Fixing Problems Before They Become Problems

For manufacturers across the globe, preventive maintenance has long been a tool used to prolong the life of the equipment and extend their Capex return on investment (ROI). Its importance has coalesced along formal and informal lines with homegrown programs based on observation and experience, manuals supplied by OEMs, and sophisticated software that helps companies stay on a strict maintenance schedule.

But while the concept of preventive maintenance has been around for decades, many of those in the industrial sector consider how much more effective it can be. While few managers willingly allow machines and parts to run to failure and shorten equipment lifecycles, others wonder if preventive maintenance has been optimized to its maximum. And if so, are growing trends such as predictive and prescriptive programs made possible by IoT the next logical step?

What is Preventive Maintenance?

Preventive maintenance, also known as Preventative Maintenance, or simply PM, is a formalized program used within manufacturing to optimize and extend the life cycle of production equipment. By scheduling maintenance on equipment systematically, manufacturers seek to identify and fix problems before they become failures.

Preventive maintenance can be calendar-based, where parts are replaced before breaking or wearing. It can also be usage-based, designed to take run time into account in environments such as 24/7 continuous operation factories. Or, it can be condition-based, where the visual or measured condition of parts and equipment is used for manufacturing environments that run with different degrees of wear and tear depending on what product is running.

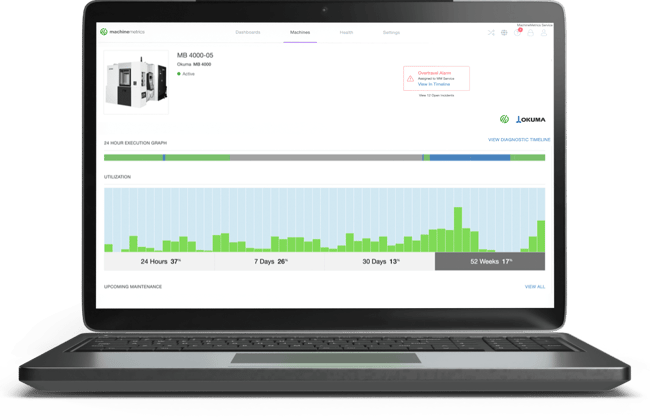

IoT can help unlock a more effective maintenance program by using real-time machine data to drive maintenance.

IoT can help unlock a more effective maintenance program by using real-time machine data to drive maintenance.

The Importance of Preventive Maintenance

Preventive maintenance was the industry's first attempt to systemize and improve equipment performance. Historically, companies ran on "reactive maintenance" where parts could run to failure before being repaired. It was intended to capture the longest possible run conditions before losing valuable time for repair.

However, as measurement and statistical sampling became more available, maintenance professionals discovered that preventive maintenance was a better solution in almost every circumstance. The importance of preventive maintenance was evident in its planned and scheduled approach.

Companies could design preventive maintenance programs that accounted for runtime, usage, conditions, and other factors. From this approach, they could develop specialized training, more accurate budgets, and better Capex plans.

Benefits and Advantages

There are numerous benefits to a well-designed preventive maintenance program, including:

Cost Savings

By replacing parts before they fail, there is less chance of surrounding parts being excessively worn or damaged. This practice results in cost savings overall.

Safety Improvements

Often, parts are allowed to wear until failure can disintegrate and cause damage to other parts in a domino effect. By replacing parts before this point, equipment is safer for operators and technicians.

Improved Quality

Production equipment today relies on a high degree of precision to produce volume goods in little time or tightly specified parts for made-to-order applications. By replacing a part before it is worn, machine tolerances are maintained, resulting in higher first quality goods.

Reduced Downtime

Parts that prone to failure often result in more extended downtime as they may become fused or embedded in other parts of the machine. This failure increases the time required to clean out debris and loosen parts from frozen shafts and other mechanisms. Replacing the part in a PM program means faster repair during planned downtime and reduces unplanned downtime.

Improved Reliability

Because preventive maintenance is planned and scheduled, the reliability of production schedules is greatly enhanced. Managers understand that maintenance is systemic and that they no longer need to "cross their fingers" and hope for the best.

Increased Equipment Lifespan

By enacting a formal preventive maintenance plan, the lifespan of a machine can be greatly extended for years or even decades. This longer lifespan reduces valuable investment dollars required for Capex programs and allows companies to plan Capex strategically instead or from necessity.

By analyzing the health and performance of equipment, maintenance teams can take a more proactive approach and use data driven insights to make more effective decisions.

Disadvantages of Preventive Maintenance

Preventive maintenance programs are based on assumptions and probability. Of course, these can be sharpened in many cases to match the lifespan of a part closely. But as a probability-based system, basic preventive maintenance strategies lack precise data to become more effective.

Because of this, there are many disadvantages to the most popular forms of preventive maintenance, including:

Over-Maintenance

Because PM programs rely on assumption and probability, over-maintenance is always a problem. This may mean excessive time and labor expended to check and recheck for issues that may not be there. Or, it may result in replacing parts based on charts and graphs of OEM-supplied maintenance intervals that do not account for particularly heavy or light duty applications that affect parts wear. In either case, over-servicing can add cost.

Unexpected Failure

Even the best-designed preventive maintenance programs cannot account for unplanned machine failure. Because PM programs are assumption-driven and not data-driven, random failure and unexpected wear may not be detectable between PM intervals.

Extensive Ongoing Training

While a solid PM program offers the opportunity for specialized training, this can become expensive over time. As new equipment comes online, training must be refreshed to account for fresh functionality. PM systems must be updated alongside this, and the process becomes less cost-effective.

Types of Preventive Maintenance

If you would like to dive deeper on the different types of maintenance manufacturers can use, read the complete article. Here is a summary of the different preventative maintenance strategies:

- Time-Based Maintenance: Establishing a calendar with intervals for maintenance activity.

- Usage-Based Maintenance: You replace parts when the machine has been used a certain amount before they break.

- Condition-Based Maintenance: You replace the parts when they seem like they are getting too worn out to continue to function appropriately. Learn more about machine condition monitoring.

- Predictive Maintenance: You utilize historical data to make predictions about when a part will break and replace the parts based on these predictions, prior to them breaking. This usually, but not always, utilizes artificial intelligence and machine learning.

- Prescriptive Maintenance: Advanced data analysis methods are used to do more than predict failure points, but instead provides hypothetical outcomes in order to choose the best action that can be taken prior to failure, safety hazards, and quality issues arise as well as the timing of implementation.

BC Machining: A World Class Example of Preventative Maintenance

For Bob and his employees at BC Machining, broken tools and scrap parts were just a fact of life. They were so ingrained into the business that Bob ran the machines at 200% capacity, simply accepting the lost time and materials due to tool failure that it became the norm and not an anomaly.

In Bob's words, “When you break tools and make a scrap part, you’re just throwing money away.”

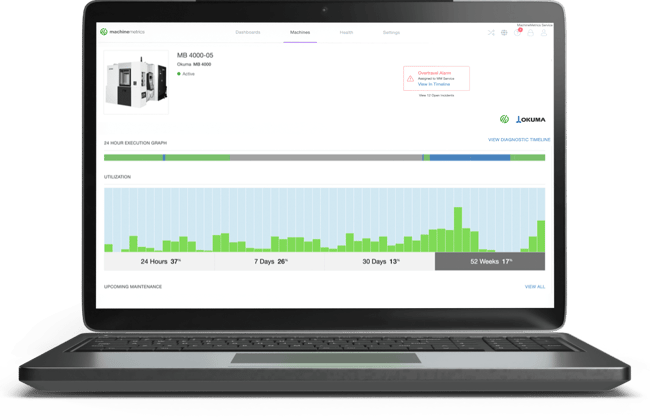

To finally address this problem, Bob enlisted the help of MachineMetrics and our groundbreaking new product offering MachineMetrics Predictive, a solution enabling them to diagnose, predict, and automatically prevent these machine tool failures on their Star CNC machines that lead to broken tools, scrap parts, and costly downtime.

After a quick and successful deployment, in just a few weeks the results spoke for themselves: "Since using the MachineMetrics’ predictive tool breakage technology, almost all of our waste has been eliminated. We've calculated the savings at our Swiss turn machines to be about $72k annually...it's been monumental to say the least.”

Within this case study interview, the BC Machining team share their experience using MachineMetrics Predictive and the dramatic impact that the technology has had on their shop floor and their bottom line.

Read the Complete Case Study.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments