The expense of tooling combined with scrapping defective parts makes extending tool life an important objective for metal cutting companies. Traditional machining relied on settings determined experimentally to determine the life of a machine tool. Operators could log part counts until a tool failed or began developing out of spec parts. The average of these part counts could be used to establish a threshold for the life of the tool. Alternatively, they could use the machine tool OEM’s provided part count to establish the cadence of tool changeover.

These solutions are inaccurate, leading to one of two things:

- A tool is under-utilized, meaning that a tool is replaced before it has reached end of life

- A tool is over-utilized, resulting in scrap parts and downtime

Tool monitoring allows manufacturers to monitor and optimize the life of their tooling to ensure they can get the greatest ROI from their tools without suffering the consequences of catastrophic tool failure.

What is Tool Life?

Tool life refers to the useful life of a machine tool. It can be expressed in the amount of good parts that a given tool is capable of machining. Once a tool is worn to the point that the parts being created are out of spec, it’s life is effectively over and the tool should be replaced.

Tool wear, tool failure, and tool life are a reality of cnc machining. All tools experience tool wear and will eventually fail if they continue to do work. However, it is in managing the lifespan of the tool effectively that manufacturers can drive the most efficient use of their machine tools.

The only possible way to increase machine tool life while preventing scrap parts and failures is to collect machine tool data and use it to determine when a tool changeover should take place.

All tools have predictable lifespan curves – the time period that a tool is expected to last and produce parts to desired quality standards. However, tool life can be difficult to determine accurately, especially if done manually, due to the wide variety of factors that affect the lifespan of a tool. For example, the material being worked upon, the type of cut, the speed and feed rates, etc.

As a result, manufacturers can use software and AI-driven solutions like MachineMetrics Tool Anomaly Detection to identify tool failures and maximize the life of their tooling.

Source

7 Ways to Improve Tool Life

While no tool lasts forever, there are many factors affecting tool life. Here are a few methods to reduce tool wear and tear:

1. Use Appropriate Speeds and Feeds

While the cutting tool rotates, bores, or cuts at a set cutting speed, it also traverses along the workpiece. Using the right speed and feed settings will increase tool life significantly. While actual cutting time is always a consideration, the proper settings for speed and feed can extend the tool's life.

2. Apply Cutting Fluid

The cutting process generates a lot of heat due to metal-to-metal contact. The right type of cutting fluid and the right amount of fluid application will prolong tool life.

3. Do Not Re-Cut Chips

Chips are the way to have the metal material removed from the workpiece after cutting. They also carry away excess heat generated during cutting. But settings must be correct to prevent re-cutting chips resulting in flank wear increases, crater wear, and other tool wear causes.

4. Use the Right Tools

The complexity of the workpiece, surface roughness, required machining accuracy, tolerance requirements for the finished part, and other considerations are critical. For example, some workpieces may be strong enough to need a high-speed steel tool. Knowing these parameters will help select the right tool for the combination of factors.

Want to See the Platform in Action?

5. Distribute Wear over the Cutting Edge

Programs and cutting plans should be designed to utilize as much of the cutting edge as possible. Continuous focus on one part of the cutting tool can increase tool wear.

6. Control Runout

Age of equipment can affect runout in machining. Modern-day machines may have an automated tool holder. This tool holder ensures proper positioning and securing of the tool. For older machines, runout comes from misaligning or securing the center of the tool shaft relative to the centerline of the central axis and can result in scrapped parts and lower tool life.

7. Control Deflection

As heat builds and cutting is underway, tremendous cutting forces are happening as material characteristics affect both tool and workpiece. The chips that are formed as metal is removed and exit the workpiece push back when they build up. If variables are not correct, this can bend or deflect the tool.

| A Case Study on Tool Life: BC Machining had been experiencing excessive tool breakage in their Swiss CNC machines, creating scrap both at the point of breakage and near-end-of-tool-life when parts can vary out of spec. Using MachineMetrics, BC was able to identify tool breakages to prevent scrap parts. Read the full story. |

Factors Influencing Tool Life

Using a tool life curve calculation such as Taylor's Tool Life Equation, different factors can be plotted to project different tool life curves for a tool depending on the combination of variables that applies. These include:

Cutting Rate

Faster is not always better. Workpiece hardness, different tool materials, the complexity of cuts, and other factors mean an optimum rate for each combination of factors.

Feed Rate and Cut Depth

Like cutting speed, feed rate and depth of cut can also be optimized. And that optimal point will be determined by the aggressiveness of the required cut.

Workpiece Hardness

Tools used to cut very hard material will wear faster than those used in cutting softer metals. The different hardness of the workpiece can trigger different tool wear types. Built-up edge can occur in soft metals such as aluminum. Metals like titanium can cause catastrophic failure to an incorrect tool.

Tool Material

Like workpiece hardness, tool material must have performance characteristics that meet or exceed the cut piece. Some tools can be specially hardened to work with material life-hardened steel or exotic metals like titanium. But they must also be designed to work with metals that have a poor surface finish.

Type of Cutting

Some cutting tools impart light abrasion to create a surface finish. Others are more aggressive. Like the cutting speed and feed rate, the type of cutting must be considered in plotting tool life curves and reducing wear.

Maximize tool life and eliminate scrap

Using MachineMetrics to Extend and Optimize Tool Life

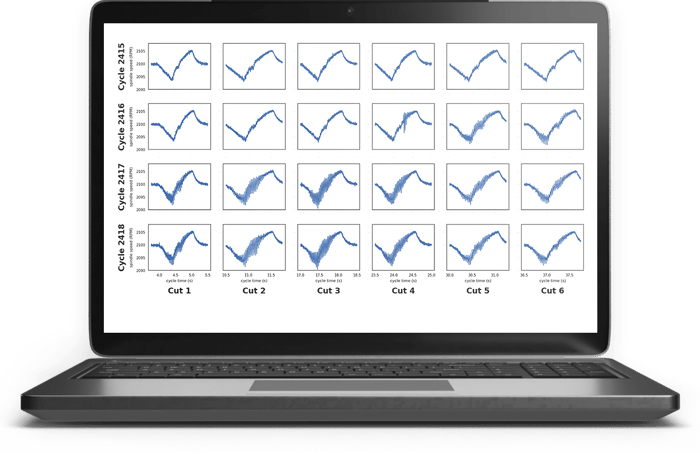

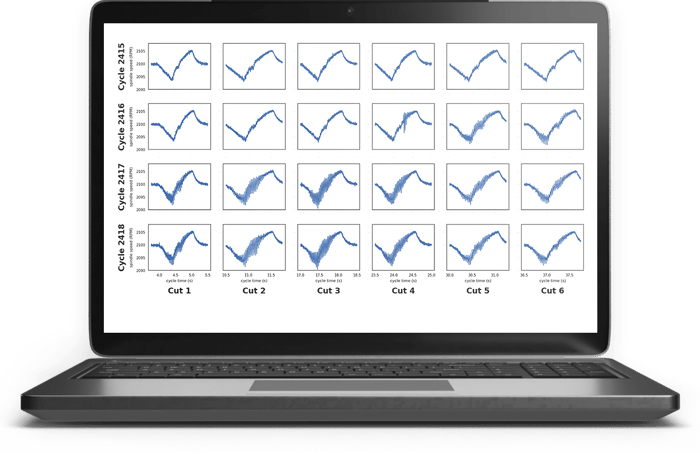

MachineMetrics Tool Anomaly Detection captures machine data straight from the machine control, providing accurate, real-time data on machine performance and health. Data can be collected to monitor the machine tool and develop thresholds for when tool failure is imminent.

.png?width=700&height=467&name=MachineMetrics%20Tool%20Anomaly%20Detection%20(1).png) Using AI to identify anomalies that may indicate an impending tool failure..

Using AI to identify anomalies that may indicate an impending tool failure..

Further, this data can be used to develop algorithms to predict and prevent catastrophic machine tool failures. Rather than manually collecting part counts or using a machine tool OEM’s tool life recommendation, users can leverage the accurate machine tool data to establish more effective tool life parameters.

Machine tool analytics can be leveraged to optimize processes around the machine, enabling communication and automation that supports the maximization of tool life. For example, operators can be notified of imminent tool failure to proactively replace the machine tool.

This ensures several major benefits:

- Catastrophic tool failures can be avoided

- Reduction in downtime from tool failures or excessive tool failures

- Tool life maximized to ensure the greatest ROI from your tooling investment

- Higher quality products with greater first pass yield

Plug-and-play Machine Connectivity

Case Study: How BC Machining Predicts and Prevents Tool Failure

“Previously, we would often lose a third of our shift’s worth of parts, not to mention spending at least an hour sorting through parts to identify the scrap. Since using the MachineMetrics’ predictive tool breakage technology, that waste has been eliminated.”

- Mike Driskell, Manufacturing Engineer, BC Machining

BC Machining, a manufacturer of fabricated metal parts, was producing such large quantities of scrap that they were forced to run their machines at 200% capacity just to hit their production goals. With no insight into when tools were worn or about to break, BC Machining accumulated significant costs from producing scrap and replacing broken tooling.

To prevent scrap production and maximize tool life, they partnered with MachineMetrics. Read our case study to learn how BC Machining virtually eradicated scrap from tool wear, significantly reduced their changeover times, and saved $72k per machine annually.

Read the complete case study.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.png?width=700&height=467&name=MachineMetrics%20Tool%20Anomaly%20Detection%20(1).png)

.gif)

Comments