Optimizing Production Efficiency through Data-Driven Manufacturing Strategies

Although diverse data capturing technologies exist, manufacturers still struggle to use them. It's due to this major challenge that the goal of data-driven manufacturing seems all the more unachievable.

However, there are a few data driven approaches you can take when optimizing production efficiency. These approaches include making use of Industrial IoT to capture shop floor data, deploying shop floor edge computing devices, or manually inputting machine statistics into excel sheets for further analysis. The prior two options are digital solutions with automated processes while the latter is manual. As is to be expected, digitization wins and makes capturing shop floor data and putting it to work, a more streamlined process.

With this in mind, it will be helpful to dive deeper into what it means to be a data driven manufacturer, what benefits and challenges you may experience from launching data-focused programs, and what tangible strategies you can adopt as you progress in your analytical maturity.

What is Data Driven Manufacturing?

The MachineMetrics performance dashboard on the shop floor.

The MachineMetrics performance dashboard on the shop floor.

Data driven manufacturing is an approach to production that allows facts and a strict set of manufacturing KPIs to guide decision-making, as opposed to guesses, anecdotal evidence, or “gut feelings.”

It is an approach that leverages data from shop floor equipment, operators, the supply chain, among other sources, to enable manufacturers to make better decisions as they work to reduce costs and increase operational efficiency.

Emerging technology is giving more manufacturers the ability to collect and process data from their operations, which is leading to a surge in solutions that can extract insights from manufacturing data in real-time. However, not all analytics are the same.

In order to successfully leverage data in an operation, you first need to be able to collect accurate data that can be effectively processed and displayed in such a way that is easy for the user to consume.

For example, if you were to manually collect machine performance data on a clipboard, there is not only a large commitment of time to complete it, but there is also a high likelihood of human error. On the other hand, collecting data directly from machines via the PLC produces a highly accurate and unbiased stream of data. Both solutions here can be considered “data driven” but the latter is far superior and will lead to better decision making.

Benefits of Being Data Driven in Manufacturing

Increased Visibility: The allure of data driven manufacturing is that leaders on the shop floor and the corporate office can have a deeper understanding of performance based on the data being collected across the organization. Data provides insight into not only individual asset performance, but operations as a whole. This helps decision-makers pinpoint areas for opportunity, whether it be poor performing shifts, recurring machine downtime, or other production bottlenecks.

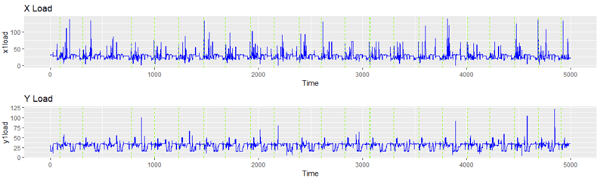

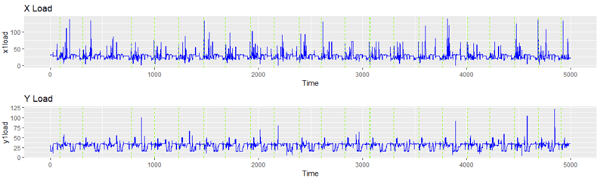

AI and Machine Learning: With large data sets, manufacturers have the ability to run machine learning algorithms that help to solve complex problems. For example, our data science team leveraged unsupervised machine learning to detect CNC anomalies. It’s with analytical efforts like this that manufacturers can adopt advanced practices such as predictive maintenance. Without the processing capabilities or access to data, even simplistic forms of data-based decision-making would not be possible.

Automation: There are two categories of automation that data driven strategies can support. The first is the automated collection of data. If an operation is properly outfitted with devices to collect data and software to process it, the process of data collection no longer requires manual effort.

The second component of automation is the use of data for automated decision making. As manufacturers progress in their analytical journey, they move from descriptive to predictive analytics. This means that they first use data to understand what has happened or is currently happening, but eventually mature to understand what can happen and have the opportunity to take action on it autonomously.

Cost Savings: Data complements lean manufacturing as it gives manufacturers the information they need to streamline production processes and minimize waste. Without the hard data, it’s difficult to accurately measure production improvements and be sure that changes have resulted in cost savings.

For example, Carolina Precision Manufacturing, a small-diameter, close tolerance CNC Swiss turned parts manufacturer, saved $1.5 million in one year by rolling out an IoT platform to ensure full data visibility. In the case study, it explains how they were able to increase production efficiency, optimize machine utilization, and drive operator accountability.

Challenges of Data Driven Manufacturing

Siloed Data Sources and Legacy Systems: Many systems and equipment were not built with the intent of talking to one another. This may be the result of separate operating systems among different departments, legacy equipment, or simply a lack of documentation and communication. The problem here is that it can be difficult to aggregate data across disparate systems, meaning that you will get less value from the collected data. An IoT platform that connects multiple levels of systems and brings legacy equipment online helps to solve this problem.

Security Threats: The problem of industrial IoT security has arisen due to two primary reasons. First off, as more devices are connected there is a greater chance of creating vulnerabilities for a breach. Secondly, security has not been addressed at the machine level before, which means there are no standards or protocols developed. However, there are solutions for mitigating risk.

Data Storage: The more connected devices and systems that a data-driven manufacturer enables, the more data will be collected. On the surface, this is a strong benefit if the user can gain insight from the data being collected. However, the growing data stream needs a place to be collected and processed, which can be a difficult challenge. This is especially cost-intensive if the user is to store data on-premises, which makes a strong case for the use of cloud computing.

Data Driven Manufacturing Strategies

Data-Driven Process Optimization Strategy

The first step to optimizing the production capacity of a machine is having an understanding of its capabilities and the working conditions around it. These working conditions could include knowledge of the available inventory and the speed at which materials get to the machine. To acquire this knowledge, the integration of data capturing solutions such as human-machine interface devices will be required. The collected data and the ability to visualize KPIs provide great insight into industrial processes for both the decision-makers and employees within a shop floor.

These insights can then be put to work in developing a process optimization strategy that ensures production continues at its optimal level. A data-driven approach to process optimization also makes it possible to identify factors limiting productivity.

An example is the use of MachineMetrics to drive process optimization within a discrete manufacturing facility. In this example, data is collected daily from machines, categorized and compared against optimized KPIs to discover the specific equipment not meeting its target and why. The targeted insight into the challenges affecting a machine’s productivity then serves as the basis for correcting the issues limiting it from functioning optimally.

Data-Driven Predictive Maintenance Strategy

Machines within shop floors are expected to be continuously maintained to ensure they function optimally which is why every manufacturer has a maintenance strategy in place to deal with part failure. In many facilities, a reactive or run-to-failure approach to maintenance is still being deployed as a strategy for keeping machines running for longer periods. Statistics show that this strategy hinders productivity by approximately 20% and can also lead to unplanned downtime if machines break down during an actual production cycle.

A data-driven strategy brings a preemptive approach to machine maintenance through the monitoring of every performance index that describes the health status of the machine and components in it. With this approach, unplanned downtimes will be eliminated, thus optimizing production efficiency.

An example of this is the use of MachineMetrics Anomaly Detection Engine to track components and machine performance. Through an API, the engine analyzes machine data to develop customized maintenance strategies for the different machines within a shop floor. The analyzed data inform the manufacturer about parts that require frequent replacements and insight into how to develop replacement schedules around production cycles. This ensures the manufacturer’s spare parts inventory is always updated and maintenance is executed within specified timelines.

The Three Stages of Data-Driven Manufacturing Optimization

Defining or creating a data-driven strategy to optimize manufacturing processes includes the following stages:

- Capturing and monitoring data: The ability to collect data in real-time provides the basis for putting your data to work. MachineMetrics is a plug and play solution that collects data such as operational speed, equipment temperature, and energy consumption rate from discrete manufacturing equipment and IoT devices.

- Categorizing and visualizing data: The collected data must be processed and analyzed to receive insights from them. MachineMetrics leverages AWS cloud to deliver out-of-the-box applications that make visualization and reporting shop floor data through optimized workflows a streamlined process.

- Business intelligence and action: Reports and workflows are provided to ease the decision-making and strategy creation process. Once machine data has been collected and analyzed, developing actionable strategies to optimize production efficiency and implementing them becomes possible.

Your Manufacturing Analytics Journey

To get your data working for you, connecting your enterprise’s manufacturing machines to the MachineMetrics Platform kick starts the journey to production optimization. MachineMetrics universal connectivity capabilities support machines with both digital and analog I/O which makes it possible to collect data from legacy machines within your shop floor. Thus, eliminating the challenge of collecting the usable data needed to develop data-driven strategies for your manufacturing facilities. You can learn more about the value proposition of enterprise-grade industrial analytics platforms by analyzing the features of MachineMetrics IoT Platform.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments