In the ever-evolving landscape of manufacturing, the ability to monitor and manage operations efficiently has always been pivotal. As market conditions become increasingly competitive and the availability of skilled labor diminishes, manufacturers are compelled to innovate and adapt. This journey from past practices to modern strategies is not just about technological advancements; it's about survival.

The Past: Manual Data Collection and Analysis

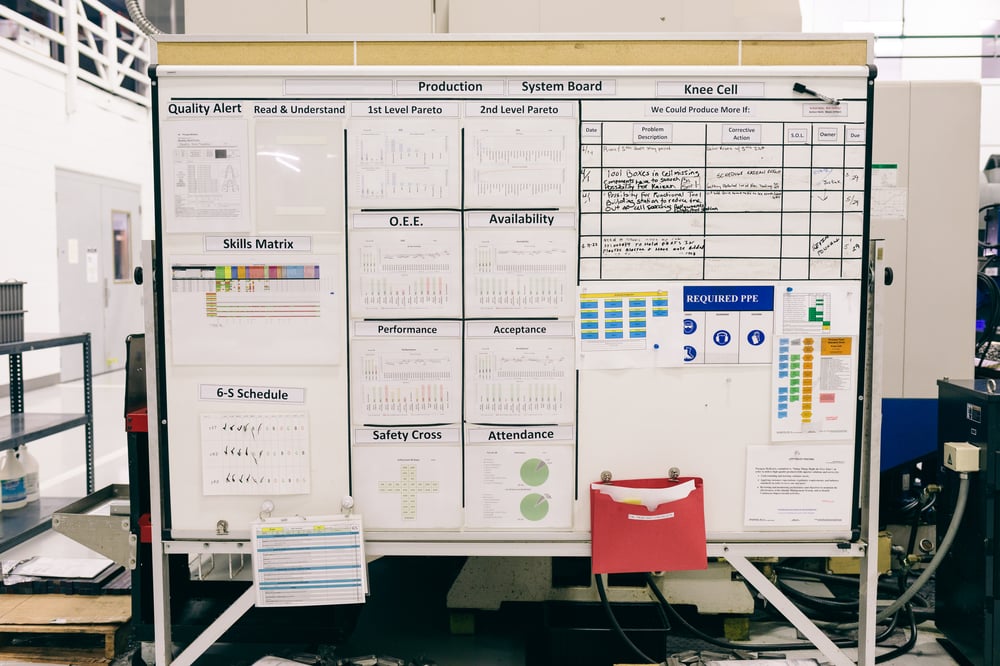

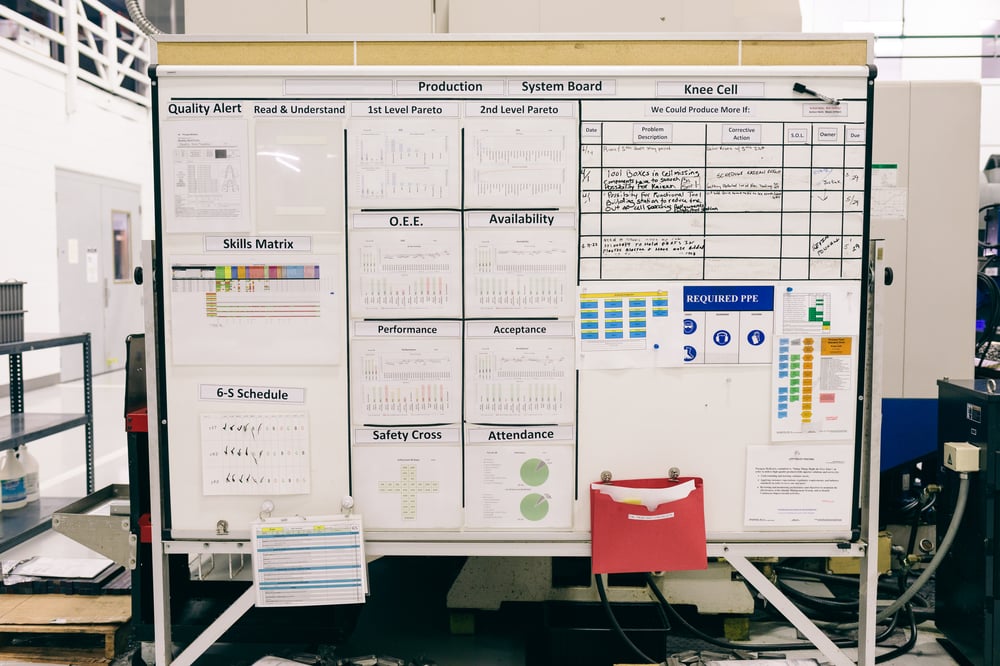

In the early stages of industrial manufacturing, production monitoring was heavily reliant on manual processes. Operators recorded machine performance and operational data using paper-based systems, leading to delayed responses and data inaccuracies.

Legacy systems like MES and ERP, while providing a structured approach to data organization, were rigid and inflexible, often leading to a primitive, material-centric view of operations. This manual, process-driven approach was inefficient, especially in the face of a growing labor crisis.

Many manufacturers continue to operate within this traditional manufacturing mindset. It leaves them with little to no insight into the current status of operations, and a poor set of data to make decisions with.

If everyone on the shop floor does not have basic visibility into production status, how can they make fast, effective decisions?

If everyone on the shop floor does not have basic visibility into production status, how can they make fast, effective decisions?

The Present: Basic Monitoring Solutions

Presently, many manufacturers find themselves trapped between the past and the future. While some have embraced basic digital monitoring tools, these systems often require manual data entry and provide limited operational insights.

This forces operators to do much of the manual work on the front end, capturing and entering data on a daily basis. Further, it tends to cause issues on the back-end when it comes to compiling and analyzing the data.

Manufacturers need more than basic production data. They need deep insight into machine performance and health. Further, this data needs to be presented within the context of the business and the operations.

"Basic" monitoring solutions support basic use cases, but do not offer the digital infrastructure poised to disrupt and drive the business forward.

The Future: Next-Gen Production Monitoring Solutions

The future of production monitoring is set to undergo a transformative shift from basic data aggregation to the generation of actionable insights that support every level of the operation. This evolution represents a significant leap in how manufacturers manage and enhance operational efficiency. And it has already begun.

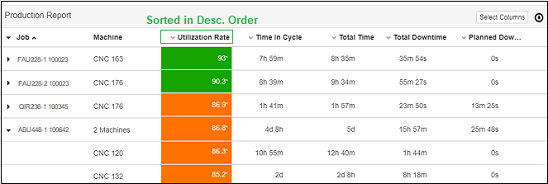

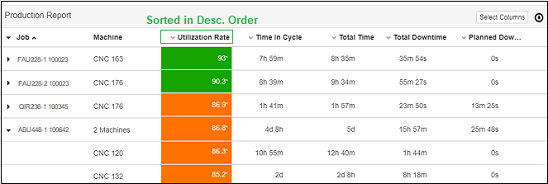

Sophisticated Analytics and Data Utilization

The next era of industrial analytics will be defined by solutions that extract maximum value from machine data. While the market currently offers a plethora of basic solutions—primarily capturing limited data from machinery—there is a growing differentiation at the upper market level. Advanced production analytics platforms are leading this charge. They offer a comprehensive data value chain encompassing deep machine data collection, standardization, contextualization, and insightful analytics. Key business and operational context is intertwined into the data, enabling users to truly understand the performance of each machine, person, job, and part.

Actionable Insights: The Value Beyond Data Itself

The future lies in not just collecting data but transforming it into actionable insights. This shift is critical, as raw data alone is insufficient for effective decision-making. What is essential is the contextualization of this data: understanding when and how machinery operates, who operates it, and under what specific conditions. This information is crucial for bridging the gap between Information Technology (IT) and Operational Technology (OT), ensuring that data is not only collected but also effectively integrated into operational and business processes.

Predictive and Prescriptive Analytics

MachineMetrics is at the forefront of this evolution, turning production data into critical insights at various operational levels. The trend is towards predictive and prescriptive analytics, where systems not only report what has happened but also predict future outcomes and prescribe actions for improvement. This approach is about getting ahead of problems before they occur and optimizing operations in real-time.

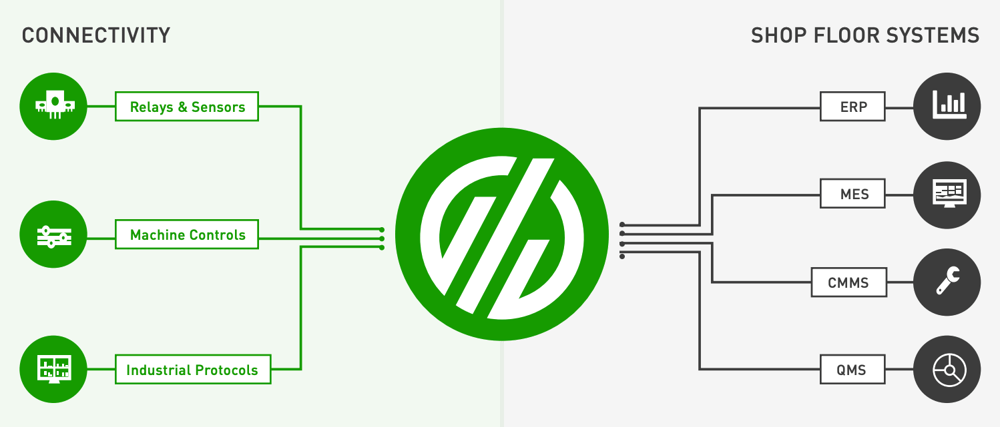

Integration and Interoperability in Specialized Software Systems

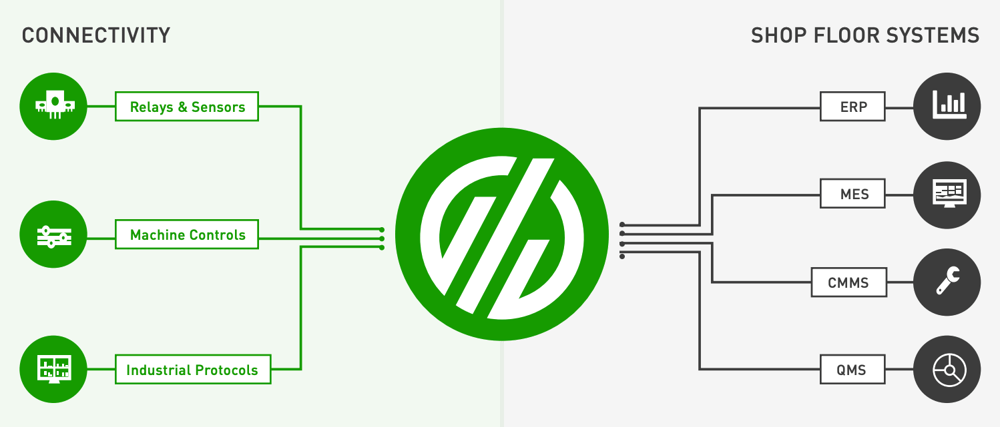

Despite the persistence of ERP and other enterprise systems, there is a noticeable trend towards the proliferation of specialized software solutions for distinct manufacturing functions like maintenance, quality, inventory, and quoting. These specialized systems offer capabilities far beyond what generalized management systems can provide.

The goal is to create a connected factory ecosystem where these specialized solutions work cohesively, supported by seamless vertical and horizontal integrations. Solutions like MachineMetrics, with their extensive pre-built integrations and open API, are pivotal in making these integrations more effective and efficient. The ability to enable bi-directional data flow between systems, especially between ERP and shop floor systems, is fundamental in realizing the full potential of a connected factory.

Driving Insights and Answers with Data

The evolution from manual, process-driven systems to connected, machine-driven solutions reflects the broader transformation in manufacturing. The future lies in unlocking production data at the shop floor level, allowing it to inform and drive technology stacks and associated processes. As manufacturers navigate this transition, the adoption of interconnected, intelligent monitoring solutions will be crucial for optimizing operations and maintaining competitiveness in a rapidly evolving global market.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments