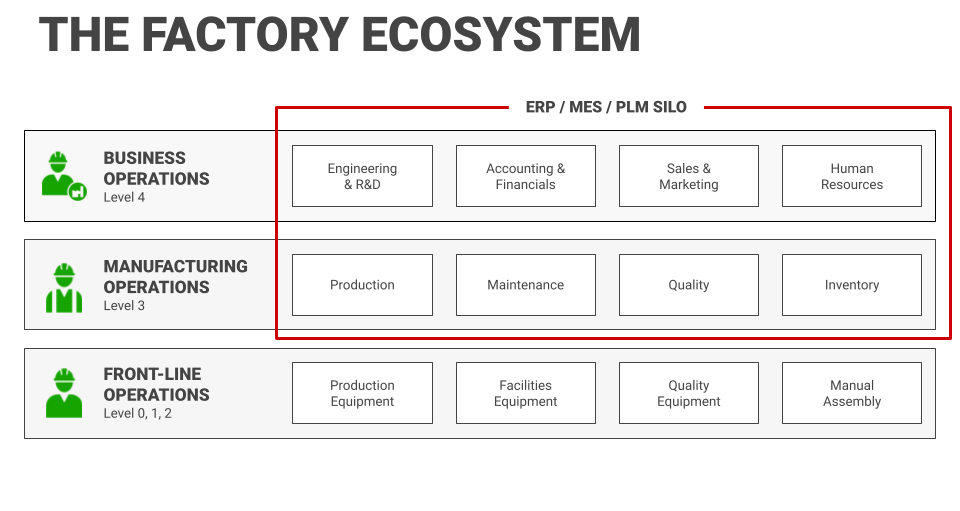

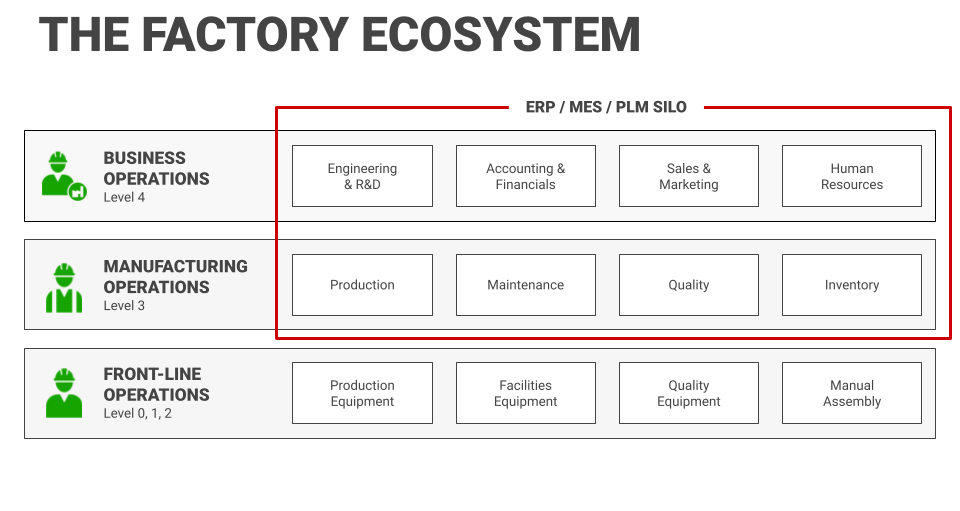

The manufacturing landscape is evolving, and so are the challenges manufacturers face when managing shop floor operations. Manufacturing Execution Systems (MES) have long been heralded as the solution to bridge the gap between factory floors and enterprise-level planning. But as technology advances and operational demands grow, MES systems have continued to fall short of expectations.

Manufacturers today are left with a pivotal question: should they build an MES from scratch or buy an off-the-shelf solution?

Our answer lies somewhere in between.

The Foundation of MES

Within a manufacturing production environment, there are any number of tasks and functions that must be addressed. However, there is a common thread that exists across all manufacturers. The Core 4 showcase the jobs-to-be-done that nearly every manufacturing team must account for when building or buying a manufacturing execution system:

- OEE Analytics: This measures availability, performance, and quality, giving manufacturers critical insights to enhance operational efficiency.

- Downtime Tracking: By identifying and categorizing unplanned downtime events, teams can address inefficiencies and minimize disruptions.

- Work Order Management: This provides real-time visibility into job progress, streamlining execution and reducing delays.

- Scheduling: With dynamic resource allocation, scheduling ensures optimal machine usage and adapts to real-time conditions.

Keep these capabilities in mind whether you are building a solution from the ground up, or selecting one off the shelf.

Problems with Build and Buy

Traditional MES solutions are divided into two broad categories: off-the-shelf systems and custom-built (DIY) solutions. There is almost everything in between as well, with many manufacturers still relying on cobbled together systems stitched with Excel, paper, and whiteboards. While both the build and buy approaches have benefits, they also come with significant challenges.

Buying Off-the-Shelf MES

Off-the-shelf MES solutions are marketed as comprehensive, out-of-the-box systems that serve every need. However, their rigidity often creates obstacles for manufacturers with unique workflows. Extensive customization is typically required, inflating both costs and timelines. Furthermore, these solutions often lack flexibility, with implementations taking years to deliver value. The reliance on manually captured data further hampers real-time decision-making, leaving manufacturers stuck with incomplete, or nonexistent, insights.

Building MES from the Ground Up

On the other hand, building an MES from scratch promises ultimate customization and control. Yet, this approach is resource-intensive, requiring significant time, money, and technical expertise to develop and maintain. Scalability becomes an issue as operational needs evolve, and the delayed return on investment (ROI) often makes DIY solutions unsustainable for many manufacturers.

Evaluating Key Factors

When deciding between building or buying an MES, manufacturers must carefully evaluate several key factors.

- Cost of ownership is one of the most critical considerations. Building a custom MES requires a significant investment in development, integration, and ongoing maintenance, while off-the-shelf solutions often entail hefty customization costs.

- Time to value is equally important, as manufacturers cannot afford to wait years for their system to deliver operational improvements.

- Scalability is another essential aspect, as MES systems must evolve alongside the organization’s needs. Put another way, the system must align with both immediate operational goals and long-term strategic objectives - or even unforeseen future needs.

The reality is clear. No off-the-shelf MES will meet all your needs perfectly, and building one from scratch is often prohibitively expensive, time-consuming, and rarely scalable. The optimal solution lies in a hybrid approach - selecting a modular MES platform that delivers the core functionalities with the ability to build and configure to support additional use cases.

A Hybrid Approach: Modular MES

MachineMetrics offers a pragmatic solution to the build vs. buy dilemma. Designed specifically for discrete manufacturers, MachineMetrics combines out-of-the-box functionality with configurability.

With the ability to deploy the Core 4 - OEE analytics, downtime tracking, work order management, and scheduling - MachineMetrics provides a configurable platform that allows manufacturers to tailor workflows and dashboards to their specific needs without requiring technical expertise. Real-time data integration ensures seamless connectivity between machines and ERP systems, delivering actionable insights that drive efficiency.

By striking a balance between rapid deployment and long-term adaptability, MachineMetrics empowers manufacturers to achieve both immediate results and sustained growth.

[Full size diagram]

[Full size diagram]

MachineMetrics in Action: Practical Scenarios

For manufacturers currently using or considering a DIY MES, MachineMetrics serves as an accelerator. By providing pre-built functionalities like real-time machine data collection, OEE tracking, and downtime analytics, MachineMetrics reduces the burden on technical teams and ensures faster deployment.

Augmenting MES

For instance, a mid-sized manufacturer struggling to manage machine connectivity and integrate data into operational workflows can leverage MachineMetrics to establish a robust foundation for their shop floor data.

Real-time data feeds directly into ERP systems, enabling accurate job tracking and resource planning. With this connectivity, the manufacturer achieves a streamlined process without the prolonged development cycles associated with a full custom-build MES, or the lack of connectivity that generally occurs with off-the-shelf solutions. If a user were to build completely from the ground up, they would have to build a connectivity layer that enables data capture, standardization, and normalization - this resource-intensive project would likely be attempted with a solution like Kepware or Ignition.

Automated MES

For manufacturers without any MES, MachineMetrics can act as a standalone, automated MES. Its "Core 4" functionalities - OEE analytics, downtime tracking, scheduling, and work order management - offer a practical starting point. This modular design allows organizations to begin with essential features and scale their system as operational needs evolve. For example, a manufacturer looking to optimize scheduling can rely on MachineMetrics Production Schedule Intelligence, ensuring resources are allocated efficiently and workflows are adjusted dynamically based on real-time conditions.

When it comes to discrete manufacturing environments, the flexibility and scalability of MachineMetrics empower manufacturers to continuously refine and adapt their operations, achieving immediate ROI and positioning themselves for long-term success.

The Future of MES

The days of rigid, one-size-fits-all MES systems are over. Modern manufacturers require agile, modular solutions that cater to their unique needs while adapting to evolving demands. By adopting a hybrid approach - combining off-the-shelf core functionalities with tailored configurations - manufacturers can achieve faster ROI, reduced complexity, and long-term scalability.

MachineMetrics exemplifies this hybrid model, empowering discrete manufacturers to harness real-time data and actionable insights to transform their operations.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments