Key Takeaways:

- Leveraging data helps manufacturers make agile, informed decisions during uncertain times.

- Data-driven insights support operational resilience and adaptability to market changes.

- Investing in data infrastructure ensures long-term stability and growth amid uncertainty.

In this difficult time, while some manufacturers have been forced to change strategies temporarily, others have a need to double down on what you do best. By enabling mobile workers, industrial companies are better able to ensure the safety of their workers while continuing to serve their customers. Many of our customers are on the front lines delivering solutions during this crisis; MachineMetrics is committed to supporting the front-line worker on the manufacturing floor and in the medical field.

Thoughtful management of your people & resources, and using data to make good decisions is critical. There will be a lot to balance in the coming weeks - customer needs, supply chain challenges, staffing considerations, but having a strategy to leverage data to aid in decision-making is the key.

It’s undeniable that the impact of the virus will permeate numerous areas of manufacturing. MachineMetrics hosted a recent virtual panel discussion with Steve Kline, Chief Data Officer at Gardner Intelligence, Bill Berrien, CEO at Pindel Precision, Vicente Martinez, Project Leader at Rassini Brakes, and myself on the short and long-term impacts of the coronavirus. Here were some of our key takeaways:

- Currently, there has been little adjustment of production capacity. The biggest changes have been to staffing, budgets, and contingency plans: the need to have and manage cash flow, especially for those outside of the medical industry, has never been more important.

- To increase your chance of properly managing and surviving a disruption of this magnitude requires risk assessment—looking for points of failure coupled with a continuous improvement program. This crisis, for example, will accelerate the reorganization of the supply chain as people have been made aware of the risks.

- Investments in automation, Industry 4.0, virtual manufacturing, machine monitoring, and additive manufacturing are paying off during this time. Shops now realize their true underused machine capacity and the need to get people more productive with the equipment they have. This crisis is a great time for any manufacturer to analyze what they are doing when it comes to data collection and analysis. It is a good time to reflect without urgency when shops are in full production again. Take time to do a little industrial meditation.

- We need to upskill the workforce and double down on skills. Revenue per employee is a predictor of profit margin. How much can a shop get through each employee? How do I organize my business to get the most out of my employees? For example, implementing a continuous improvement plan.

- We need to pivot with a bias towards action. For example, emergency POs take priority. With every PO, a message is sent to the sourcing managers that jobs with deliveries two weeks out need to be reprioritized, and they are encouraged to reach out to industry groups to outsource that work … get help.

How can we help?

While some manufacturers have been forced to change strategies temporarily, others have a need to double down on what you do best. By enabling mobile workers, industrial companies are better able to ensure the safety of their workers while continuing to serve their customers. Many of our customers are on the front lines of delivering solutions during this crisis.

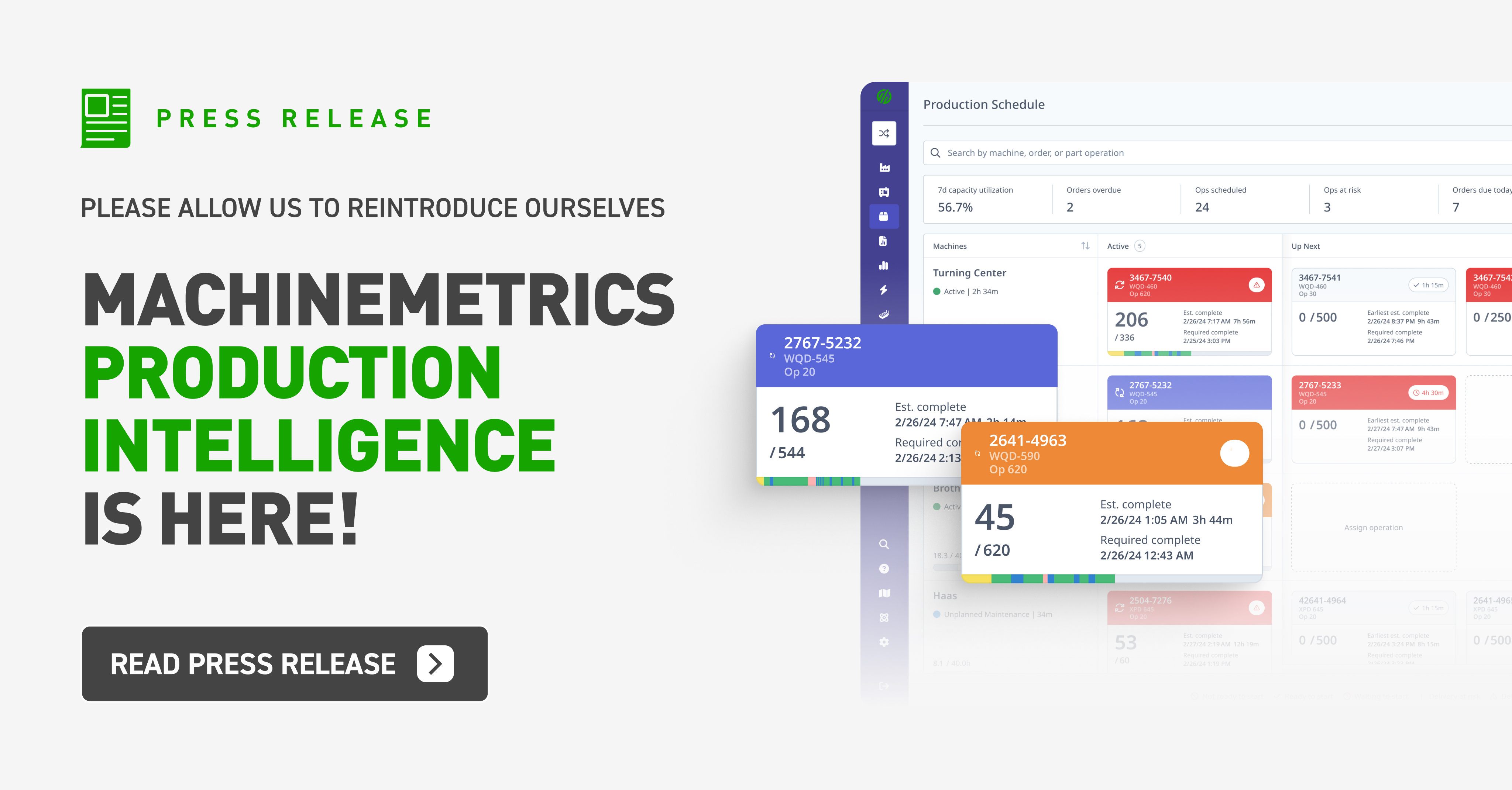

At this critical moment, MachineMetrics has decided to launch of a program to provide remote monitoring capabilities to support manufacturers on the front lines delivering solutions during the COVID-19 crisis.

The program features free access to the MachineMetrics IoT Platform including its automated data collection and remote monitoring applications for any manufacturer involved with the production of Ventilator parts, test equipment, protective equipment, or any COVID-19 related manufacturing support. MachineMetrics currently supports a number of the top precision component and medical device manufacturers in the world and is uniquely capable to support this initiative. Our platform is plug-and-play, with no on-site set up required so any manufacturer can install it themselves. Most modern equipment can be connected within minutes

Secondly, we’re offering our manufacturing consulting services free of charge. MachineMetrics customer solutions team has first-hand experience leading digital transformations in manufacturing across the industry, including regulated medical device and precision component environment. They’ll partner with you to support training, use case consultation, and continuous improvement activities needed to ramp production fast and reliably, as well as to help companies produce new products, increase production volumes, and bring therapies faster to market.

Any manufacturer can now leverage the MachineMetrics' platform and its digital apps designed to enable social distancing and remote work. By enabling mobile workers, industrial companies are better able to ensure the safety of their workers while continuing to serve their customers.

There are a few ways our platform is empowering them to work remotely and continue to keep their plants running during this difficult time.

Monitor Production from Anywhere

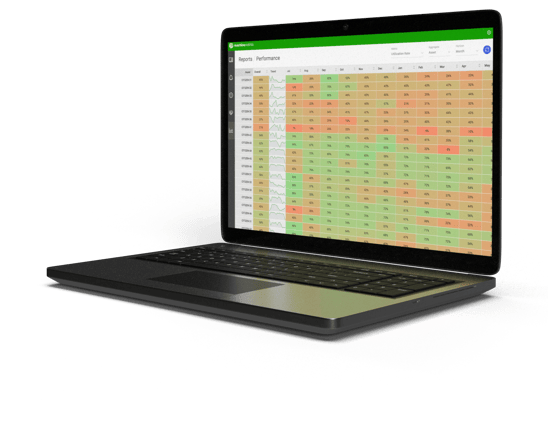

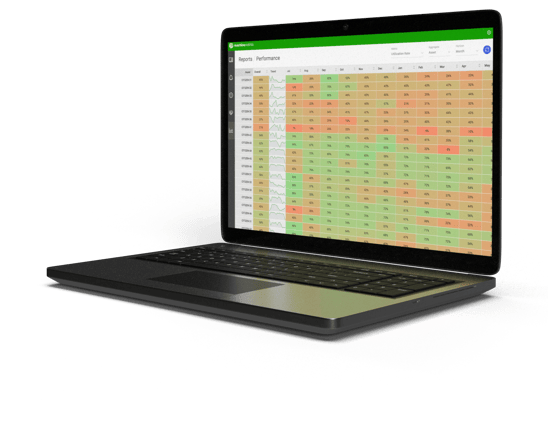

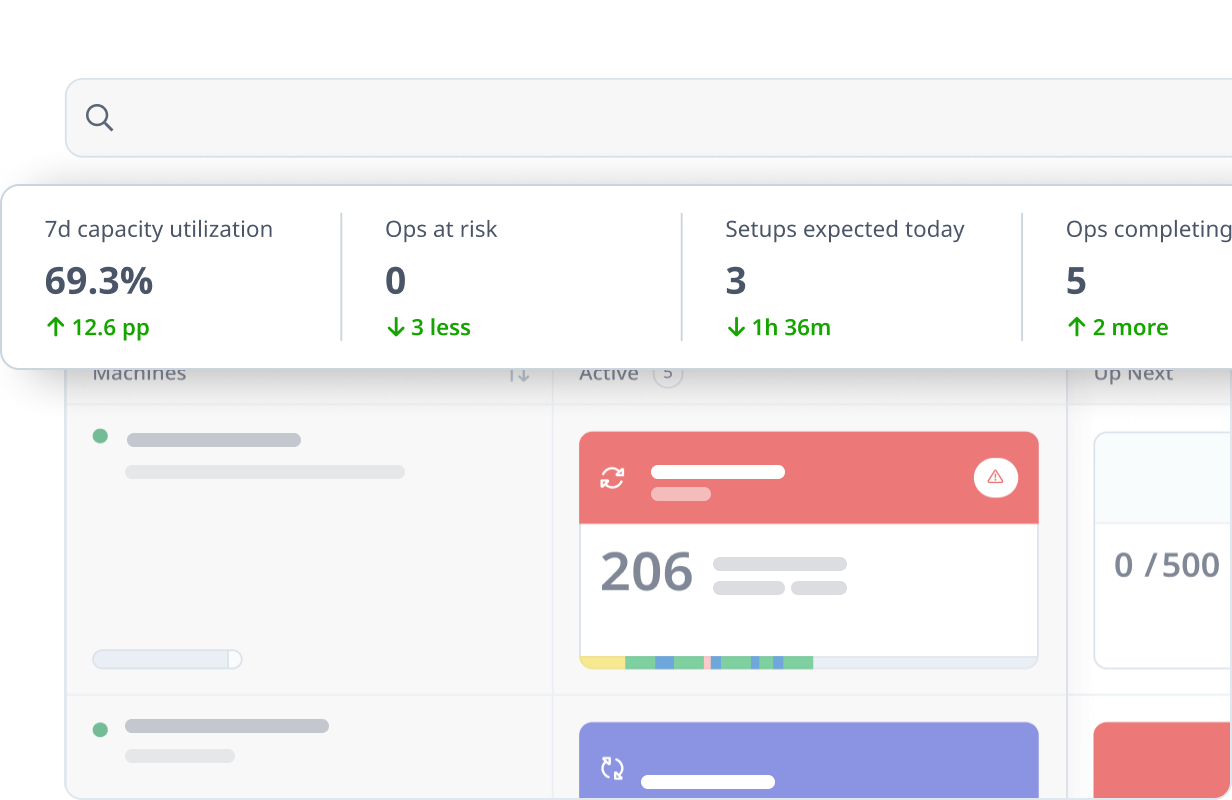

- Whether you’re social distancing or simply working away from the manufacturing floor, use the real-time visibility in MachineMetrics to understand what’s happening in your shop from anywhere. Using any internet-capable device, views such as the Current Shift Dashboard and Production Report will easily allow you to remotely monitor the progress of your factory floor. You can also invite additional employees to access your data remotely at no additional cost, so take a quick look at your current Users and consider adding to your list.

Enhance Communication

- Timely communication of critical information is always important on the shop floor, but the importance will be magnified as daily routines are impacted in the coming weeks. Consider developing an internal strategy for using notifications to your advantage. There’s no better time than now to start enabling real-time notifications triggered by what’s actually happening on the factory floor. You have at your fingertips, the ability to send notifications for significant utilization drops, specific machine downtimes occurring, individual alarms, etc.

Make Informed Scheduling & Staffing Changes:

- Balancing your customer needs with staffing considerations will be key in the coming weeks. Having the data needed to staff strategically is an important advantage our customers have. By using key data points, such as week over week machine utilization and critical job performance, you can make informed scheduling and staffing decisions. Historical data can also be leveraged to quantify the impact current conditions are having on your business and make projections about the future.

Confidently Maximize Lights-Out Capabilities:

- Although not everyone has the ability do lights-out manufacturing, if you have invested in robotics, palletized machines, bar feeders and other automation, now is the time to leverage them to their fullest. Running lights-out will help you keep your critical jobs running while spacing out your employees tending machines to mitigate risk. Using our Operator Insight feature, you can see operators signing in while tending machines. Setup monitors with notifications for when your bar feeder alarms or when the machine requires lubrication. You can also be alerted about any critical alarms throughput while the machine is unmanned, and respond to any critical issues or alarms quickly.

Remote Machine Maintenance and Service

- MachineMetrics: Remote Service feature enables your equipment providers and service teams to help you diagnose and resolve machine issues without having to step foot in your facility. The historical and real-time machine data collected allows equipment manufacturers to gain insight into customers’ equipment health and condition, deliver early warning of potential equipment failures, highlight elevated risk areas that lead to machine downtime, or even determine to take preventative action before it impacts your machine performance.

We’ve set up a dedicated website so you can learn more about our COVID-19 Response Program here.

It’s an honor to offer our services to all manufacturers and manufacturing efforts to empower them to work remotely and continue to keep their plants running during this crisis.

What’s Next?

In any time of economic uncertainty, there is an even greater need to be well-informed, in order to make smart business decisions for the good of your organization

Over the coming days/weeks, our data science team will be focusing their efforts on reporting the impact of Coronavirus on the manufacturing industry. We’ll be making this information regularly available on our blog and through social media with the goal of providing as much insight as we can to our customers and the manufacturing community as a whole.we’ll also be posting regular updates on our blog and social media regarding the impact

We’ll also be hosting our third State of the Industry panel on Thursday, April 30th where we'll be shifting our focus to the global stage. Our special guest moderator Francisco Betti, Head of Advanced Manufacturing and Production for the World Economic Forum, will lead a discussion between industry leaders including representatives from SECO Tools, Boston Consulting Group, and MachineMetrics.

Topics include:

- What's happening right now from an economic perspective

- How it will affect the near term global manufacturing economy

- How this will impact the long term outlook of the manufacturing economy

We'll also be diving into how manufacturers are pivoting to support demand for medical devices, and how this pandemic is bringing the manufacturing community together like never before.

Until then, stay tuned and stay safe.

Click here to get started with remote machine monitoring today!

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments