Since the beginning of industrial automation, the manufacturing industry has utilized sensors. Originally, they were used to trigger mechanical responses to reduce manual labor. As sensor technology evolved, the devices were improved to collect data from individual machines so companies could use the data to analyze production processes and identify areas for improvement.

Given the rise of machine monitoring solutions and industrial IoT, manual analysis of data and simple mechanical responses to sensor inputs have become inefficient and unnecessary. With exponential increases in the ability to collect data and analyze it at breathtaking speed and precision, sensor technology has evolved to feed the IoT system rather than be the stopping point for automated processes.

Today, manufacturing sensors remain an important piece of the IoT and data collection puzzle. Manufacturers are finding that while industrial sensors will be needed for the foreseeable future (due to legacy equipment), advances in IoT have helped define their role on the factory floor and in data collection.

What Are Manufacturing Sensors?

Manufacturing sensors are used in data acquisition to measure physical conditions on a machine. They consist of a device that receives or measures inputs and generates an output in data. This data can be used to trigger a machine response, or it can be used to collect data for analysis and storage.

Industrial sensors exist for a wide range of measurement types. Today, smart sensors can transmit data to the edge of the cloud where an intelligent device or platform can process and analyze it, prior to it being sent to the cloud. This information can then enable actionability, whether that be populating a production dashboard, triggering a maintenance request, or simply collecting data for historical analysis.

An example of a manufacturing sensor. These devices have the ability to connect legacy, or "dumb" equipment and monitor various machine and environmental conditions.

An example of a manufacturing sensor. These devices have the ability to connect legacy, or "dumb" equipment and monitor various machine and environmental conditions.

Using various communication methods such as 5G, Wi-Fi, a cellular connection, and EtherNet, real-time data collection allows the platform to generate insights that help improve production processes, reduce costs, and enable predictive maintenance. But sensors alone don't collect enough data to deliver insights into total machine health. This is why they remain a complement to a complete connectivity solution, rather than a solution in and of themselves.

Sensors are rather simple devices. They help to unlock data that was never intended to be shared, such as in the case of "dumb" equipment (ie. equipment that is not IoT-enabled) or in the case that equipment does not natively provide a data point that an end-user requires.

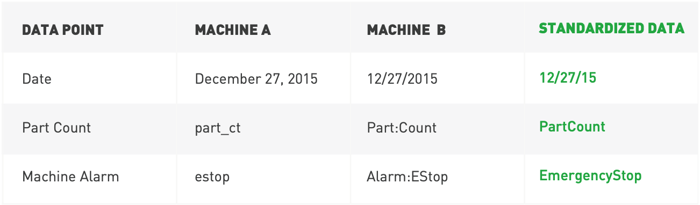

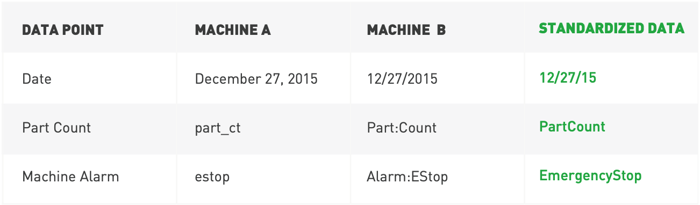

Machine data platforms enable data collection along with sensors to ensure that raw data is captured from all equipment and standardized into a common model to enable actionability.

With sensors alone, manufacturers would have to manually collect and standardize the data. And then manually analyze it or build applications that can enable analysis and actionability.

Types of Sensors Used in Manufacturing

What are some of the common types of sensors used in industrial environments?

1. Tri-Axial Accelerometers

There are many turning parts in manufacturing equipment. A tri-axial accelerometer monitors and measures vibration on rotating parts and equipment. These smart sensors can also measure other variables like displacement, acceleration, and velocity. In conjunction with IoT advanced analytics, this data can yield valuable insights to let managers and technicians know whether a machine is operating in good health or if a deviation is a one-time event or a troubling pattern.

2. Temperature

Moving equipment generates a lot of heat, and many industries use additional process heat for their factory floor. Heat is an excellent indicator of the overall health of a machine. Temperature sensors can help identify machine wear, damaged sections, and overheating, leading to failure and quality control problems.

3. Vibration Sensors

Vibration doesn’t just occur on spinning parts. Vibration sensors can be used with conveyors, panels, and other machine parts to let operators and technicians know when something is amiss.

4. MEMS (Micro-Electromechanical Systems) Sensors

MEMS sensors are motion sensors that track movement and performance. In their simplest form, they detect motion and trigger a machine response to realign a component of the equipment. In CNC machining, they can be more complex, tracking tilt, acceleration, and gravity on an axis grid to help maintain precision machining.

5. Torque Sensors

High-speed motors can create powerful torque force on a machine. These forces are even more significant under load. When torque sensors monitor a motor or shaft, the insights can help manufacturers ensure quality, reduce machine wear, and troubleshoot problems before they occur. These smart sensors are often combined with other sensors to create a highly detailed view of equipment health.

6. Pressure Sensors

Pressure sensors monitor any machine component used by fluid or gas, including hydraulics, water, chemicals, air, and nitrogen. They can be set to alarm the factory monitoring system when high or low limits are reached.

Data Management for Smart Sensors

Smart sensors unlock big data potential because they deliver the data needed for IoT's advanced analytics to work. However, this data requires contextualization and standardization in order for it to drive value for users and systems.

Contextual

Contextual data means adding relevant real-world information to sensor data sent to the IoT platform. Without context, raw data may not be helpful to end-users. For example, tracking and analyzing downtime events is important for manufacturers. But without operator input as to the “why” behind a downtime event, the data is less helpful.

Relevant Data

It's not enough to simply capture data - the data collected must be relevant. This means that smart sensors must pick out high-value information and discard the redundant or unnecessary information.

Standardized Data

Sensors can provide data, but an IoT platform's job is to ensure the data is standardized across all equipment and devices. Without data standardization, there will be a mess of varying data types that will not allow actionability on the part of stakeholders and other systems.

Actionable Data

Equipment data is vital to increasing operational efficiency and productivity since it offers an accurate picture of production performance that can be delivered to the entire shop floor as actionable insights. Actionable data with real-time notifications allow operators to take proactive steps to reduce downtime and failure across machines. Plus, it gives managers complete operational visibility.

How Industrial Sensors are Improving Manufacturing

Industrial sensors improve manufacturing by integrating with advanced IoT platforms to deliver actionable insights to the production floor and beyond. Smart sensor technology contributes to this ecosystem to provide superior visibility of machine conditions, processes, production, and more.

In this ecosystem, industrial sensors (combined with a direct connection to machine data where sensors aren't needed) help capture data that can improve production processes, enable the design of predictive maintenance programs, and lower operating costs.

Applications of Digital Sensors in Manufacturing

There are many applications of digital sensors in manufacturing, including:

Data-Driven Insights

When combined with advanced IoT, industrial sensors collect data that can be returned to users in real-time as valuable and actionable insights. This revolutionizes the factory and shop floor by allowing staff to monitor, regulate, and enhance operations.

Safety

Because they’re part of a system deeply tied to AI-powered analytics, digital sensors can deliver safety benefits to a company. This could include precise stoppage of work when danger is discovered or real-time notifications to emergency staff before a crisis. For example, if a machine tool is experiencing a greater load than normal, it can be automatically stopped to avoid a catastrophic tool failure.

Improved Maintenance Programs

IoT with digital sensors can detect equipment failure, allowing maintenance staff to begin a procedure before equipment fails. It can also be used to schedule maintenance at the optimum time.

Accurate Historical Data

Many manufacturing companies deal with extensive regulatory compliance. With data returned from smart sensor technology and organized in the cloud, precise production records allow better transparency and product chain of custody. This enables managers to set accurate production benchmarks and forecast performance.

Procedure and Quality Notification

Many manufacturing companies require stringent adherence to SOPs. This is especially true in industries like CNC machining for medical and aerospace. Because these procedures can be added in as contextual data, sensors can detect if a procedure is off track and alert managers. The same is true for quality notifications, an especially important function in high regulatory environments.

Improve Information Flow and Market Response

The power of real-time data lies in its ability to take immediate and proactive action. This means that information is at the fingertips of everyone in the enterprise. Response to market trends – good or bad – can help a company navigate rapidly changing conditions and remain competitive.

The Future of Sensors in Manufacturing

Sensors make a truly connected operation possible by delivering real-time diagnostic data that enables deep insights from advanced analytics engines in the cloud. This ensure manufacturers can get access to all equipment data, even legacy assets, and makes the case that sensors will continue to play a part in the foreseeable future.

However, sensors alone are not capable of driving advanced use cases or effective machine monitoring. They require technical resources to collect, standardize, and visualize data. But sensors, along with an IoT Platform, help to ensure accurate, reliable data capture across the shop floor.

MachineMetrics enables direct integration with machine controls and offers the ability to add sensors to collect a lot more data in a plug-and-play fashion that immediately transforms data into a common model across all equipment. Further, we offer pre-built and customizable reports for immediate actionability out-of-the-box.

Connecting directly to machines is a critical component of the MachineMetrics system, as is the data transformation. The MachineMetrics platform turns machine and sensor data into a common model which stakeholders and systems can rely on for better, faster decision-making.

This ensure manufacturers can effectively monitor their production while creating a foundation for continuous improvement with more advanced use cases.

Want Complete Operational Visibility?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments