For anyone associated with manufacturing there is a familiar image that comes to mind when they hear the word “maintenance”. The image is of a lone mechanic pulling a toolbox on wheels across the production floor to a machine that has suddenly stopped or needs service or repair. This has been a stock image for many years, even after the development of concepts such as preventive maintenance. As even with preventive maintenance, the opening of machine doors, covers and guards was often met with surprises in the form unexpected wear, added downtime and a hurried search for the right parts to affect the repair.

For anyone associated with manufacturing there is a familiar image that comes to mind when they hear the word “maintenance”. The image is of a lone mechanic pulling a toolbox on wheels across the production floor to a machine that has suddenly stopped or needs service or repair. This has been a stock image for many years, even after the development of concepts such as preventive maintenance. As even with preventive maintenance, the opening of machine doors, covers and guards was often met with surprises in the form unexpected wear, added downtime and a hurried search for the right parts to affect the repair.

While it is true that the concept of preventive maintenance improved downtime and reduced long-term costs in its day, it still left open the possibility of those unexpected surprises and the associated cost in downtime that accompanied them. This reality existed because it was left to the skillset and intuitive understanding and experience of the mechanic, coupled with a “fingers crossed” hopefulness of the preventive element of the maintenance regime to keep the machine performing within optimum range. But the lack of capability to assess machine operability in real-time left the door open to the often costly “surprise-of-the-week”. In the end, human intervention simply couldn’t optimize machine operation effectively.

The Future of Maintenance

As Industry 4.0 advances and technology for the Internet of Things ingrains itself within manufacturing, the concept of predictive maintenance has emerged as a successor to preventive maintenance. The concept of Conditions Based Predictive Maintenance promises to bridge the gap between the failings of reliance human intuition and experience for repair and the ability to not just prevent failure, but to predict it and optimize maintenance and repair to save time and cost.

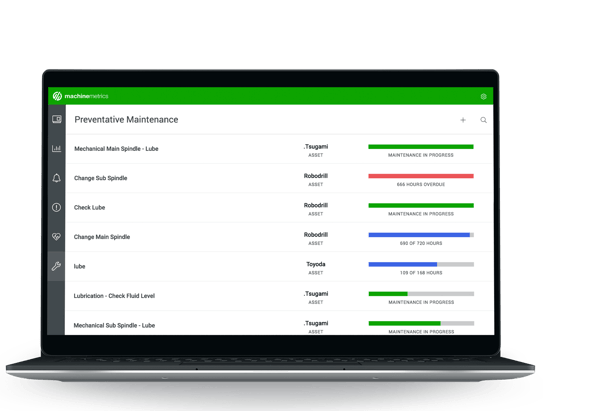

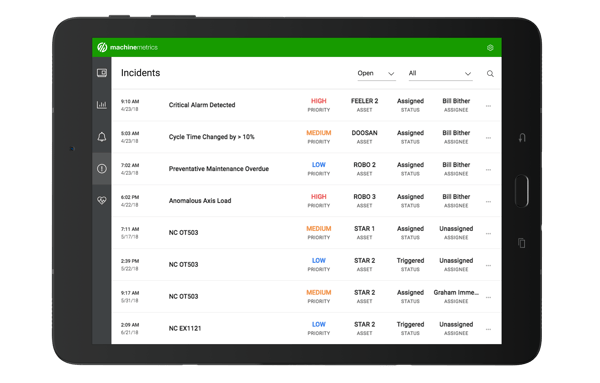

Condition Based Predictive Maintenance has several key elements. Namely, data acquisition, data processing and maintenance decision making. By acquiring data through a factory wide deployment of IoT technology, data is captured for analysis. Then, using a platform that can analyze the data in the cloud to pinpoint problems and develop maintenance strategies, the data is processed and analyzed. Finally, maintenance decisions are automated to tie all aspects of maintenance into a predictive regime that reduces downtime and costs and truly blends maintenance into the operation as part of the production process instead of being a barrier to it or a “necessary evil”.

Better Maintenance for Better Margins

The ability to use tools such as machine learning and cloud-based analytics of the acquired data allows companies to develop customized maintenance solutions that can be machine and product specific. By doing so, time, quality and cost are all improved. One study indicates states that with predictive maintenance, productivity increases by 25% and downtime drops as much as 75% with lower maintenance costs reaching 25% as well.

Here are four key areas where predictive maintenance can save money:

Failure Analysis - With data acquired through IoT technology, platforms exist that can analyze data across the entire operation to monitor for system disruptions. Temperature sensors, flow regulators, valves and other components within a machine can be monitored in real-time, compared to OEM parameters and analyzed in concert with corresponding parts on other machines and against historical data to predict when a specific component is – or will be -out of synch or malfunctioning.

In many cases, the adjustment can be made electronically. In others, notification can be sent to maintenance that a part should be replaced during an upcoming changeover cycle if the failure is not imminent. Cost is reduced through significantly less downtime.

Parts Inventories – Manufacturing operations have always struggled to achieve the right level of spare parts to assure proper service levels for all equipment. This analysis was often done manually and through schemes such as “min/max” programs to ensure that parts inventories were neither too high nor too low. But again, accuracy of such programs is based on human decision-making and costly shortages or equally costly oversupply meant more money had to be tied up in spare parts.

With predictive maintenance, parts inventory costs can be reduced through the use of precise analytics. Simple min/max ranges can be replaced by analysis of current and historical part consumption and failure rate. Estimates show that optimized parts inventory in a predictive maintenance program can reduce carrying costs by 20-50%. Re-ordering can be automated to match the historical consumption rate and parts – like raw materials in the production component supply chain – can be moved to a JIT footing.

Energy Savings – With preventive maintenance, if a machine veered from spec shortly after scheduled service, maintenance staff had to either bring the machine down an additional time to make the repair or wait until the next scheduled down cycle. And in many cases the variance may not be noticed until the next down cycle. This meant that equipment relying heavily on excess electricity use, water flow, or fluid or particulate flow for their production expended cost in the form of energy inefficiency or waste as the equipment struggled to produce the correct amount while using more resources.

With predictive maintenance, energy, water, natural gas and product flow can be precisely monitored to know exactly when and by how much the machine has varied. In many cases the adjustment can be done automatically and at the point of detection. In others, the program can pinpoint the areas of concern or the part running inefficiently, schedule the appropriate staff and time and assure the parts are available for the repair. This improves energy efficiency and lowers utility cost. Predictive maintenance can also monitor energy and water rates to signal the optimal time of day to capture the lowest kilowatt or per gallon cost for maintenance and changeovers by scheduling maintenance at off peak hours for those tasks.

Quality – Every industry has an established fallout rate usually expressed in terms of percentage. A robust predictive maintenance program can direct and focus repairs to the proper fail point or automate adjustments to keep equipment not only within established fallout ranges. Further, by introducing faster response to equipment failure, those fallout ranges can be reduced, saving money for the entire operation through increased efficiency and production of more first quality goods.

The key to using predictive maintenance to save money lies in the ability to analyze available data. And while many companies are adding IoT functionality, data usage in decision making is still lagging. Selecting the right platform to analyze the data and provide actionable real-time maintenance will be needed to improve interoperability between different IoT technologies. With such a platform in place the image of the mechanic shuffling his toolbox toward a breakdown with little or no knowledge of what he or she will find can be replaced by an advanced program of predictive maintenance that saves money and increases margins.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments