Key Takeaways:

- The COVID-19 pandemic highlighted vulnerabilities in supply chains and workforce management in the US manufacturing sector.

- Manufacturers are adopting digital technologies, such as IoT and automation, to mitigate future disruptions.

- The pandemic accelerated the push toward Industry 4.0, with companies investing in smart manufacturing solutions.

The entire world is on edge with the Coronavirus epidemic - we hope it’s not going to turn into a pandemic. The media is stating that U.S. manufacturers are experiencing supply chain issues from China. MachineMetrics is in a unique position to comment on this crisis given it has aggregated anonymous machine utilization data from manufacturers. We’re able to see economic trends in manufacturing from thousands of machines in real-time. Recently, we posted our first 2019 state of the industry report. Reading this report will give you a better idea of how we collect and aggregate data.

Given the significant changes to our economy over the last few weeks, our data science team has been paying particular attention to this data to help understand how manufacturing is being impacted by these events. We plan on posting the results at a greater frequency given the potential global economic impacts this is having.

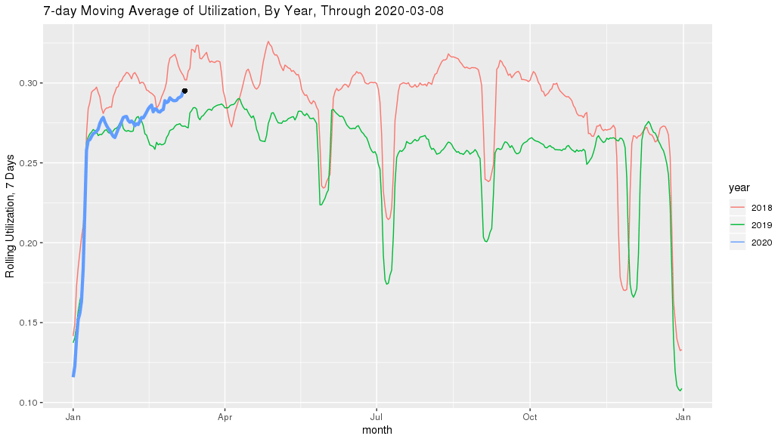

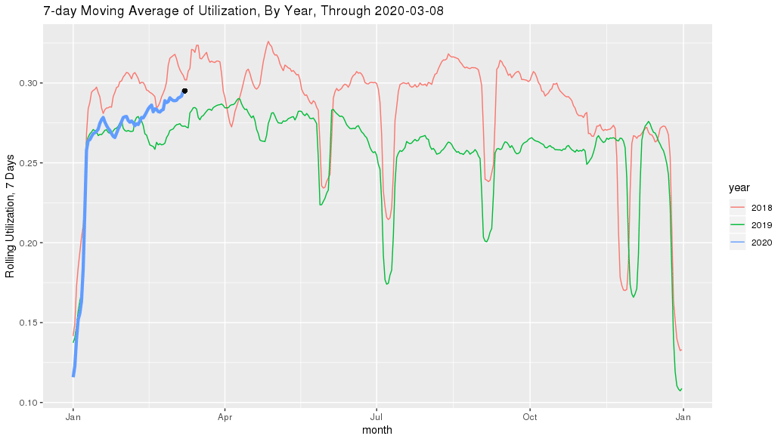

This plot shows 2018, 2019, and 2020 rolling 7-day machine utilization rate:

The green plot represents 2019 and as we can see is significantly lower than the red 2018 plot. The Institute of Supply Management correlates with the MachineMetrics machine utilization data.

2020 has shown a faster ramp-up of machine utilization, which an average utilization rate of nearly 30% for the first week in March, the first time we have seen this since October 2018. This is a great sign of the industry’s performance to date. Supply chain issues and travel restrictions seemingly have not impacted U.S. manufacturing yet. Could the supply chain issues temporarily be boosting U.S. manufacturing output as manufacturers choose domestic sources? Is inventory high enough that the supply chain impact is delayed? The market is certainly afraid of what might happen if supply chain issues do cause a slowdown in production with stocks tumbling over the last 2 weeks, and futures for March 9 looking poor as I write this. When will this impact manufacturing? We will have to just wait and see. Stay tuned for next week’s summary when we post an update. Will the strong U.S. manufacturing performance continue, or will we start to see a slowdown?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments