Key Takeaways:

- MachineMetrics helps manufacturers detect and address quality issues in real-time, reducing defects and improving production.

- Real-time monitoring enables faster response to machine performance deviations, preventing quality problems before they escalate.

- Continuous data collection allows manufacturers to track quality trends and implement long-term improvements.

Quality Tracking and Reporting

There is no better cost to eliminate than the cost of poor quality. Scrap material and lost labor hours add no value to an operation. Poor quality leads to unhappy customers. Unhappy customers leads to lost business. In order to best eliminate these wastes, a strategic approach to quality improvement is essential.

As we discussed last week, the first step to solving any problem is defining the problem. Knowing when, where, and how quality issues occurs is essential to knowing how to prevent them. Thus, your first and most important step towards creating a strategy that reduces your quality issues is to carefully and accurately track when and where quality issues occur through the implementation of data collection tactics. However, the majority of manufacturers that attempt this data collection use inaccurate, inefficient manual tactics like paper and excel that only allow for retroactive insights and decision making. That’s where MachineMetrics comes into play.

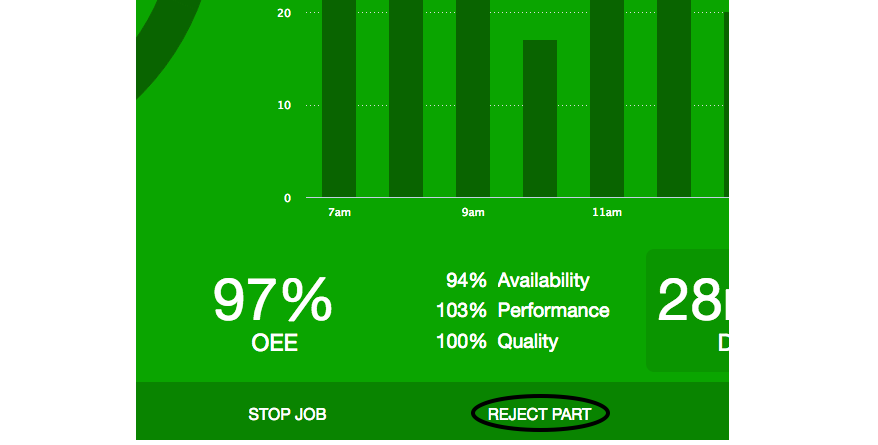

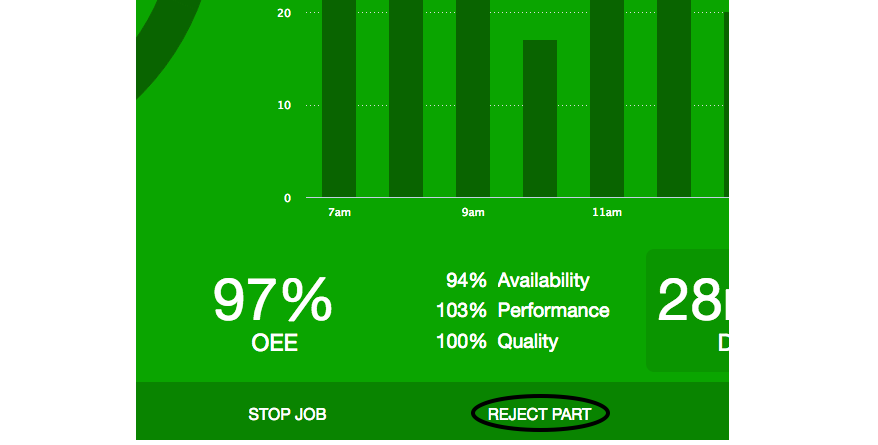

Using MachineMetrics, an operator can reject a part using the Operator View (as we’ve discussed in previous posts, the Operator View is visible through tablets that are magnetically mounted directly at the machine tool). Quality managers are then able to view the quality data via quality pareto charts in real-time. When there are new rejects, they can head to the machine in question, re-inspect the parts and re-allocate as necessary. All quality data can be tracked in MachineMetrics, eliminating the need for the ineffective tactics discussed before.

Here’s a brief tutorial on how easily MachineMetrics allows you to track and categorize your quality issues:

Any part that is not considered "good" needs to be rejected in order to remove it from the good parts count. There are two ways to reject parts in the MachineMetrics system; one from the Operator View and from the Quality page.

First, from the Operator View:

On the bottom of the screen, select "Reject Part".

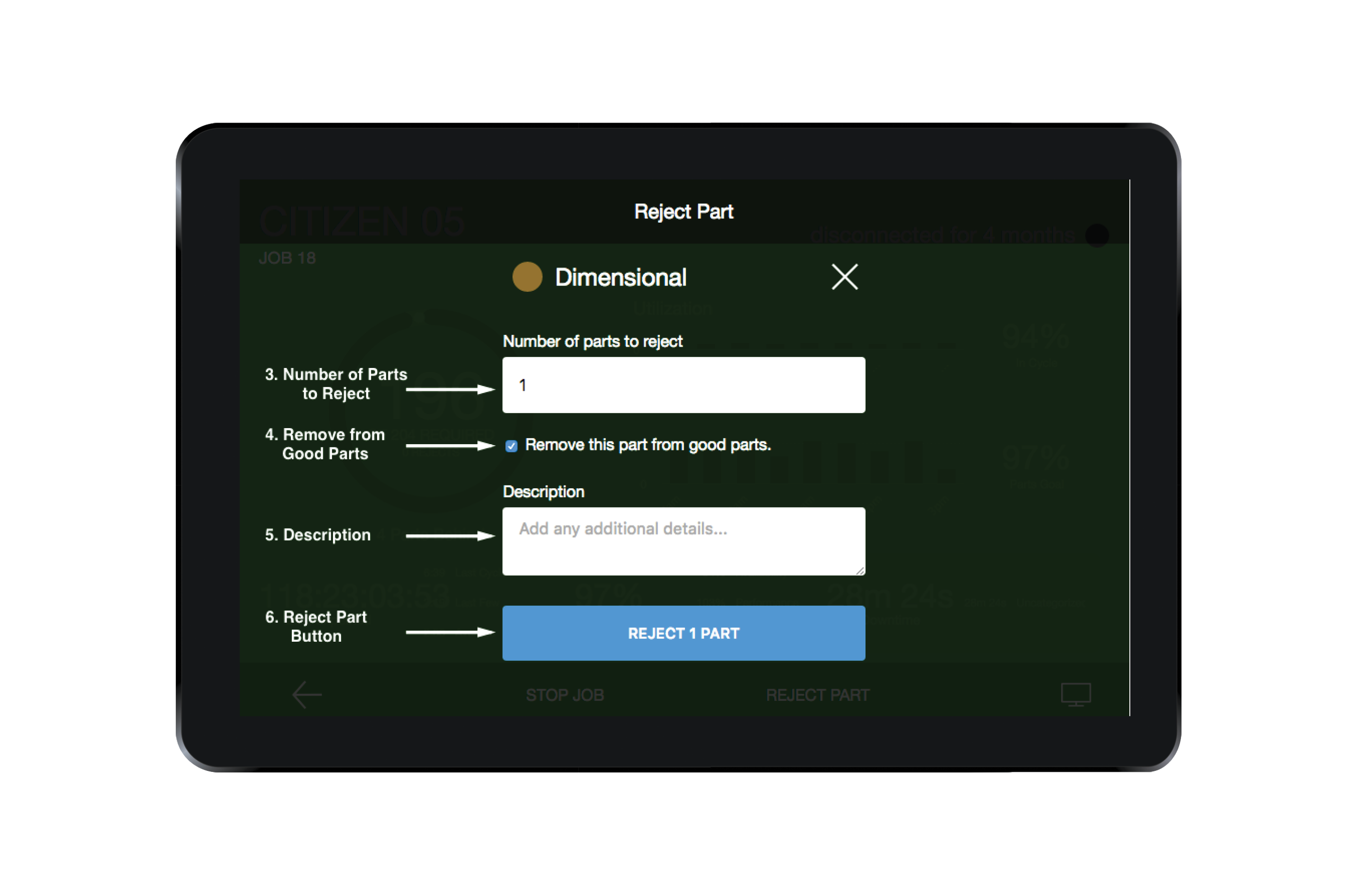

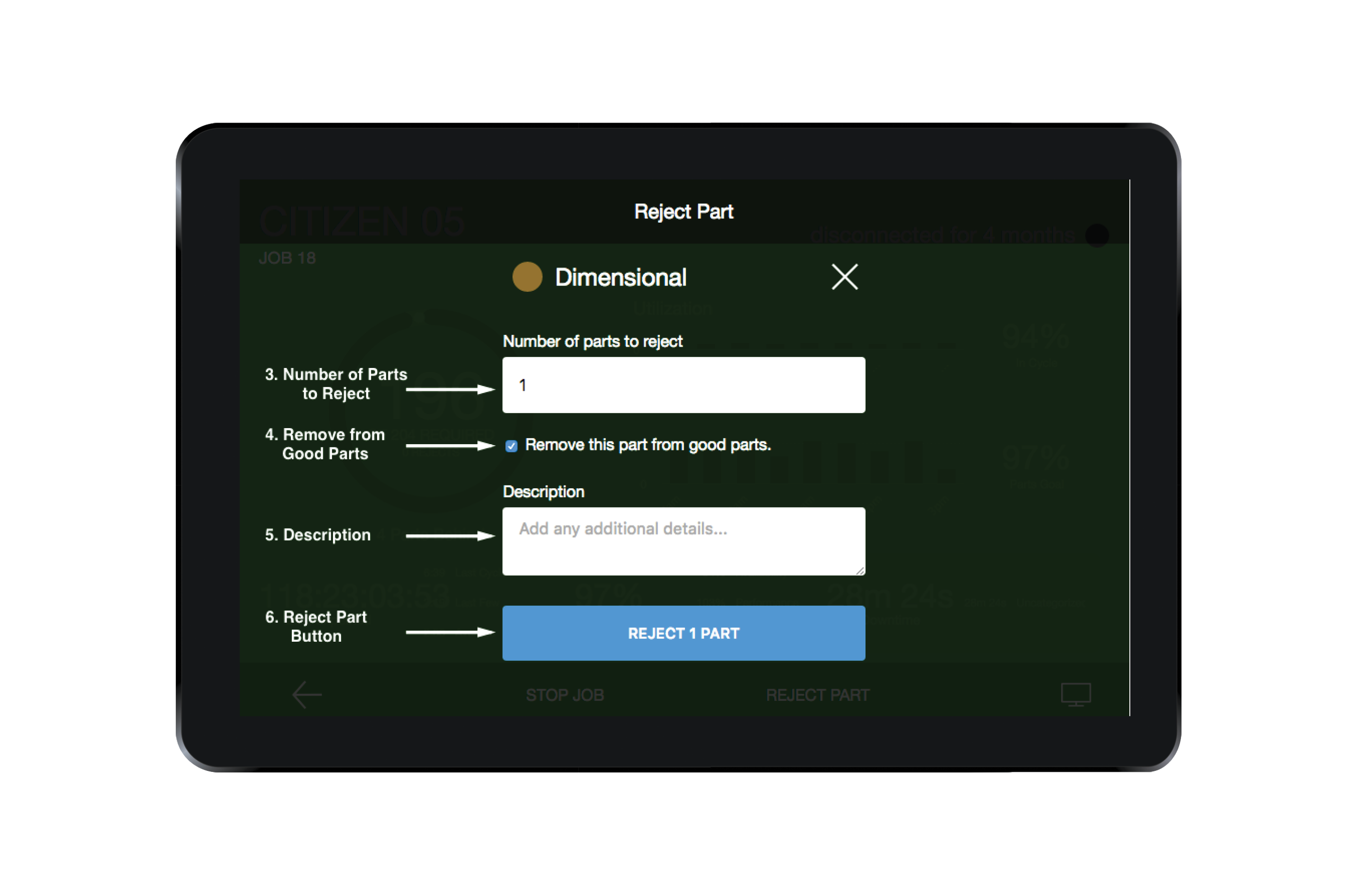

This will bring up the "Reject Part" screen, where you can choose the specific reason (customized for your business):

Once the reason is chosen, you will be prompted to add context to the rejection. You will find the descriptions for each part of these screens below:

- Rejection Category Indicator - A color-coded visual indicator assigned to each category of part rejection. This allows users to identify part rejection patterns for a given workcenter and potentially identify recurring issues with a machine.

- Rejection Category Name - A descriptor for a category that allows users to identify the reason a part is rejected.

- Number of Parts to Reject - The number of parts to reject for the given reason.

- Remove from Good Parts - A checkbox to subtract these parts from the good part count. This is enabled by default. In some cases - typically during setup - the machine will not report that a part is produced, but the operator should still indicate that a part was rejected. Uncheck this box to increase the number of rejected parts without deducting from the number of good parts.

- Description - This allows the user to add additional details as to why the the parts are being rejected. This is an optional but highly recommended field.

- Reject Part Button - Once all of the other information is filled in, the user selects this button to reject the parts.

The second way parts can be rejected is from the MachineMetrics Quality page for a specified workstation.

On the right-hand side of the screen at the top of the "Rejected Parts" section, select the "Add Reject" button. This will bring up the "Reject Part" prompt.

From this prompt the user can reject parts similarly to the workcenter view. The main difference when rejecting parts from the Quality page is that parts can be rejected from past jobs rather than just the current job. These are the following steps:

- User selects the date and inputs the time from which they want to reject parts.

- Enter the number of parts rejected in the Count section and select a reason from the Reason dropdown. Just as in the workcenter view, they can add a description in the Message text box which is an optional field but highly recommended.

- Finally, the user hits save and logs the rejected parts.

*Note: Part rejections can also be edited by selecting the row representing the parts the user wishes to edit. This will open a Reject Parts prompt in which the user can change any of the information for this rejection or delete the rejection altogether.

As seen above, Quality managers are then able to view this data via quality pareto charts in real-time. The pareto will allow managers to understand where the quality issues are occuring, which are the most, and track those issues over time. When there are new rejects, they can head to the machine in question, re-inspect the parts and re-allocate as necessary.

A Complete Guide to Quality Assurance

In summary, ineffective data collection is one of the top challenges to identify and solve quality issues.

How do you know if your quality initiatives are the right ones? Do you know what the problem is that you were trying to fix? The key lies in the development of a strategic plan to improve quality. Without it, you’ll just move from one guess to another. MachineMetrics not only allows you to take the guessing out of identifying your quality issues, but it provides the quality data in real-time from the shop floor to upper management so you can implement proactive changes now vs reactive ones later. This data collection is also the first step toward predicting quality issues, but for now let’s take this quality thing one step at a time :).

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments