Key Takeaways:

- Manufacturing analytics powered by IIoT improve customer experience by providing real-time insights into production performance and quality.

- These analytics enable manufacturers to deliver higher-quality products on time, increasing customer satisfaction and loyalty.

- Leveraging data insights allows manufacturers to anticipate and resolve issues before they impact customer outcomes.

In today’s world, consumer tastes change rapidly. Customers expect new product rollouts and new iterations of older product lines more frequently than ever before. In many cases this includes customized versions as well. For service industries such as banking and app based on-demand companies, data has always been easier to capture and analyze compared to traditional manufacturing equipment providers. Historically, manufacturers have utilized an array of different production equipment or a fleet of far-flung equipment in customer locations that often was not connected in any way to gather and analyze data.

Customers at MachineMetrics experience this and have solved the problem by deploying the MachineMetrics Industrial IoT Platform. In conjunction with sensors and edge devices, we have bridged the gap to allow for the realization of a smart, connected factory or a fully connected service provider. By collecting and standardizing data for use by MachineMetrics’ advanced cloud-based computing platform, the value of deep analytics in modern advanced manufacturing is becoming more and more accessible. Manufacturers and service providers are finding that its use allows them to reach further into the customer experience and understand what drives consumer tastes and expectations.

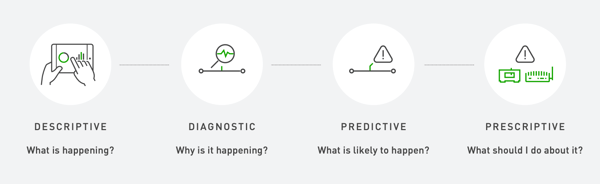

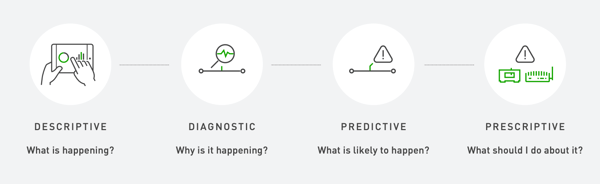

Four Types of Data Analytics Used for Improving the Customer Experience

Thanks to the power of data collection, companies have a vast amount of customer data immediately accessible. This data, when used together, allows manufacturers and service companies to provide an improved customer experience.

- Descriptive Analytics - Descriptive analytics consists of using historical data and analyzing it to determine what happened. By having a store of past customer data, you can easily pull information on customer requests, contact information, who they have been in touch with, and more.

- Diagnostic Analytics - Diagnostic analytics provide an analysis of historical data which is useful in understanding why something happened. For example, diagnostic analytics may help manufacturers identify why a particular customer’s demand for parts suddenly dropped.

- Predictive Analytics - While descriptive and diagnostic analytics focus on the past, predictive analytics focuses on the future. It takes the data and insights provided by descriptive analytics and employs statistics, machine learning, data mining, and simulation to predict what will happen. Predictive analytics helps identify the data that accurately predicts outcomes. A simple example may be that, after running a correlation analysis, you determine that as part quality increases, customer satisfaction does as well.

- Prescriptive Analytics - Prescriptive analytics uses the conclusions and trends identified by descriptive and predictive analytics to recommend a course of action. These outcomes are not singular or linear. There can be multiple outcomes based on the goals and outcomes the company desires to target specific customer needs. Because the outcomes can be determined, companies can adjust their decision-making to provide an improved customer experience for the product.

Improving the Customer Experience with Analytics

Today, customer interaction is multi-channel. Email, call centers, chat programs, and social media are all used to measure and gauge customer experience. But these channels are often siloed and making sense of the data and determining its value across channels is difficult. We’ve seen this many times at MachineMetrics and by using our advanced analytics software, this data can be un-siloed for both manufacturers and service providers.

For manufacturers, this means utilizing the four types of analytics to proactively identify problematic product lines and address them proactively. It can also help manufacturers craft warranty, return, and service procedures that address key concerns of customers up front.

For capital items, consumer electronics, or complicated products such as those with complex engines, motors, or drives, data can continue to be collected in the field once the product is in consumer hands, allowing companies to understand the problems as they occur and develop responses proactively. This is particularly useful for machine builders and OEMs.

For commodity and consumer goods, if customer data shows that demand is low for one model or iteration of a product, predictive analysis can help identify specific defects or defect levels, lot specific issues, or spoilage that drives that abandonment. By knowing this, and by tying it to the data coming through multiple channels, companies can take proactive steps to correct the problem either at the factory level for new lots or through customer outreach to acknowledge the problems and notify them of improvements.

For service providers who provide fleet equipment, MachineMetrics’ solutions allow remote monitoring to improve field service. Techs can diagnose problems in the field in real-time and predict equipment failures before they occur. Through MachineMetrics, customers can prescribe solutions proactively as well as track equipment utilization over time to improve service offerings, identify which vendors’ equipment works best for their business model, and discover opportunities for new products and revenue streams.

Customers are more informed and sophisticated than ever before. And as that sophistication increases, companies must stay ahead of the curve by providing an experience that sets them apart from their competitors. Using the descriptive, diagnostic, predictive, and prescriptive analytics capabilities inherent to cloud based IIoT technology and software gives companies the ability to reduce warranty and return costs and create customized customer experiences. It also allows them to act in real-time to address customer concerns faster than ever before which helps to retain customers and solidify brand reputation.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments