Key Takeaways:

- MachineMetrics provides executives with real-time insights into machine performance and operational efficiency across their enterprises.

- These insights enable better decision-making, allowing executives to optimize production and reduce costs.

- By leveraging data from MachineMetrics, executives can drive strategic growth and ensure alignment with business objectives.

Manufacturing executives are responsible for making prompt, informed decisions to keep their operations running smoothly. They need accurate, real-time data to help them identify areas for improvement, manage risk, and drive performance across the enterprise based on what is happening “now.”

Solutions that leverage machine data to make more informed decisions are rapidly becoming essential components of any successful manufacturing company, with many focusing primarily on shop floor operations and basic data collection.

But what about the executive level? How do factory managers, multi-plant general managers, and C-suite executives leverage this machine data at a higher level?

How are production metrics informing decision-making that truly impacts the bottom line?

Challenges Facing Executives

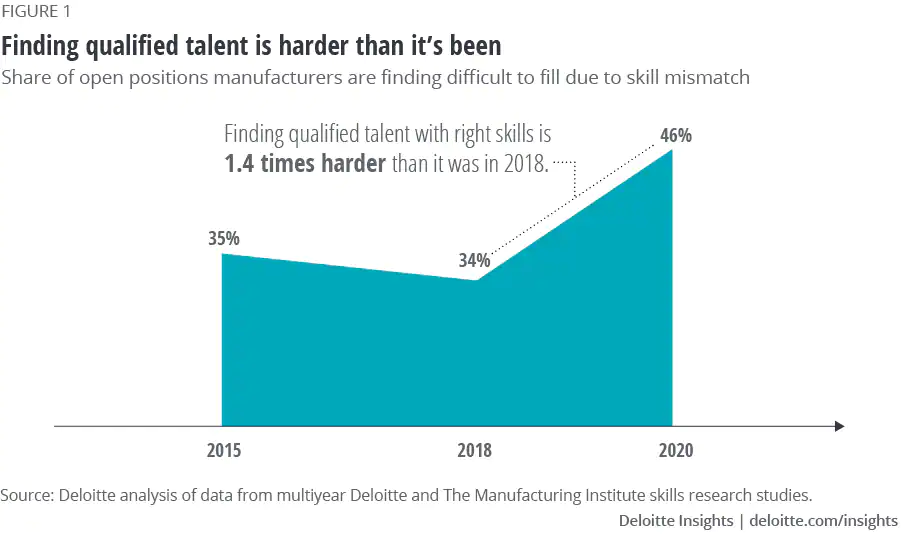

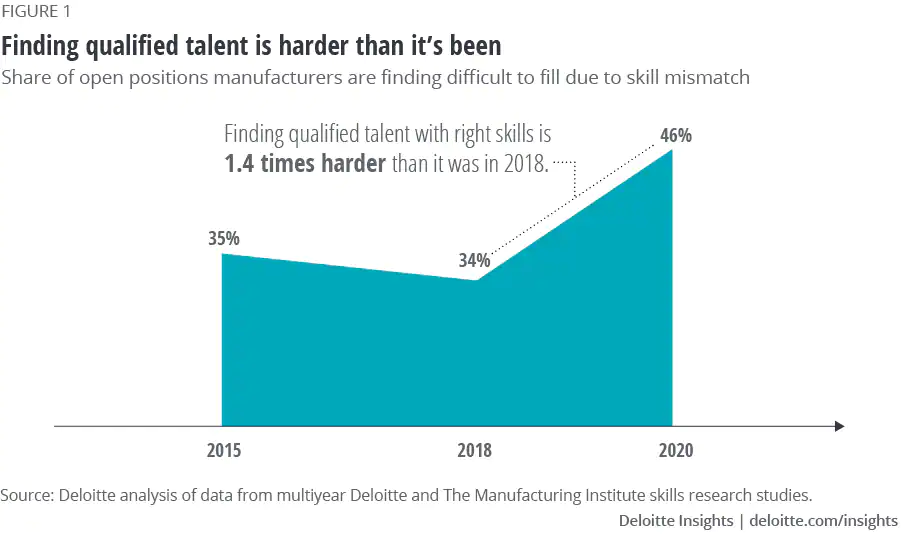

One prevalent and growing issue is the shortage of skilled manufacturing labor. With several generations having sidestepped manufacturing as a career choice, these positions are often left unfilled. And while Industry 4.0 and IIoT solutions reduce the labor needed to run complex manufacturing, there is still a need to train those who take these positions.

Executives have also traditionally struggled with a lack of production visibility. Many manufacturing companies have complex production cycles and lack visibility from machine to machine, department to department, and plant to plant, making decision-making difficult.

A lack of visibility leads to low equipment utilization, as companies can’t optimize processes that they can’t accurately measure. With low overall equipment effectiveness (OEE), much of a machine’s capacity lies hidden under the surface, to the surprise of executives and others.

The Value of Production Monitoring

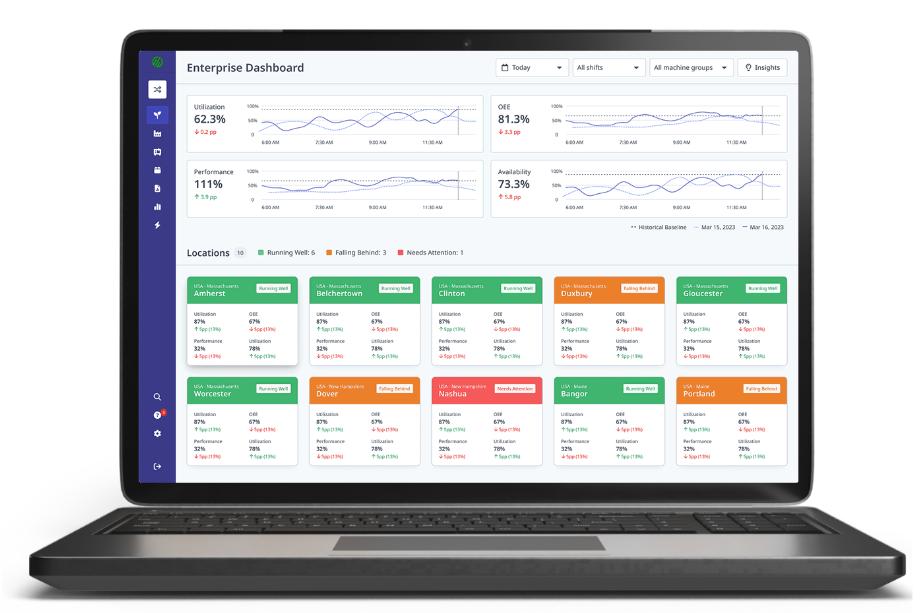

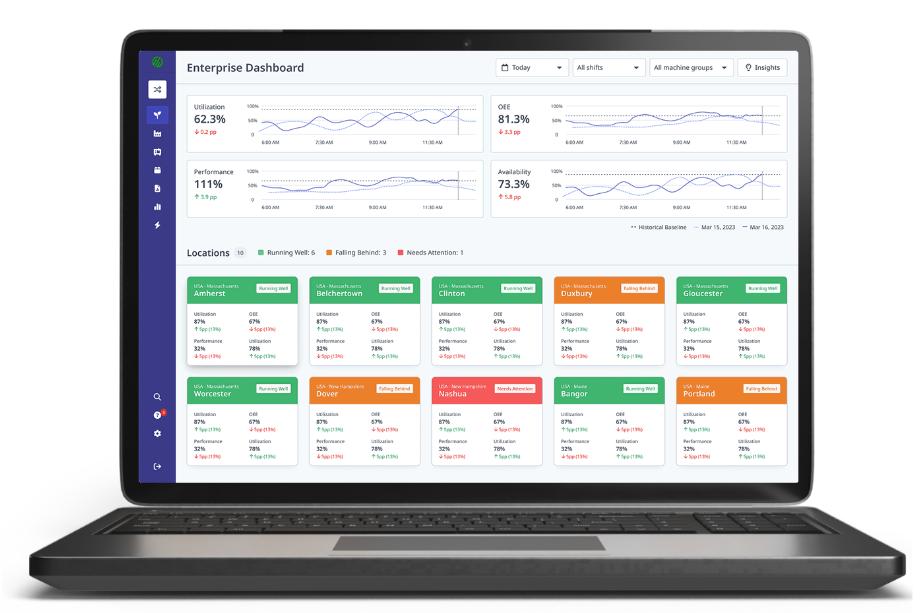

The MachineMetrics Platform is a data-driven solution that leverages real-time insights, enabling executives to make accurate decisions to improve business performance at the micro and macro levels.

One of the primary benefits of MachineMetrics for executives is that it provides a holistic view of their entire manufacturing operations, regardless of the number of facilities, production lines, or machines. This capability is particularly valuable for multi-plant operations, where executives must monitor and manage performance across multiple locations.

The platform can collect data from every machine in the company, providing executives with a single source of truth. This enables them to identify trends and patterns and make informed decisions about resource allocation, production planning, and capital investments.

Multi-plant analytics to address enterprise resource planning, capital equipment expenditures, and labor challenges.

Use Cases for Executives

Executives need different analyses and views of the operation than operators, and their planning extends beyond the plant floor to the entire company. Use cases for high-level managers include:

- Visibility: Executives can visualize performance and trends across all facilities or zoom into a specific plant, machine group, or machine. This feature helps in capex planning, long-term production planning, and more.

- Benchmarking: Executives with access to real-time machine data and analysis can benchmark performance across all machines or facilities. This capability allows them to move production to smooth out complexity across the organization. It may also inform them of which products are more profitable than others.

- Capacity Analysis: MachineMetrics unlocks hidden capacity for operational improvement. Managers can use this capacity for sharper and more effective labor and resource capacity planning.

- Production Planning: Accurate data on part counts, defect levels, cycle times, and more are valuable for all user levels. Executives can use the insights to ensure material planning, labor, equipment, and other resources in the supply chain are where they need to be for all facilities.

The Power of MachineMetrics

MachineMetrics enables executives to identify opportunities for improvement and act quickly. With real-time data on machine performance, they can identify waste areas, reduce downtime, and optimize production processes at the enterprise level.

The accurate, real-time data from the shop floor can be aggregated and sliced to generate insights across labor, machines, and operations, while still providing executive leaders with a high-level view that can be used as a starting point for drill-down analysis.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments