Machine Downtime Tracking Software

Maximize capacity with production downtime tracking powered by real-time machine data.

Use out-of-the-box dashboards and visual reports as well as automated alerts to resolve downtimes and machine failure fast.

Plus, track other key metrics including machine utilization, OEE part counts, and more, all in a plug-and-play solution.

Benefits of Automated Downtime Tracking

Know exactly when machines are falling behind production goals and enable instant notifications whenever equipment downtime occurs. Give your operators and managers the tools to make better, faster decisions with downtime dashboards and reports.

How MachineMetrics Eliminates Downtime Fast

Connect Machines Quickly and Easily

Begin collecting machine data in a matter of minutes. Connect via MTConnect or OPC UA, as well as directly to CNC machine controls. For older equipment, we can install an inexpensive PLC.

Real-Time Equipment Downtime Tracking

Use real-time machine data to know exactly when equipment is down or falling behind expected performance. Automatically trigger alerts to respond to failures and quality issues to ensure maximum uptime.

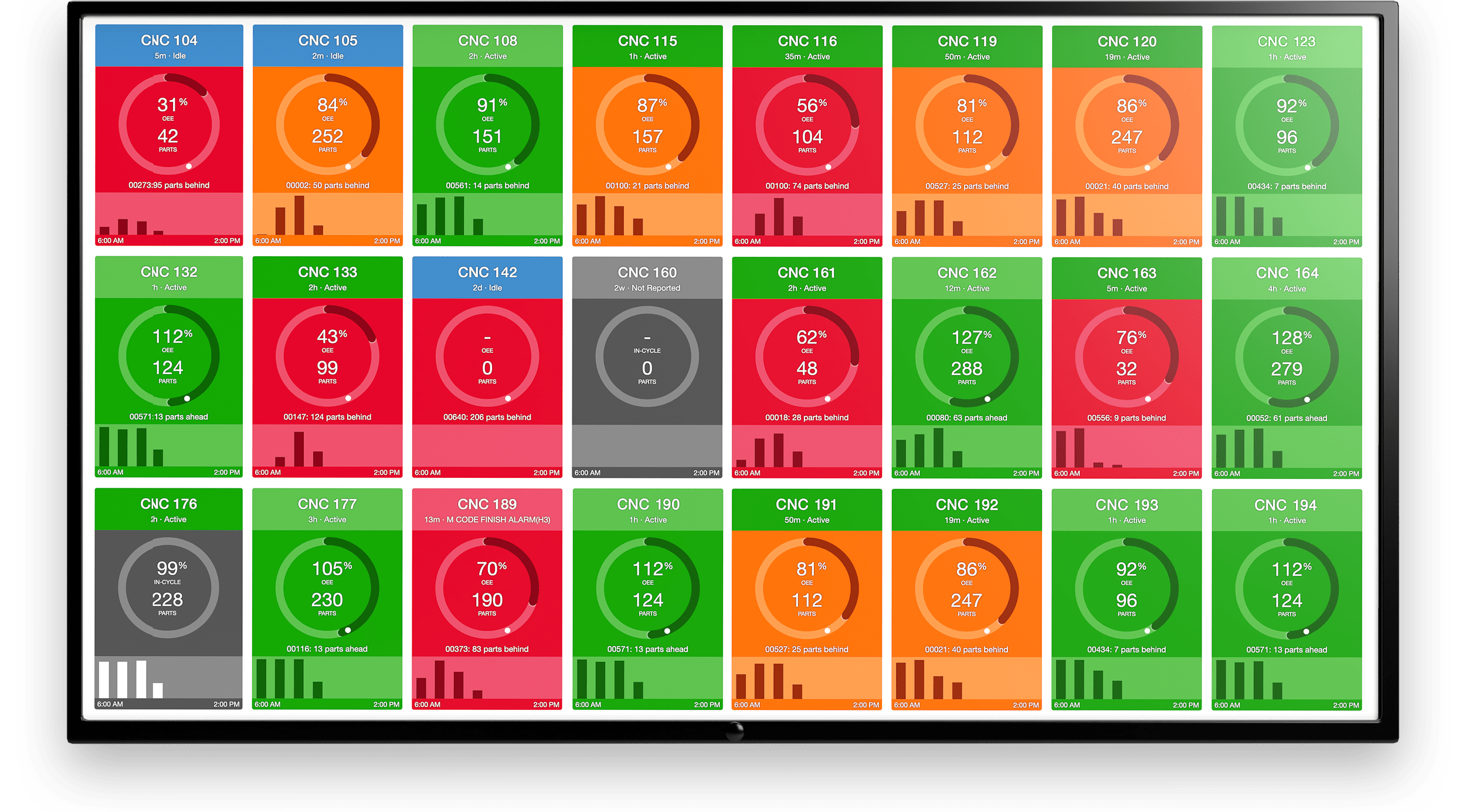

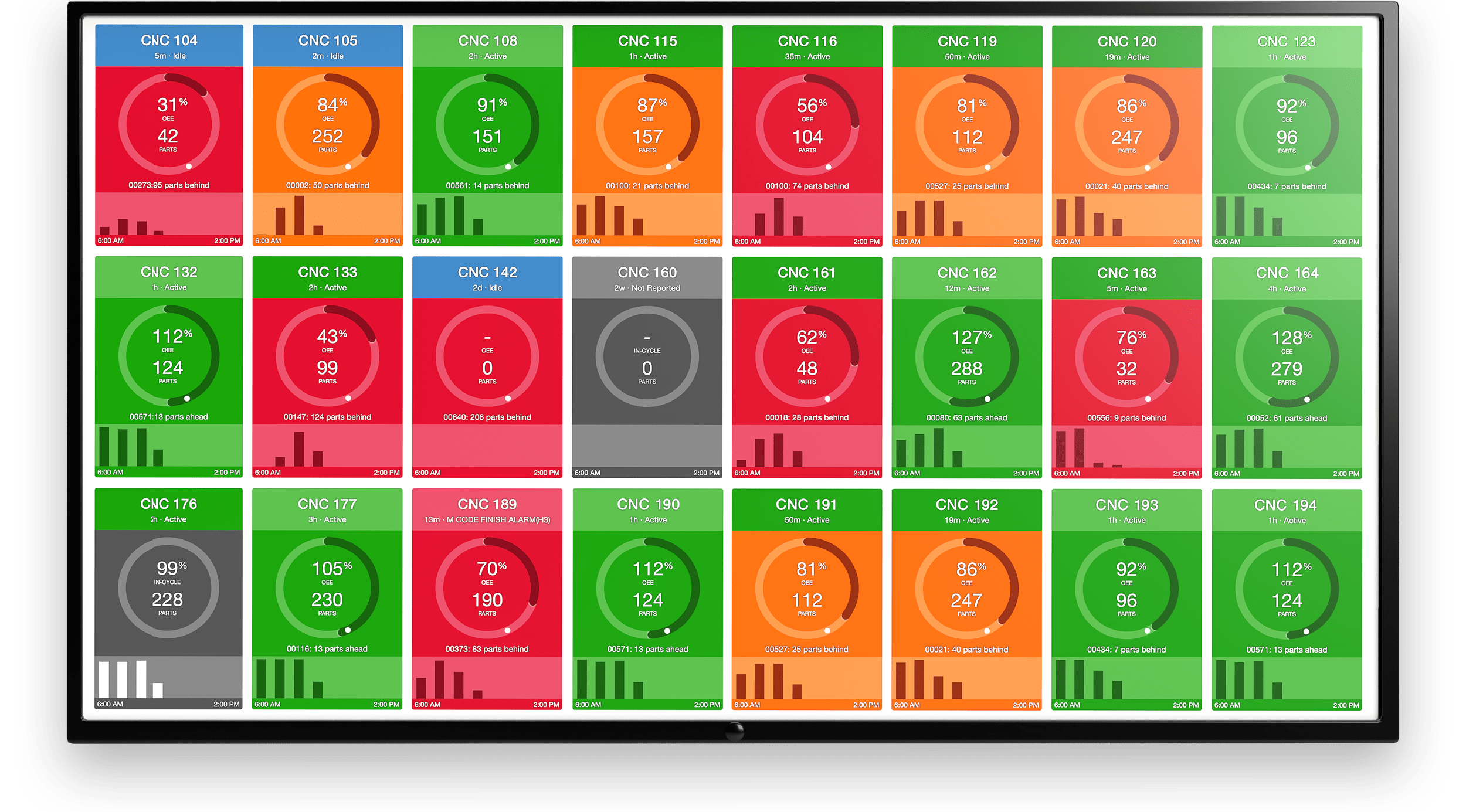

Real-Time Visual Downtime Dashboards

Track machine utilization, part counts, production downtime, OEE, and more in real-time for complete visibility and control of the shop floor. Aggregate historical data to run downtime reports and understand the root cause of problems.

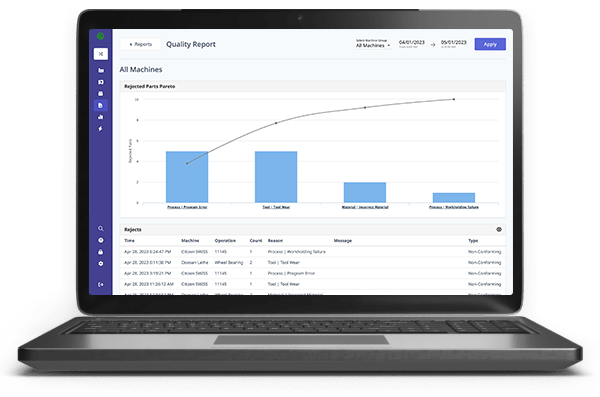

Use Historical Data to Spot Downtime Trends

Leverage out-of-the-box reports to analyze historical data and get to the root cause of your downtime issues. Engage in a machine downtime analysis using Pareto charts, or identify and spot production bottlenecks that are leading to waste.

Request A Demo

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowBook A Demo

Empower every team in your organization with real-time data and insights.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.