Organizational change can be organic and incremental. But it can also be rapid and nerve-wracking, triggered by technology advancements, disruption, or both.

Over the last decade, manufacturing has often been on the losing end of change when finding and retaining employees. Faced with decades of cultural bias that negatively defined manufacturing to those entering the workforce, producers were already disadvantaged. The promises of an academic degree, high-tech employment options, and other changing technology also reduced the pool of available workers and were hard to overcome.

[Image Source]

These challenges have been enhanced in recent years by unprecedented market disruptions, like mass customization and changing consumer tastes. But what if the same technological advancements that triggered disruption and pulled employees out of manufacturing could be leveraged to reverse the trend? What if the solution is embracing those technologies to turn manufacturing skills into technical skills?

The Crossroads

Today’s manufacturers are at a crossroads. Powerful technological forces are available to digitize and transform the industry using AI, machine learning, edge and cloud computing, and more. These advancing forces promise to leverage operational data to supercharge a company’s automation and efficiency.

Intersecting this technological reality is a massive cultural shift in how we work and perceive value in work. Covid-19 alone disrupted a formerly slow-paced “work-from-home” movement and used technology to make it a highly preferred work method.

These disruptions resulted in many potential employees like engineers and skilled technicians working from home or in startups where the work/life balance was perceived to be better, and their skill sets were continually refreshed in a flexible environment.

The Staffing Crunch

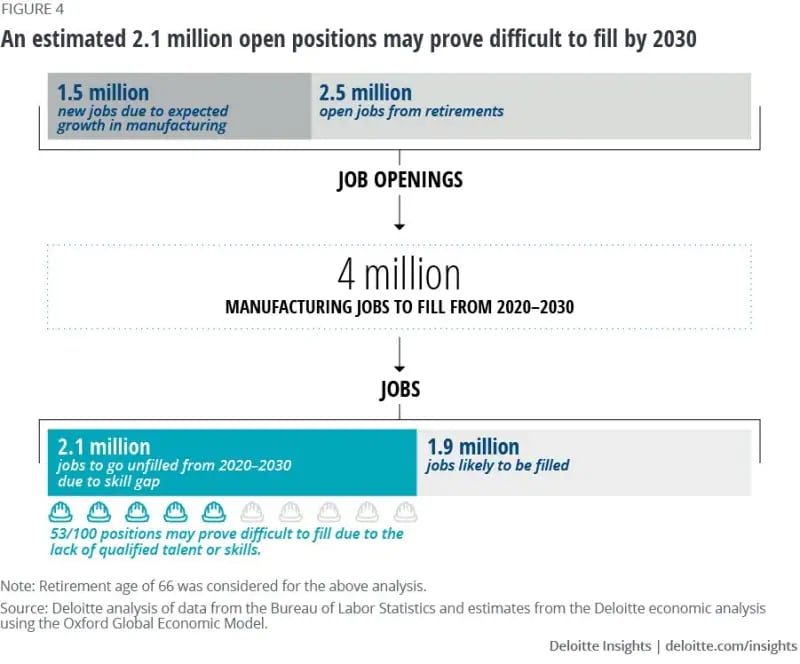

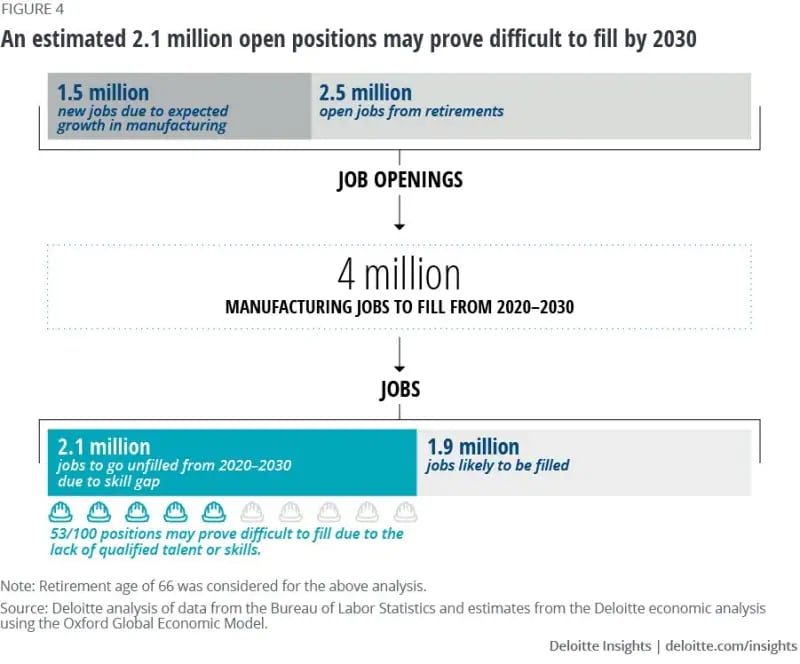

The numbers are scary. One report from NAM indicates that there could be as many as 2.1 million jobs unfilled in manufacturing by 2030.

As skill sets become more scarce, companies are forced to consider new options that allow them to do more with less. But the terrifying thing about those numbers is that they make up only half the problem; the same cultural phenomenon is creating an issue just as daunting as the lack of people.

With the remainder of Baby Boomers and now Generation X workers preparing to retire, those remaining in manufacturing carry a lot of tribal knowledge about their company’s machines and processes. And as more workers leave, much of the knowledge base goes with them.

This challenge creates an even greater urgency. Any new workers have grown up with technology and may balk at leaving the familiarity of interfaces and instant information behind to run mechanical processes and go “old school.”

The Future of Manufacturing

Just because you’re at a crossroads doesn’t mean you have to stay there. Manufacturers can leverage the same technologies transforming other industries to do more with fewer people and forever close the knowledge gap. The key lies in allowing new employees to use tools and systems they’re familiar with to move past the bias that manufacturing is dirty, manual, and unpleasant.

Advanced systems like MachineMetrics uses machine data to create a fully digital and visible shop floor. Production performance, KPIs, and other critical data can now be put into the hands of workers empowered to make decisions previously reserved for knowledge experts like engineers.

Using real-time data and analytical insights means poor work methods, manual data entry, and handwork are replaced with digital tools. And because processes and work instructions are digitized, the gap closes between those leaving with a headful of knowledge and those coming in who require access to it.

As old and new employees have access to automation and data-driven tools from platforms like MachineMetrics, they’re empowered to increase their skill set and make the most of the technology available to them. This helps position manufacturing as an opportunity for workers to compete in high-tech roles rather than tedious, manual environments.

Start Doing More With Less

MachineMetrics has seen these trends across many industries. We can help you do more with less while creating a high-tech environment on your factory floor to preserve your critical knowledge and democratize it across your operation.

Tackling the labor shortage and supply chain challenges begins with understanding the performance of your operation so that you know exactly where opportunity exists for unlocking capacity and improving processes. MachineMetrics can highlight these opportunities by tapping into an accurate, real-time stream of your production data by autonomously connecting to equipment.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments