The explosion of new technology within Industry 4.0 as well as the speed of advancement of these technologies has created strong new opportunities and new revenue streams for manufacturing companies. By leveraging access to vast amounts of actionable data, companies can drastically improve their efficiencies and operating processes. As a result, improvements to quality, OEE, maintenance and labor utilization can comprehensively add value to the performance of the operation resulting in strong improvements to the bottom line.

But as Industry 4.0 revolutionizes modern manufacturing, it isn’t just manufacturing and operations managers who are challenged and affected by new and better ways of operating. Chief Financial Officers are also finding that their processes and overall approach to finance management require changes as well. And while many of these changes are required to stay apace with the operation, Industry 4.0 is opening new ways for CFOs to impact their organization and drive improvement.

The Proof is in the Product

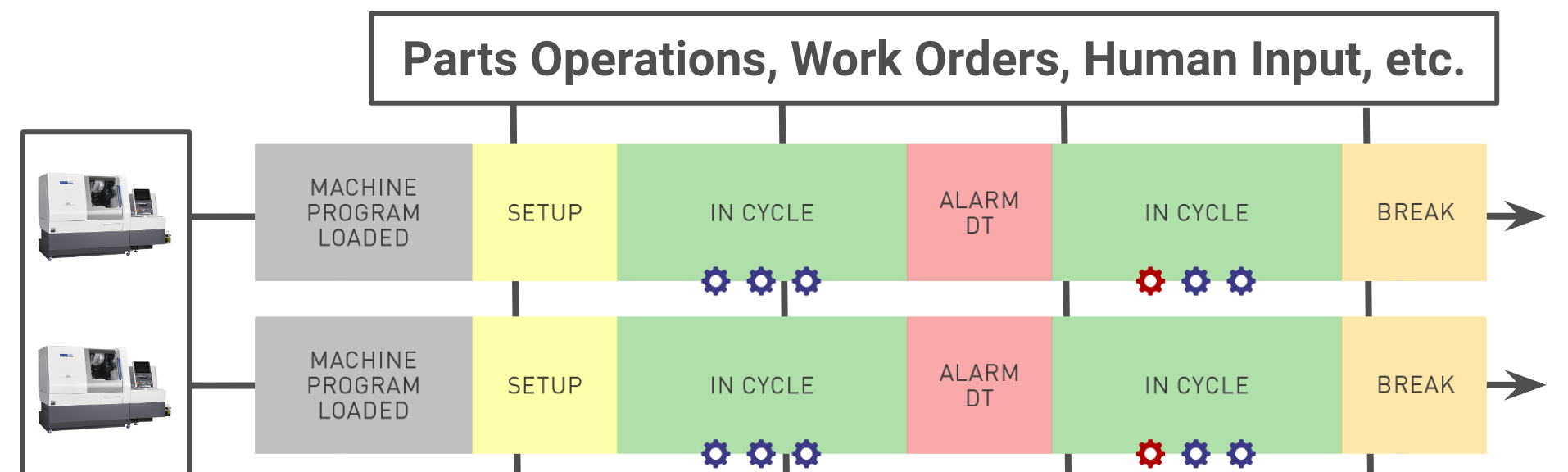

CFOs have traditionally followed established best practices with a wide range of influence over inventory valuation, purchasing, equipment procurement, cash flow management and a host of other responsibilities. And just as traditional manufacturing, a high degree of those functions required a lot of manual input and “after-the-fact” analysis. However, as data acquisition and analytical capabilities are being ramped up through the digital transformation of the shop floor, finance managers are realizing that while they too need to update their processes to take advantage of the new capabilities, they are also finding ways to contribute value and drive additional efficiency within their area as well.

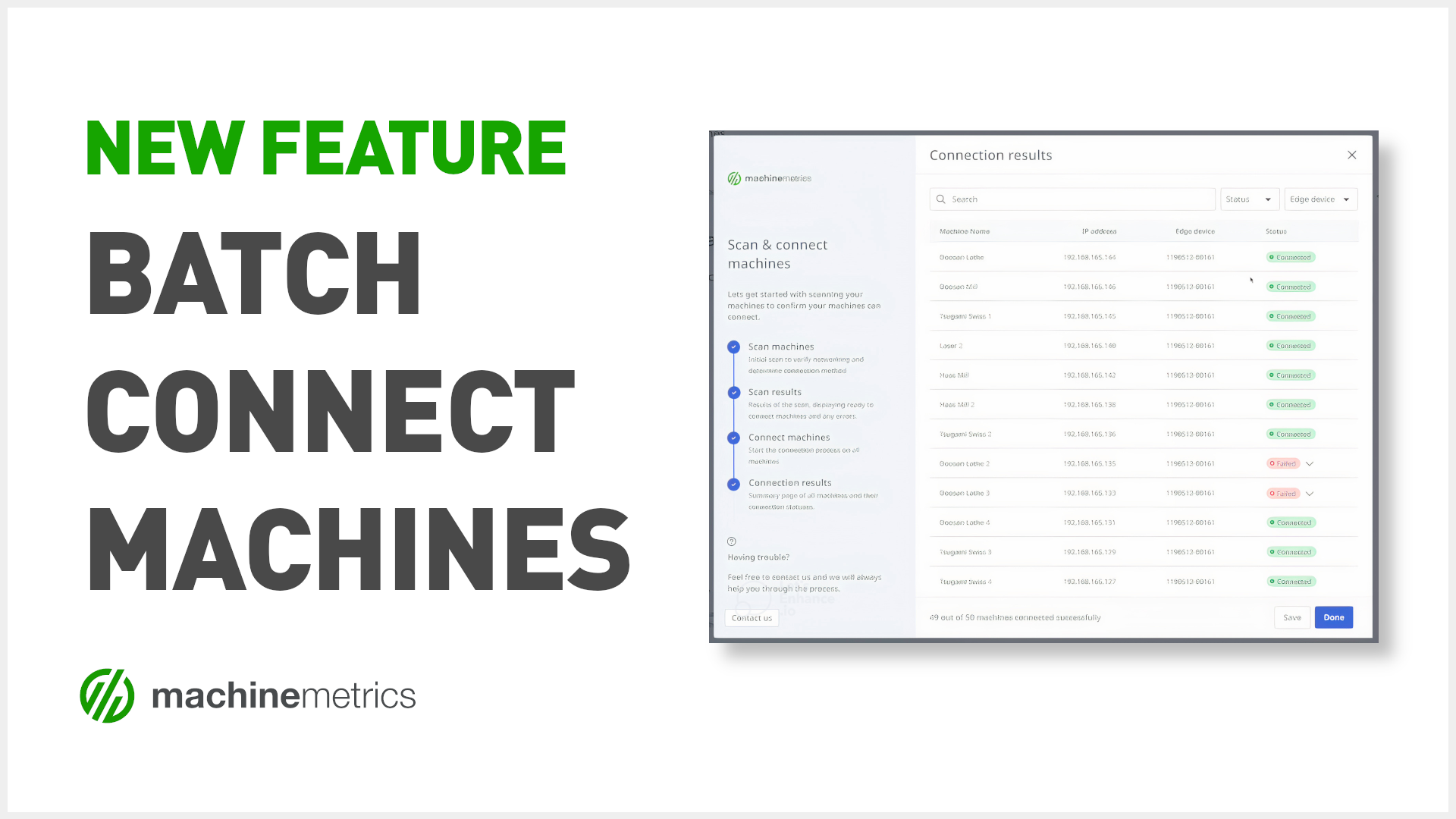

Enter: MachineMetrics. The use cases for our Industrial IoT platform for Machines extend far further than machine and process optimization on the shop floor but in reality to anyone within a manufacturing organization that wants to drive process improvements around machine data and insights. When Carolina Precision Manufacturing (CPM) was looking at ways to improve their OEE and monitor and manage data within their operation in real-time, they turned to MachineMetrics. Our platform allowed CPM to collect and analyze data across their operation and use this data to improve their processes. The results were transformative.

CPM was able to increase capacity by $1.5 million within a single year through an addition of 688 additional operating hours per machine. By capturing simple and usable data and providing an infrastructure across the operation to use this data to create improved workflows, CPM realized a return on investment in only 11 days.

In another deployment, process improvements driven by MachineMetrics insights allowed AccuRounds, a producer of precision machine components, to realize an ROI in only 60 days while achieving a 20% increase in OEE a 90% reduction in past dues and a 15% reduction in tooling spend.

From the Manufacturing Floor to the Finance Department

With results such as those, it’s easy to understand the impact on CFOs across manufacturing companies. And while it does require changes in daily operating procedures within those departments, opportunity is being created to leverage the finance functions to build upon the results and further improve process and performance.

Here are a few of the ways that MachineMetrics can enable a CFO’s opportunity to drive value:

- Revising Business Strategy – As improvement is driven across production, manufacturing goals not previously possible are now achievable. In the case of many discrete manufacturers, this can include very small lot sizes, even lot sizes of one by capturing efficiencies in setup and changeover comparable to volume runs. This will render most standard manufacturing cost models obsolete and require that finance deploy cost functionality that is causally tied to the data being captured as processes improve. By extension, CFOs have a more accurate understanding of actual costs and can impact everything from raw materials procurement to price considerations for sales since the data and analysis are more accurate.

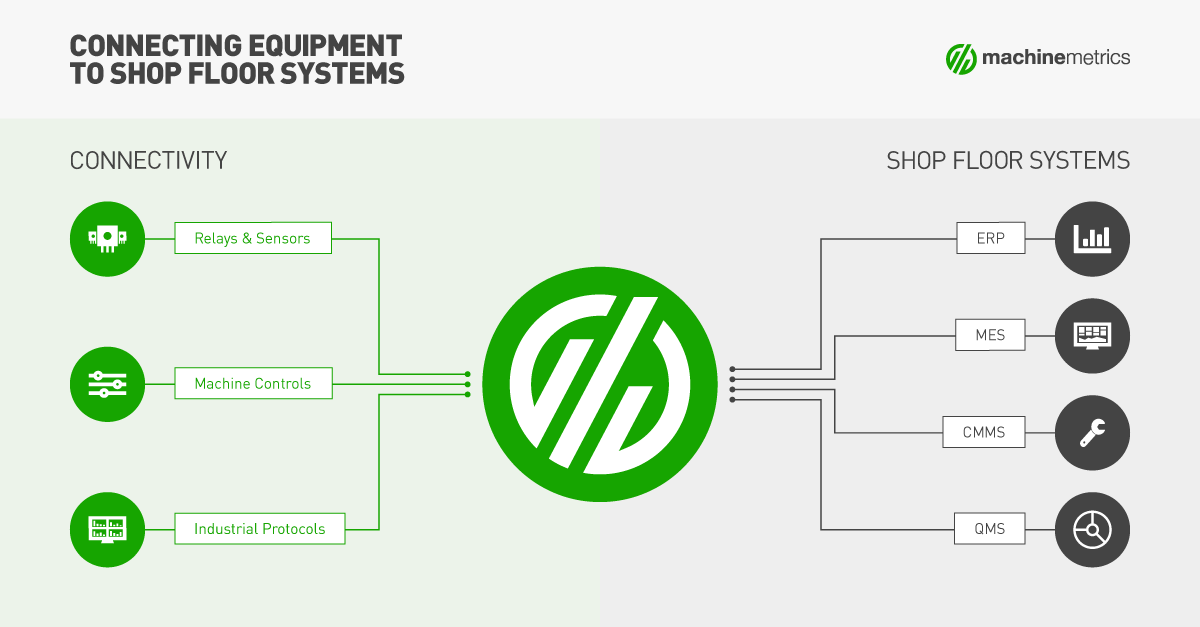

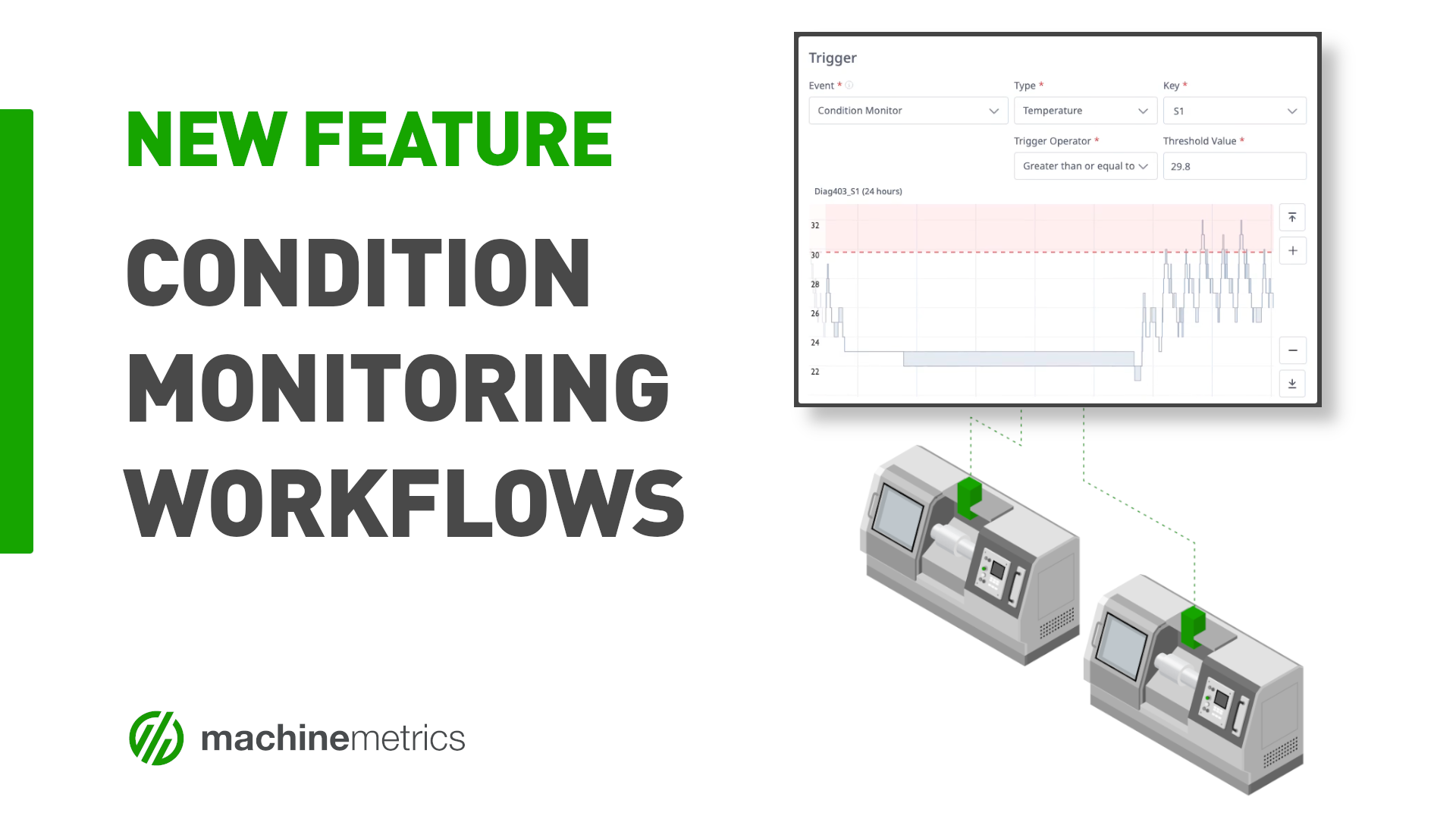

- Aligning Finance and Operations Data – In an industrial IoT platform, data isn’t just valuable because it is captured in real time. The analytical capabilities of platforms such as MachineMetrics can be used to develop prescriptive and predictive solutions to further improve processes. Because data is examined continuously and improvements can be deployed quickly, finance departments must align their operations to match the production floor’s capabilities. The deployment of an industrial IoT platform allows finance to measure data causally and allocate finance resources accurately. And as finance functions are tied to the incoming data and analytics, critical decisions such as cash flow management become more accurate as well. One study by McKinsey estimates that changes in finance management after the deployment of an industrial IoT platform can result in as much as a 122% improvement in cash flow for a manufacturing company.

- Capital Investment – CFOs are always heavily influential on capex decisions within manufacturing. This includes not only equipment but IT infrastructure as well. But the effect of a digital transformation and deployment of an industrial IoT platform can deliver opportunity for CFOs to spend capex funding strategically. Equipment is often purchased even though existing equipment is heavily underutilized. Understanding the bottlenecks of current manufacturing processes and reducing unnecessary downtime will optimize the use of current equipment. Benchmarking reports provided by MachineMetrics from aggregate utilization data can then help decide to purchase new equipment, or invest in process improvements. While cases such as Carolina Precision Manufacturing’s realization of and ROI of 11 days and AccuRounds realization of a 60 day ROI after the deployment of MachineMetrics are eye opening, it is clear that the effect on a CFO isn’t just limited to the positive effect of the rapid ROI on the platform itself.

Unlocking of “hidden capacity” through use of platforms such as MachineMetrics allows greater flexibility for capex decisions on production equipment. The bottom line is that the rapid ROI on an IoT platform combined with the improvements in OEE, maintenance and labor provide improvements to efficiency that give CFOs the ability to purchase capex items strategically rather than purchasing based on antiquated forecasts. This can impact the type and cost of new equipment acquisition allowing companies to purchase better, faster and more automated machines. Or, as the platform drives improved OEE resulting in more production output with existing equipment, it may allow that certain capex decisions be deferred to focus on other investment priorities that are more critical…priorities that would not have been possible to manage without the efficiency gains made with MachineMetrics.

Smart Finance for a Smart Factory

The power of a strong and flexible industrial IoT platform such as MachineMetrics is evident in the process improvements it delivers. The platform helps identify inefficient processes and deliver prescriptive workflows that optimize efficiency and decision making. By connecting to any machine and uncovering insights into what’s happening on the production floor, our platform can help not only diagnose and predict problems that lead to inefficiencies, but deliver workflows that empower manufacturing teams to act and improve.

But the improvements aren’t just limited to the production floor. As the data is simplified and standardized, its impact can ripple throughout the organization driving process improvement in sales, distribution and all the way up through C-suite managers including the CFO. These departments too must change their standard operating procedures to match the new capability on the production floor. By doing so, the direct benefits of industrial IoT are driving change and efficiency at the production level. They are also driving change within the realm of finance, allowing smarter, more accurate and more strategic allocation of financial resources as well.

Contact us to learn more about how MachineMetrics will affect you.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments