Manufacturers need a sound strategy to compete, and that strategy must have a solid foundation in truth; knowing exactly what is happening across the operation. So few manufacturers have this source of truth to rely on, leaving them with a quasi-truthful stream of information to make decisions with. Ultimately, poor data, or a lack of data altogether, lead to ineffective decisions and missed opportunities.

The State of Data Analytics in Manufacturing

Many companies still do things the traditional way with paper, clipboards, whiteboards, and Excel spreadsheets, even though the drawbacks are well documented. Many companies still rely on their ERP to understand operational performance on a day-to-day basis to fill in the gaps. At worst, valuable time is lost and opportunities for change are missed.

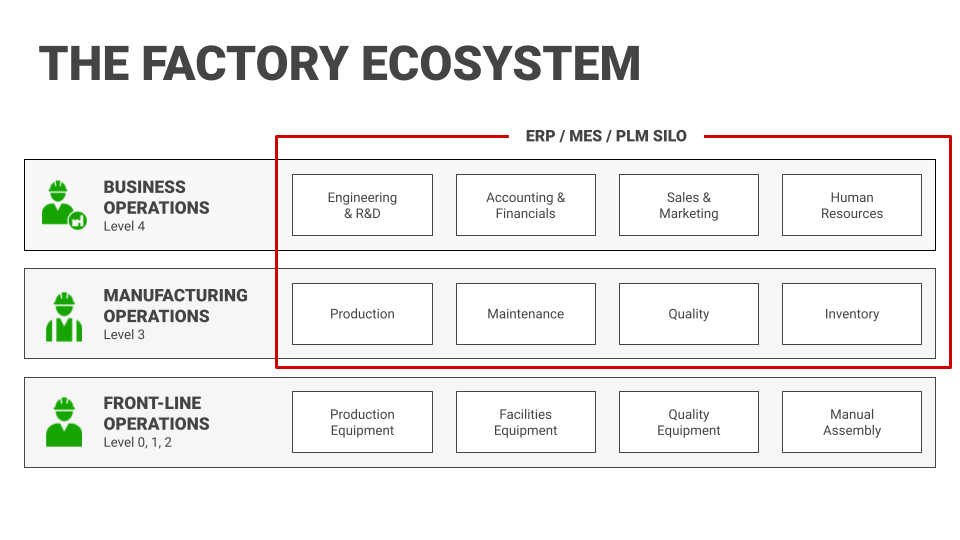

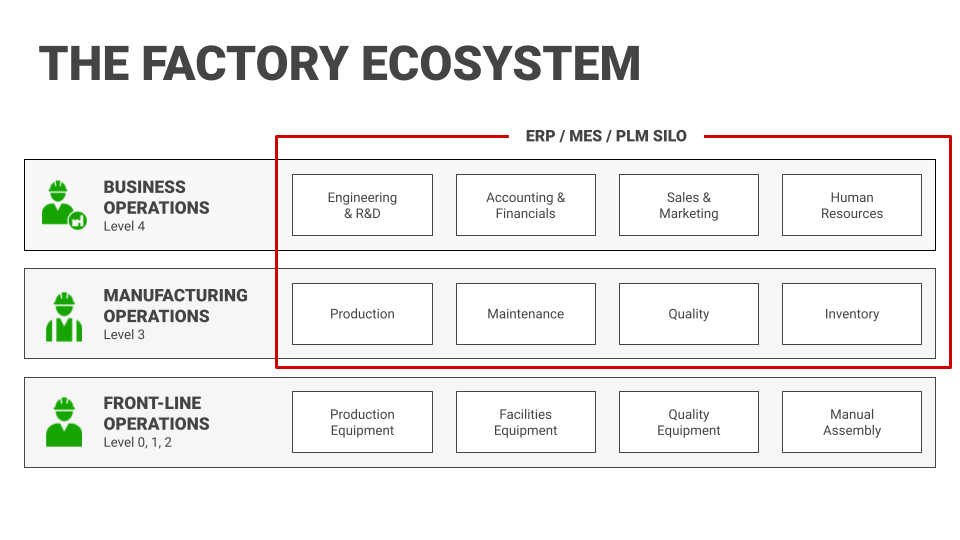

Decision-making is usually decentralized for different departments. Functional areas like finance may have advanced and highly accurate software for performing their tasks. Other departments, like inventory control, may operate from an older system, dependent on manual inputs that must be exported to other systems. Production and quality teams may operate off a hybrid solution with software, minus an update or two, receiving some data automatically while other data must be manually imported.

The siloed state of data between IT and OT continues for many, with IT systems lacking access to shop floor data. Without a data strategy, the bridge between IT and OT will come at the expense of continuous improvement.

The Case for a Data Analytics Strategy

In the above examples, there is no central strategy for data analytics. An overarching strategy is essential for achieving operational efficiency, reducing costs, improving quality, and increasing customer satisfaction.

With a data analytics strategy, manufacturers can gain accurate operational visibility that yields opportunities for immediate and long-term improvement. They can also leverage advanced analytics tools and techniques to identify patterns and anomalies, make data-driven decisions, and optimize processes.

A comprehensive data analytics strategy should encompass data collection, integration, analysis, and visualization while involving cross-functional collaboration across departments.

With a clearly defined strategy, data structure and analysis can be united under one umbrella. Then, software can be deployed to best utilize the real-time insights for each functional area.

The Benefits of a Comprehensive Data Strategy

Implementing a comprehensive data strategy in manufacturing has several benefits:

- Improved Efficiency and Productivity: By analyzing data generated by the manufacturing process, companies can identify bottlenecks and inefficiencies in the production process. This information helps them optimize processes, reduce downtime, and increase productivity.

- Better Decision-Making: With access to real-time data, manufacturers can make informed decisions based on actual data rather than assumptions or intuition. This process leads to better decision-making and more accurate planning.

- Cost Reduction: By identifying and addressing inefficiencies in the manufacturing process, companies can reduce costs and improve their financial performance.

- Quality Improvement: Manufacturers can identify trends and patterns by analyzing data related to product quality. This analysis allows them to make necessary adjustments to production processes to improve product quality.

- Predictive Maintenance: Using data analytics to monitor equipment performance and identify potential issues, companies can implement predictive maintenance to reduce downtime and increase equipment lifespan.

The most significant advantage of a data strategy is the unification of data collection and analysis under a single source of truth to deliver each benefit.

What Does a Comprehensive Strategy Look Like?

The disparate nature of most data analytics systems in traditional manufacturing is due to overlapping and competing architectures. To develop a comprehensive strategy that works across the enterprise, companies must adopt technology that eliminates hierarchies and department-centric systems.

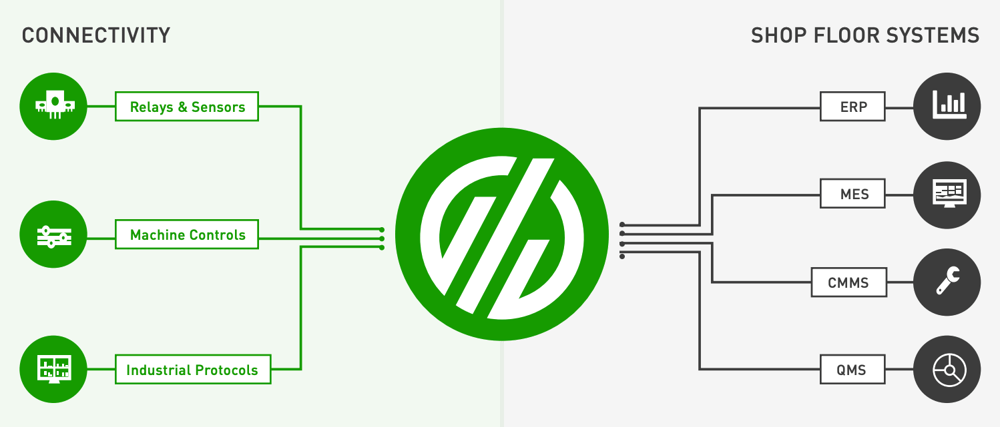

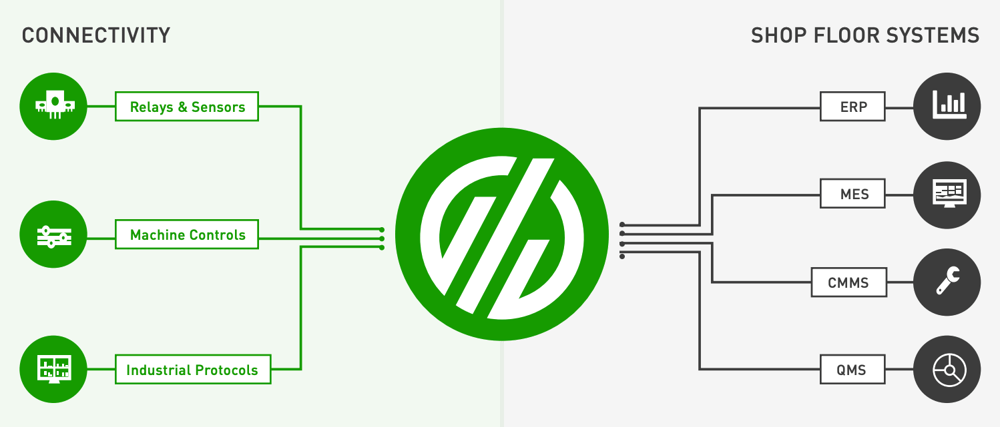

The best way to do this is by focusing on machine connectivity so data can be seamlessly transferred, analyzed, and consumed based on a common data model. In this type of system, shop floor data and enterprise data are part of the same ecosystem and are available for real-time analysis to generate actionable insights.

These systems use dynamic dashboards with customizable views depending on who is accessing the information and what KPIs they need. Executives can consume trends and predictive analysis to develop improvement or long-term plans. Operators can also use the same data to intervene at the machine or spindle level to reduce downtime.

By rooting the strategy entirely in real-time data analytics from fully connected equipment, the enterprise moves from hope to facts based on actual performance.

Picking the Strategy that is Right for You

Developing your strategy requires choosing a provider that speaks to the issues above. You should also look for a system that uses advanced analytics to deliver insights that lead to action, driving better decision-making at the machine, plant, and enterprise level.

MachineMetrics offers the depth and breadth of connectivity to ensure data capture from all equipment, as well as the ability to standardize and contextualize the data. The platform also connects quickly to machine assets so production visibility is immediate. This immediacy empowers continuous improvement by enabling users to leverage their data for more advanced use cases as they identify and solve issues.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments