As the proliferation of the Industrial Internet of Things (IIoT) progresses, there will come a time when few companies without connectivity will survive. The benefits in cost, efficiency, and improved profit margins make IIoT a necessity for doing business in manufacturing.

As recently as 2020, the global market for Industrial IoT was only 198.25 billion. However, as the trend toward digitizing manufacturing continues, that number will explode to 1.495 trillion by 2030. That kind of growth indicates a sea of change underway in how we make things across the world.

A significant challenge to the growth of IIoT is how to handle and process an unimaginable amount of data produced by machines. When everything can be measured and analyzed, bandwidth, processing power, and other computing variables become critical to maintaining the system's integrity.

One way manufacturing manages the incredible amount of data to leverage the power of IoT analytics is through Machine-to-Machine (M2M) technology. M2M offers a way to increase the power and utility of a cloud-based analytics platform while addressing many challenges brought about by the amount of data produced.

What is Machine-to-Machine Communication?

Machine-to-Machine communication, or M2M, is the transmission of machine data between mechanical or electronic devices using wired or wireless tools.

Depending on the reason for the transmission, it may be as simple as measurement or as complex as if/then instructions. The exchange of data is done automatically without human intervention.

M2M communication can occur through many formats and access methods, including serial ports, traditional PLCs, or wireless connections through cellular, Bluetooth, Wi-Fi, RFID, or fiber. These transmission formats allow data from sensors, tools, and other devices to be transmitted to another device or an edge computing device to report status, log a transaction, or give or request instructions for the device itself.

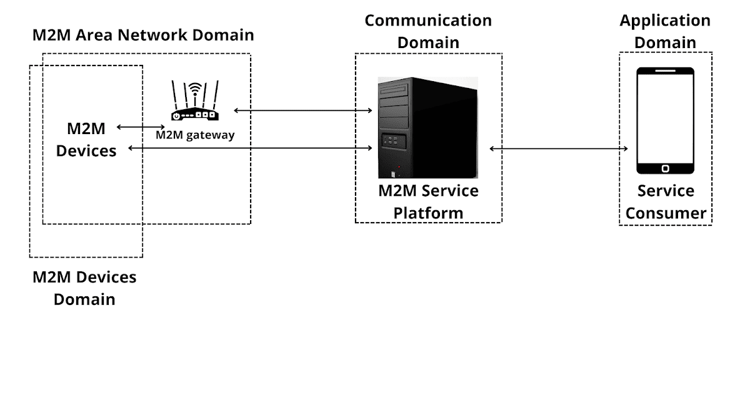

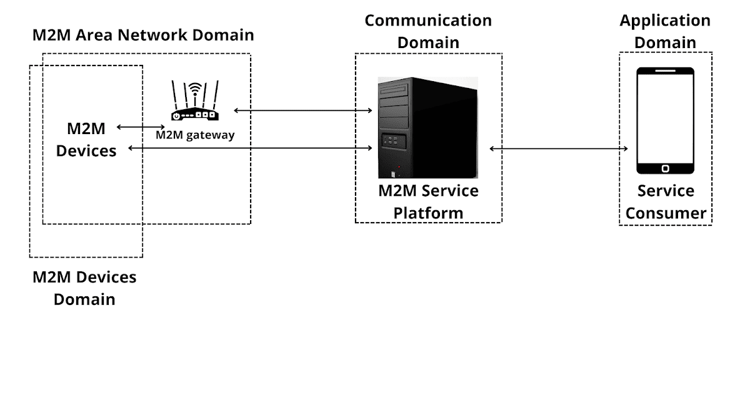

A basic diagram of an M2M network. [Source]

A basic diagram of an M2M network. [Source]

Why is Machine-to-Machine Used?

Machine-to-machine communications reduce time, bandwidth, and latency while facilitating autonomous actions between machine assets.

One of the most significant reasons for the use of machine-to-machine communication is to reduce human intervention and tasks. Because data collection is automated, many tasks traditionally performed manually can be transferred to mechanical machine control systems. This process frees operators and technicians for more value-added tasks that do require human context.

Machine-to-machine technology also reduces network bandwidth, allowing for better network efficiency. Companies rely on wireless technology like wireless networks, cellular networks, radio waves for Wi-Fi, and traditional wired networks like cables or telephone lines to enable communication between machines.

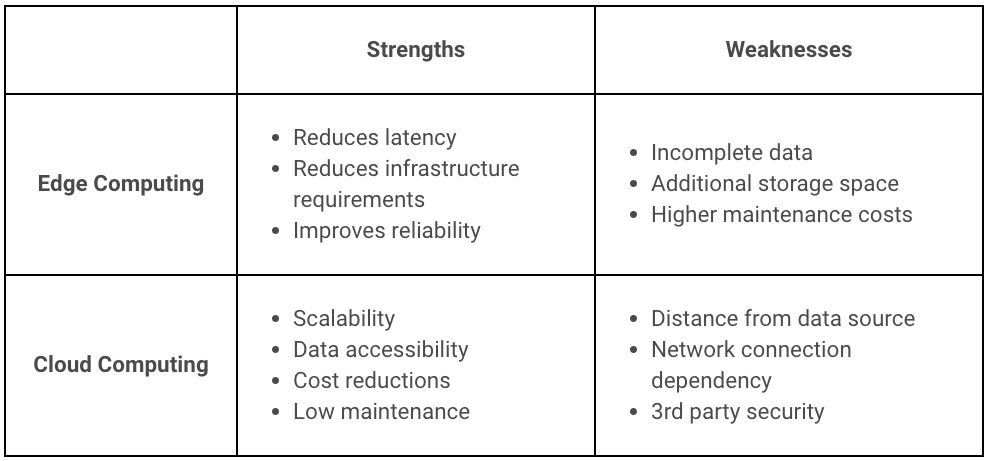

Additional devices can be used to enable communication between machines without cloud access. Edge computing is vital to M2M communication because it can partially process information in a data transfer and send instructions back to the correct machine without needing to access the central platform.

Machine-to-machine data is used in advanced IIoT systems utilizing artificial intelligence to create connected smart factories and drive superior process improvement.

How Does Machine-to-Machine Differ from IIoT?

M2M communication can exist as part of an IIoT ecosystem. The difference is that Machine-to-Machine communication is a direct exchange or transmission of specific data to another device that triggers an action or response from that device.

One example would be an RPM sensor that measures the rotation speed of a camshaft or spindle and sends that speed to an edge device, such as an IIoT gateway. Before sending an alert, it may also have parameters that set minimum and maximum acceptable speed variances.

IIoT, on the other hand, is the comprehensive system of all connected devices within the factory that drive machine intelligence. This may include sensors, edge devices, and ethernet cables.

Where M2M is specific between two devices or sensors on a machine, IIoT can take the data generated, analyze it against all machines or factory production, and deliver trends. With a machine data platform like MachineMetrics, these insights can help optimize operations, identify maintenance needs, and offer prescriptive solutions for decision-makers based on a holistic analysis and monitoring of the entire operation.

The Value of Machine-to-Machine Technology in Manufacturing

M2M technology delivers value to manufacturing in many ways. These include:

Bandwidth

One of the most significant challenges in the growth of IIoT is bandwidth usage. M2M offers ways to help manage the traffic for the data generated by machines. Machine-to-Machine technology can act as a control for the volume of data by:

- Delaying data transfers to a time when the network is less burdened

- Scheduling delivery or receipt of data to optimize load

- Turning devices on or off as needed or as they’re moved

- Using less power

Remote Monitoring

In traditional factory monitoring systems, the presence of a technician was required to assess a condition. This was time-consuming because of the transit time across the shop floor and back to where the condition was logged (Not to mention, the inaccuracy and limitations of the data collected manually).

Using M2M technology allows machines to transmit alerts and alarms to technicians who can come prepared to repair the system or make adjustments that reduce downtime. In many cases, technicians can implement an adjustment remotely, using a PC, tablet or other remote monitoring tools making changes and adjustments from an accessed terminal without going to the machine.

Asset Tracking

M2M technology isn't confined to machines. It can be included on pallets, containers, and bins to transmit data so the more extensive IIoT system can track its location. This is especially helpful in highly regulated industries where material tracking and product health for temperature, spoilage, or other variables are required for safety and regulatory compliance.

Operational Efficiency

One of the most significant values of M2M technology is operational efficiency. M2M communication enables the sending of alerts for machine conditions, raw material stock levels, and automatic adjustment for variances.

The technology has a direct impact on quality as well. Because problems are detected and alerted faster than human intervention, less material is lost and fewer parts are scrapped.

How Machine-to-Machine Communication Works with Different Device Structures

IoT Devices and Sensors

While M2M communication can work outside an IIoT platform, IIoT platforms are dependent on M2M. IoT devices and sensors are inextricably linked to the kind of data and communication occurring along with M2M communication.

While the M2M may independently communicate instructions or record information to another device for optimized operation, the IoT device and sensors will transmit the data to the cloud. This ensures that it’s analyzed based on programmed parameters and analytics to deliver actionable insights.

MachineMetrics Machine Data Platform receives millions of data points and then contextualizes and standardizes the data to render such insights.

Embedded Devices

Many OEMs have embedded sensors for M2M and IIoT in their equipment. With MachineMetrics, a connection can be made with any OEM to eliminate interoperability concerns. This means that data collected from one OEM machine can be directly included in the analysis using data from another OEM of the same machine type, or any other machine type for that matter.

The result is that machine health and performance become agnostic of OEM manufacture. It also ensures the data, insights, and nature of the instructions used by the M2M network are consistent. The individual M2M devices continue to communicate while an IoT platform can use the data for analysis.

PLCs

PLCs have long been part of industrial automation. Machine-to-Machine communication can be programmed through PLCs to create automation, set alert parameters, and more. But like OEM machines, PLCs from different suppliers may be more complex in programming.

Once again, we run into a scalability challenge. There are many brands of PLCs available. Manually building M2M connected across them will be time-intensive and expensive to maintain. Solutions like MachineMetrics can enable connectivity across the different PLCs to ensure complete visibility and control.

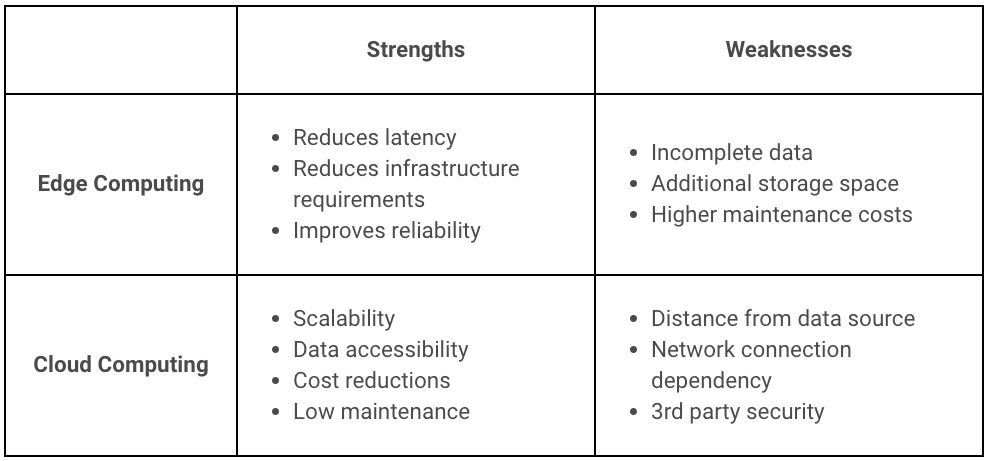

Edge Devices

Edge devices are one of the most vital links between M2M communication and its role in the IIoT system. Edge computing has helped mitigate bandwidth and latency issues as a data stream increases.

Edge devices can partially organize, clean, and structure data. The insights delivered from data captured by M2M communication can be analyzed and returned more quickly, rather than sending all the data to the cloud.

Edge devices may also send instructions to more than one other device along its network. One edge device may be capable of handling an entire machine or entire facility's spindle sensor inputs to provide instructions and alerts while still feeding critical data into the IIoT system for analysis.

Machine-to-Machine Communication and Security

Statistics show that new devices may be under attack within five minutes of connecting to the internet. And 75% of the time, attacks come through the router as their entry point. Other common breach points include insecure web interfaces, network services, encryption, and mobile interfaces. Login and credentialing are also common points of access.

Companies can mitigate this risk by segmenting their IT network so that machines' components are separate from the network that houses the company's IT infrastructure balance. They can also integrate more robust password protection, training, and discipline for in-house and mobile interfaces.

Collecting and Standardizing Data from Equipment

MachineMetrics is a Machine Data platform that connects quickly to both modern OEM machines and legacy analog equipment. With complete access to a common model of data from all shop floor equipment, manufacturers can optimize their production and automate processes.

This all takes place with a scalable platform that delivers value immediately. No need to manually engage in data-tag mapping, build DIY software solutions, or maintain servers.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments