Key Takeaways:

- Effective communication helps overcome morale challenges related to machine monitoring.

- Transparent data sharing builds trust and encourages employee buy-in.

- Clear communication aligns teams and improves adoption of new technologies.

Originally published on Modern Machine Shop.

When pen-and-paper methods of tracking job efficiency left AccuRounds’ engineers and managers in the dark, the shop switched to MachineMetrics. But machine monitoring brought morale challenges along with it.

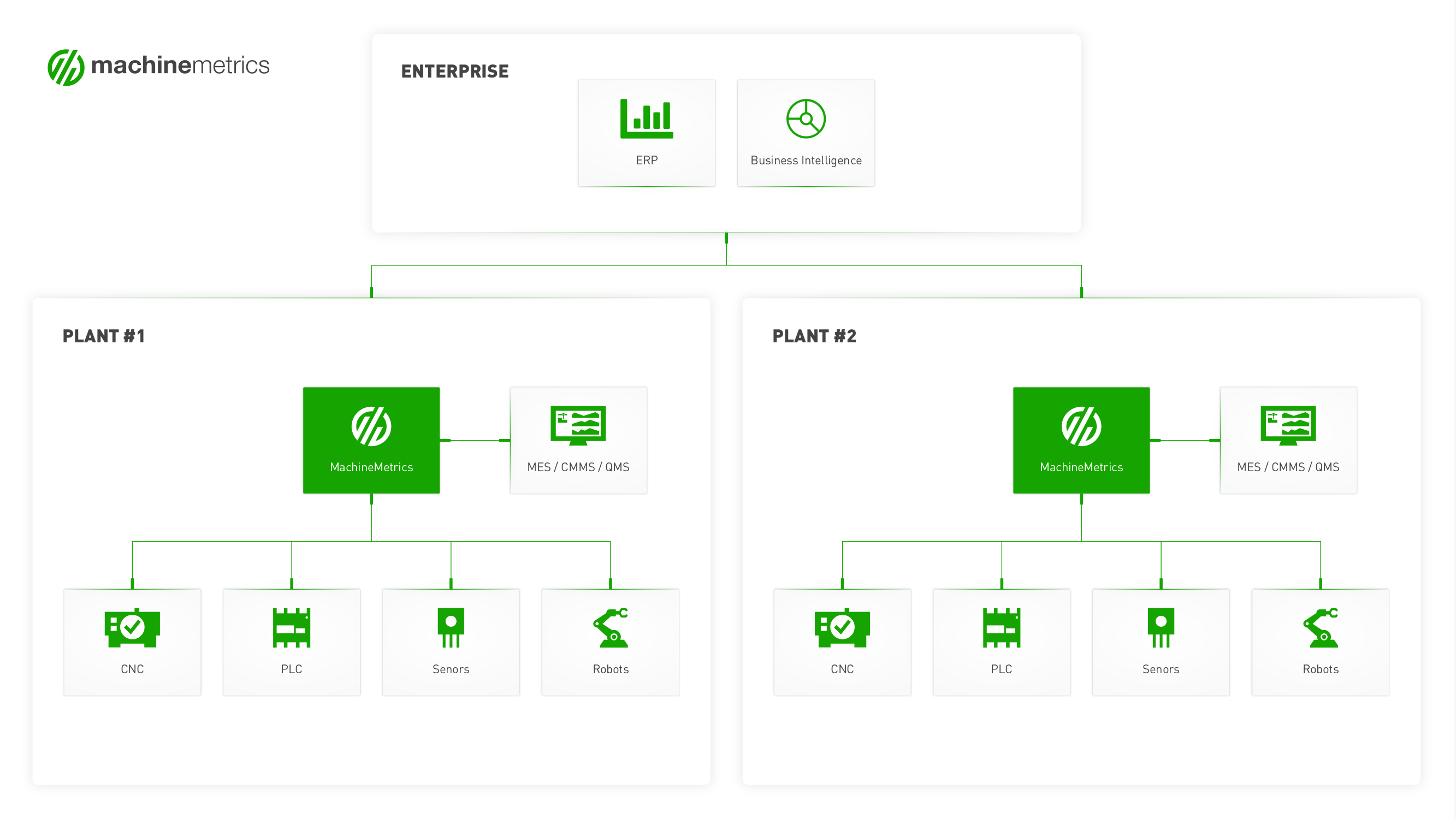

After trying to track shopfloor efficiency with pen and paper, AccuRounds chose to implement a machine monitoring system with the help of MachineMetrics. This data-driven practice quickly demonstrated the benefits of real-time monitoring. It also brought some tensions to the surface among shopfloor employees. AccuRounds’ story can serve as a case study for how to implement such technology effectively.

AccuRounds, based in Avon, Massachusetts, is a second-generation, family-owned, advanced manufacturer that provides machined components to industries including medical and aerospace. Mike Tamasi, AccuRounds’ president and CEO, credits his people with the shop’s success.

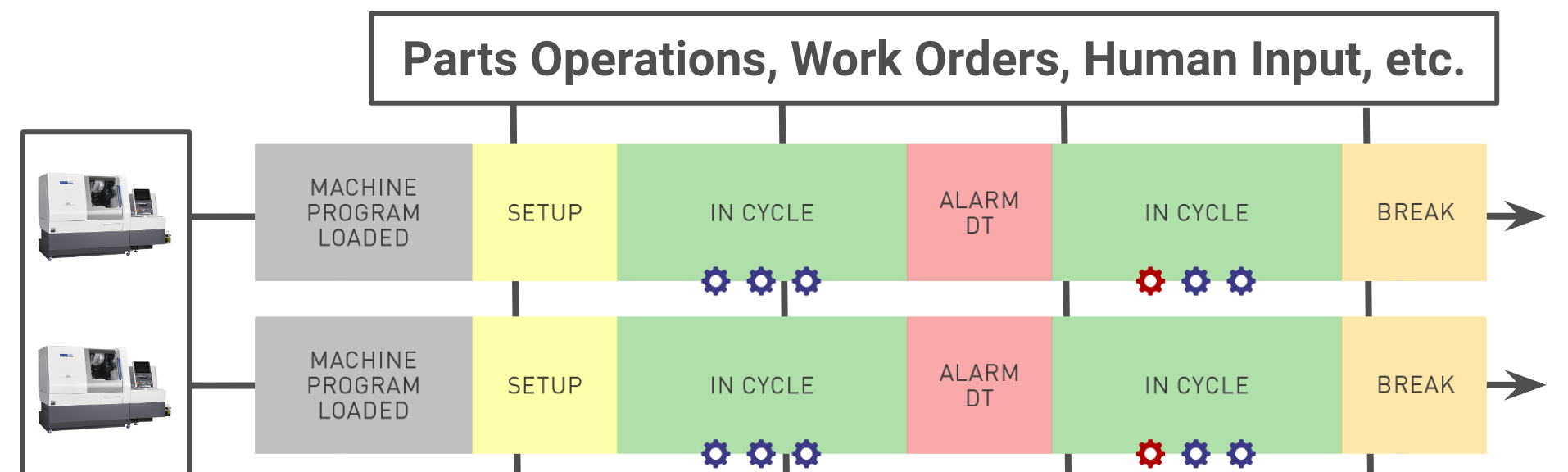

In 2017, AccuRounds began talks with MachineMetrics and installed its machine monitoring system on 10 CNC machines in early 2018. Within a year, the shop had connected another 13 machines and had improved processes as well as collaboration between engineers and machinists. Because AccuRounds had a history of building a strong culture from the front office to the shop floor, management worked deliberately to manage the discomfort among machinists that arose during the first few months after installation.

Moving Away from Manual Tracking

AccuRounds’ goal was to measure the efficiency of the shop’s machining processes. “At one point, we were doing that by hand, on paper, hourly, and my feet live to tell about it,” says Jim Fruzzetti, manufacturing engineer. “It was not the most efficient.”

"Sometimes things were not running well. The time it took to find that out was a liability."

Process engineer Paul Cabral remembers how things were before MachineMetrics: “We would record how much [our machinists] were hitting as far as rates and parts an hour. Their information was getting lost in time. You would go out on the floor, and they would say, ‘Things are running well.’ You would take their word for it.” But sometimes, Mr. Cabral says, things were not running well. The time it took to find that out was a liability. “If a job was scheduled to run for three days, we just expected on that third day for it to be done. If it wasn’t, then maybe that’s when we would interact with that operator. We were beginning to realize how important it was to track that.”

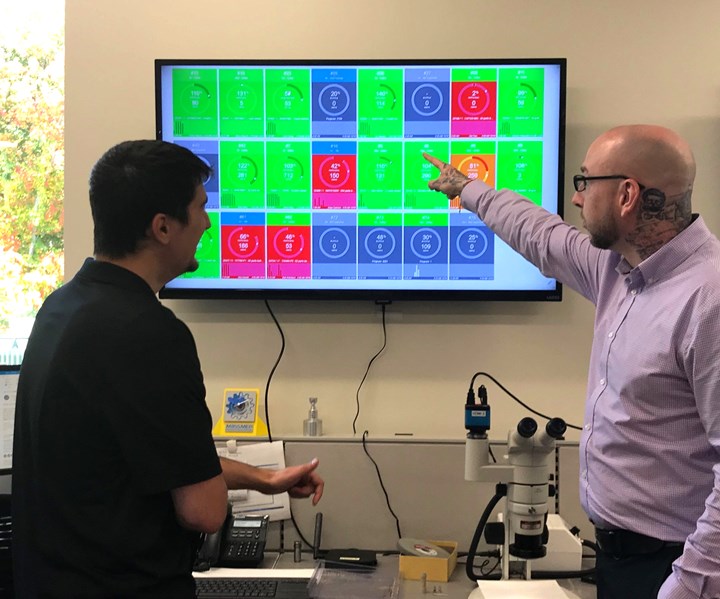

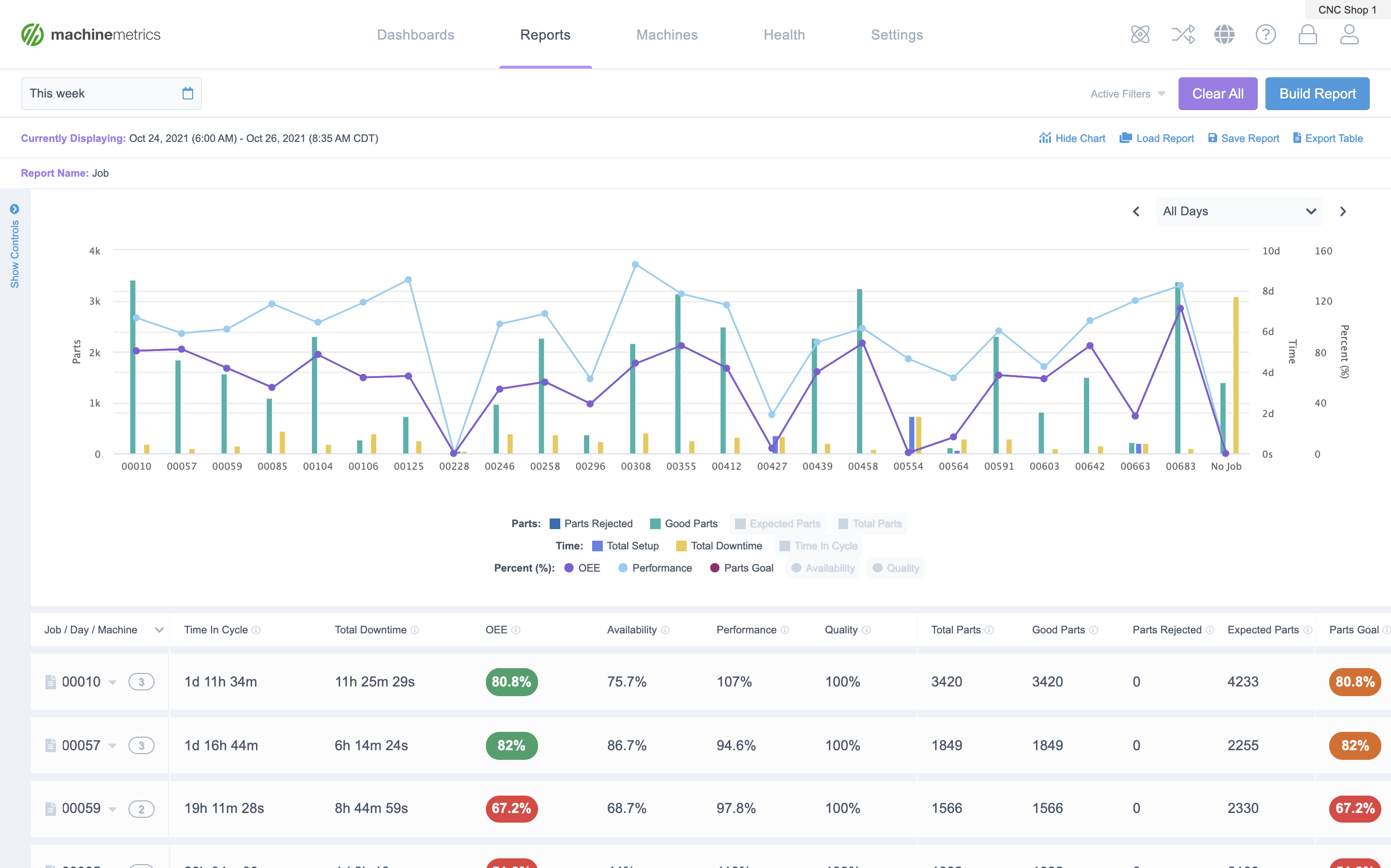

Paul Cabral and Jake Perry, two of AccuRounds’ process engineers, review MachineMetrics’ real-time machine monitoring dashboards.

After looking at a couple of different machine monitoring systems, Mr. Tamasi says that MachineMetrics “felt right to us.” The fact that it too is a Massachusetts-based company was a nice bonus. Another was the platform’s open architecture. “If we come up with an idea and MachineMetrics implements it, then everybody wins,” he says. “Likewise, if there's another customer that comes up with something, MachineMetrics just opens it up to everyone so we get to take advantage of that. That’s not a philosophy of, ‘We’re going to keep things secret.’ It’s a sharing environment.” That sharing culture was what Mr. Tamasi hoped to achieve with the software’s implementation in AccuRounds as well.

Process Monitoring, Not People Monitoring

Mr. Tamasi and shop management anticipated a little resistance to such a radically different process technology, and they talked it up a bit before installation.

“I don’t think people really grasped what this was going to be until they said, ‘Oh, there's a tablet in front of me. Wow, look at the color, and what does that all mean?’” he explains. “We only started with the 10 machines that we thought were the better performers — those on which it would be easier to implement monitoring and would yield less resistance.”

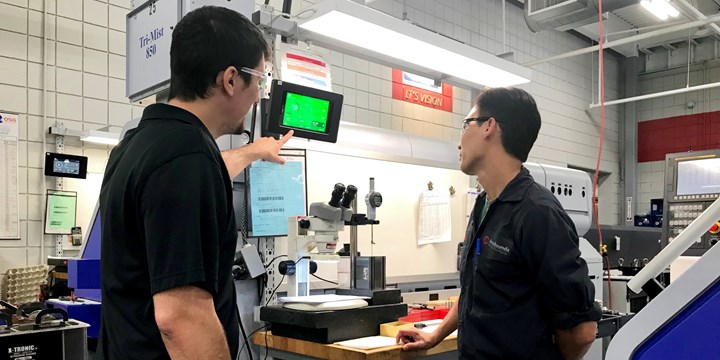

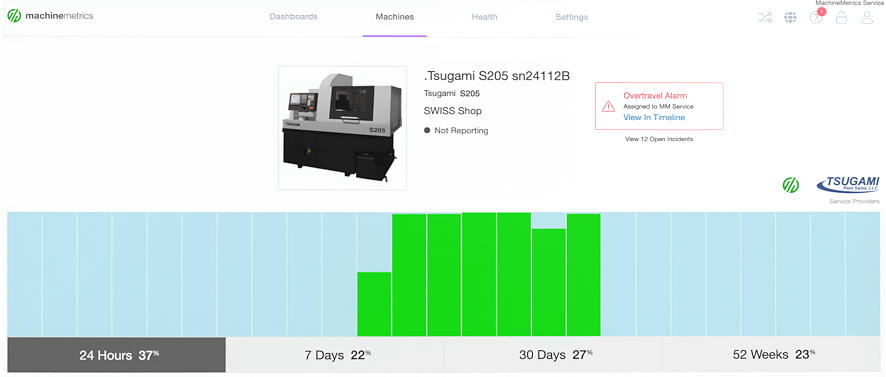

Mr. Cabral discusses run rates using MachineMetrics’ Operator View with Thu, a machine operator.

In addition to picking higher-performing machines, management chose individual shopfloor employees who they thought would quickly grasp and welcome the technology.

"The focus of machine monitoring is on the process, not individuals."

Mr. Tamasi was not naive about the potential morale hurdles such changes might bring. “I think one of the challenges through implementation was getting past the whole human element of, ‘Why are you watching what I’m doing?’” he says. For example, when individuals run two machines, it can be challenging to keep them both “green.” Some operators feared being penalized for one machine going “red,” when in reality they were producing something at 50% versus zero. “So they're getting 150% production versus nothing on that second machine. And that's okay,” Mr. Tamasi says.

In Mr. Tamasi’s view, the focus of machine monitoring is on process, not individuals. Rather than using the technology to discipline individual workers, he uses it to see where a process is breaking down.“We have not taken any type of disciplinary action on an individual's part. It’s really a question of figuring out where the process is breaking down.” For example, he says monitoring might reveal that a lack of training has set up a worker to fail: “A person could be on a machine that he or she shouldn’t be on, and it’s red because they just don’t have the proper training. So that’s on us — that’s on the company to get that individual the proper training. The more those instances came about, the more they were addressed the right way, and the more comfortable our team became utilizing MachineMetrics.”

The Machinist’s View

How did things feel from the machinists’ perspective?

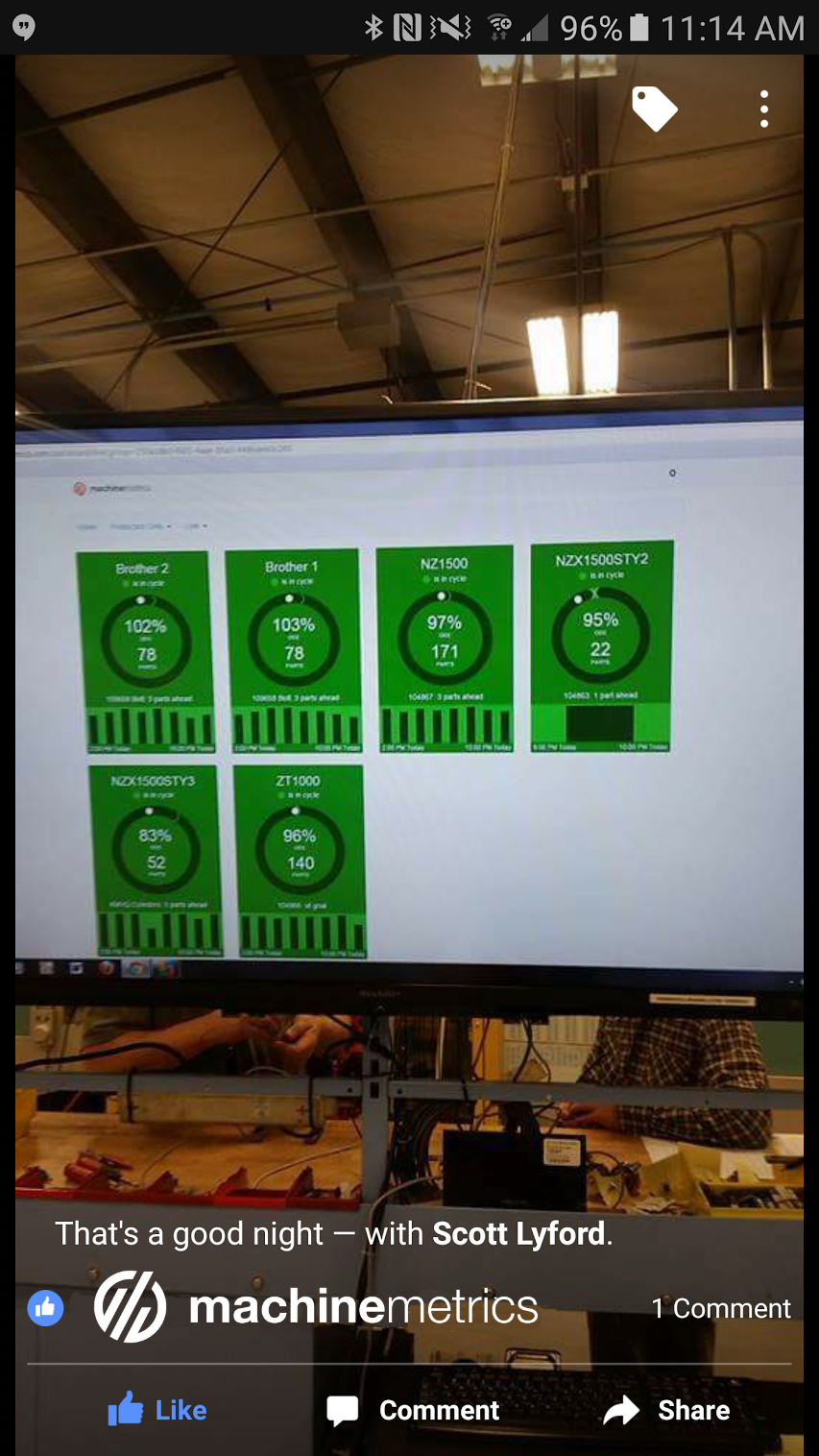

“We had it at my old company, but only the supervisors could see it, so they would know when the machine is off,” says one. “It’s cool that we can see it too, so we know if we’re behind.”

“It’s not measuring me, it’s measuring the process,” says another operator. “If it’s red, there's less chance for a bonus, but I don’t panic. Sometimes it’s a mismatch, the wrong expected time, or a tool that takes longer. It may depend on if they're experimenting with tooling. We’re always trying to improve the process.”

A third machinist says, “I usually don’t like to look at the screen, because then you micromanage yourself.” Still, he adds, it is nice to be able to see improvements “When I came over to this cell, my tool change was nine minutes, and I got it down to seven minutes 30 seconds.” The first things he tells trainees is “Don’t look at the screen.” “They might want to make the rate,” he says, “but then half of their parts are bad. A month in, you should be orange all the time.”

The Benefits of Machine Monitoring

The benefits to shop efficiency are undeniable: a 20% increase in overall equipment effectiveness (OEE), a 15% reduction in tooling spend and a 52% reduction in turnover rates. After 60 days, the company says it had achieved a full return on its investment.

Mr. Cabral says that MachineMetrics data amounts to a Pareto chart to see where training efforts should focus. For example, if downtime is attributable to tool change, and that tool change is taking an operator 30 minutes, maybe retraining that machinist can bring it down by five minutes.

The green screens on these machines represent MachineMetrics’ Operator view in action.

For Jake Perry, another process engineer, the system has helped the shop identify problem jobs and processes more quickly and efficiently. Before machine monitoring, figuring out what went wrong on a job meant going to the machinist days after the job had been done. The operator, having set up multiple jobs since then, often could not remember the details. With MachineMetrics, the machinist can put notes within the downtime categories explaining what happened or what recurring issues there may be.

“Communicate, Communicate, Communicate”

AccuRounds’ management of initial troubleshooting issues stemming from shift scheduling serves as an example of why the greater amount of data visibility required more, not less, communication.

Back when the shop’s first shift ended at 3:30 p.m., some of the second-shift employees began at 4 p.m. This meant they arrived at a red screen, since the rate was being measured from a 3:30 p.m. start time. It may eventually turn to orange and perhaps green by end of shift, but these second-shift machinists were playing catch-up the whole time. Meanwhile, some first-shift operators who could stay past 3:30 p.m. complained that MachineMetrics kicked them out of the program, forcing them to clock out and then back in for the last half hour.

Because MachineMetrics is used to track machine uptime generally, the shop now measures efficiency with a 24-hour virtual “shift” within MachineMetrics for simplicity.

Having ridden the waves that come from implementing machine monitoring, Mr. Tamasi’s advice to shops looking at adoption of this data-driven technology is all about communication. “Start small,” he says. “Don’t try to do the whole shop.” Having done this, he recommends celebrating the wins with shopfloor workers. “Celebrate the opportunities for improvement. Communicate, communicate, communicate.”

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments