As technology advances at a blistering pace, many industries are finding new and creative ways to create and sustain value through its use. With a regular stream of news stories about drones, 3D printing, and a host of other attention-grabbing tech innovations, many overlook one of the biggest growth areas for the deployment of new technology – traditional manufacturing.

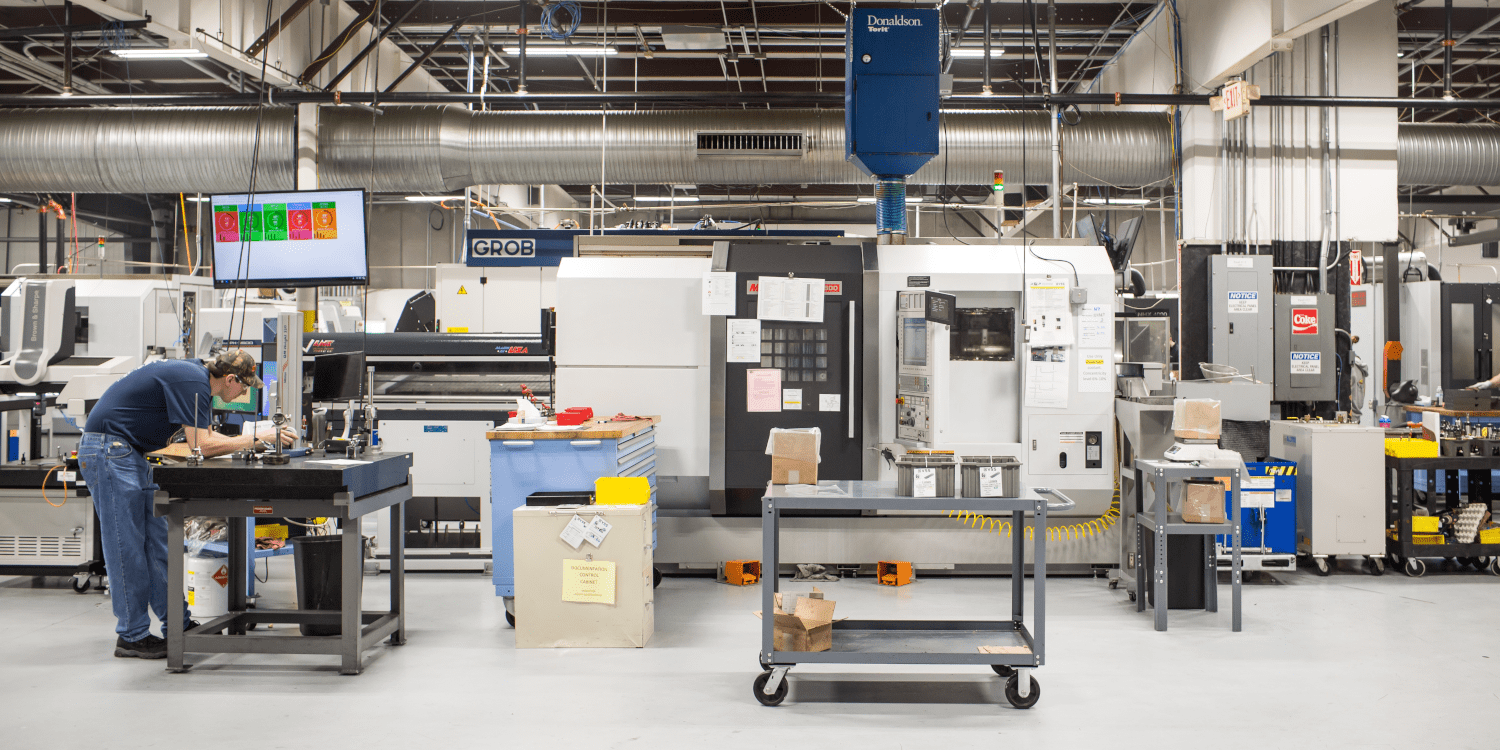

For many, the word “manufacturing” conjures up stock images. From dull, loud, and dirty factories to tedious labor performed manually by operators, manufacturing stereotypes have remained consistent over the last few decades. But in recent years, manufacturing has gotten a facelift and a new image, thanks in large part to the same technology capturing consumer attention in the form of cool tech products. This wave of tech is reinventing the modern factory into a smart, connected, and digital entity.

Industrial Automation

Industrial automation (complete article on Industrial Automation here) is the use of computers and robotics to perform machine functions at a faster and more precise rate than human operators. By utilizing industrial automation tools, factories can realize several benefits:

- Increased Productivity – Production performed using robotics and other sophisticated equipment improves productivity. In one example, Ford’s auto plant in Germany realized a 16% growth in productivity annually. Fatigue, illness, human error, and attrition can impact a factory’s day to day operations. However, automated production machines suffer none of these problems.

- Improved Quality – Industrial automation can also reduce line errors to an infinitesimal amount compared to human operators. The reduction in waste and lost production time reduces costs and enhances brand reputation among consumers.

- Better Control – In highly automated factories, automation can lead to greater control over equipment at both the micro and macro level. Robots can often be re-tasked without the accompanying training curve humans require. And decision making by managers can be improved through the use of high-quality data captured by the machines themselves.

Industrial automation can be integrated at different levels throughout a factory. These areas include the field level where sensors and actuators detect conditions and trigger actions. Automation can also take place at the control level where PLCs and other logic programmable devices receive signals from these sensors and instruct the machine in taking next steps at the optimal moment. And it can be used at the production control level by monitoring production targets and calculating minimal downtime during changeovers.

Industrial automation can be used to build an integrated production system narrowing quality parameters and achieving higher productivity as these assets work in concert in an integrated system of automation.

Innovative Manufacturing

While much has been written on agile manufacturing - the ability to adapt to change and manage it quickly and effectively - innovative manufacturing has risen to the forefront in recent years because of the innate relationship it has with technology. Innovative manufacturers, as you may expect, drive change through innovation by utilizing new technology to drive higher value, create processes, develop products, and even disrupt entire markets.

Innovative manufacturing can be product driven by introducing new and unique products to capture consumers and market share. However, the innovation can take place in other areas as well:

- Source Innovation – Constant evaluation and search for new materials and vendors within the supply chain.

- Process Innovation – Using technology to radically alter production time and to lower cost.

- Management Innovation – Using the data and technology available with modern day deep analytics to create new markets or new business models.

But technology advances have also progressed to allow for a more comprehensive approach to innovation. With data, analytics, automation, and a host of other tools, entire factories can be built specifically to facilitate innovative manufacturing.

For example, equipment may be chosen that will allow the manufacturer to create new and unique products. And in many cases, the entire factory layout, staff schedules, and production system is built around allowing the highest degree of innovation in the creation of new products. Furthermore, departments such as product development, product engineering, and designers are also factored into the equation, using the newest technology, modeling software, and other data tools to significantly reduce time to market for those products.

By utilizing an automated factory and combining the automation technology with an innovative strategy, factories of all sizes can improve productivity and enhance brand image while cutting costs and remaining competitive.

Industrial Internet of Things

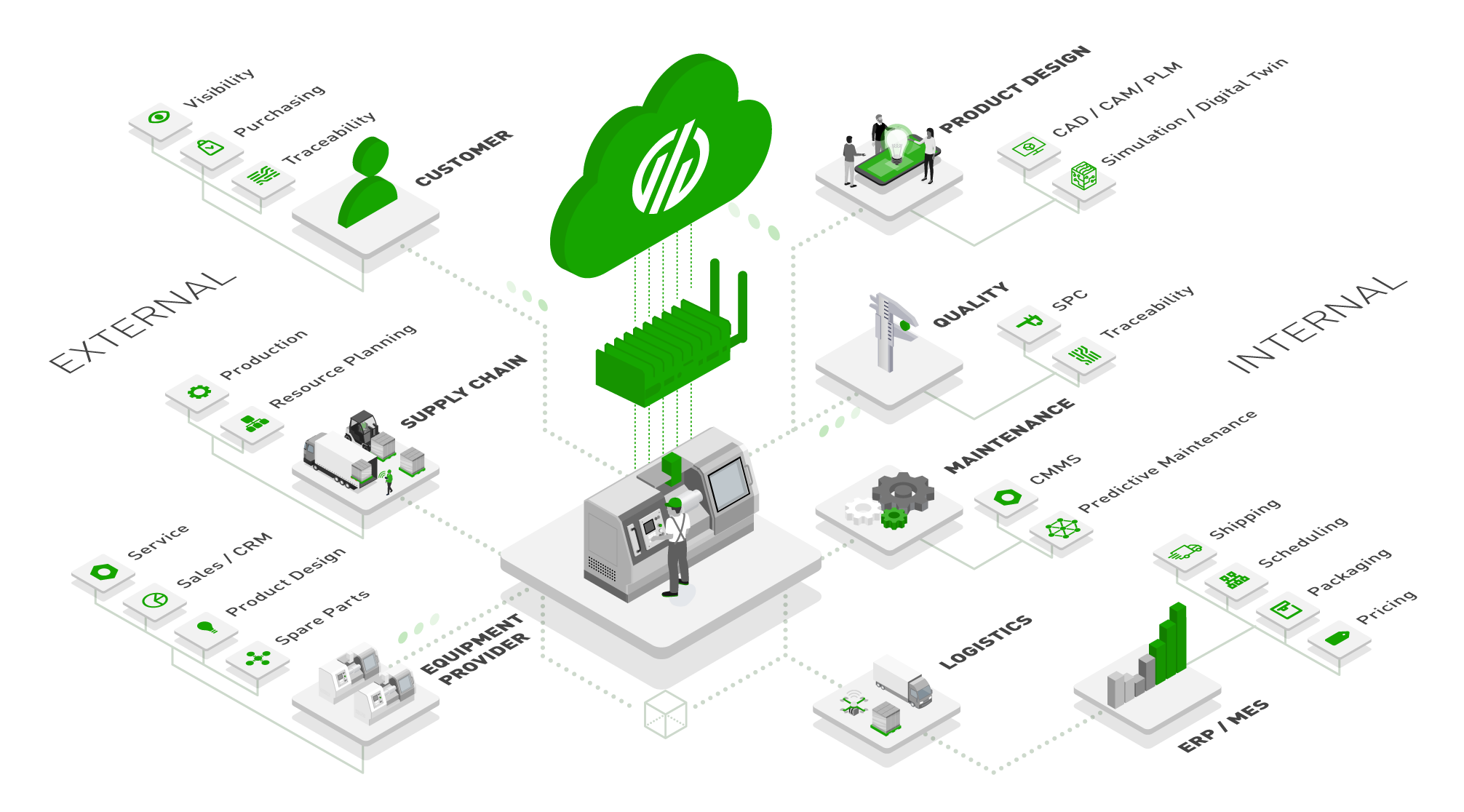

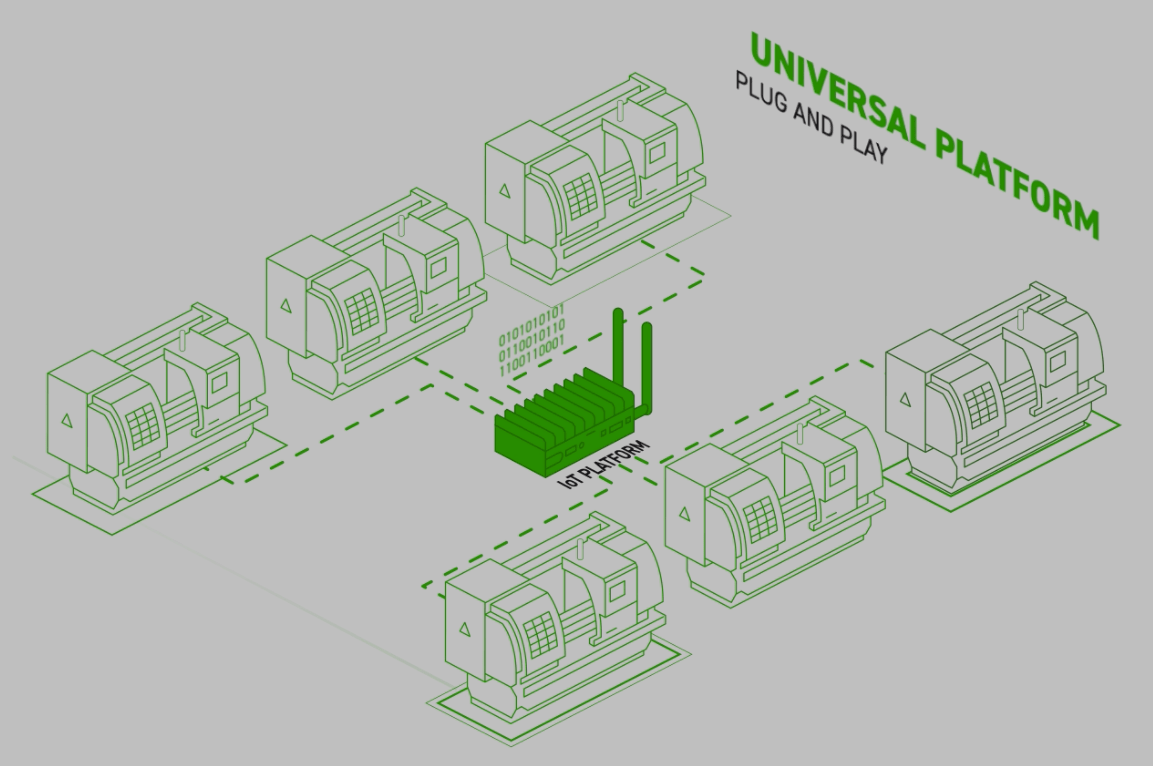

While industrial automation and innovative manufacturing are strong players in today’s hyper-competitive manufacturing environment, it is the current and future possibilities of the Industrial Internet of Things (IIoT) that has the capability to tie them all together. Using real time data captured through sensors and other embedded hardware, IIoT uses deep analytics, AI, and machine learning to allow companies to save time and money by identifying trends and areas for improvement.

Today's IIoT systems are also capable of proactive intervention. This allows for minute adjustments to either the operation of the machine itself as well as in planning and scheduling tasks, such as changing production schedules to minimize turnover times.

IIoT devices also allow factories to adopt predictive maintenance strategies to identify part failures in advance, schedule the repair at the optimal time, notify and relieve spare parts inventory, and notify technicians of the upcoming repair. All of this happens without human decision-making and the results of those deploying predictive maintenance have been impressive. Many operations have achieved up to 25% drops in spare parts inventory and 25% increases in productivity.

Using IIoT technology, companies have almost complete visibility over production processes. And the impact is felt throughout associated functional areas as well. IIoT can allow for a complete view from raw materials and component sourcing (and therefore traceability), into and through production, as well as the shipment of finished goods.

IIoT technology can act as a force multiplier for the benefits of both industrial automation and innovative manufacturing. Having designed a production system with robotics and fully enabled PLCs, it can analyze the data from these automated devices and provide valuable production, maintenance, supply chain, quality, and management data.

The ability to identify trends, formulate, and hone responses through machine learning, develop and autonomously deploy strategies for scheduling, staffing, and a host of other operations, allows the concept of innovative manufacturing to ramp up. With its heavy emphasis on design iteration change and new product development on a short lead time, innovative manufacturing plants are more effective when coupled with IIoT technology.

The Growth of IIoT and Industrial Automation

IIoT technology is poised to grow at an exponential rate. With connected devices expected to exceed 75 billion by 2025, the stakes and the benefits are high. But while already a disruptive player in manufacturing, IIoT becomes even more powerful when coupled with factories that have a high degree of industrial automation or those built around the framework of innovative manufacturing. And when all are combined, they form a powerful trio and a model of what is to come.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments