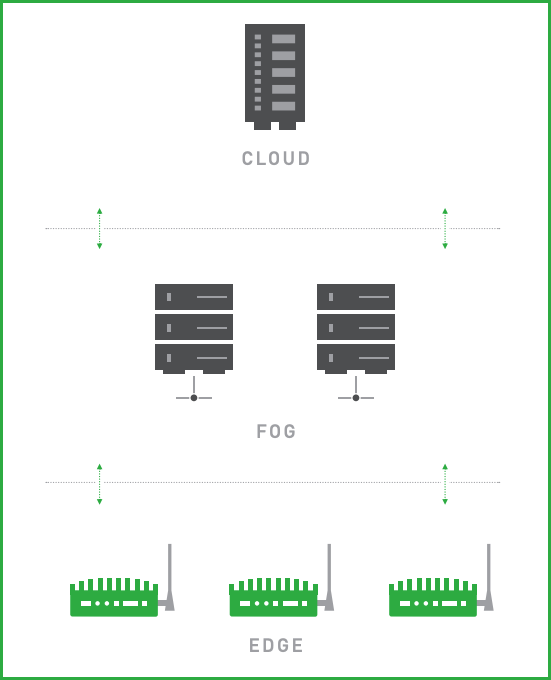

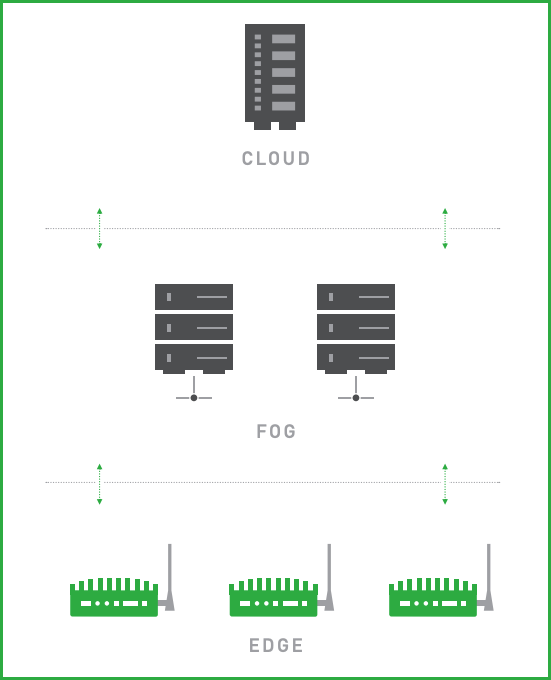

In a traditional IoT Platform set up, the data produced by a device in the field (for all intents and purposes, let’s call that a machine tool) that is collected via an IoT device (something like MachineMetrics Edge) is relayed back to a central network server (pushed to the cloud, if you will).

In the cloud, all data is gathered and processed in a centralized location, usually in a data center. All devices that need to access this data or use applications associated with it must first connect to the cloud. Since everything is centralized, the cloud is generally quite easy to secure and control while still allowing for reliable remote access to data.

Once that data is processed (“analyzed”) in the cloud, which happens pretty dang quickly, it can be immediately accessed through an IoT Platform (such as MachineMetrics) in a number of ways, whether it be via real-time visualization, reporting, diagnostic analytics etc., to help improve your ability to make decisions based on real data.

The problem: the situation gets more complicated when it comes down to decisions that need to be made extremely quickly.

First, it takes time for data to travel the “distance” from the edge device back to the cloud. This slight delay might only be a matter of milliseconds, but it can be critical for certain decisions such as stopping a machine tool from breaking.

Secondly, these machines produce a crazy amount of data (hundreds of datapoints every millisecond) and all that data traveling back and forth between the edge and the cloud strains that communication bandwidth.

The solution: rather than constantly delivering every piece of this data back to the cloud, edge enabled devices can gather and process data in real-time right there, at the “edge” of the machine, allowing them to respond faster and more effectively.

The integration of edge hardware and edge computing within manufacturing facilities is set to disrupt industrial efforts in many ways. Take Predictive Maintenance for example. The ability for machines to analyze the data they produce at the edge allows for the integration of preventive maintenance business models in manufacturing. Here, assets within the shop floor will continuously create alert tickets to notify enterprise systems about underperforming components. These assets also create preemptive maintenance schedules that drastically reduce the possibility of unplanned machine downtime. The value-added propositions that come with a data-driven predictive maintenance business model include:

- Reduced downtime

- Reduced maintenance cost

- Increased reliability and equipment efficiency

For example, when you are dealing with a CNC machine tool, in-cycle stoppages to the machine tool are an edge decision, while end-of-cycle ones can be a cloud decision. This is because in-cycle stoppages often require a very low, near-zero, lag time, while the end-of-cycle stoppages have a more lenient lag time. In the former scenario, the machine would have to leverage edge analytics when in-cycle to adapt and shut down the machine automatically in order to avoid potential costly downtime and maintenance.

So, what does this mean for our customers? To be clear, Edge computing will not replace cloud computing, though the two approaches can complement each other. Cloud computing is a more general-purpose platform for data collection, analytics, and historical reporting, but there are hundreds of use cases where reaction time is the key value of the IoT system, such as certain predictive maintenance events, where sending real-time data to the cloud prevents that analysis from happening quickly enough.

Manufacturing companies need to be able to make decisions at three different levels: at the machine level, at the factory level, and at the business level. MachineMetrics delivers both an edge platform and a cloud platform to enable the analytics required for decision making at each of these levels. It’s all about delivering the right information to the right people at the right time so they can take action. By incorporating edge computing with cloud computing capabilities such as those delivered through MachineMetrics, companies can maximize the potential of both approaches while minimizing their limitations.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments