Key Takeaways:

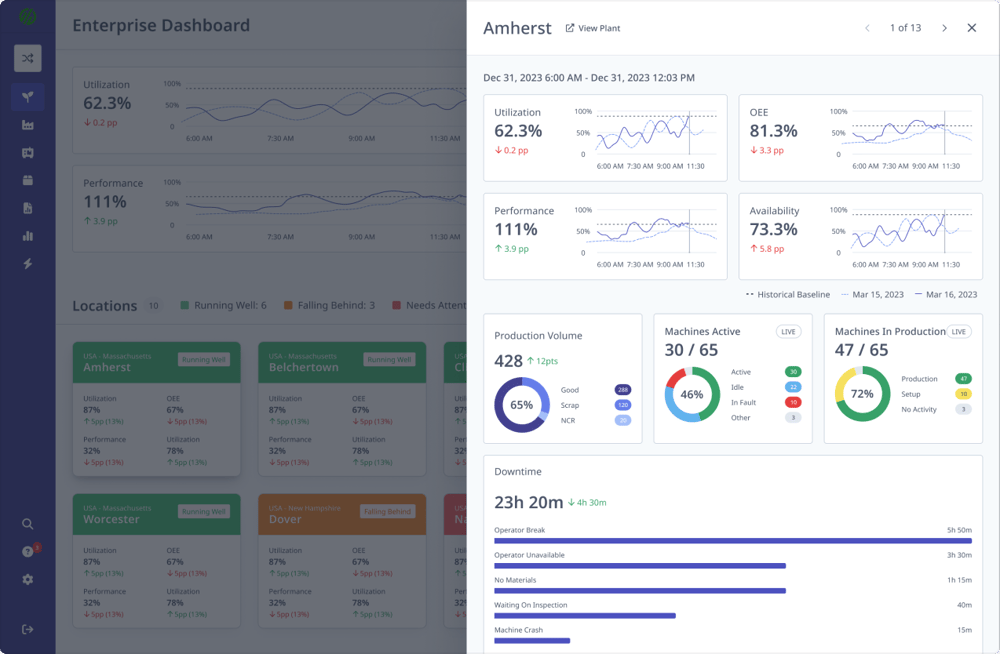

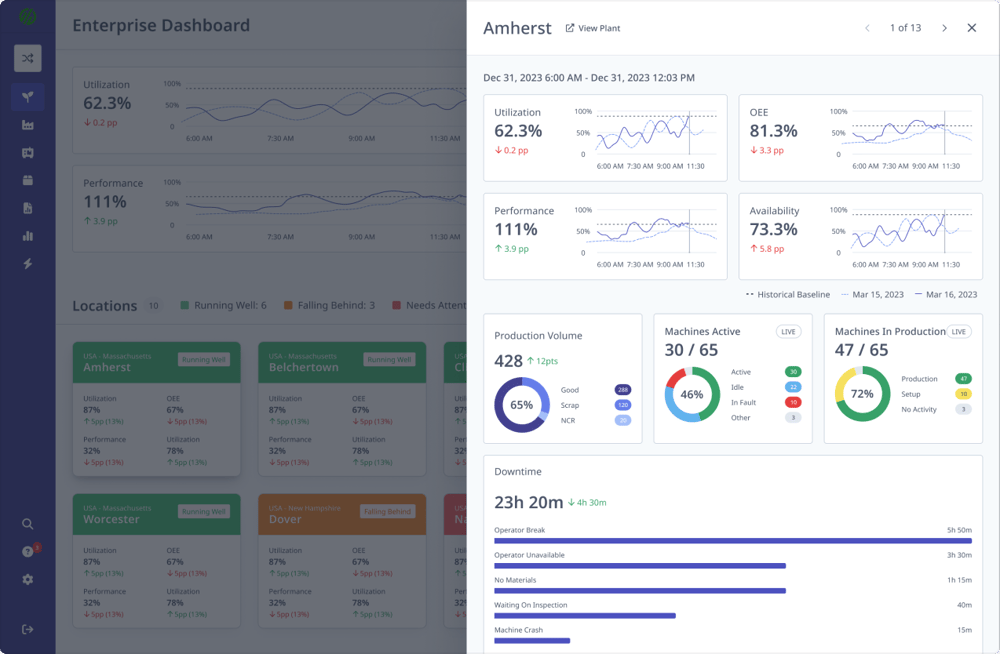

- MachineMetrics provides enterprise-level insights through its real-time machine data monitoring platform, enabling strategic decision-making.

- These insights allow manufacturers to improve operational efficiency, reduce machine downtime, and enhance overall productivity.

- By utilizing comprehensive data analytics, manufacturers can align their operations with business goals, driving performance improvements.

This article is part of a series discussing the value of machine data for every level of an organization, including the machine level, plant level, and enterprise level. The MachineMetrics platform's flexible and extensible nature enables users to get started quickly while ensuring they can get accurate production data everywhere it needs to be, both horizontally across their shop floor operations, as well as vertically to support management and the enterprise as a whole.

Other articles in this series:

- Machine Level Insights:

- Plant Level Insights:

- Enterprise Level Insights:

- The Value of Accurate Machine Data for the Enterprise [You're Currently Reading]

Giving the Enterprise a Source of Truth

Machine analytics at the machine level supports operators, drives processes, and enables real-time response to production issues. Plant-wide analytics allows complex manufacturing facilities to share real-time insights to optimize entire departments and facilities.

But these same machine insights can also be applied to the enterprise level. Manufacturing enterprises with large plants and multiple facilities are able to aggregate the data, enabling high-level business insights.

This economy of scale empowers an enterprise's facilities to achieve deep production visibility. Also, every system can be empowered by accurate production data, bridging the gap between OT and IT systems.

The Value of Enterprise-Wide Insights

Production insights available at the enterprise level grant an all-encompassing view of operations, labor utilization, and efficiency across all production facilities. This helps manufacturers compare different facilities and, in turn, unearth patterns, identify inefficiencies, and emulate successful practices.

Further, accurate production data ties shop floor performance and continuous improvement initiatives to the bottom-line benefits experienced by the business. Without this thread of connected data, the two layers of the business will have to be manually juxtaposed.

The richness of the insights derived from advanced analytics platforms greatly enhances strategic decision-making. Using these insights, decisions are made faster and with greater accuracy. Operators, managers, planners, and executives can all identify potential issues at their respective levels before they escalate.

Enterprise Level Insights

Advanced analytics platforms are critical in shaping manufacturing enterprises' efficiency and financial health. Through the lens of enterprise-level insights, the ability to achieve complete visibility, plan effectively, and compare performance drives OEE and lower costs throughout the organization.

As a result, organizations can better plan for and meet demand, optimize their pricing, allocate resources efficiently, and reveal hidden capacity across their factories.

Plant Visibility

Accurate, real-time production data from connected assets at each department and facility empower a deep view of operational performance. With plant-to-plant visibility, managers can monitor and analyze each facility at both the macro and micro levels.

This capability lets them “see” and understand efficiency and throughput across a wide range of KPIs. They can compare production lines, jobs, labor performance, and processes.

Benchmarking

Executives, planners, engineers, and other staff require a global view of the company’s performance at a facility level. Machine analytics lets these stakeholders uncover deep operational insights from facility to facility.

These insights can be used to benchmark and compare performance across each plant and use the best results as a guide for implementing process improvement at other facilities.

Capacity Analysis

Machine analytics delivers the long-sought goal of unlocking hidden capacity. Analyzing the enterprise opens up significant machining and labor capacity for machines and product lines.

For example, if analytics indicate a constraint for a specific production line, work can be shifted to other locations with available capacity. Capacity analysis can lead to the deployment of new production optimization strategies and may also significantly impact capex planning.

Production Planning

With supply chains becoming more complex and volatile due to continuous disruption, planning teams need all the help they can get. Using machine insights to analyze enterprise-wide production helps these teams manage rapidly changing demand.

Because the platform delivers accurate and real-time machine data like part counts, cycle times, and other variables, planners can effectively plan labor, equipment, and materials at the right time.

Facilitating Business Growth

Enterprise-wide insights derived from machine data are about improving current operations and facilitating business growth. With full visibility of the enterprise, managers can plan production and capacity better while gleaning insights from benchmarking that can be applied throughout the company.

MachineMetrics gives companies the data, tools, and insights to understand their operations better and creates opportunities for continuous improvement, innovation, and growth at every level of the operation.

Further Reading

This article is part of a series discussing the value of machine data for every level of an organization, including the machine level, plant level, and enterprise level. The MachineMetrics platform's flexible and extensible nature enables users to get started quickly while ensuring they can get accurate production data everywhere it needs to be, both horizontally across their shop floor operations, as well as vertically to support management and the enterprise as a whole.

Other articles in this series:

- Machine Level Insights:

- Plant Level Insights:

- Enterprise Level Insights:

- The Value of Accurate Machine Data for the Enterprise [You're Currently Reading]

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments