Today is a once-in-a-generation opportunity for manufacturers to capitalize on the reorganization of the global supply chain. To do so, Manufacturing today is undergoing a significant transformation from manual “Lean” systems to connected systems that rely less on human interaction. Yet, most factories still have disconnected operations. Machines are disconnected from the people who operate them and the systems that manage day-to-day operations.

Simply put, The tools of yesterday aren’t cutting it. A recent survey suggested that over 80% of companies either disliked or even hated their manufacturing operations software. These all-in-one systems that were uniquely designed for individual organizations, require spreadsheets or paper to fill the gaps.

-

“Jacks of all trades” and “Masters of none”

-

They require too much manual data entry

-

They don’t play nicely with your other systems

-

They’re a real pain to maintain and update

We can’t solve the problems of tomorrow with the tools of the past. A new school of thought is emerging led by visionary software companies with one shared goal: Accelerate our industry’s ability to connect, optimize, adapt, and evolve no matter what the circumstances may be. We call ourselves The Connected Factory.

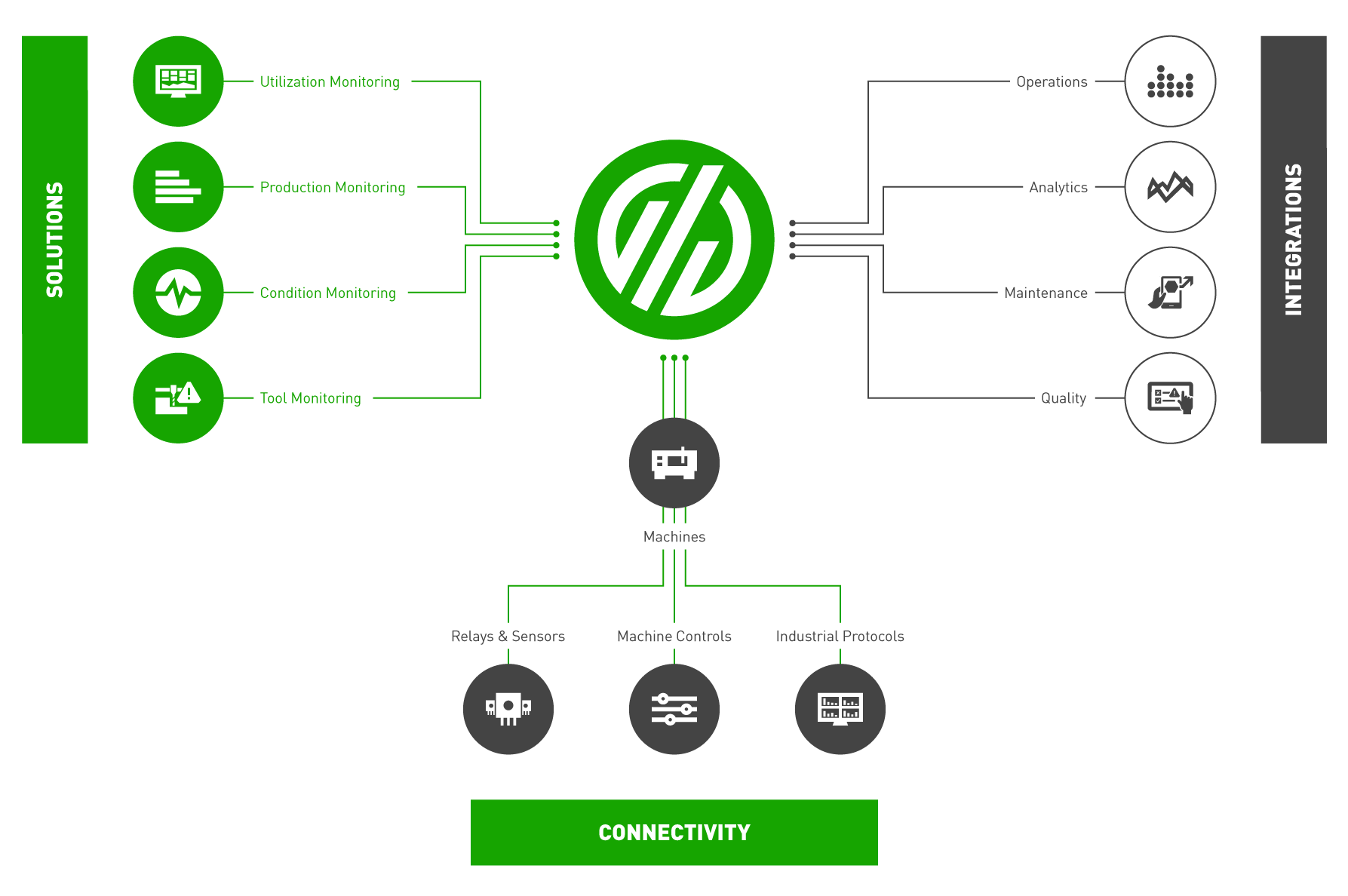

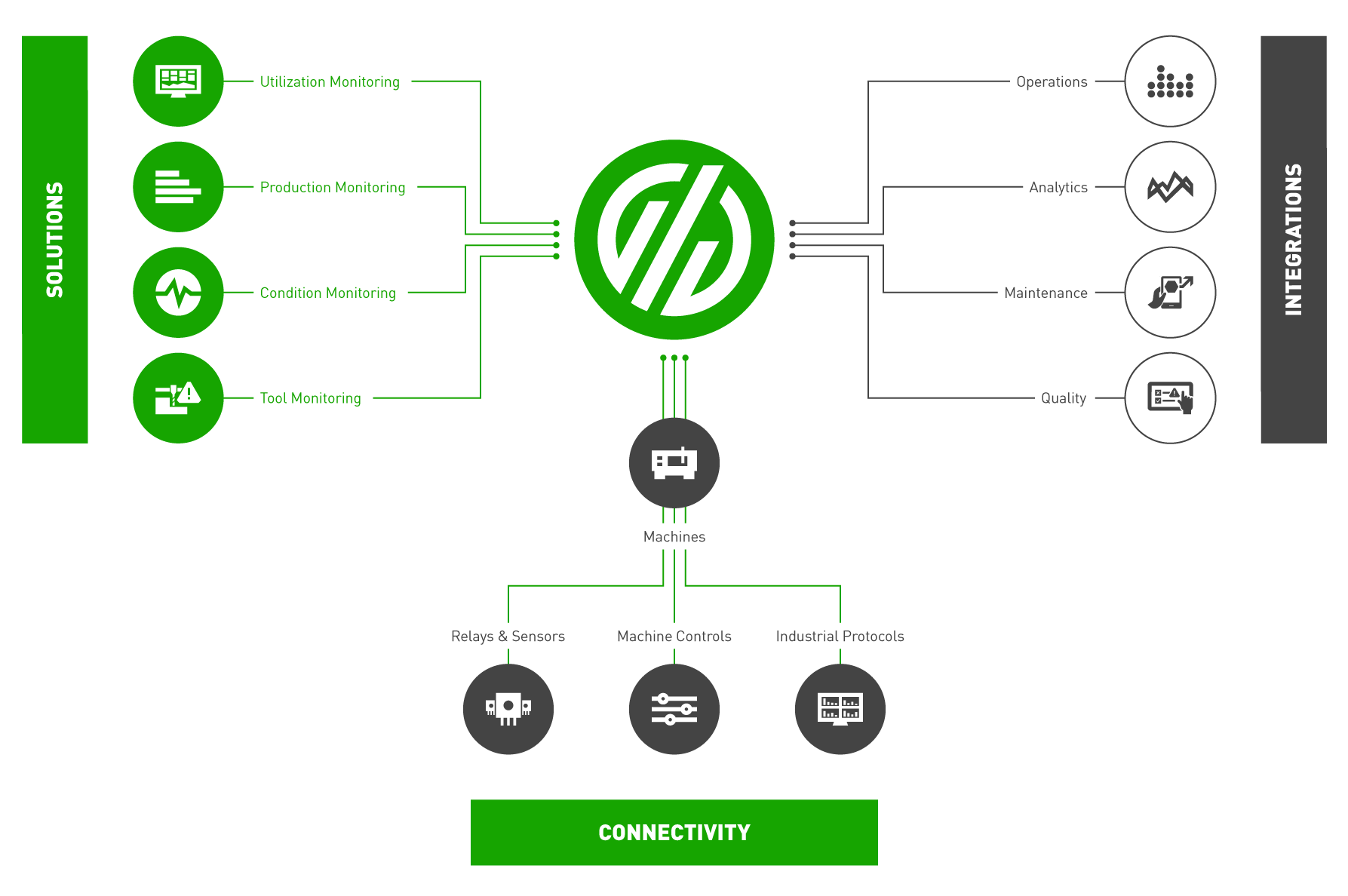

The Connected Factory features best-of-breed systems that each solve a specific manufacturing problem, with their own workflows and easy access to data via APIs, all connected in one digital thread. From Production to Maintenance, to Quality, to Operations, this emerging ecosystem is able to leverage now-proven SaaS technology to provide the best possible experience for the user with the least possible manual data entry.

At IMTS 2022 in South Building, Level 3 — booth 338248, the power of The Connected Factory will be on display for the first time via a live demonstration featuring MachineMetrics, MaintainX, VKS, Fulcrum, FANUC, and Universal Robots. We’ve assembled a semi-automated manufacturing line driven entirely by machine data, with front-line workers only participating when entirely necessary. In the middle is a bar-fed FANUC Robodrill making components. A UR co-bot will take and polish/debur the piece before handing it off to another co-bot that will pass it to an assembly station. A front-line worker inspects the piece with a connected caliper, where SPC data is captured, then assembles the pieces together with a fastener. Finally, a cobot collects the finished part and places it into a container for shipping, The entire manufacturing process is monitored in real-time and production data is automatically passed into the MES as each operation is completed. An io-link sensor mounted to the CNC machine monitors vibration and temperature levels and when these levels are exceeded at which time a maintenance work order is created that instructs maintenance to repair the machine.

All maintenance and production workflows around the line are automated through a modern cloud software stack that connects and minimizes human data entry. This data can be used to provide better insights, improved quoting, and improved user experiences for all those involved.

MachineMetrics provides the machine connectivity and the real-time data that optimizes workflows around the machine but also connects to maintenance and production systems to deliver real-time visibility into production performance. No operator data entry required.

MaintainX delivers automated maintenance workflows driven by real-time machine diagnostics that identify and trigger maintenance tasks when they should be performed to prevent unplanned downtime. Say goodbye to calendars.

Fulcrum integrates real-time production, maintenance, and quality data to enable production managers to produce detailed BOM and routing, build adaptive schedules, and view live tracking of all work in process, inventory, and quality. Adios old-school ERP.

VKS delivers digital work instructions based on current production activities and an inspection/assembly workbench that’s connected to the MES to guide the efficient capture of quality data and eliminate errors. That’s tribal knowledge, democratized.

Excited? So are we. With the Connected Factory Ecosystem, you can now gain value in weeks, not years. What are you waiting for? Meet us at IMTS and let's get connected!

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments