The need for knowledge transfer has always existed, from verbal stories handed down over generations to handwritten notes passed from an existing employee to a new one. The same need has always existed for manufacturers to ensure product consistency and equipment operation. But today, it’s even more critical.

As other employment opportunities have grown, manufacturing companies have found themselves without enough skilled workers. In many cases, more “head” knowledge is lost than can be made up for or transferred. And the more manual the transfer system, the more rapid the loss becomes.

There's an additional problem here. While it is getting more difficult to recruit skilled labor, there is also a growing number of baby boomers retiring, and with them much of the key knowledge required to operate manufacturing businesses effectively.

Taking on this people problem is the promise of advanced technology and automation. Let's dive a bit deeper into this challenge to see how manufacturers can contend with such a large, industry-wide crisis.

The Business Value of Automation

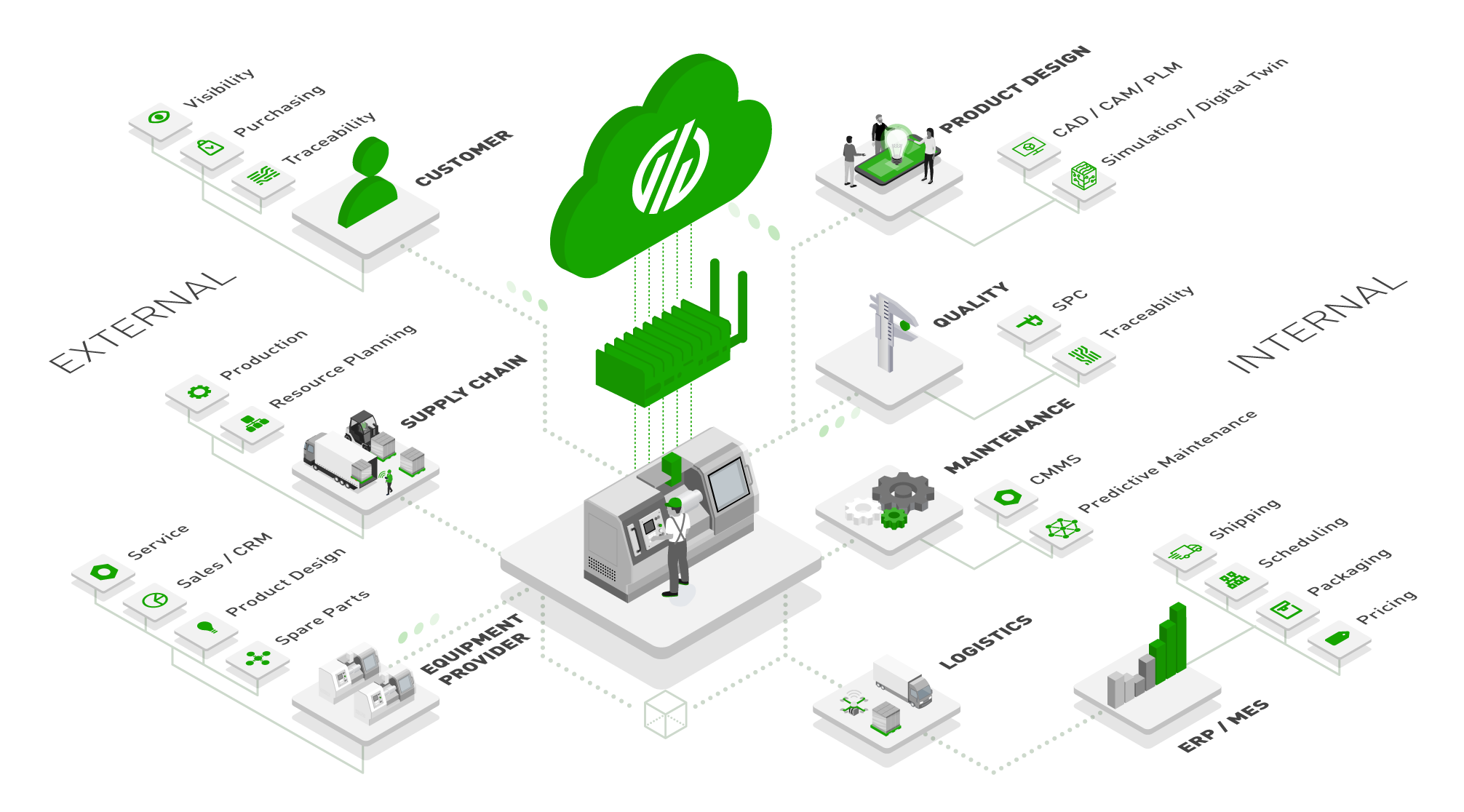

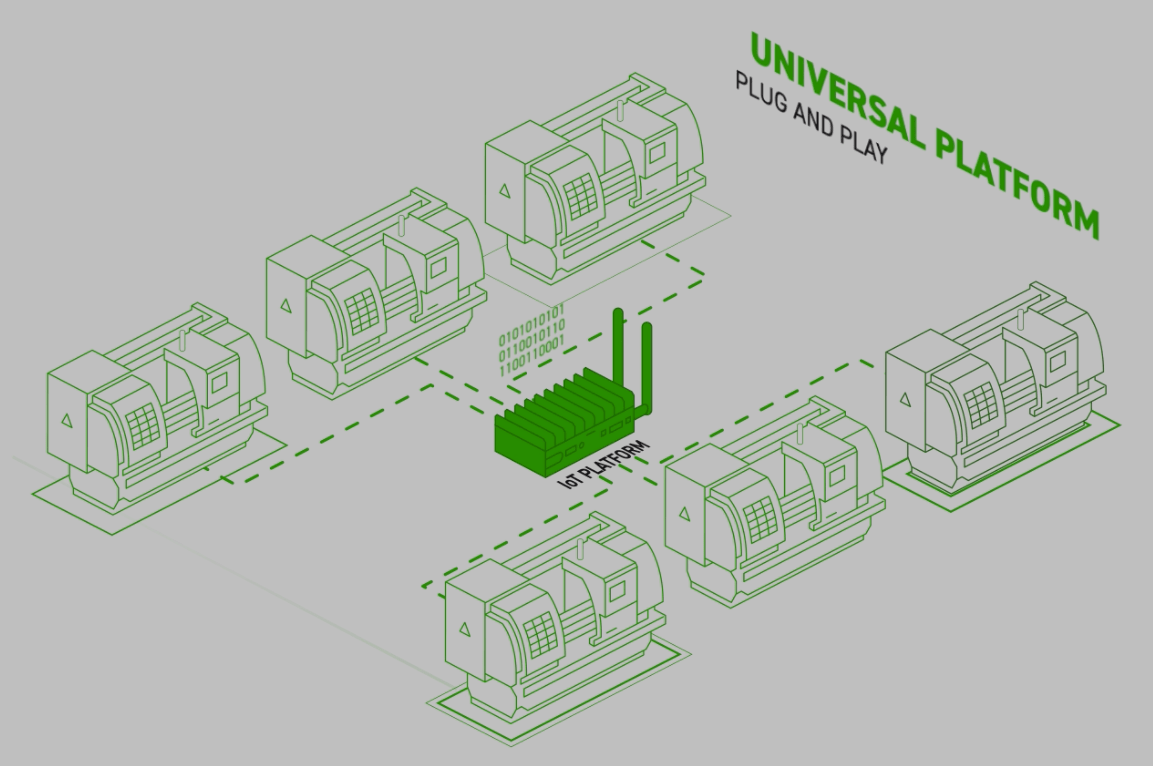

Automation has many forms, with new technology and the growth of IoT offering the ability to operate more effectively with fewer hands-on processes.

- Efficiency: Automation has enabled manufacturers to streamline processes, reduce or eliminate errors, and increase throughput. The results have been greater output, reduced lead times, and lower costs.

- Quality: Automated manufacturing processes have delivered higher product consistency and reduced defects.

- Flexibility: Automation has enabled manufacturers to adjust production lines on the fly to respond to demand. This capability makes manufacturers more responsive to market changes, seasonality, and consumer tastes.

- Reduced Labor Costs: Automation has significantly reduced the need for manual labor, and many companies have used it to lower costs and increase profits.

- Data Collection and Analysis: Automation helps manufacturers collect and analyze machine and process data to drive process improvements.

All these benefits were revolutionary at the tail end of Industry 3.0, where computers, electronic management systems, production software, and automation drove progress.

Automation Isn’t Enough to Overcome the Skills Gap

As powerful as automation is, it can’t overcome the challenges manufacturers face regarding skills and knowledge transfer. This reality is reflected weekly in the news as the number of available manufacturing jobs rises.

So, what’s missing? A leap forward akin to the one where automation displaced manual tasks. A leap that captures the knowledge required for the remaining employees to perform tasks consistently and accurately.

As Industry 4.0 accelerates into this century, such a leap is possible, closing the knowledge gap and addressing the labor problem on two fronts with the same solution. IIoT automation can support both.

The Labor ROI of IIoT Automation

Before the arrival of automation in Industry 3.0, employees were required to run nearly all operations and processes manually. The arrival of automation saw many production systems reduce the need for manual processes and labor, generally increasing overall efficiency.

Today, IIoT automation can significantly lower the labor needed for the remaining tasks, like quality measurements and production monitoring. Many tasks can be done through connected equipment like sensors, and cloud-based analytics allow them to be done autonomously or semi-autonomously.

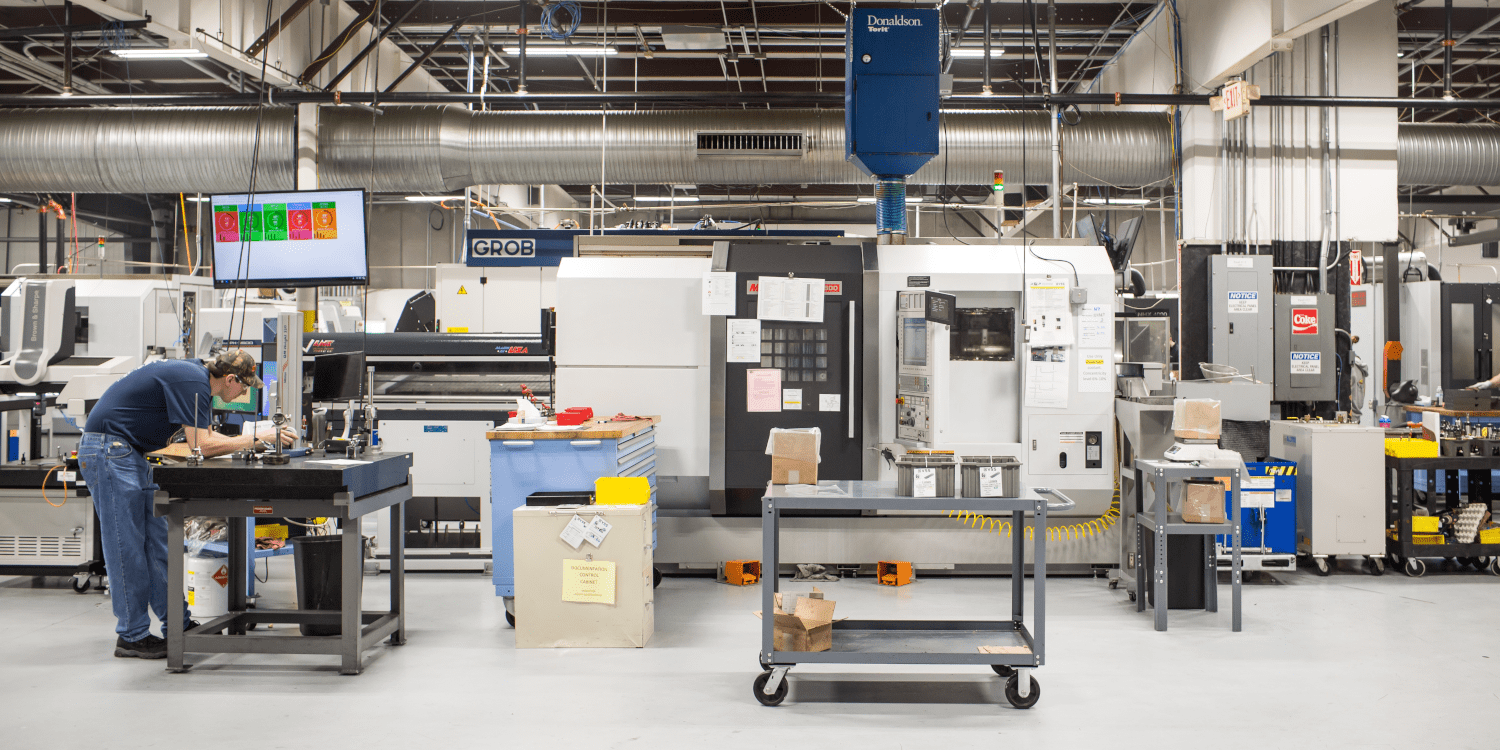

The reduction in labor is significant. Perhaps before Industry 3.0 automation, a manual task required multiple employees per machine to complete all functions. By connecting the machine to an advanced production monitoring platform, this equipment may only require a single operator, and this operator may be able to run multiple machines.

Whereas past configurations may have required multiple staff, a single operator with a customized and real-time dashboard on an HMI can manage multiple functions efficiently.

Closing the Knowledge Gap with IIoT Automation

IIoT automation will likely empower more “lights out” manufacturing, enabling manufacturers to extend their production hours. Through these tools and business models, the future factory will look less like your grandfather’s shop floor and more like a high-tech, autonomous work center with few but highly skilled operators managing the IIoT system.

What's the first step? Beginning to digitize operations by capturing production data at the heart of the operation: your machines.

Drive deeper on machine data collection, or watch our platform in action.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments