Digital transformation has become a necessity for manufacturers aiming to compete in an increasingly complex and fast-paced global market. However, the journey to achieving a fully integrated, data-driven operation has proven far more challenging than expected. A 2020 McKinsey & Company study revealed that 70% of digital transformation initiatives fail to meet their goals, underscoring the difficulty of connecting factory operations with business systems like ERP.

For decades, Manufacturing Execution Systems (MES) have been seen as the answer to this challenge. Yet, traditional MES solutions repeatedly fall short due to:

- Excessive manual data entry, which creates inefficiencies.

- Over-ambition, as they try to solve every problem but master none.

- Prolonged implementations, which take too long to deliver value.

- High maintenance demands, making them costly and cumbersome.

These shortcomings have forced many manufacturers to consider building their own MES solutions tailored to their specific needs. While the allure of customization is strong, the reality is that building an MES from scratch is a costly, time-consuming endeavor that is rarely sustainable. Instead, the optimal approach is to buy the core functionalities of an MES and build additional use cases using a configurable, easy-to-integrate platform.

Why Traditional MES Solutions Fail

- Lack of Accurate, Real-Time Data: While MES Systems have data collection capabilities, they generally rely on people. As a result, the data is biased, inaccurate, delayed, or simply omitted. This means that all the functions that an MES is meant to manage are thus executed with a poor source of information, resulting in processes that cannot be optimized.

- Lack of Customization and Flexibility: By attempting to do everything, MES often doesn’t do anything well. The general, off-the-shelf systems are unable to meet the specific needs of manufacturers, especially within discrete industries. The result is a management system that cannot adapt to the systems it is intended to manage. This often forces manufacturers to rely on system integrators or expensive in-house technical teams to customize their system.

- Prolonged Time to Value: Whether building from the ground up or selecting a solution off the shelf, delivering a solution that drives ROI is incredibly difficult. IDC's Manufacturing Insights highlighted that traditional MES implementations often take 12 to 24 months to deploy, significantly delaying ROI.

- Excessive Maintenance Needs: Over time the wants and needs of an organization will change. Updating software, adding (or building) modules, scaling to new facilities, adding customization, and other initiatives will put pressure on a fragile legacy or DIY solution.

A New Paradigm: Unified Namespace and Modular MES

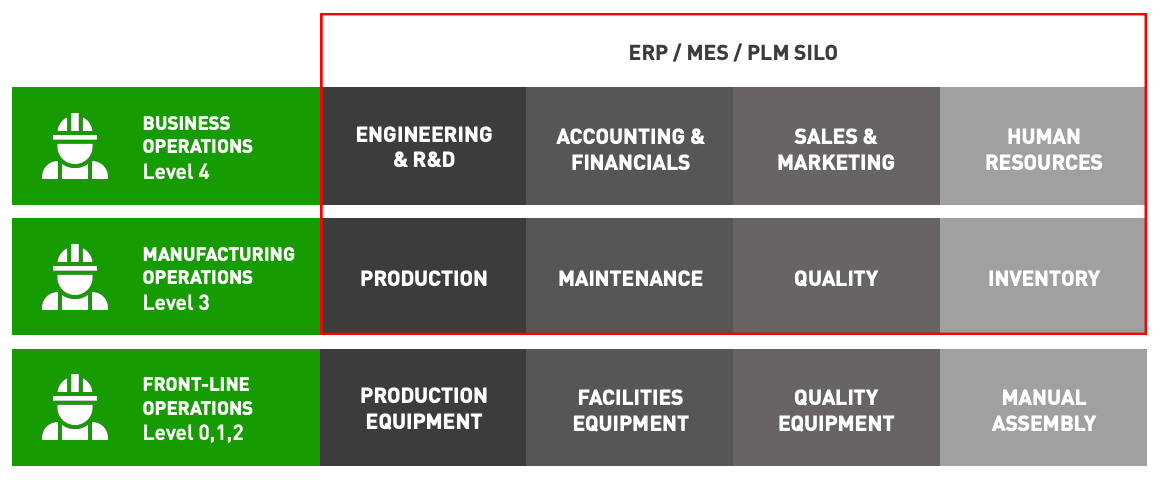

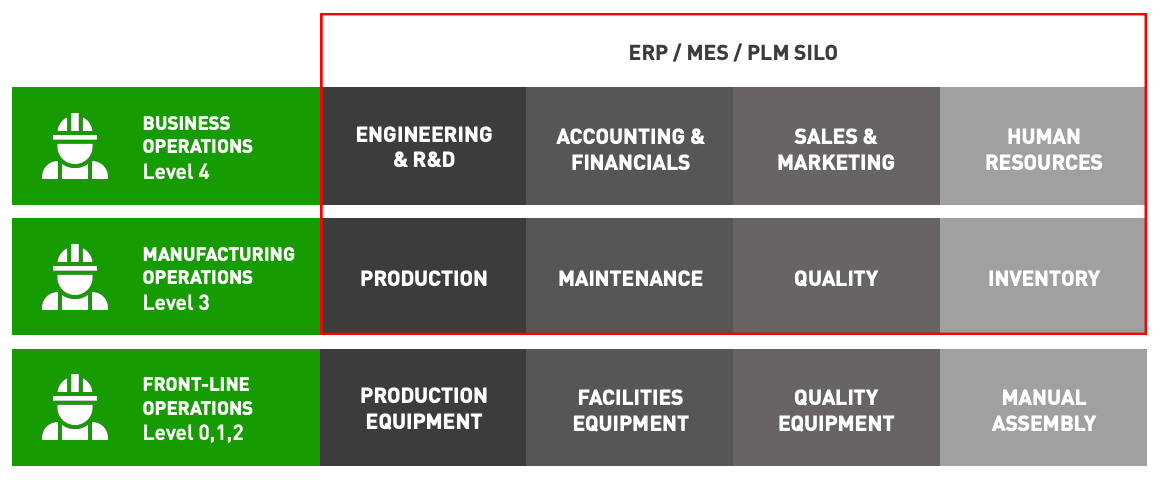

The traditional ISA95 model, which has long dictated manufacturing architecture, is being disrupted by the rise of the Unified Namespace (UNS). UNS provides a framework for seamless, real-time communication across systems, enabling manufacturers to escape the rigidity of legacy architectures. This evolution allows for a new approach to MES—one that focuses on modularity, real-time integration, and configurability.

Whether a manufacturer is pursuing a tech stack focused on the legacy architecture of ISA-95 or attempting to develop a UNS, leveraging the Core Four approach to MES can be a good decision.

The MachineMetrics Approach: Buy Core, Build Smart

There has been an ongoing paradigm shift in how manufacturers oversee and optimize their production processes. There is no longer the dilemma of selecting between an off-the-shelf system that does everything poorly or a DIY MES system that breaks the bank.

At MachineMetrics, we believe the best path forward is to buy the core four MES functionalities -leveraging a scalable, real-time data platform - and build or compose additional use cases to meet specific needs. Our solution focuses on enabling manufacturers to achieve their goals quickly and sustainably by addressing the most critical jobs to be done.

- Overall Equipment Effectiveness (OEE): Gain insights into your machinery's performance, identifying improvement areas to enhance efficiency.

- Downtime Tracking: Address downtime with detailed analysis, enabling process improvements to reduce and eliminate unplanned downtime events.

- Work Order Management: Optimize WIP management with real-time production data tied to every operation and work order.

- Scheduling: Build schedules based on past performance. Adapt schedules dynamically, optimizing resources and meeting production demands when plans change.

Why This Approach Works

- Faster Time to Value: By providing pre-built, integrated core functionalities, MachineMetrics eliminates the need for lengthy customizations, allowing manufacturers to realize value in months, not years.

- Configurability Without Complexity: MachineMetrics empowers teams to build additional use cases using an intuitive, no-code platform. This reduces the need for IT intervention and lowers the overall cost of ownership.

- Alignment Between Machines and ERP: By focusing on real-time data integration, our platform ensures that factory operations are seamlessly connected to business systems, driving better decision-making across every level of production.

- Reduction in Manual Work: Automation of data collection and workflows reduces the burden on employees, allowing them to focus on higher-value tasks and cover more ground.

Embracing the Future of MES

Building an MES from scratch may seem like a path to ultimate customization, but it’s a costly and unsustainable strategy for most manufacturers. By purchasing the core functionalities of an MES and leveraging a platform like MachineMetrics for additional use cases, manufacturers can achieve digital transformation faster, more efficiently, and with less risk.

At MachineMetrics, we’re not just providing a better solution for MES - we’re enabling the future of real-time, data-driven manufacturing. With universal machine connectivity, seamless ERP integration, and configurable, no-code workflows, we help manufacturers bridge the gap between their factory floors and core business systems.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments