CNC machines are the lifeblood of manufacturing facilities, taking in parts and outputting assemblies ready to be shipped. These machines are used for cutting, drilling, shaping, carving, and other manufacturing tasks. CNC equipment is invaluable in today's assembly line environment due to its high degree of precision that would be impossible or impractical using manual labor.

When CNC machines are down, manufacturing plants can be crippled with thousands of dollars worth of unmet shipments, wasted hours, and lost customers. CNC machine services should include scheduled inspections and preventative measures that can reduce production delays caused by malfunctions. Inspections should include a physical check of the equipment, including the control panel and all parts.

To reap the maximum benefit of CNC machine maintenance, ensure you follow your machine's recommended maintenance guidelines to keep it in tip-top shape. Further, leverage real-time equipment data to enable a usage-based or condition-based maintenance strategy.

|

How do I move from reactive or preventive maintenance to a usage or condition-based strategy?

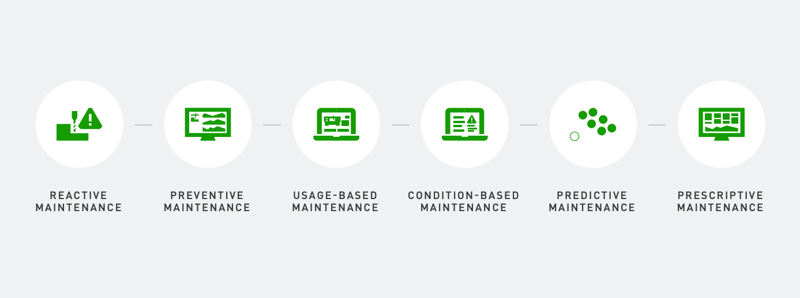

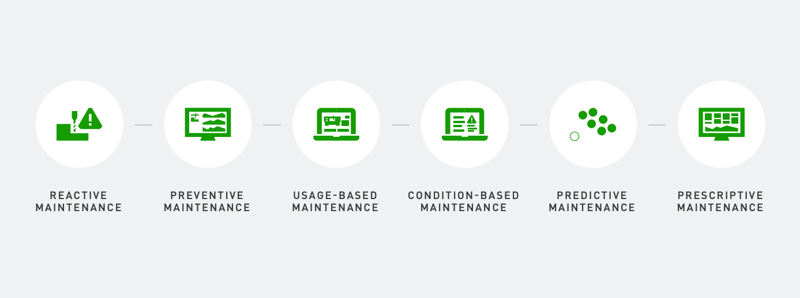

Within this guide, we will explore different maintenance strategies and discuss a roadmap to digital maintenance automation: "The Roadmap to Digital Maintenance Automation"

|

Why Do We Need CNC Machine Maintenance?

Without proper CNC machine maintenance, businesses may experience unexpected downtime and production delays. Scheduled inspections and preventive measures are two key ways to ensure these machines stay in good operating condition.

Many users rely on the expertise of maintenance personnel to maintain their machines and avoid any unexpected downtime. According to , 80% of maintenance personnel favor preventive maintenance.

Maintenance Tasks and Procedures for CNC Machine Checks

Since there are various CNC machines, it is important to always adhere to the maintenance guidelines specific to your machine. Other factors, such as the machine's average run time and materials used, can affect how often it needs servicing. In general, CNC machine checks should be done at least once a month. Below, we'll dive into some of the top CNC machine maintenance procedures.

Create a Custom Maintenance Task Schedule

To create a custom maintenance schedule, consider the following tasks:

1. Daily Tasks

- Inspect all covers, guards, and safety devices

- Inspect spindle bearings for oil leakage

- Check coolant level and quality; replace coolant as required

2. Weekly Tasks

- Inspect and adjust machine slideways (if required)

- Clean the control cabinet's filter to allow air to pass through for cooling

3. Biweekly Tasks

- Clean the machine thoroughly with compressed air or a non-flammable solvent such as acetone

4. Monthly Tasks

- Make any necessary adjustments to limit switches and emergency stops

- Inspect the quill area for damage or burrs

- Check the condition of all electrical wirings and motor brushes

Provide Channels for Reporting Issues

Your preventive maintenance program should include a set procedure for reporting issues and an accessible communication channel for doing so. Having a clear reporting procedure makes it easier for problems to be reported and fixed promptly.

Always Keep Spare Parts on Hand

Keep spare parts on hand to eliminate downtime during repairs. For example, you could purchase replacement parts ahead of time or buy them in bulk. This eliminates the need to order parts and wait for them to arrive in a scenario where you need them urgently.

Keep Accurate Records

Maintain accurate records of machine activity and repairs. Keeping this information will help track machine usage history over time and calculate how frequently you need to service various components. Many computerized maintenance management systems are available to store these records efficiently.

Plug-and-play Machine Connectivity

The Advantages of Routine Maintenance for CNC Machine Tools

Following the recommended maintenance procedures for CNC equipment helps ensure better quality control, longer machine life, and improved productivity. This is especially important for companies that rely heavily on their CNC machine for production. The following are a few of the main ways you can use routine maintenance to your benefit:

- Reduce downtime - Necessary machine repairs can take away valuable machine time. Regular maintenance procedures can be scheduled for a time convenient for you and will reduce unexpected downtime later.

- Improve tool life - By performing proper inspections and timely part replacements, you can significantly extend the machine's life.

- Maintain your investment - Your CNC machine tool is a significant financial investment; proper care will ensure that it stays in top working condition.

- Increase quality - Regular machine maintenance helps reduce scrap rates and improves overall product quality.

The Move from Preventive to Predictive Maintenance

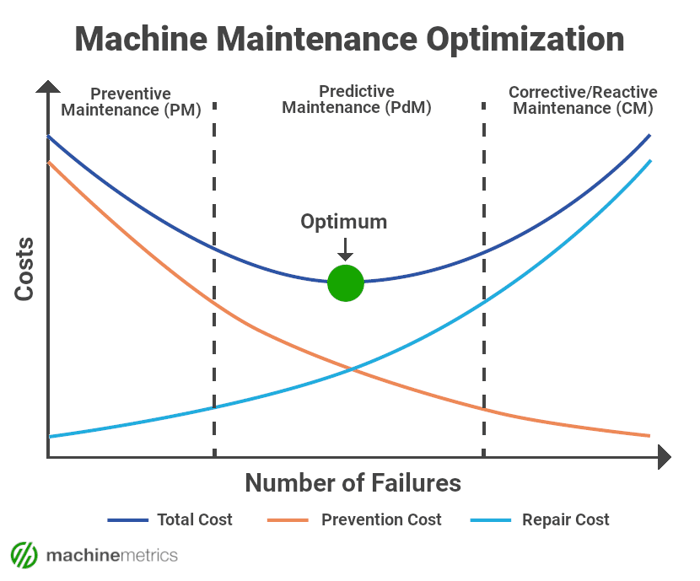

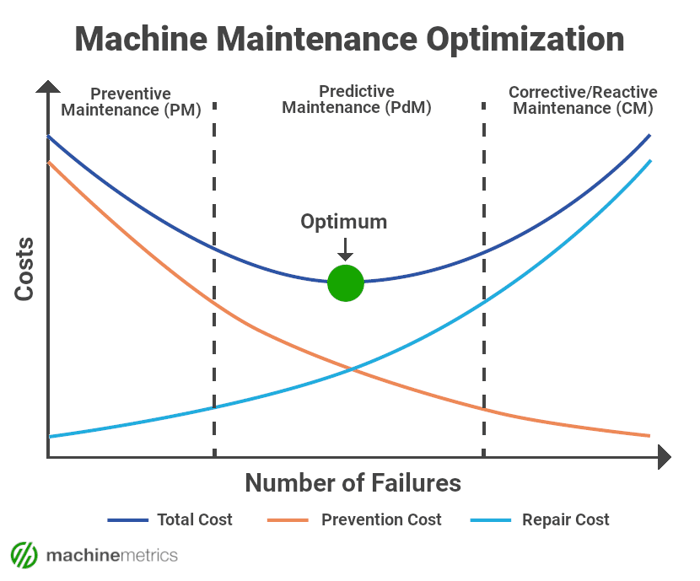

There are a number of different approaches that can be taken to maintain or take care of your machines. Preventive, two-times-a-year planned maintenance usually identifies issues before they happen, but doesn't help when there is an unexpected breakdown. On the other hand, predictive maintenance uses technology to monitor machine health and lets you know when something is about to go wrong so you can take steps to avoid downtime. The difference between preventive and predictive maintenance is significant in terms of cost savings and customer satisfaction.

For important assets, predictive maintenance is preferable over preventive maintenance. Proper use of is necessary to achieve the maximum benefit of predictive maintenance. With condition-based CNC machine monitoring, technicians monitor machine performance to predict which parts need servicing before they fail. Some examples of predictive maintenance include:

- Placing sensors on rotating equipment to detect when bearings are getting close to failure. When an issue is detected, lubricant can be added or the bearing can be replaced before it fails completely.

- Placing sensors on motors and other electrical equipment to ensure they are receiving sufficient ventilation and cooling. Heat buildup in these components will cause them to fail earlier than expected.

- Using wireless monitoring systems that send machine condition updates to technicians' smartphones or tablets. This provides instant information about machine conditions rather than limiting information to regularly scheduled maintenance times. This makes it easier to promptly schedule repairs and replacements, resulting in less downtime for your business.

Predictive maintenance results in fewer unnecessary repairs, which means less wasted time and money, resulting in higher profitability for your company.

Summary

CNC machine maintenance must be done consistently to achieve desired results and avoid performance issues.

Be sure to invest time and effort into preventive or predictive maintenance to keep your machine running smoothly. If you're unsure where to begin, consider hiring a third-party company that provides CNC services, repairs, and training.

MachineMetrics monitoring solution provides real-time analytics to enhance performance and productivity. As a global industry leader in predictive maintenance software for machine tools, we work with leading manufacturers to reduce costs, increase productivity, and prevent unplanned downtime. Reach out to our team today for a demo or more information.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments