Key Takeaways:

- Manufacturing companies can attract workers by offering modern tools, such as IIoT, to create safer and more efficient work environments.

- Emphasizing career development opportunities and providing a culture of innovation can help address the labor shortage.

- Leveraging digital technologies not only improves productivity but also enhances worker satisfaction and retention.

Updated May 13, 2021

The Looming Manufacturing Talent Shortage

It has never been more difficult for the manufacturing industry to recruit key skilled personnel. As older skilled workers with vast amounts of tribal knowledge continue to retire in droves, millennials are opting for industries outside of manufacturing.

Here are some key statistics to highlight the major pain point manufacturers are experiencing, and will continue to experience at an alarming rate:

- Baby boomers are retiring from all sectors at a rate of 10,000 a day in the United States, taking their institutional and technical knowledge with them into retirement. (Source: IndustryWeek)

- The manufacturing skills gap could result in 2.1 million unfilled jobs by the year 2030. (Source: The Manufacturing Institute)

- K-12 enrollment in vocational courses has dropped significantly since 1990, as well as federal and state funding for Career and Technical education. (Source: National Center for Education Statistics)

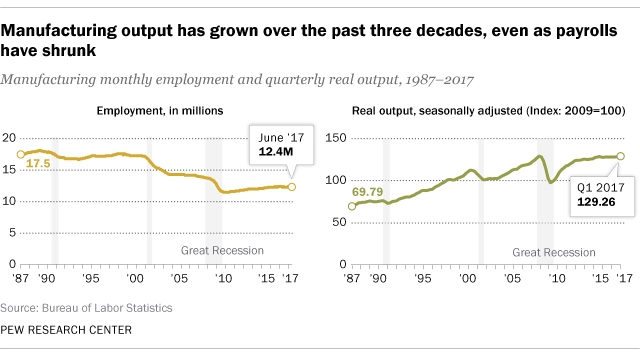

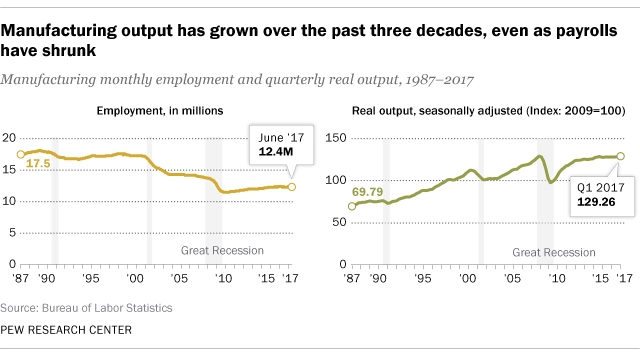

What can the manufacturing industry do? One comforting fact amidst this major challenge is that the manufacturing industry continues to increase output even though jobs have declined. This chart from the Pew Research Center illustrates this seemingly contradictory fact quite well:

This is a reality all manufacturers will have to deal with and at an increasing rate.

In this article, we discuss a variety of strategies for finding skilled manufacturing employees as well as retaining a skilled workforce so your operation can continue to operate efficiently, and, if successful, thrive.

Manufacturing Recruitment: How to Find and Retain Skilled Workers

There’s certainly no easy answer with this challenge. The problem is far-reaching and the impact can be felt in a number of ways. Below you will find several solutions for dealing with the labor shortage and appealing to the millennial generation.

Pass on Tribal Knowledge

The retiring boomer workforce has loads of task and industry-specific knowledge locked away. Extracting this knowledge and passing it on to the next generation is incredibly important and could take a variety of forms. For instance, manufacturers can document tribal knowledge before workers retire or they could set up mentor programs to ensure that new workers are coached properly. This can help to bridge the knowledge gap and empower employees to be more successful in their careers.

Improve the Work Environment and Benefits

All industries are focused on providing the many benefits that the millennial generation is asking for. Whether this be work flexibility, paid time off, or even company initiatives to do community service, there are a variety of options and benefits that can be offered in an attempt to attract the next generation to jobs that will provide the fulfillment they are looking for.

Introduce Technology

As a generation that was born with technology, it would make sense that the work environment they select has also adopted tech. In fact, what millennials may lack in terms of on-the-job skills, they may make up for with tech-focused skills, whether that be coding or simply using Excel.

It’s up to you in regards to how you can incorporate technology into the manufacturing environment to attract (and get the most out of) this next generation of workers. Perhaps you can offer exciting research opportunities to test new technology solutions on the market, or simply have positions that handle more data-centric tasks.

Enhance Manufacturing’s Image

This is perhaps the most ambiguous option as it is more an industry problem than an individual company problem.

Unfortunately, manufacturing’s image is often less-than-desirable in the eyes of millennials. Tedious tasks in a dingy warehouse are more likely to come to mind rather than an exciting factory operation, whirring along in all its flory.

Changing this image will require some marketing on the part of manufacturing leaders and talent acquisition teams.

Partner with High Schools and Colleges

The earlier you can get introduced to potential skilled workers, the better. Despite the reduction in funding from both federal and state, the opportunity lies with manufacturers to connect with local education institutions to offer students a chance to learn more about what they have to offer.

This also coincides with the above point, as it gives manufacturing leaders a chance to paint the right picture of manufacturing. This could develop into an internship program, a chance to tour the factory, or even a direct job opportunity.

Offer Growth Opportunities

As the next generation coming out of schools is bombarded with opportunities and promises of great benefits and growth, many students have the idea that a manufacturing position is likely to end just as it started: in the same position.

If manufacturers can communicate and encourage the career roadmap for new employees, they are far more likely to effectively recruit and retain. This is partly the responsibility of recruitment, but also that of management, to ensure education and growth is encouraged.

Introduce Flexibility and Remote Work

Depending on the nature of the work being done, many positions within a manufacturing organization can be effectively done remotely. And as more technology is introduced (such as remote monitoring) more and more jobs will have the opportunity to work from wherever they would like.

Many millennials are seeking flexible work positions that rely less on the traditional structure of being at a work location during hours. Determine which positions can feasibly be offered as remote and introduce technology that can support such a transition.

Here’s to the Next Generation of Manufacturing Leaders

With new technology, a rebranded industry, and little luck, there’s plenty of hope for the next generation of faster, more efficient production in the United States. We’re personally bullish on industry growth, and amazed at how manufacturers have adapted to difficult market conditions and deployed new innovative solutions to drive greater productivity.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments