Key Takeaways:

- Manufacturers must assess their IoT readiness to ensure a smooth transition to smart, connected operations.

- Successful IoT implementation requires robust data infrastructure, skilled personnel, and clear objectives.

- Investing in IoT readiness now enables companies to future-proof their operations and enhance productivity.

This article is part of a series addressing the most pressing concerns manufacturers have when it comes to Industry 4.0 and Industrial IoT solutions. In the rapidly changing manufacturing technology space, it can be difficult to distinguish valuable solutions and approaches from shiny objects and short-term thinking. We’re here to address concerns and provide clarity around these topics to help you move forward with confidence. Explore the complete series:

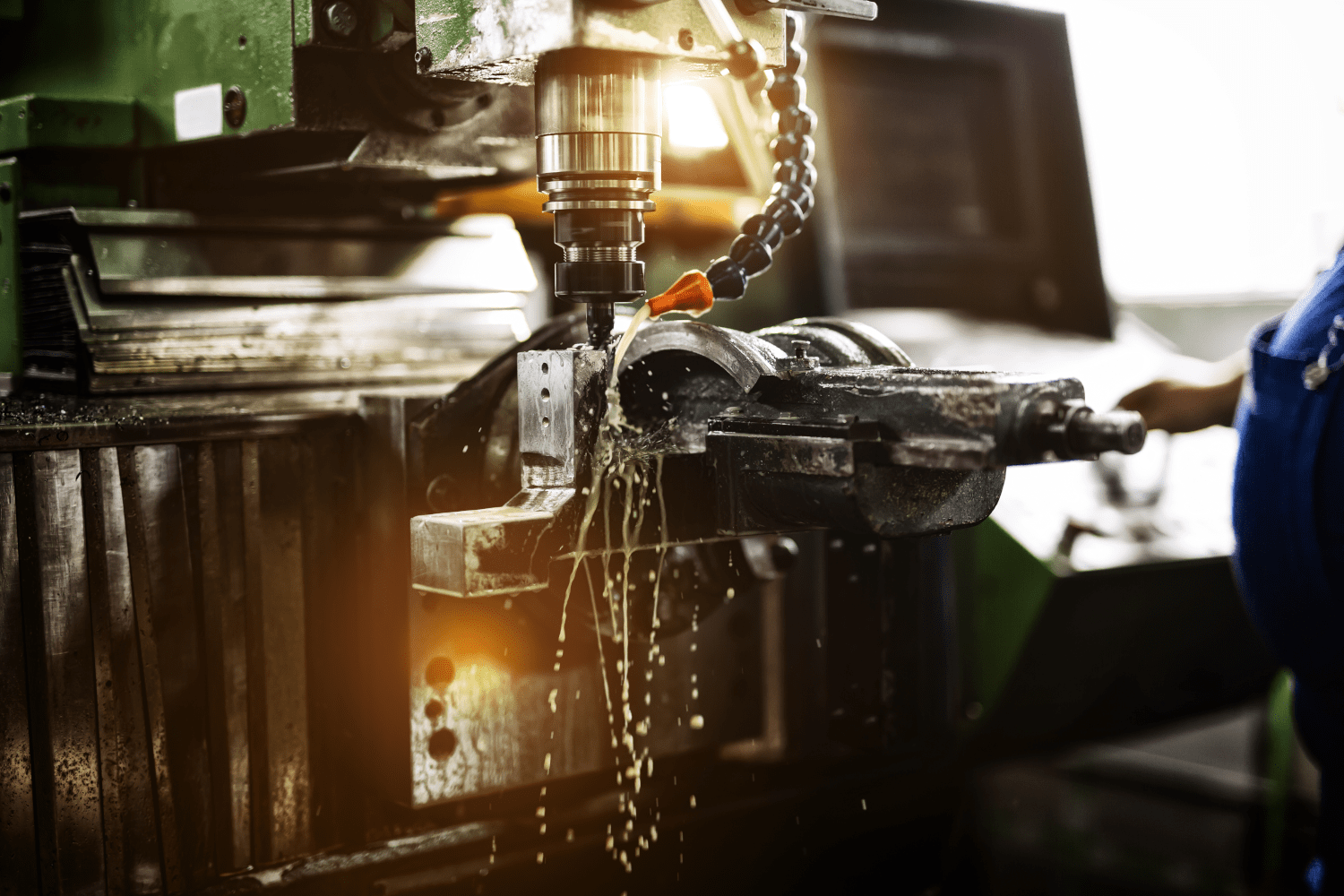

Over the past few years, there have been many significant changes in the manufacturing industry. From a global pandemic to supply chain issues to worker shortages, challenges have never been greater. Not to mention, these challenges come at a time when demand is high and manufacturing is expecting robust growth over the next decade.

Another significant change has been Industry 4.0, which has been a hot topic for manufacturers for several years now. The single best way to realize the value of Industry 4.0 is to embrace its technologies and initiatives, particularly the Industrial Internet of Things (IIoT).

| What is Industry 4.0? Industry 4.0, also known as the Fourth Industrial Revolution, or 4IR, is an all-encompassing term to refer to the way computers, data and automation are evolving and coming together to change the way work happens, and in particular, manufacturing. Read the Complete Guide. |

Still, many companies are reluctant to make the switch to Industry 4.0. Granted, with a failure rate of 75% on most IoT initiatives, reluctance is understandable. But the digitization of manufacturing is underway regardless, and companies shouldn’t wait. Lack of technical maturity, competing priorities, and resource limits are less impactful than previous years because the technology has advanced to offer turnkey solutions, intuitive platforms, and immediate results.

Top Reasons Manufacturers “Don’t Feel Ready” for IoT

There are many reasons why manufacturers don’t feel ready to undertake an IoT transformation. But regardless of whether competitors are moving to IoT in an ad hoc fashion or with an ecosystem approach, the competition is rapidly advancing. Not beginning a digital transformation to leverage the value of data is a mistake that could result in being left behind.

“We’re Still Using Clipboards on the Shop Floor”

From an IoT perspective, the answer to this should be “great,” because it signifies that you value data and are poised to make huge strides with the right initial technology investment. By harnessing machine data at this stage, companies can immediately realize value. Accurate, real-time machine data provides a strong foundation for the next steps in a continuous improvement journey. It’s cost-effective and makes IoT scaling easier because the groundwork is already set.

Prior to adopting the new technology, a company can begin documenting and mapping out their processes using the currently available - albeit flawed - data they have been manually collecting. Taking this step will pay big dividends during implementation, as manufacturers will have a strong idea of existing processes and performance baselines.

By establishing baselines and implementing one powerful technology to capture machine data, companies can quickly track their performance improvements and leverage that momentum to develop a strategy for getting their entire operation connected.

Plug-and-play Machine Connectivity

“Our ERP/MRP System is the Top Priority Now”

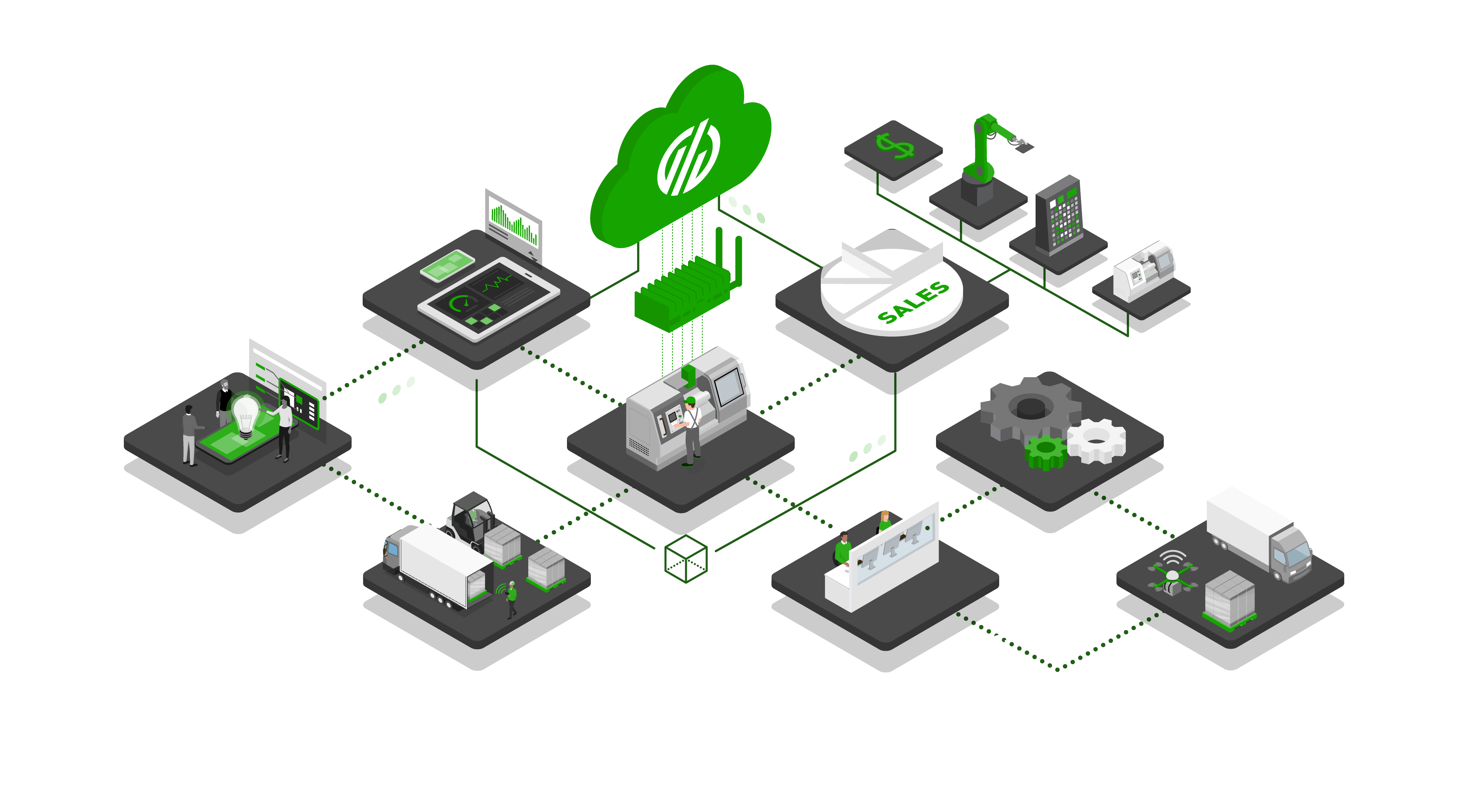

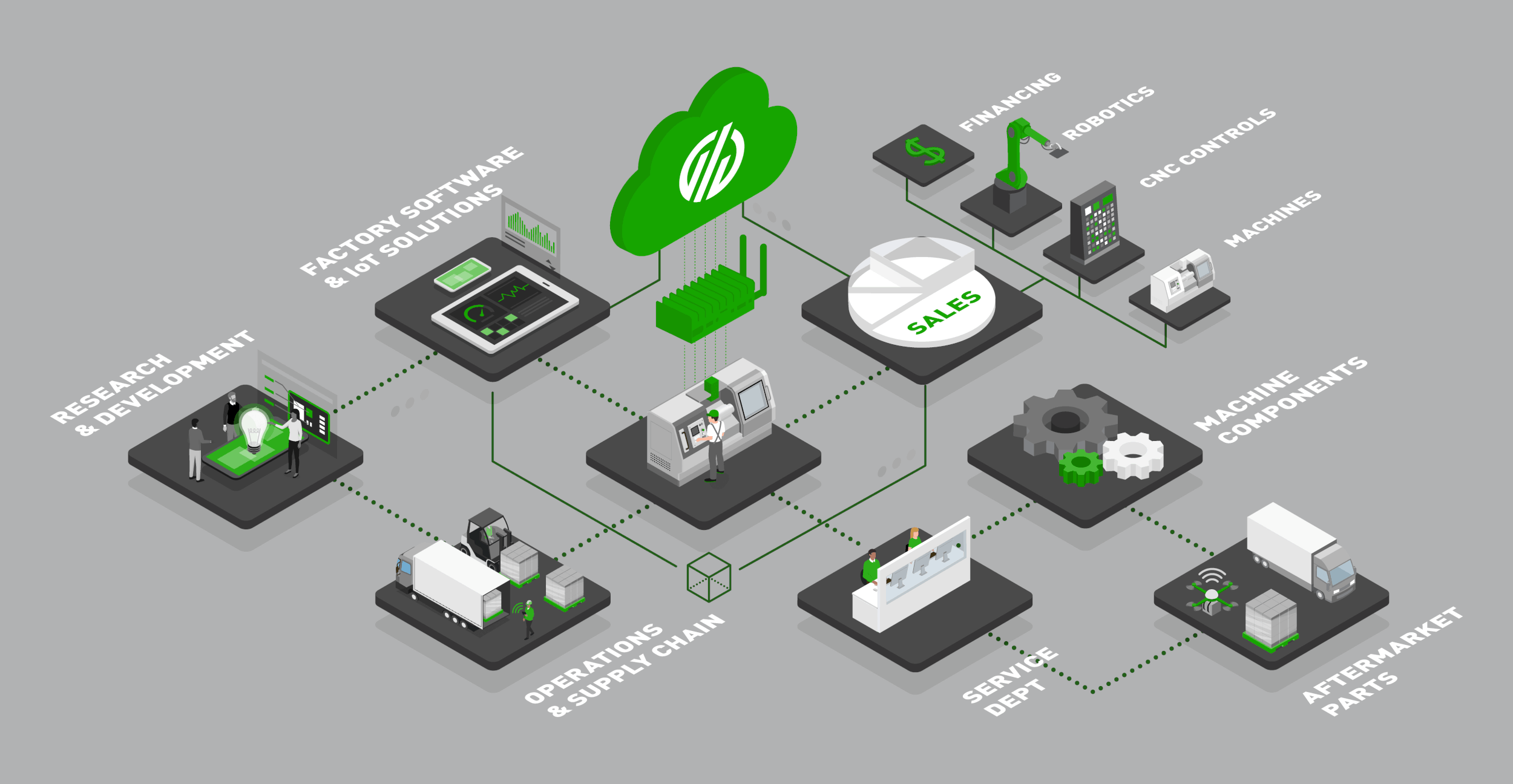

Your ERP/MRP system should be a priority, but you should never allow it to stifle your innovation. Industrial IoT platforms optimize these legacy systems by providing them with the accurate production data necessary to make better, faster decisions. This integration maximizes the ERP/MRP system’s value and enhances ROI.

Many decision-makers and managers in manufacturing have been bombarded by the “next big thing” in software. This fatigue means they must relearn new SOPs for operating software and training their staff. But manufacturing IoT platforms aren’t meant to replace these systems. They’re intended to provide real-time data that supercharges their value, allowing them to do what they were designed to do more accurately.

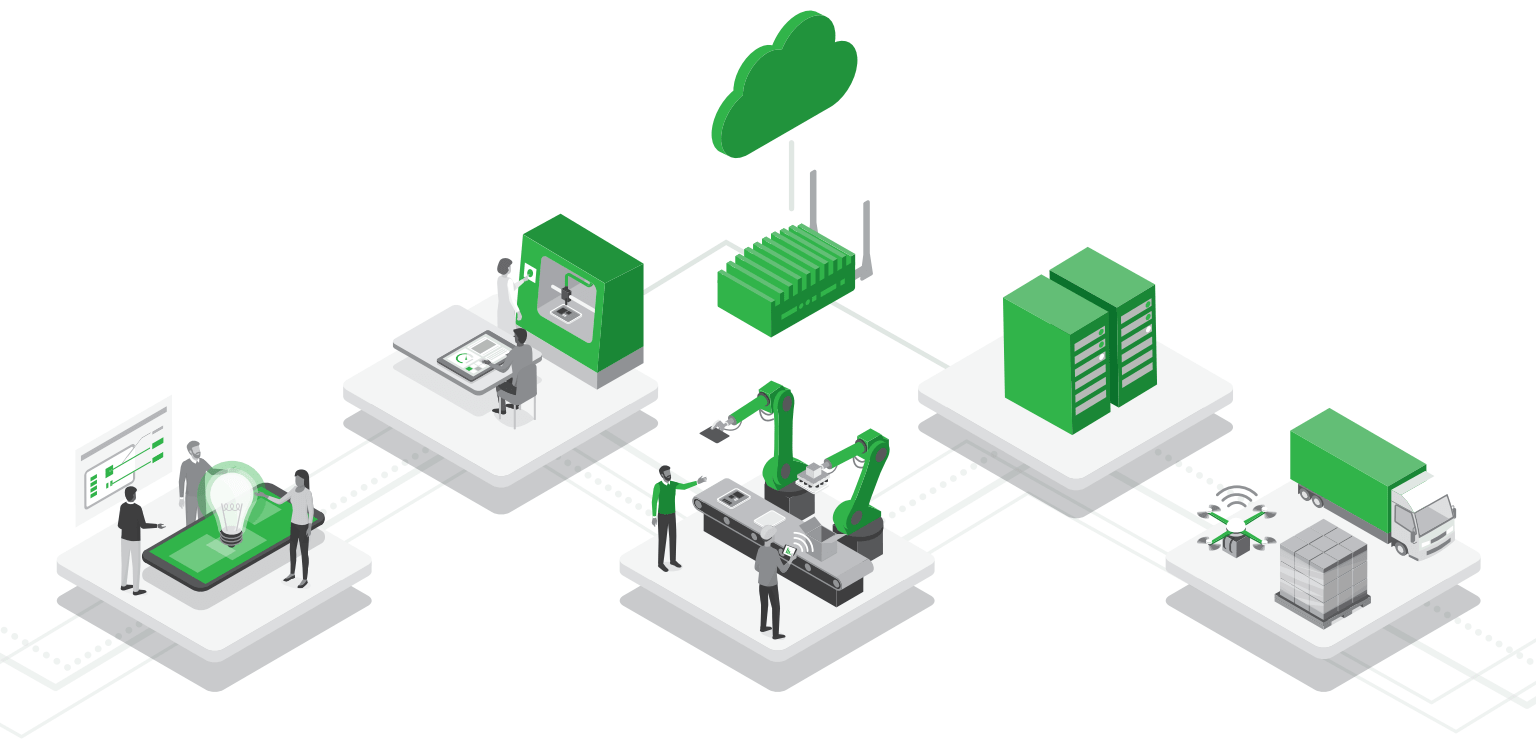

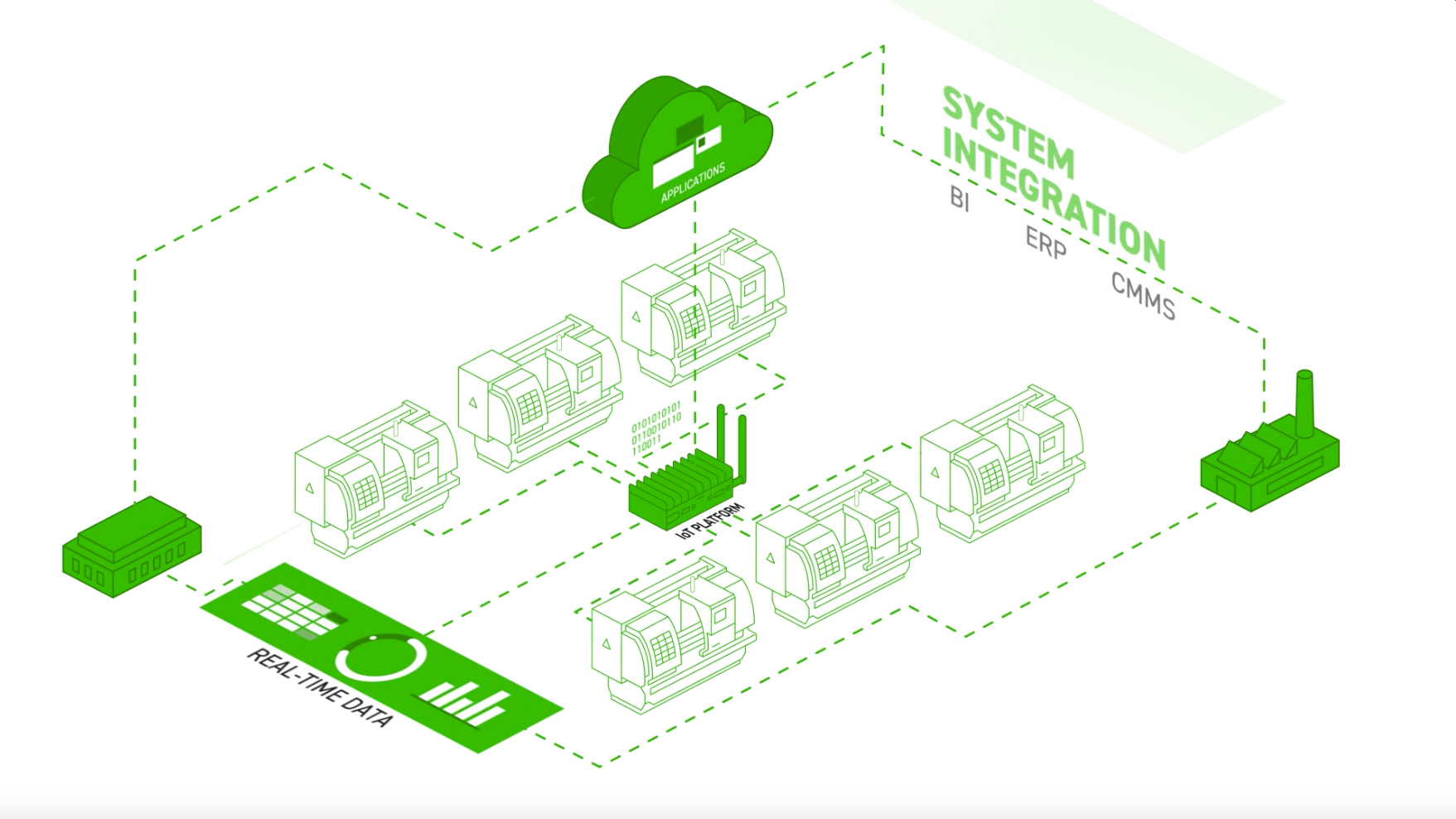

With data-centric IIoT running parallel to these systems, manufacturers can realize insights that aren’t possible with standalone ERP/MRP/MES. Data is contextualized and standardized, creating a fully visible data-driven ecosystem.

“We Need to Upgrade Our Machines First”

Given Capex costs for new OEM machines, equipment upgrades are an expensive endeavor. This mix of equipment means that as companies scale, they may have multiple generations of equipment throughout the shop floor at any time. But waiting to digitize once everything is the right vintage means it may never happen.

Legacy equipment can generate data to optimize your processes, the information simply needs to be captured with the right connectivity solution.

This myth of needing to age into compatibility is driven by the fact that many manufacturing professionals are accustomed to multi-generational equipment with software that needs upgrading regularly. They may also be accustomed to a lack of interoperability between software from OEM equipment.

MachineMetrics doesn’t rely on software rationalization to work. Even analog machines can be connected to the platform to deliver data to the system, and other equipment can be monitored with sensors. As a result, all equipment is able to be connected and data is added to the data stream regardless of the generation of the machine.

By getting past this myth, manufacturers can better understand the capacity available on the shop floor. The results are often surprising, revealing near 30% utilization rates. By unlocking the capacity of underutilized equipment, companies can avoid unnecessary equipment purchases.

“We’ve Had Too Many Failed IoT Projects in the Past.”

If this is your response, you’re not alone. Data from Cisco reveals that up to 75% of IoT implementations fail. Either they cannot create value quickly, or they can’t sustain that value over time.

But this doesn’t need to be the case. In companies where IoT projects have failed, it isn’t the concept of IoT that drags it down. It’s often the same organizational habits that have had the same effect on other improvement initiatives. This includes budget considerations, long deployment times, interoperability issues, and IT infrastructure issues. Companies experiencing these internal obstacles may approach IoT the way they approach other projects: seeking incremental ad hoc solutions or DIY devices to “homebrew” a patchwork solution.

In contrast, the MachineMetrics platform was designed as a turnkey IoT solution built for manufacturers. Companies can easily collect data and transform equipment to deliver powerful, actionable insights with intuitive, flexible platform design.

“We Don’t Have the Time, People, or Resources to Make This Happen”

Manufacturers are the experts in manufacturing, not in building software solutions. But experience has taught them that every new initiative brings about an associated strain on people, time, and resources. This is why DIY IoT solutions and horizontal software with little to no interoperability rarely accomplish what they intend.

MachineMetrics is designed with these headaches in mind. Our solution is inexpensive to implement and deploy. It drives value quickly, with most customers deploying and receiving actionable insights in a matter of days and ROI within months. In addition, 80% of our customers have been able to self-implement. There’s no code to write, no expensive consultants, and no IT hires needed. We offer an efficient, turnkey solution.

You’re Ready to Get Started. Now What?

If you’ve never taken a step toward IoT, you’re not alone. Many companies are dealing with the same fear and reluctance. That’s why now is the best time to get started.

True digital transformation begins at the machine level. Production data is collected from equipment that can drive other functions and systems to empower a best-of-breed technology stack. This equipment can be connected as-is, regardless of its age.

However, to make this a reality, companies need a machine data collection solution like MachineMetrics. Contact us today to find out how we can get you on the road to unlocking the power of your machine data.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments