We Need More People! Maybe…

What if we helped our existing team be more efficient? What if we empowered our shop floor personnel with the right information and tools to ensure they could focus on the most valuable tasks at hand?

While machines and systems are key to operational efficiency, leadership knows that people are the greatest asset on the shop floor. We need to hire, train, and upskill operators to do excellent, value-added work day after day to hit production goals and ensure customer satisfaction.

Without the right people, automation and technology can’t do much. Operators are key to the industry's success. We simply need the skills and knowledge they bring to the table.

As manufacturing leaders contend with market pressure to deliver increasingly complex parts on time, we are struggling with a major labor challenge.

The problem is two-fold: One, there simply isn’t enough skilled labor available for hire (50% of jobs are currently unfilled), and two, traditional manufacturing has often failed to empower operators to focus on the most important aspect of their job: managing machines.

Solving the first problem is a wider industry challenge. Solving the second is something you can begin working on today.

This second problem is due to a lack of visibility into production performance, poor methods for communication, forced manual data entry, and excessive time engaged in non-value added work.

It’s time to start empowering your operators and machinists, ensuring they have the right training, information, and tools to get the job done.

How MachineMetrics Empowers Your Operators

At a recent customer visit, we had the pleasure of understanding shop performance from the perspective of the production manager.

His take on operator performance was clear: If an operator was not performing his or her job well, it was the failure of the management team to provide the right training, information, and tools for the operator to correctly do the job.

This mirrored a similar customer approach, in which the president and CEO of a contract manufacturing operation explained that MachineMetrics is used to measure the performance of processes, not people.

At the end of the day, the point here is that it is the job of management to empower operators, and to analyze shop floor performance, not by pinpointing people that appear to be failing, but by understanding where processes go wrong and making the necessary adjustments.

With these refreshing perspectives in hand, let’s take a closer look at the MachineMetrics features that specifically address many of the challenges operators face on a daily basis as well as how these features help operators and machinists focus on their most important work: managing machines and making good parts on time!

Eliminate Manual Data Collection

From a management perspective, and for the sake of the operator to understand his or her performance, it is incredibly important to collect data. Part counts, cycle times, downtime, etc.

But manual data collection is time-consuming and takes operators away from value-added work. Further, it tends to lead to more manual work, such as compiling the data, building reports, uploading to systems, and then doing it all again next shift.

Many production monitoring solutions require operators to painstakingly import work order or job data from their MES or ERP system into the production monitoring solution and back again. But this approach adds unnecessary manual tasks to the workload of busy shop floor personnel and tends to result in delayed, inaccurate data.

We hear you and we have good news - MachineMetrics allows customers to manage and optimize their production without the requirement of manual operator input. As a result, operators can focus their efforts on managing machines and meeting production goals.

Going one step further, with an ERP integration, there is no need to have operators stand in line at an MES terminal to enter operational data that MachineMetrics already provides.

Want to See the Platform in Action?

Enable Shop Floor Visibility

The beauty of real-time data collection is that the information can be democratized across the organization, from corporate management down to the machinists and operators on the shop floor.

In order to improve the performance of operators, you must give them the tools to make better, faster decisions on a daily basis. This takes the form of visible dashboards across the shop floor which can inform operators of where they stand against production goals.

Further, these tools can be used to visibly identify problems (such as machine downtime events) so that issues can be resolved as soon as possible.

MachineMetrics supports this in multiple ways:

- Shop Floor Dashboards: Large monitors across the shop floor provide an overview of a given cell, or the entire shop floor, showcasing the status of each piece of equipment and where it stands against production goals. This is especially useful for spotting machines that are falling behind or are inactive.

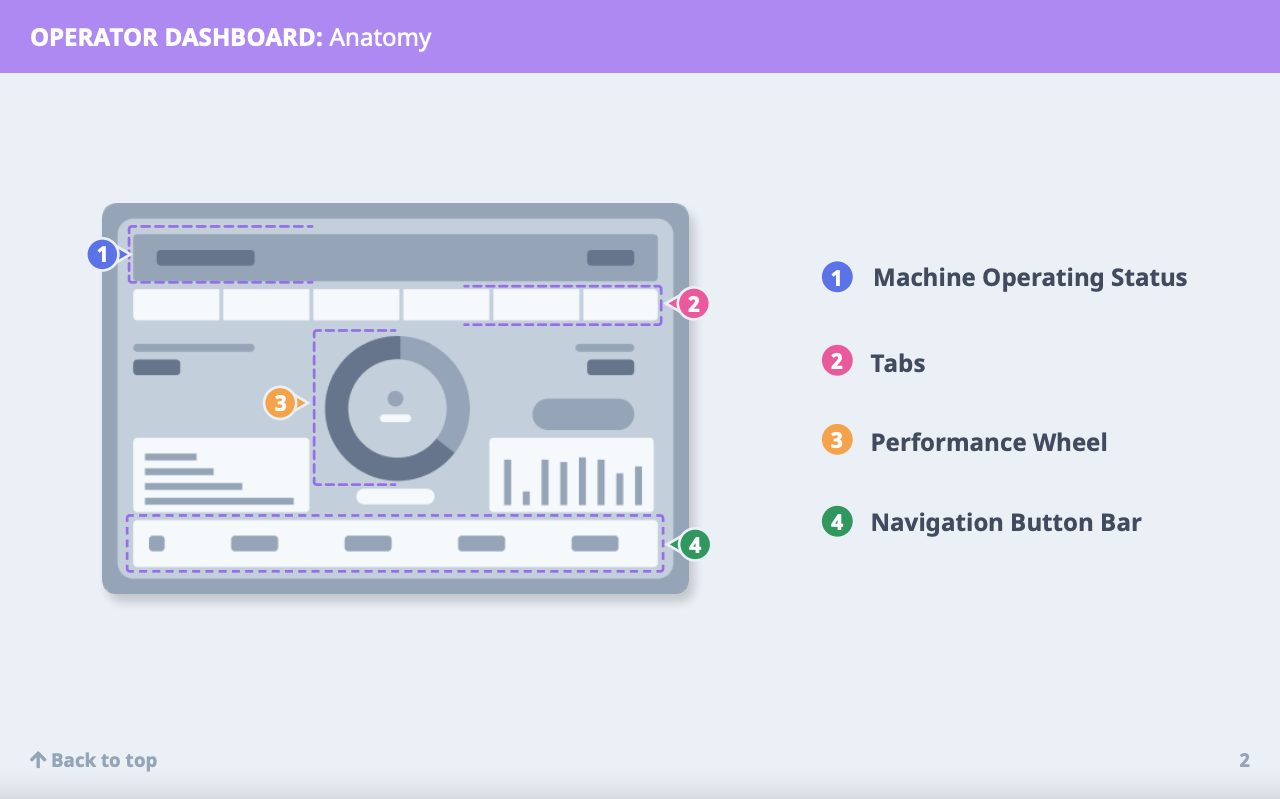

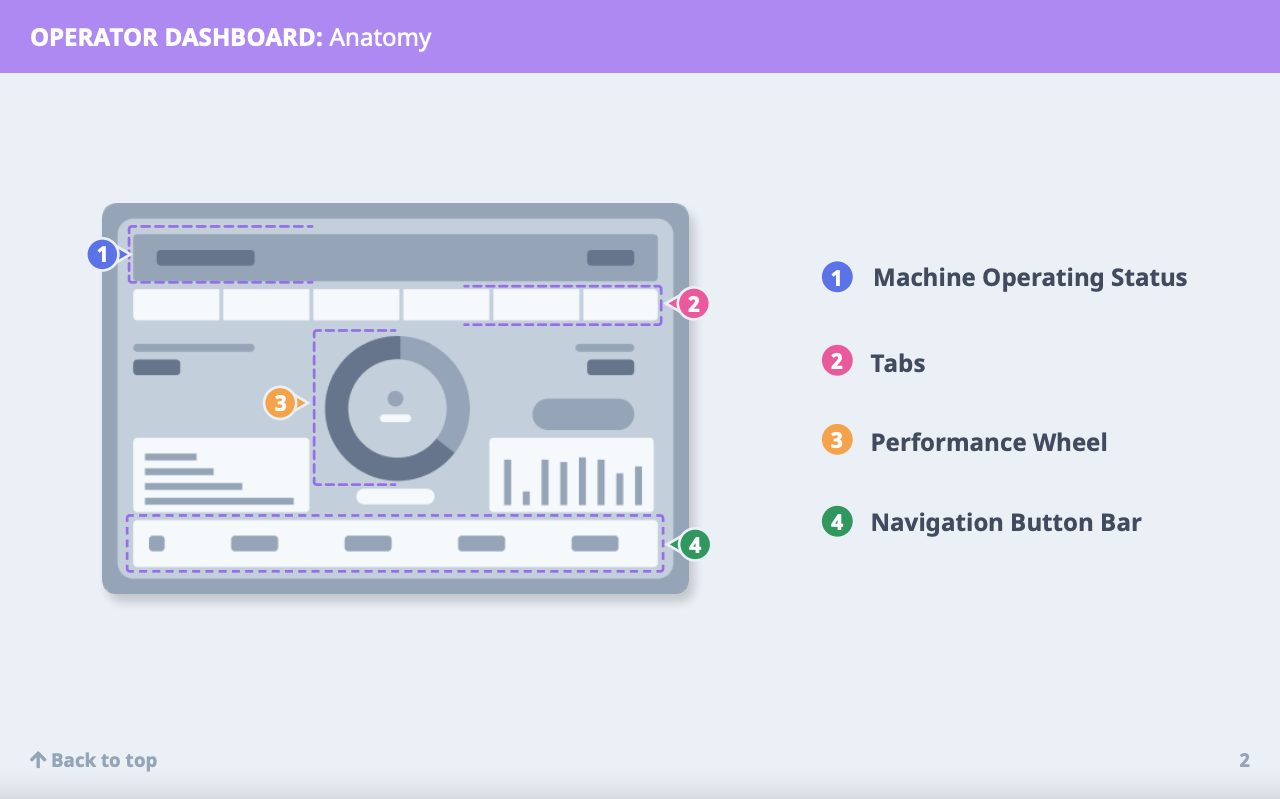

- Operator Dashboards: Placed at each machine, the operator dashboard is a tablet that operators can interact with to manage their responsibilities more effectively. They can have a close-up view of their performance against production goals, as well as document reasons for downtime and quality issues. The MachineMetrics Operator Dashboard provides immediate insight for operators. Not only can downtime and quality issues be logged, but operators can call for help or trigger workflows right from the machine.

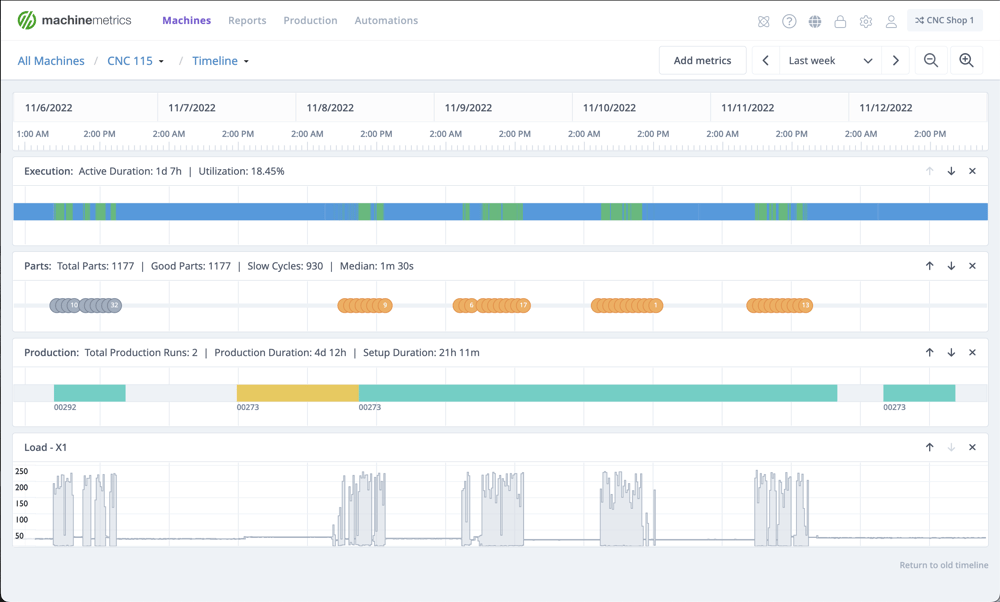

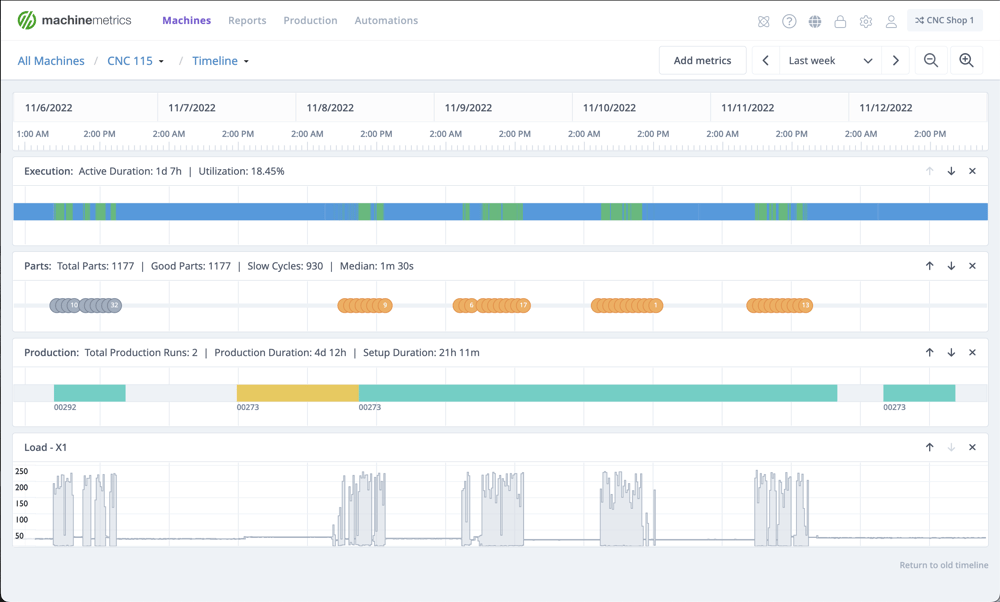

- Machine Timelines and Reports: It’s incredibly important for both operators and managers to have accessibility to the same data. The team as a whole should be working from the same source of truth so that issues can be resolved based on what the data says, not what an operator or manager says. This provides a sense of transparency, enabling managers and operators to review machine timelines and reports to see when and why downtimes, alarms, and other activity occurred. This helps to prevent conflicting reports from multiple parties.

The MachineMetrics Timeline feature is incredibly useful for root cause analysis. You can view the history of performance for any machine or operation to understand what happened, why, and when using both production and diagnostic data. Learn more about the Machine Timeline.

The MachineMetrics Timeline feature is incredibly useful for root cause analysis. You can view the history of performance for any machine or operation to understand what happened, why, and when using both production and diagnostic data. Learn more about the Machine Timeline.

Develop Accurate Standards of Work

By having accurate work standards, including jobs, setups, and cycle times, manufacturers have a better overall understanding of the actual expected production performance they should hold operators accountable against. If manufacturers do not have the data to develop accurate work standards, they will have no way of knowing if a given job or process is high or low performing.

This can create gaps between what is expected of operators and what is realistic.

With a solution like MachineMetrics, data from machines, operators, and systems can be collected and tracked in real-time, and job standards can be updated to reflect any changes. This allows manufacturers to always be working from an accurate performance benchmark.

Enhance and Automate Communication

Communication and the sharing of information is one of the biggest roadblocks to manufacturing success. Manual tracking, unconnected systems, and tedious production meetings tend to amplify the many problems operators experience on a daily basis.

MachineMetrics helps to improve communication, as well as enable automation, to significantly improve the performance of operators and other shop floor personnel by ensuring they can get help when needed.

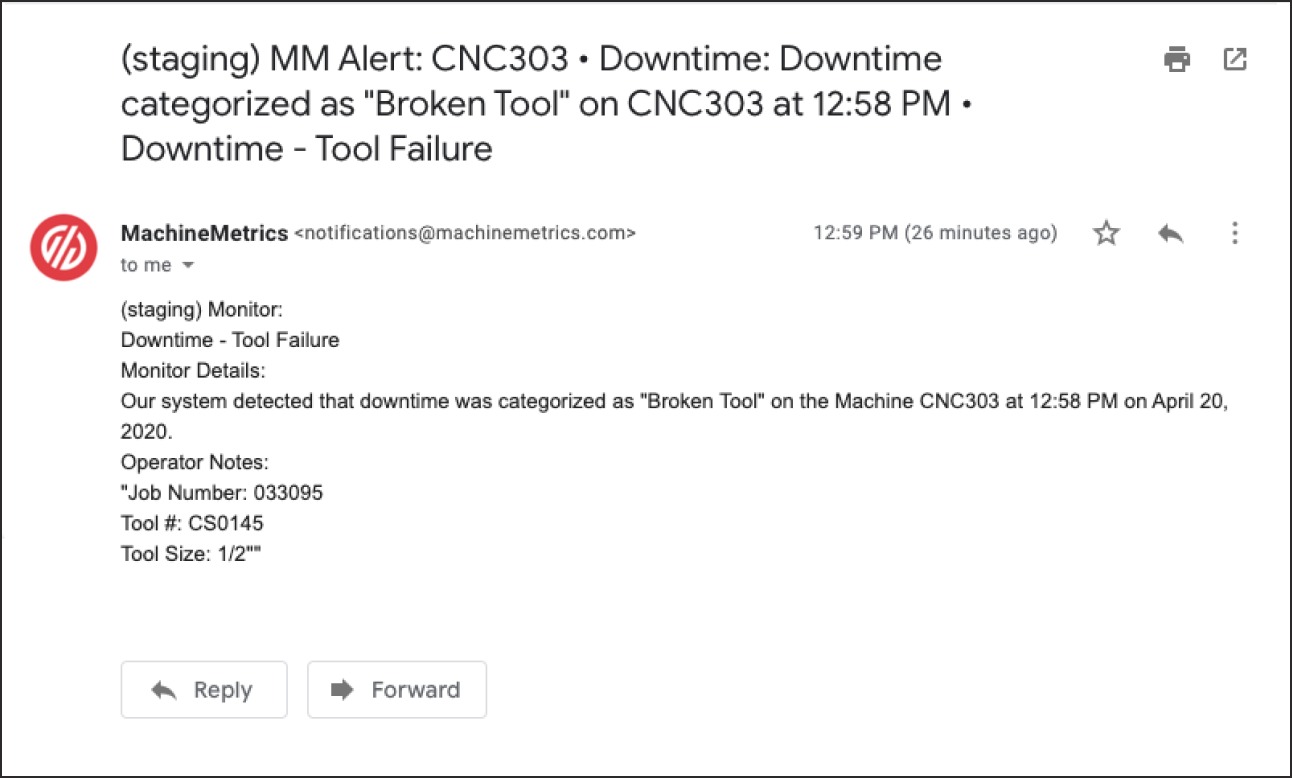

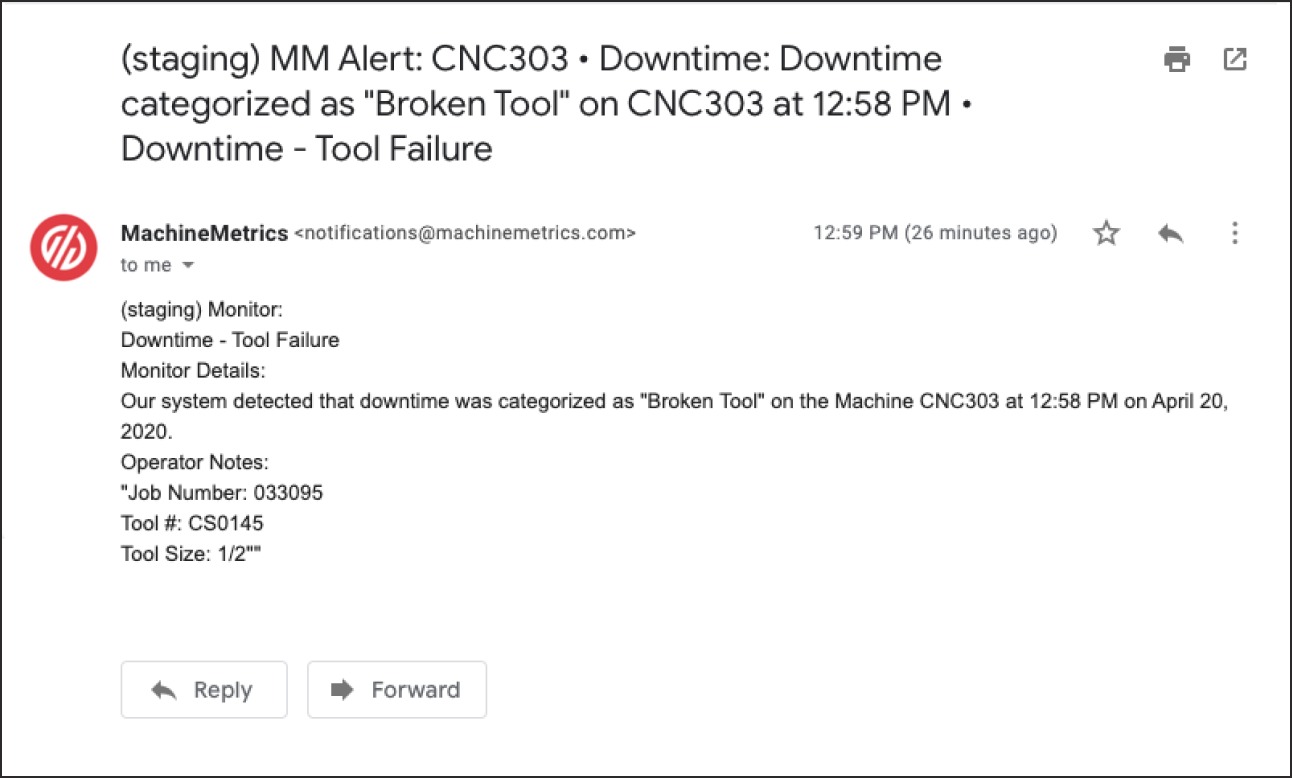

An example of an automated email that was sent to a user due to downtime caused by a tool failure.

An example of an automated email that was sent to a user due to downtime caused by a tool failure.

Directly from the machine, operators can easily notify their manager of problems or even call for support from materials managers, engineers, quality teams, or maintenance, in order to resolve problems before they even happen, or as soon a they have occurred.

Deploying a Win-Win Solution

Operators don’t want to be overseen by big brother watching their every move and pinpointing any mistake they make.

On the other hand, both frontline workers and managers want to understand the performance of the shop floor, and they need accurate data to do it. Forcing operators to manually log all their data is tedious and often faulty, leading to fudged numbers and missing data that doesn’t paint a clear picture of performance.

If the implemented solution doesn’t work, operators are going to give up, and how can you blame them?

It’s time we enable our operators and machinists with solutions to automate data collection and ensure operators have the lines of communication they need to not only focus on their most highly valued work but easily ask for support when needed.

MachineMetrics enables production visibility across all levels of the organization, creating a source of truth that each team can use to manage goals and expectations, as well as solve problems.

Plug-and-play Machine Connectivity

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments