Key Takeaways:

- Manufacturing in Industry 4.0 is surrounded by myths, such as automation replacing all jobs.

- The reality is that smart technologies enhance human roles, not eliminate them.

- Dispelling these myths helps companies adapt to Industry 4.0 more effectively.

The fourth industrial revolution is upon us, and as you may know, this means change. As an industry, it is imperative that manufacturers adopt new technologies and increased connectivity that will enable more data-driven decisions. Thankfully, this also means increased efficiency, more parts produced, more accurate bidding, happier customers and increased revenue.

Bringing these known required changes into reality can seem overwhelming, expensive and potentially insecure. Lack of information and fear surrounding change have surfaced industry wide myths that we have heard in our conversations with manufacturers in all verticals. These misconceptions and lack of information can hinder implementation of new solutions, leaving you behind the times. To help demystify Industry 4.0 and make it even more accessible, we have busted a few myths of manufacturing during Industry 4.0 for you.

Myth 1: Industry 4.0 will increase unemployment rates

Industry 4.0 includes technologies and artificial intelligence that will potentially allow manufacturers to move towards “lights out manufacturing,” where jobs can run without the presence of employees or staff on site. Surprisingly, this is not hypothesized to lead to increased unemployment rates.

As a matter of fact, Industry 4.0 will create jobs not eliminate them, and not only that; with technology that can take over the repetitive tasks, the jobs that will result will be different positions, more in the technology and data analytics vein, attracting different candidates to your shop floor and encouraging skill development of current employees. Overall, we see the technological progression of manufacturing as a positive.

Myth 2: IIoT cannot be secure

There is no doubt that IIoT can create issues and concerns regarding security. However, these issues are less about the cloud and more about implementing best security practices within your staff and organization to ensure your data is safe. Cloud-based solutions can, in fact, be safe and secure. For example, partnering with AWS includes benefits that create security for manufacturers utilizing cloud-based technologies. The AWS infrastructure puts strong safeguards in place to help protect customer privacy, and all data is stored in highly secure AWS data centers. Cloud-based solutions are best implemented alongside strategic internal security measures and employee training, as most security incidents result from inadequacies on a business level.

A quote from Richard Crowley, Director of Operations at Slack, best summarizes our feelings toward AWS and security: “The fact that we can rely on the AWS security posture to boost our own security is really important for our business. AWS does a much better job at security than we could ever do running a cage in a data center.” Security plus all of the other benefits the cloud offers make for an amazing manufacturing analytics solution. Read more from MachineMetrics on security here.

Myth 3: Industrial IoT solutions cost too much

IoT solutions actually save and make you money. One of our customers, Carolina Precision Manufacturing saved $1.5 million in the first year using machine monitoring. Another customer, Decker Machine Works, was able to completely eliminate their third shift and maintain production levels.

So how can machine monitoring have these huge impacts?

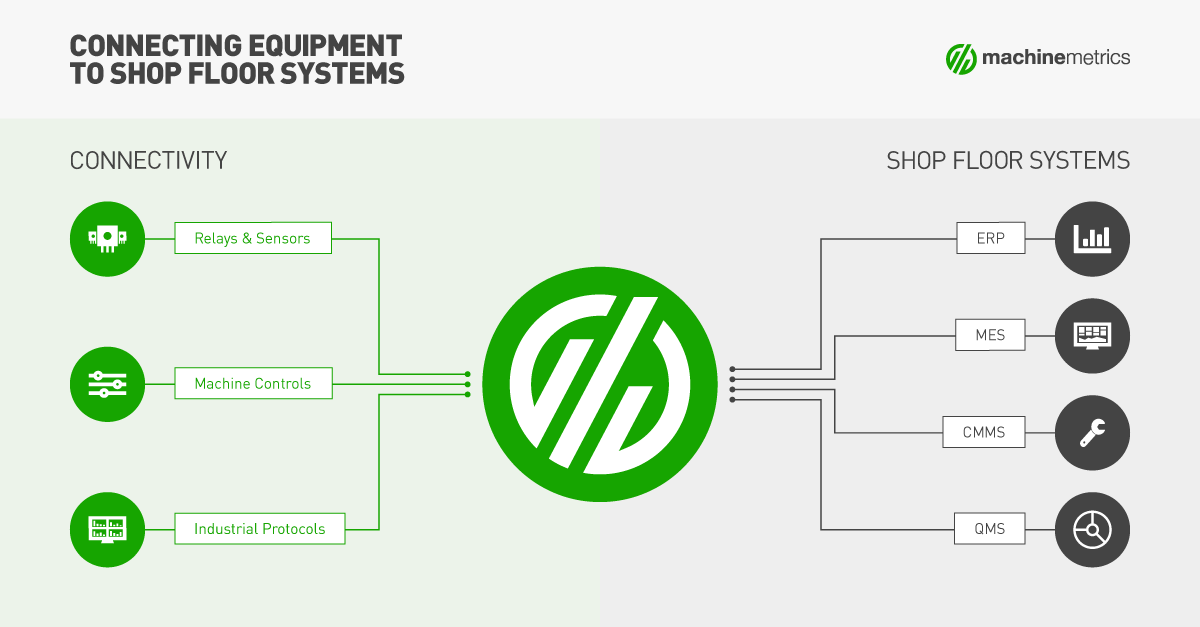

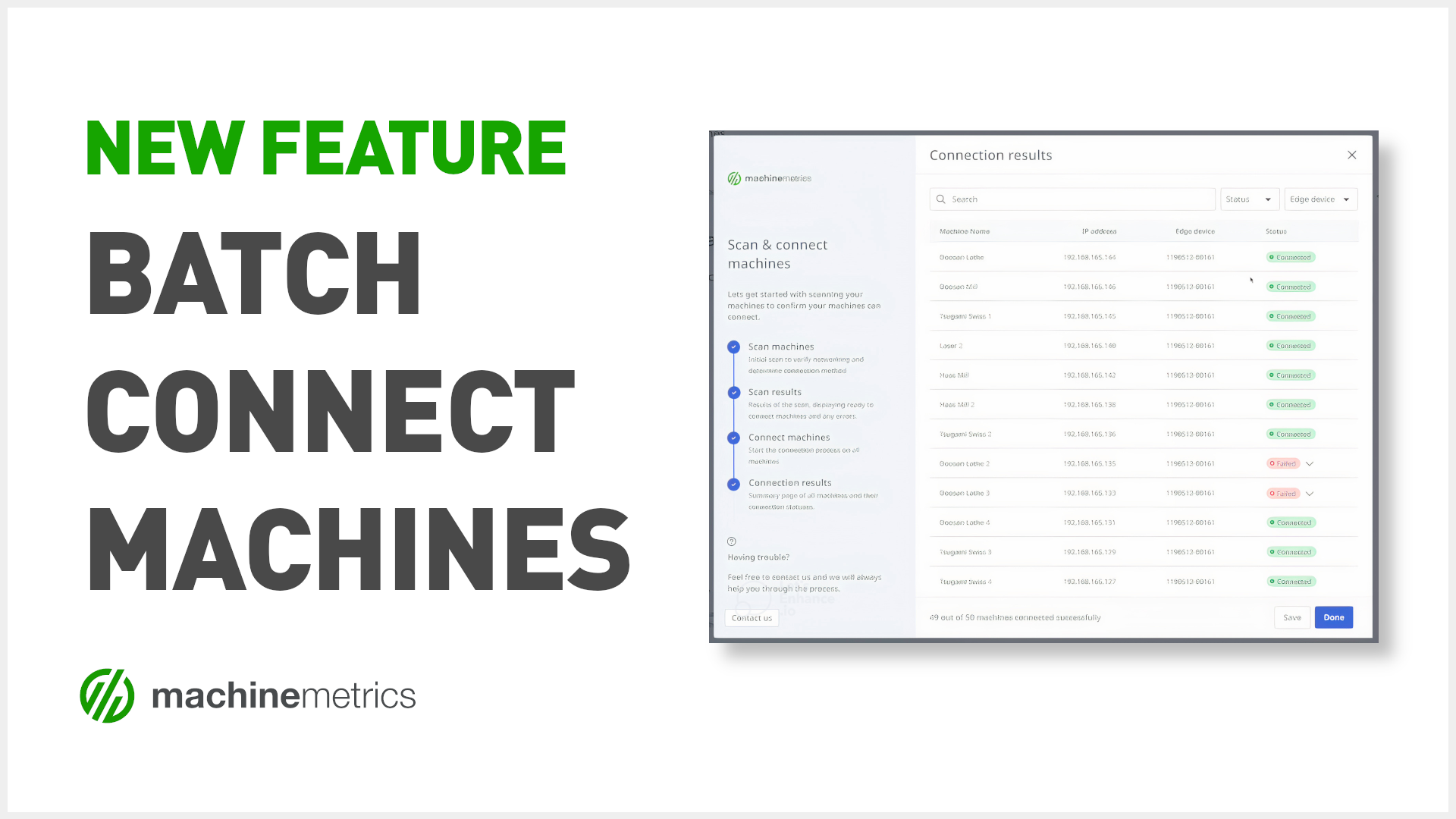

Machines on a shop floor are already generating data that can be captured by relatively inexpensive IoT edge devices. With new technologies, ease of connectivity is increasing, even for legacy machines. By tapping into the data your machines produce with these inexpensive devices, you immediately gain access to insights and real-time data right from your shop floor like never before. The financial impact that those insights can have on your business much exceed the low cost of out of the box IoT solutions available.

To really hammer this point home, when Harley-Davidson began leveraging factory data through analytics, it was able to lower new order production from 21 days to six hours resulting in a $200 million annual savings. Likewise, Hershey was able to realize up to $500,000 in savings for every one percent in improved efficiencies for its operations when it added data analysis to its operation. If we are talking risk versus reward here, it is a given that your financial gain will outweigh this up-front investment.

Myth 4: IIoT solutions are not for job shops

If anyone needs connectivity and real-time analytics, it is small job shops. With the industry moving toward digitization, the competitive advantage will be held by those factories and shops that choose to embrace technology and stay ahead of the curve. Currently, a digital factory is not the norm, but one day it will be, and those that do not embrace the change could suffer, especially small job shops.

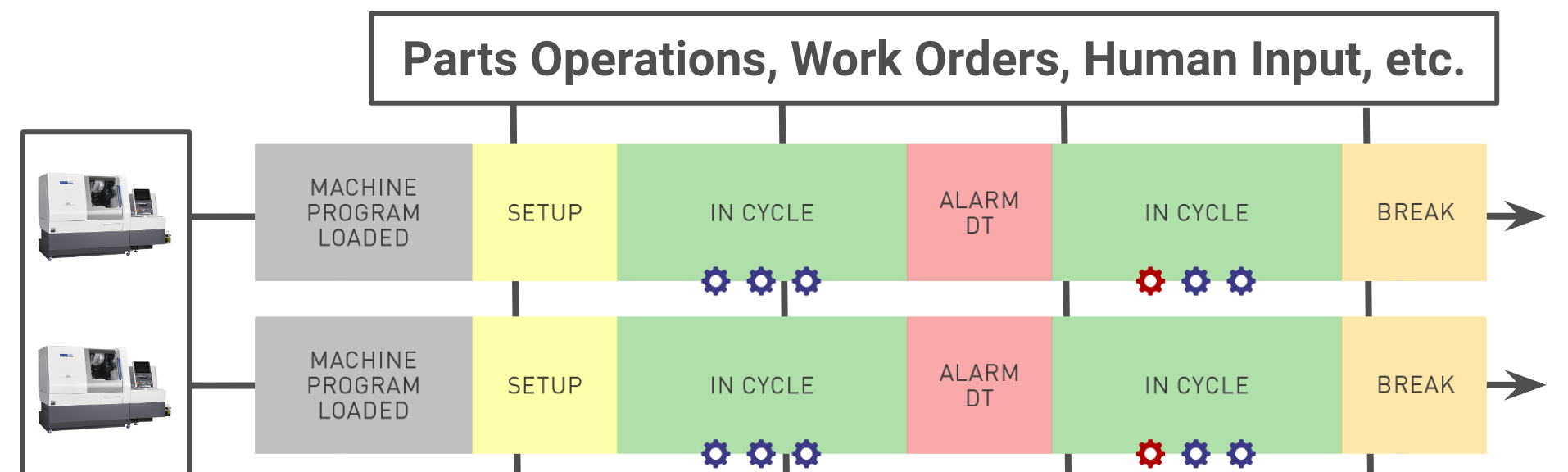

IIoT is for large manufacturers as well as smaller job shops. It is estimated that in modern manufacturing equipment, digital logs from a single machine can produce up to 5 GB of data per week. This data, for one, allows more accurate bidding on jobs. Testing the actual cycle times on parts against expected cycle times in your ERP can reveal inaccuracies that could lead to a more accurate and competitive bidding process. Although some solutions require a minimum number of machines, the industrial revolution is a movement that can empower a shop of any size.

Myth 5: IIoT only improves OEE

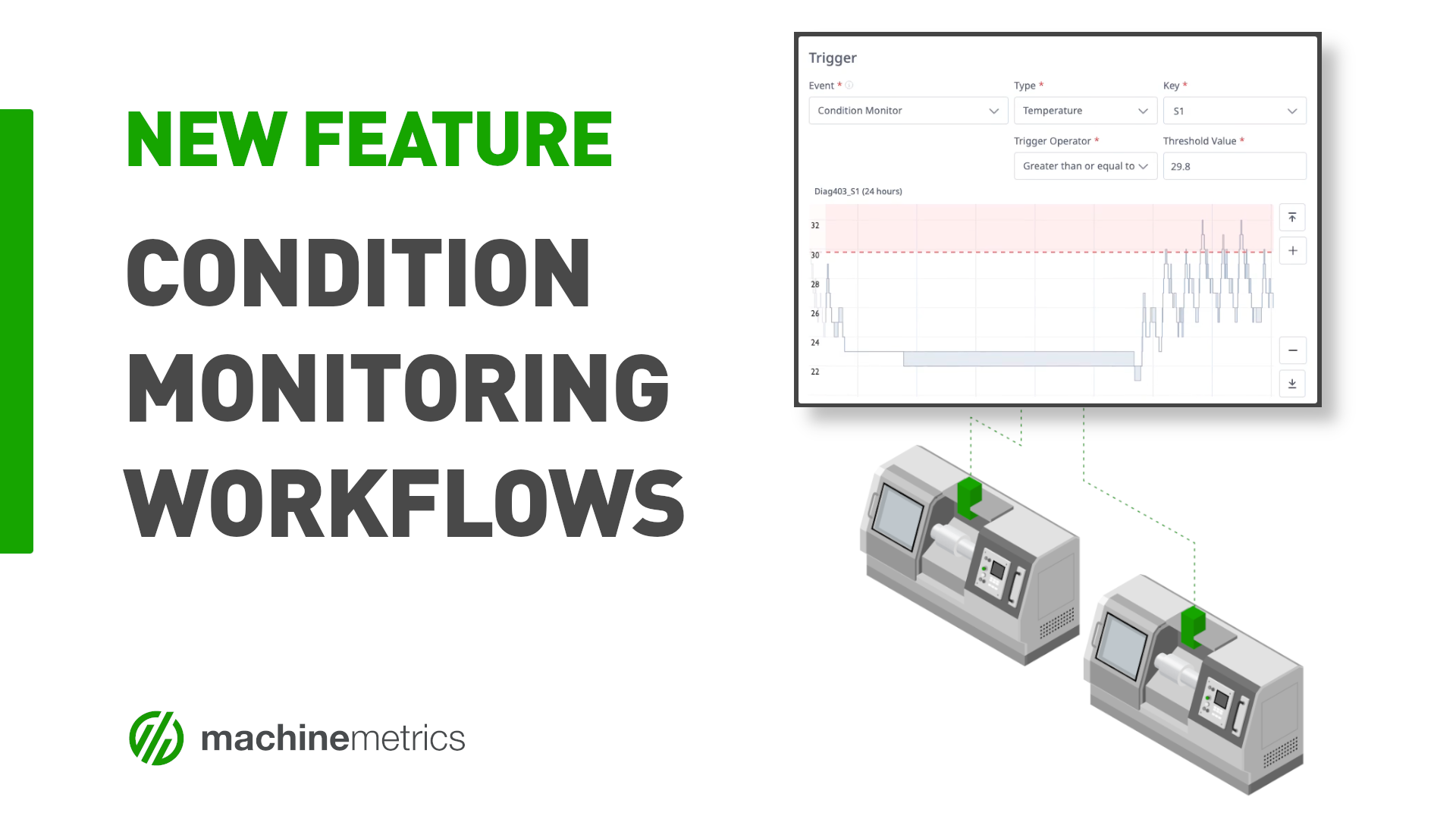

For while it is a useful metric in the production process, OEE is best thought of as one tool in an overall suite of metrics that will allow a comprehensive view of a manufacturing operation. Because of its specificity to manufacturing, OEE is limited in its utility for assessing the impact of other variables as it is disconnected from other upstream and downstream KPIs outside of manufacturing. Variables such as supply chain, inventory management and seasonal disruptions are often tracked with other software or manually through other means at the enterprise level. As a result, these may show up as an improvement or a drop in OEE that is unrelated to ongoing manufacturing improvements.

The ability to visualize production in a mix of metrics can allow companies to act on the realities that affect the entire enterprise. Coupled with OEE, the broader understanding of performance for metrics such as OOE and TEEP will allow better labor and shift planning, training and management at a local level while empowering high level managers with tools to understand manufacturing performance at the global level for issues such as supply chain and capex planning.

So, while these myths expose valid concerns about factory digitization, the truth is, with the right plan and strategy in place, rolling out and executing an IoT implementation can provide secure data aggregation, visibility, growth and even jobs while saving you money, time and uncertainty.

Getting past the myths that surround Industry 4.0 will expose the true benefits that these solutions offer. Through ease of connectivity and a customer success staff that has direct industry experience, MachineMetrics has been able to help hundreds of companies, each on their own unique path to a smart factory set up, overcome these myths and move toward better production processes and a competitive advantage.

Feeling more confident about Industry 4.0?

Contact MachineMetrics to learn the best way to get started

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments