The Challenge

According to Cisco, 76% of IIoT implementations fail. Additionally, despite manufacturing being the largest industry in the United States and producing the most raw data, it has the least amount of digitization (only 5% of processes). These statistics represent both a problem and an opportunity. At MachineMetrics, we believe the challenges are directly related to 1) the use of products, tools, and technologies that don’t meet the basic requirements of an IIoT initiative- the need to obtain immediate value while simultaneously driving continuous improvement and innovation initiatives, and 2) a misalignment of critical resources from the various participants in the IIoT solution ecosystem.

The MachineMetrics Approach

MM provides an IIoT Platform for machines. The Platform combines the innovation enablement of horizontal IoT platforms with the rapid value creation of packaged, cloud-based SaaS services, to power Industry 4.0 initiatives for discrete manufacturers. Horizontal IoT platforms often don’t produce value fast enough at an affordable price. Packaged products, applications, or point solutions, on the other hand, are limited in their ability to extend and drive continuous improvement and innovation. The limitations of both approaches are major contributors to the poor historical IIoT results. By combining the best of both approaches, MachineMetrics delivers an optimal hybrid offering which accelerates digitization in manufacturing and minimizes the risk of failed IIoT implementations.

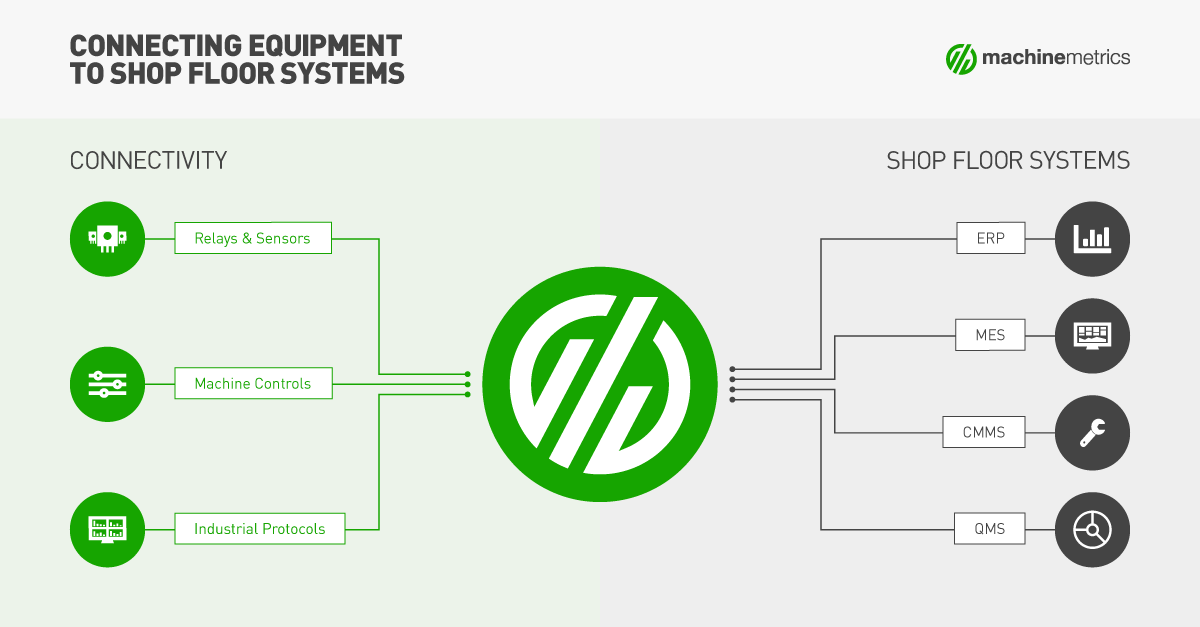

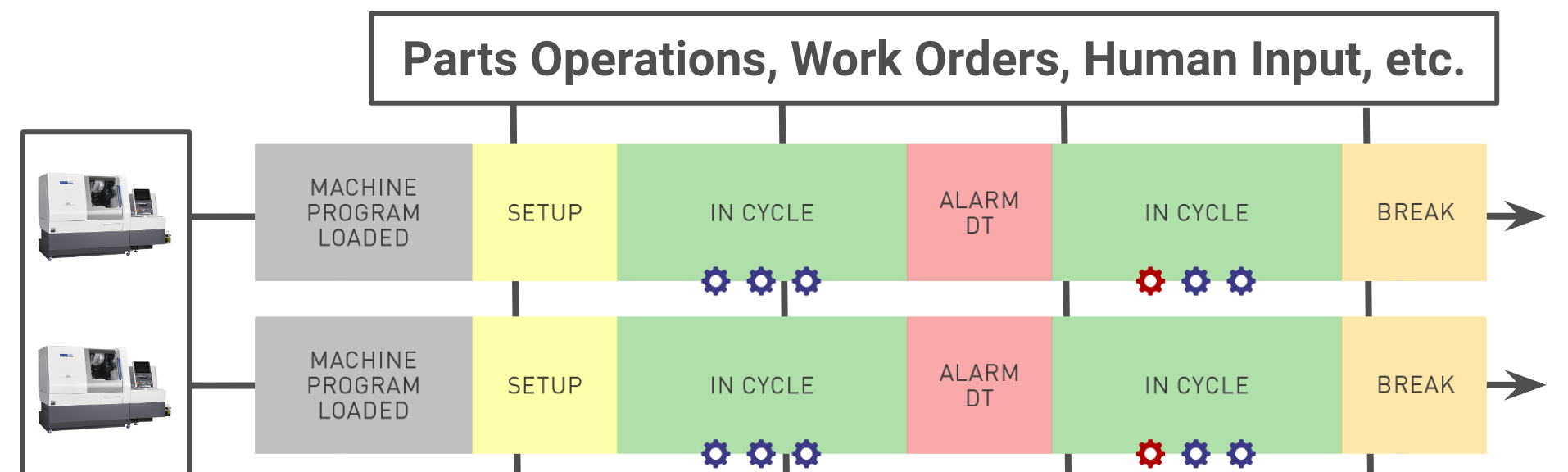

MM is also differentiated by its unique ability to automate the collection and transformation, or contextualization, of real-time machine data. MM augments machine data with data from people, other devices, and systems, to provide descriptive, diagnostic, predictive, and prescriptive analytics through packaged SaaS applications that provide immediate ROI. The platform is extensible through open APIs, connects to best of breed factory applications, and simultaneously enables customers and partners to add their own IP both at the edge and cloud layers.

The Aligned Ecosystem

The MM Platform enables an ecosystem of manufacturers and partners to accelerate value attainment, and minimize the risk of initiative failure, by optimally aligning the unique skills of the entities participating in the specific IIoT initiative.

Today’s IIoT ecosystem consists of manufacturers, machine builders, machine builder distributors, service providers, technology and solution providers, system integrators, consultants, and software providers. Each participant has their own unique capability, expertise, or intellectual property that can be leveraged to drive a successful IIoT initiative. When these resources are misaligned, or sub-optimized, IIoT initiatives often come up short in delivering on the promised value proposition, or they fail altogether as the statistics show.

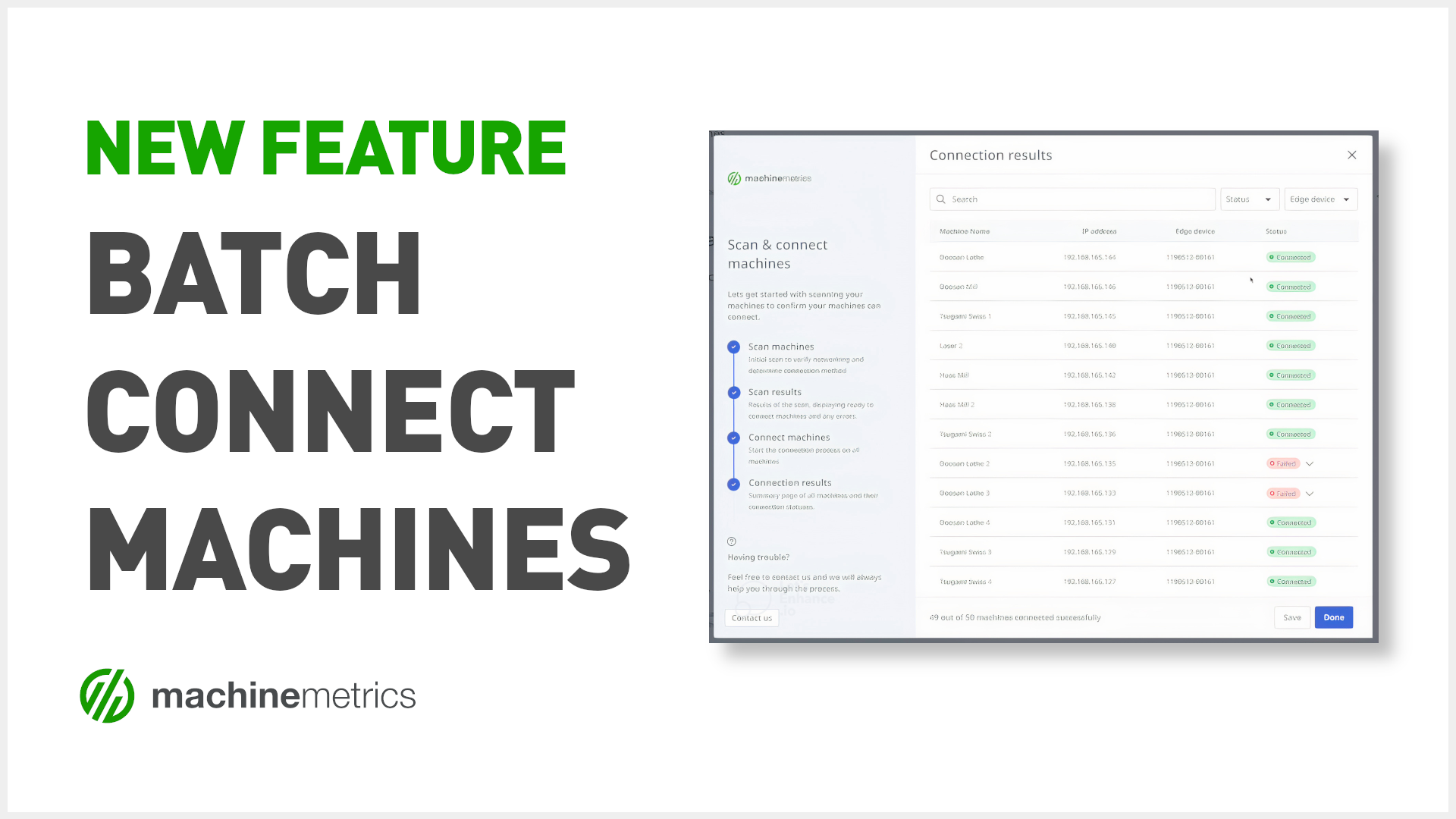

The foundation of the MM platform is the automated capture and transformation, or contextualization, of machine data. This capability enables consumable machine data and insights in a matter of minutes. Machine data capture and transformation is often glossed over, yet it is complex and time consuming, with many variables. MM has connected to thousands of machines for hundreds of customers. We have over 50 man-years invested in perfecting this underlying technology and we continue to invest to sustain and improve it. However, some manufacturers, consultants, system integrators, and others attempt to roll their own machine data infrastructure with varying degrees of success. This development effort, even when leveraging a horizontal IIoT platform, can take months if not years. And once the mechanism for capturing and contextualizing machine data has been built, it needs to be maintained. Not only is the cost of sustaining these solutions prohibitive, but the lost opportunity and value associated with mis-allocating resources to develop something that already exists results in a competitive disadvantage for the manufacturer.

Where should the manufacturer focus? We believe it is in areas that take advantage of their deep domain expertise. The beauty of the MM platform is it enables the manufacturer, and by extension, their ecosystem of partners, to optimize key processes and create innovative new processes throughout their operations. Analytics, including ML and AI algorithms, can be developed and applied both at the edge and in the cloud, using MM and/or other analytics technologies. This alignment of skills and technologies creates the optimal formula for rapid and continuous value creation for the manufacturer.

Like manufacturers, the MM Platform also enables opportunity for machine builders and their distributors. That opportunity is rooted in optimizing the performance of machines and providing superior products and service. Leveraging consumable data and insights, along with analytics technologies and tools, machine builders and distributors can take full advantage of the deep domain knowledge of their machines to drive value and create competitive differentiation. This contrasts with machine builders and control system suppliers who attempt, with limited success, to provide an IIoT infrastructure or an even more basic machine monitoring offering. There are many different machine manufacturers and very rarely, do you find a plant with only one brand of machine. The many different machines also have different control systems and communication protocols. The machines are of different vintages ranging from new with modern controls to 20 or 30 years old with limited control capability. Manufacturers will very rarely, if ever, purchase a data capture and monitoring infrastructure from one machine builder or control system supplier and apply it to another machine builder’s machines or another control system vendor’s controls. MM enables consumable data and insights through a common user experience from any machine, regardless of brand or age, or control system, in a matter of minutes. Focusing on this infrastructure component also distracts from what machine builders are uniquely positioned to address- the optimization of their machines. In addition to providing analytic tools for the machine builder, the MM Platform is also extendable through the addition of sensors and inputs through the MM edge device, further augmenting the capabilities of the machine and the machine builder.

Rapid and Continuous Value Creation

Discrete Manufacturers can be segmented based on fundamental business drivers. For capacity constrained manufacturers who produce their own products, improvements in utilization and reductions in downtime drop right to the bottom line. For low volume, high mix producers, optimizing cycle times directly impacts profitability. MachineMetrics provides out of the box dashboards, reports, and applications that provide immediate impact and value pertaining to these, and many other, use cases.

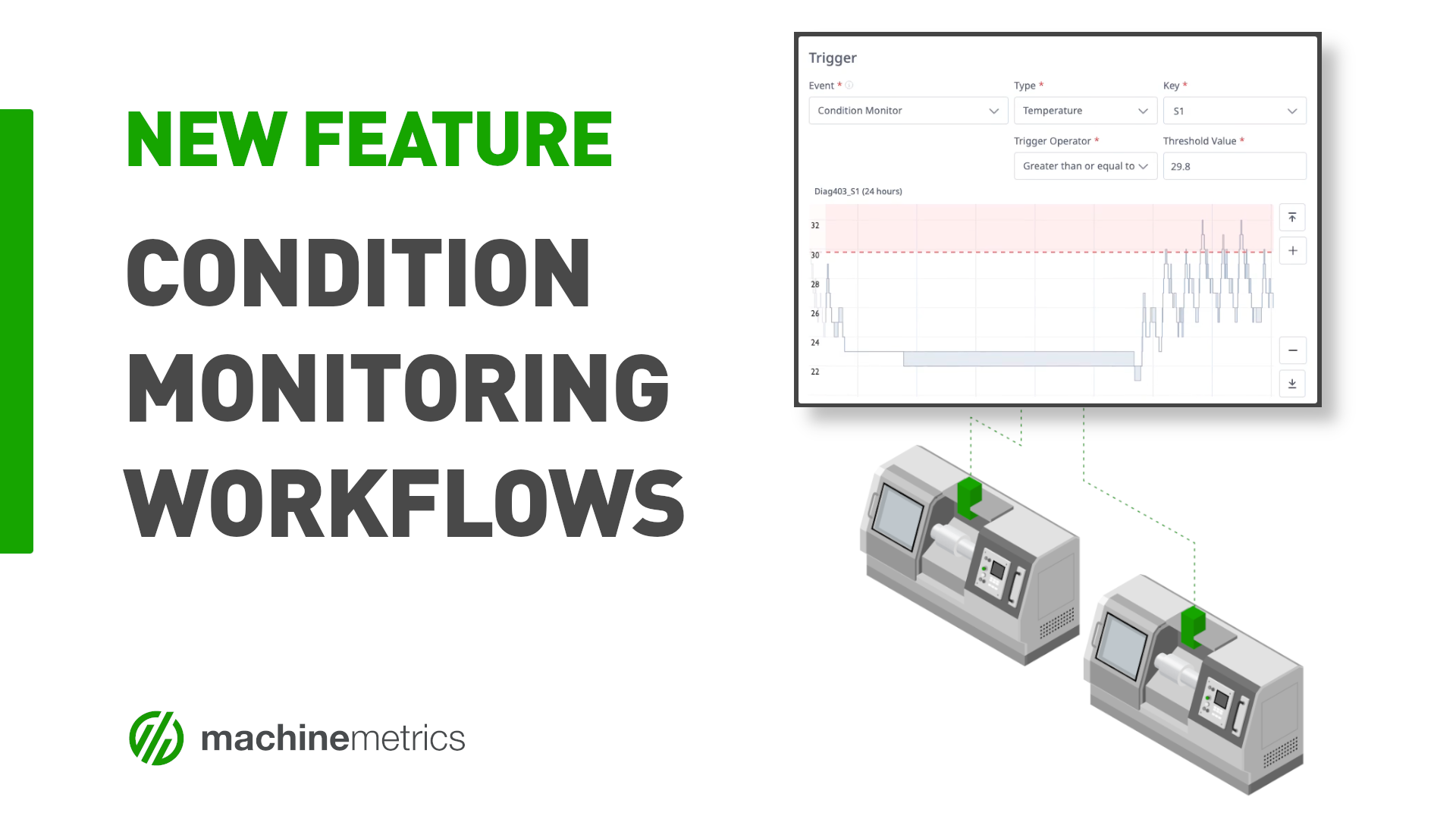

Maintaining machine health and improving the service and maintenance of manufacturing assets is an opportunity for many participants in the ecosystem. MM provides the data insights and tools for a machine distributor, for example, to remotely monitor the health of their customer’s asset. With the MM platform, the distributor can diagnose problems remotely, helping service personnel understand the problem, bring the right tools if they need to make a trip to the plant, and order the right parts in advance of a plant trip. The result is better service and improved machine uptime for the customer.

These basic examples serve as a starting point. MM partners and customers are discovering the opportunity to leverage machine insights to drive value is limitless. Working with our partner and customer ecosystem, we are learning the promise of many enterprise applications and systems is failing to be realized because of the lack of actionable data and intelligence. As an example, we have customers who have made significant investments in CMMS systems but are still maintaining their assets based on a set schedule. By integrating these systems into MM and having the system consume data and analytics related to machine runtime, load, and other variables, they are now able to change the paradigm around maintaining their equipment to one based on machine usage versus scheduled time. The result is dramatic financial savings and the realization of the value promised from their significant investment in the CMMS system.

Conclusion:

Successful IIoT initiatives require selecting the right technologies along with the proper alignment of the various entities in the ecosystem that participate in the initiative. To optimize rapid value attainment and reduce risk, that alignment should leverage the unique technology, IP, and domain expertise of each participant. A sub-optimal model, where companies attempt to focus on or recreate something outside of their core expertise, results at a minimum in wasted time and resources. More likely, the result is failure and falling behind the competition in the race to differentiate and drive incremental value.

Download our newest Case Study with SilencerCo

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments