An issue in manufacturing that is singular to machine builders is the speed with which they can respond with service to the machines, in the case of a failure. In the past, this has usually meant an actual failure has taken place. This results resulting in a reactive approach that can lead to a delayed order, scrapped parts, and potentially days of downtime. Today, remote machine monitoring is ushering in a new era for machine builders.

When customers require after-sales service, they expect their problem to be solved with minimum delay. Too many service calls require expensive and time-consuming on-site visits.

Service teams are dispatched and repairs / replacement of parts are made, but all of this takes time and creates more delay. As far as being able to predict the need for maintenance, traditional systems meant using the historical information about the machine, or simply establishing maintenance schedules, whether or not they were needed.

What is Remote Machine Monitoring?

Remote machine monitoring is the ability to track, analyze, and manage performance machine performance in real-time from any location. Manufacturers can take advantage of the latest industrial IoT and cloud-based analytics to tackle a variety of challenges. They can remotely diagnose issues, optimize performance, and proactively address maintenance without on-site visits.

This new approach transforms the way machines are managed. Teams can achieve continuous visibility into equipment health, reduce unplanned downtime, and improve operational efficiency. Leveraging real-time data from remote monitoring lets teams achieve faster response times and improve their decision-making.

The Impact of Remote Machine Monitoring

Now imagine a world where machines can be monitored remotely, providing an unprecedented service level. What if you had the ability to prove that a warranty threshold was exceeded and you could prove it? What if you could reduce service on-site visits by 10-20%? What if you could see real-time machine data and alert customers about impending issues, before any damage is done to an order is valuable? All of this is possible right now; machine builders require remote access to monitor and assist with user operations to troubleshoot problems, resolve service events and monitor preventative maintenance tasks, all without leaving their office.

“Industry 4.0 software provides analytical tools that help OEMs understand the mechanical factors and environmental conditions that lead to machine failures. Whether it’s vibration, temperature, pressure or other performance indicators, OEMs can use this software to analyze the machine data gathered from their IoT-enabled machines to perform predictive maintenance.” (Source)

Remote machine monitoring as an extension of machine service options

In fact, remote machine monitoring, enabled by industrial IoT, is the unique selling proposition that OEM and other equipment providers can offer to their clients, as part of the post sale service package.

“...machine builders can transform their approach to service with the ability to see, understand and take action on their customer’s real-time machine data from anywhere at any time.” (Source)

Reducing downtime, particularly unplanned downtime, is an essential part of keeping costs down and manufacturing levels up. Remote machine monitoring can collect data about the industrial operations of any given unit and transmit that data back via the cloud. This enables machine builders to provide peak level service response time.

Historically, this servicing would require a lengthy and costly on-site visit and possible investigation as to the issues being experienced. A maintenance team would not necessarily be able to detect at a glance which parts were malfunctioning. A manual process for checking each part was required. Instead, industrial remote monitoring systems enable machine builders to visualize the issues via the data from anywhere. Troubleshooting even the slightest alteration in a tool path can be done quickly and easily.

Improving Preventative Maintenance

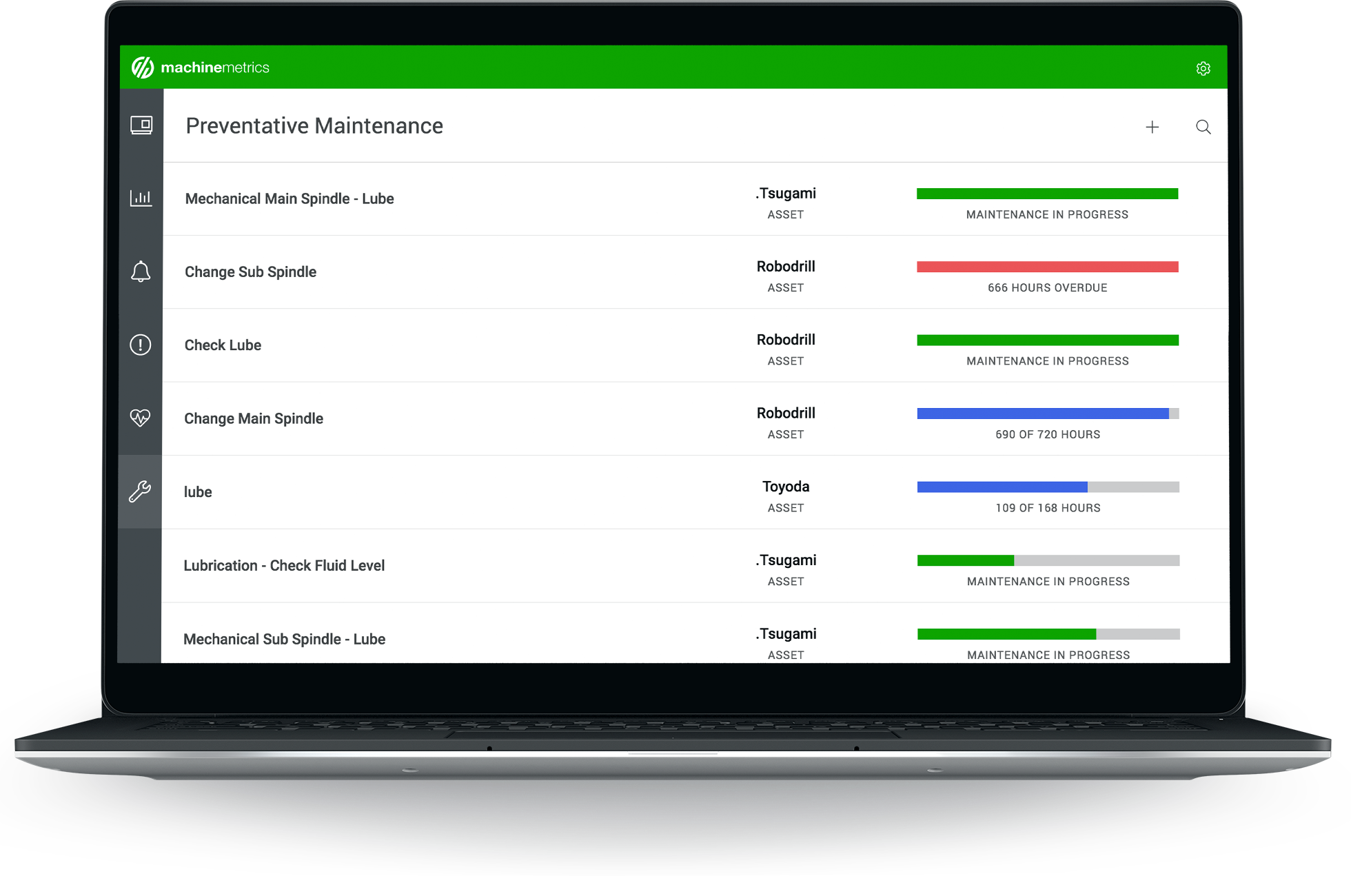

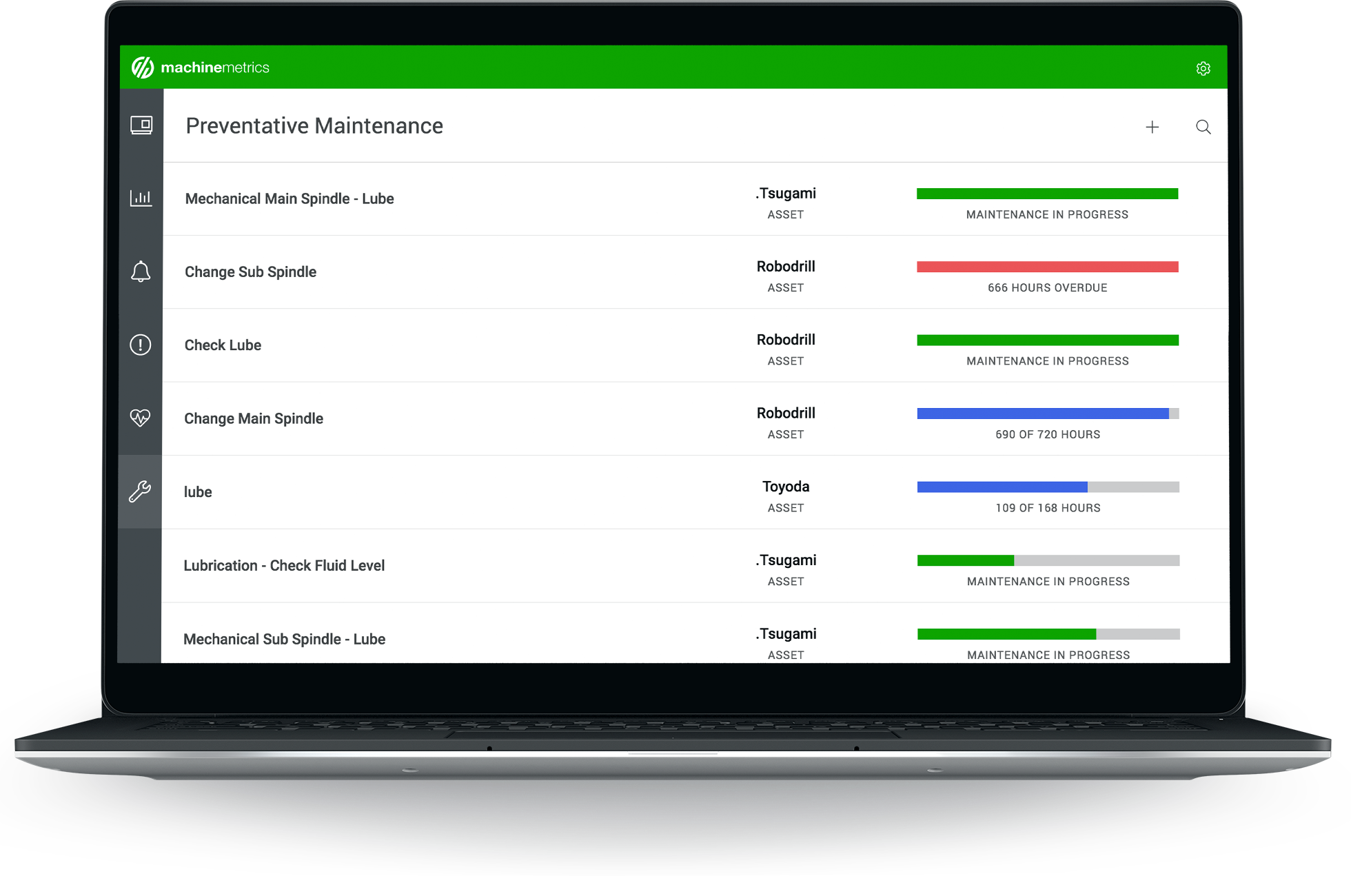

Beyond service response is the ability to predict and even prevent breakdowns that severely impact a manufacturer’s production cycle by reviewing and analyzing the data produced. With predictive maintenance, equipment can review available data, detect any exceptions or historical patterns and service the machines in advance of a problem occurring, limiting the impact. It also ensures that a manufacturer need not maintain an extensive inventory of replacement parts, but rather work on a just in time basis.

“Service departments can use data to gain insight into customers’ equipment health and condition, identify maintenance opportunities with analytics and reporting, predict and deliver early warning of potential equipment failures, highlight elevated risk areas that lead to machine downtime, or even take preventative action before it impacts a customer’s machine performance.” (Source)

The Benefits of Remote Machine Monitoring for Machine Builders

Remote machine monitoring changes the way that machine builders support their customers. Leveraging real-time data, predictive maintenance, and remote diagnostics optimizes service operations and keeps customers satisfied.

Faster Troubleshooting

Remote monitoring lets machine builders diagnose issues faster and reduces the need for on-site service calls. Real-time alerts notify service teams of potential issues before they escalate. This minimizes disruptions and improves customer satisfaction thanks to reduced downtime.

Data-Driven Design

The machine performance data collected through remote machine monitoring also supports data-driven design. Machine builders can continuously refine equipment designs and optimize scheduled preventative maintenance based on real-world data. These insights allow machine builders to create more reliable, efficient, and durable machinery.

Optimized Service Efficiency

Remote machine monitoring allows for automated diagnostics that can greatly improve the efficiency of service. Reducing response times, optimizing maintenance schedules, and minimizing unexpected failures all improve service reliability and resource allocation. Robust data also helps machine builders accurately assess warranty claims.

Competitive Advantage

Machine builders face a competitive field where manufacturers are looking for innovative solutions. Offering remote monitoring sets machine builders apart from their competitors with improved support, predictive analytics, and maintenance planning. This continuous value beyond the initial sale positions machine builders as trusted partners.

Challenges with remote monitoring

The vast changes coming with Industry 4.0 will require manufacturers to adapt or replace legacy processes, posing a variety of challenges. This is particularly true when dealing with data across organizations.

- Data integrity due of the remote access.

- Cybersecurity for the network.

- The ability of the software to work with different machines; manufacturers may be unwilling to entertain different IoT solutions for different machines. There is also the challenge of discovering the root cause of a problem should it be in a related machine that is not monitored.

With so many options, the main challenge remaining for machine builders is to integrate best-in-class solutions quickly and reliably. For example, there are a myriad of PLCs, controllers and sensors available to control machines and track variables like temperature, pressure, or strain. IoT systems need to be able to connect to a variety of Edge devices with proprietary protocols and data formats.

Secondly, most manufacturers have little interest in software companies integrating with their internal networks via ethernet or wi-fi. To that end, many industrial machines were not designed to connect to the Internet and therefore would be exposed over an open network. As a result, many manufacturers do not have the proper security in place to protect data from being stolen or equipment from being hacked.

Navigating Remote Machine Monitoring Challenges

SaaS platforms that enable machine monitoring—such as MachineMetrics—address all of these issues, including the ability to encrypt data before transfer, leveraging MachineMetrics Edge that allows the transfer of data via Cellular to circumvent a manufacturer's internal network entirely, and an easy self-installed interface with a range of machines, enabling manufacturers to limit their concern about having to use different monitoring solutions on their factory floors.

The future opportunities for machine builders: predictive maintenance and beyond!

The ability to identify service opportunities and measure ongoing process improvements, such as ongoing machine health monitoring, is important to after sales service but take innovation a step beyond into the realm of future design specifications!

Machine builders and equipment providers will be able to leverage the data that they receive from their customers to improve on their existing designs or even create better, more enhanced machines because they will have easy access to the data that shows them how the equipment is being used. This presents a huge opportunity for the OEM to ensure that they stay ahead of their competition.

Furthermore, machine builders can use this data to create, manage, and deploy optimized preventative maintenance schedules that are tied to calendar time, usage time, or initiated from machine conditions. Assign maintenance tasks through a workflow, and keep track of customers maintenance to better plan inventory and service needs. This is Preventative Maintenance optimized with Industrial IoT.

With industrial IoT in the mix, the equipment manufacturing industry has an amazing opportunity to provide real value-add to their service packages, making them indispensable to the manufacturers they service.

A Case Study featuring MachineMetrics

Companies are starting to offer Remote Monitoring and Management (RMM) for these IoT enabled industrial devices. A key example: MachineMetrics.

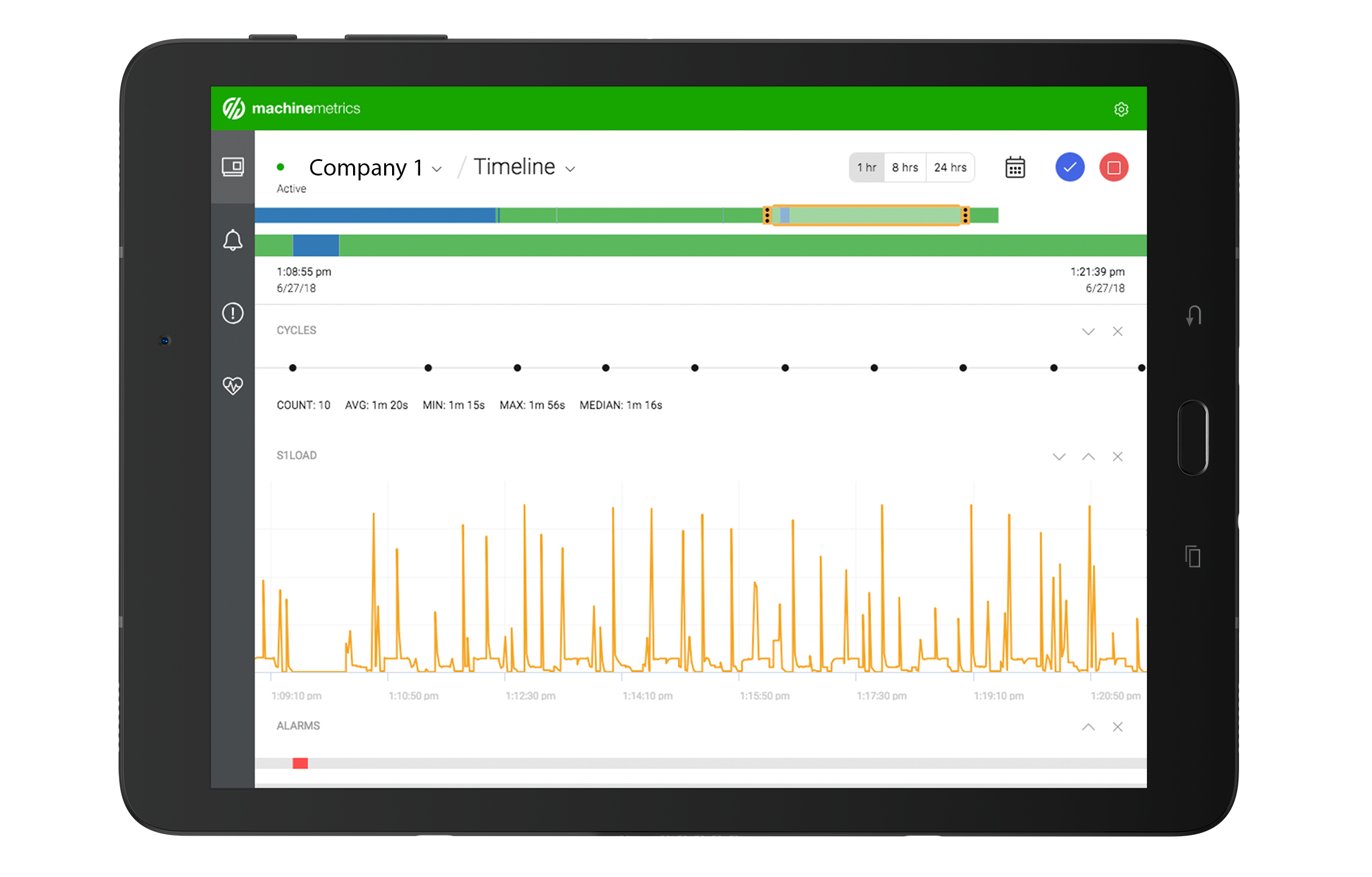

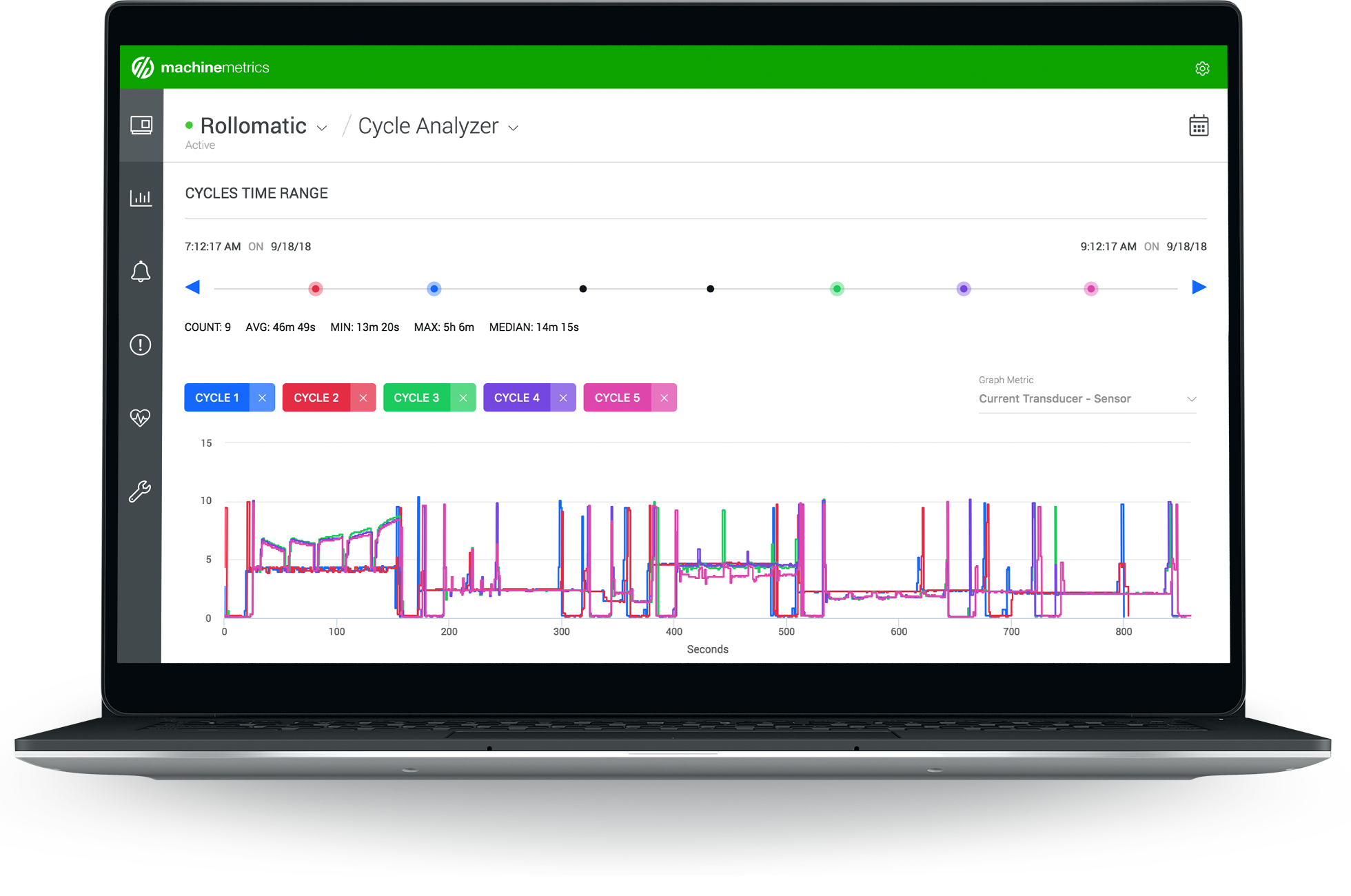

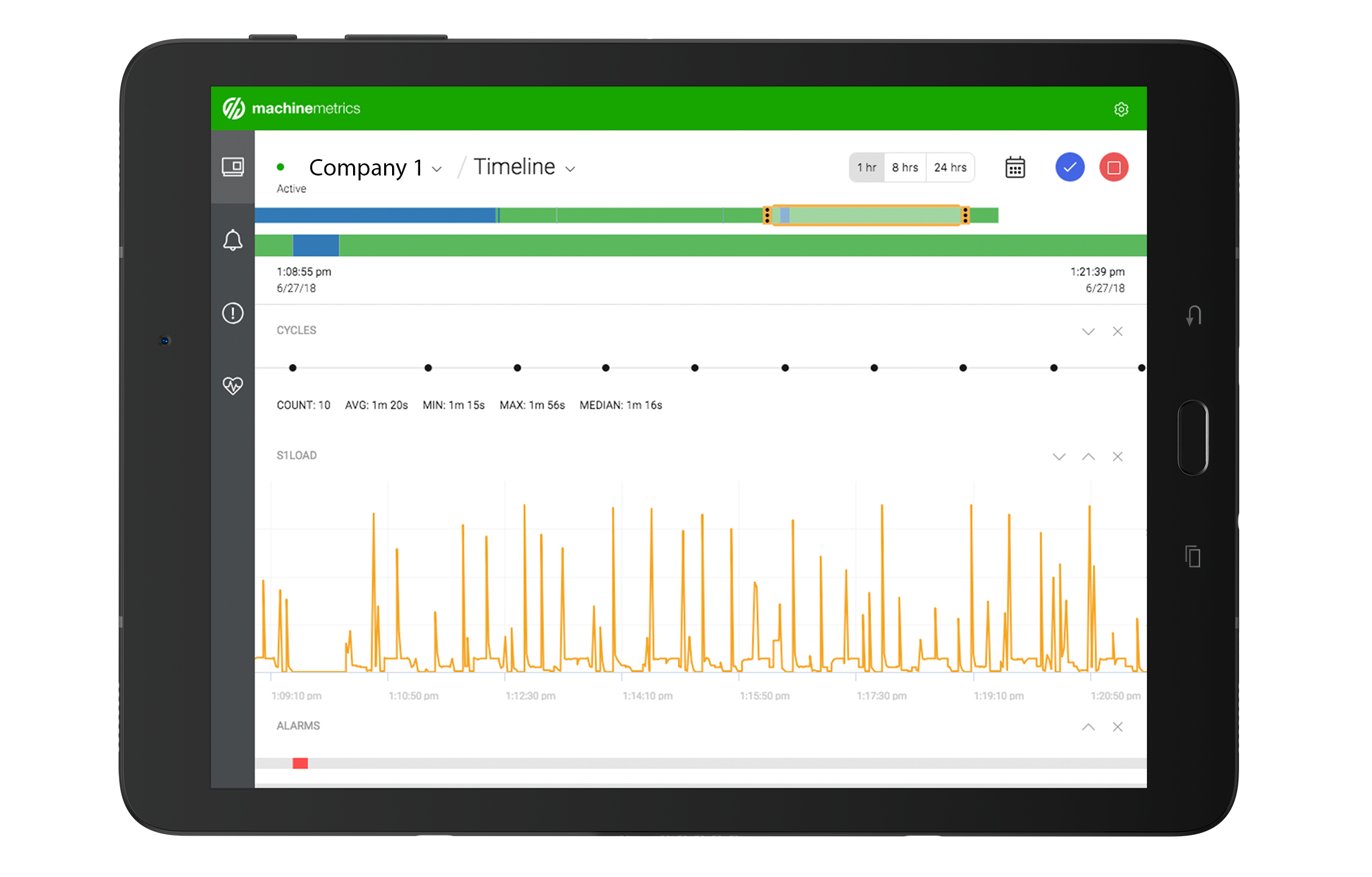

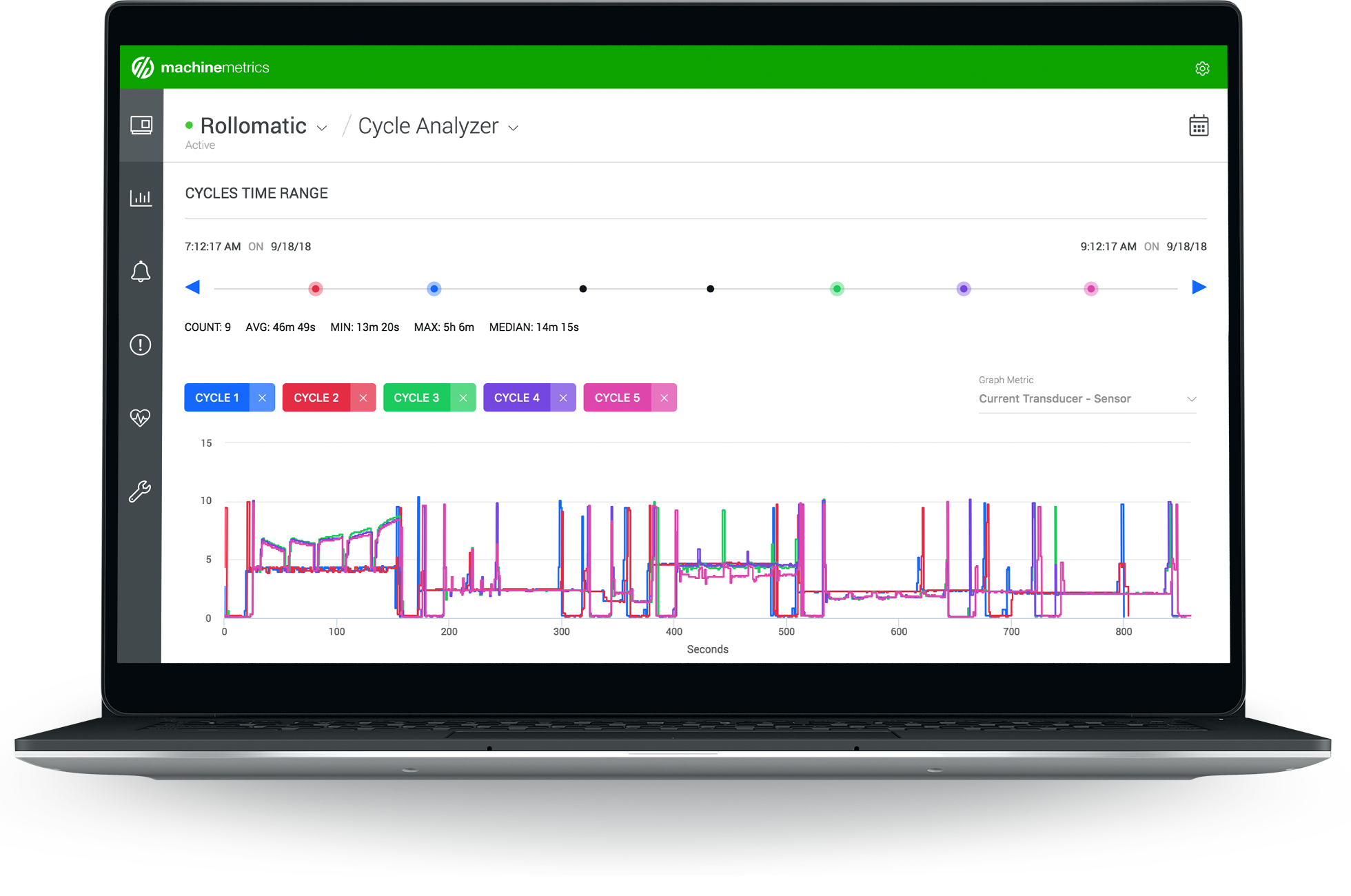

MachineMetrics Service is the industry's first AI-driven remote machine monitoring solution designed for CNC OEM’s and Equipment providers; a predictive analytics application on the MachineMetrics Industrial IoT platform that allows service teams to remotely monitor and manage machine assets in the field and at customer sites in real-time. Using MachineMetrics Service, machine builders can see, understand and take action on their customer’s real-time machine data from anywhere at any time.

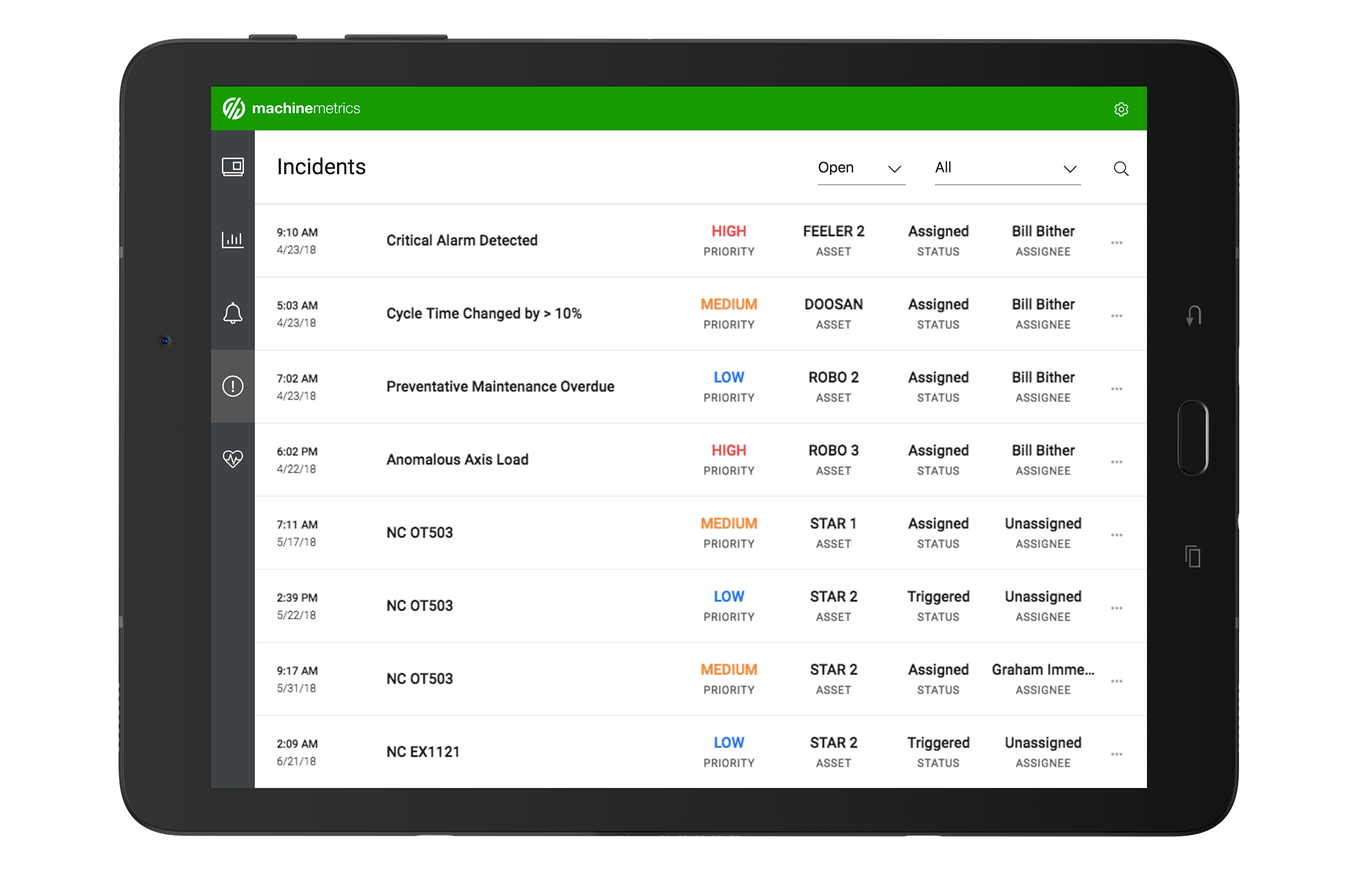

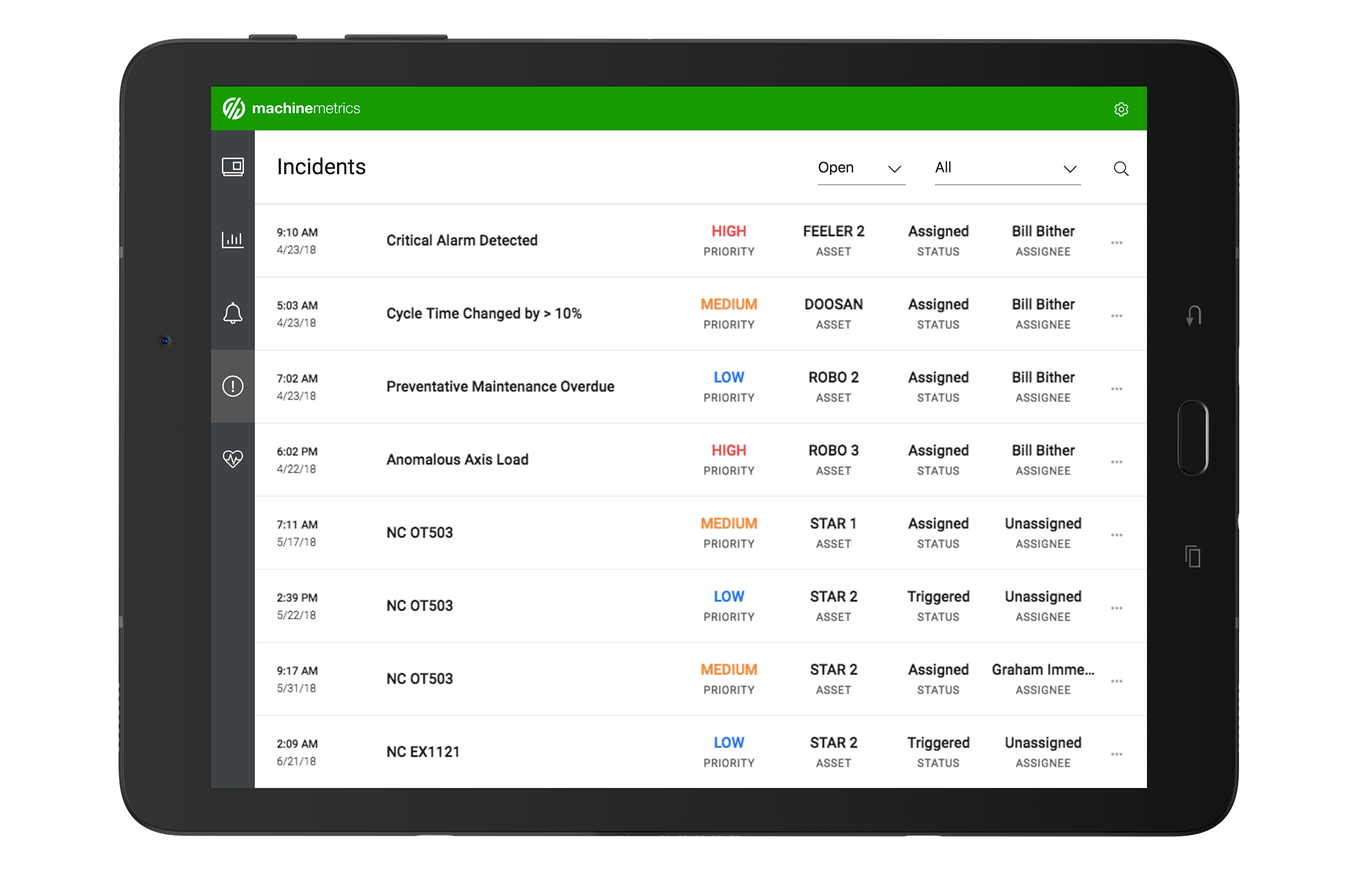

With MachineMetrics Service, Service managers and technicians can remotely monitor, manage, diagnose and resolve customer’s machine issues for any piece of connected equipment in the field and in real-time using MachineMetrics cellular edge device. The historical and real-time machine data collected allows machine builders to gain insight into customers’ equipment health and condition, identify new service opportunities with analytics and reporting, predict and deliver early warning of potential equipment failures, highlight elevated risk areas that lead to machine downtime, or even determine to take preventative action before it impacts a customer’s machine performance.

MachineMetrics Edge

Any equipment builder, OEM or distributor, can install MachineMetrics Edge device on a new machine sold to a customer or retrofit any machine currently in the field. MachineMetrics Edge has the ability to connect to the machine’s PLC and any additional IoT sensors into the electrical cabinet of the machine and allows for the industrial data to be shared with the equipment provider. There’s no need to install on customer’s internal IT infrastructure as MachineMetrics Edge comes with included cellular support. Once installed, the provider can add the device to a list of machine assets accessible via the MachineMetrics Service app and associate that machine with the location of the customer. Once the customer receives the machine and powers it on, that machine will appear active on the provider’s list of assets.

Data Security

Encrypted data is then streamed to the secure MachineMetrics cloud where the data is structured and aggregated to enable visualizations and analytics for service teams to monitor. Access to the historical and real-time data is available through open APIs. Real-time dashboards, historical analysis, and integrations with other systems can be built with these APIs.

Advanced Analytics

The MachineMetrics analytics engine monitors any connected machine’s conditions and other manufacturing data points and initiate an action, such as text notifications when a monitor is triggered such as an alarm state, a limit being exceeded, or any other anomaly in the machine’s health is detected. A rules engine is provided for deploying monitors based on machine condition data and patent pending advanced machine learning algorithms can be deployed for detecting anomalous behavior.

Using this data, equipment service providers can notify machine operators to change a tool before it breaks or even notify maintenance managers when an anomaly is detected that could lead to a breakdown. This ability can prevent thousands of dollars of equipment replacement costs and days of downtime, not to mention unearth new service opportunities that were never visible to service teams before.

Data from thousands of connected machines allow the MachineMetrics Data Science team to work with service teams to identify trends and develop standard preventative maintenance and repair schedules that benefit both the service team and the customers. So while service teams are focusing on addressing issues that may immediately impact their customers, MachineMetrics is keeping an eye on big-picture issues that benefit both the machine builder and the end-user.

“For years now we have been working directly with manufacturers to improve manufacturing equipment uptime, OEE and productivity with real-time machine monitoring and analytics,” said Bill Bither, CEO of MachineMetrics, “By allowing machines to be monitored remotely and in real-time, we are enabling OEM’s to extend these benefits to their customer base while providing them with faster, better service. Our data science team is working closely with the data to deliver optimized preventative and predictive maintenance specific to their machines to improve machine uptime.”

OEM’s are already experiencing the benefits of implementing MachineMetrics Service: “Tsugami/Rem Sales is thrilled to be working with MachineMetrics, bringing cutting edge, disruptive technology directly into our end-users’ businesses,” explained Michael Mugno, Vice President, Tsugami/Rem Sales. “The addition of MachineMetrics Service to our Swiss-turn machine platform packages allows users to collect data on machine health, production status, down-time, and so much more that they may never have known existed - bettering businesses across the industry.”

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments